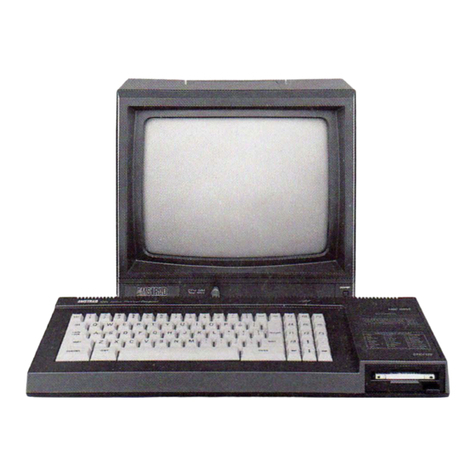

AMSTRAD CPC6128 User manual

Other AMSTRAD Desktop manuals

AMSTRAD

AMSTRAD 464 Plus User manual

AMSTRAD

AMSTRAD CPC664 User manual

AMSTRAD

AMSTRAD PCW9256 User manual

AMSTRAD

AMSTRAD Notepad NC100 User manual

AMSTRAD

AMSTRAD CPC464 User manual

AMSTRAD

AMSTRAD PC1640 User manual

AMSTRAD

AMSTRAD TS80 User manual

AMSTRAD

AMSTRAD CPC6128 User manual

AMSTRAD

AMSTRAD PC1512 User manual

AMSTRAD

AMSTRAD CPC464 User manual