CONTENTS

Safety Note

Technical Specification

Servicing Note

FD-3 Flow Chart

FD-3 Flow Chart

FD-3 Servicing Information

FD-3 Exploded View

Cabinet Diagram Exploded View & Parts List

Electrical Parts List

Cabinet Diagram Exploded View

CPU P.C.B. Assembly Component Side

Exploded View CPU Unit

Hard Disc Installation Instructions

Alignment Instructions PC-CM

Alignment Instructions PC-MM/PC1512

Cabinet Diagram &Parts List PC-CM

Cabinet Diagram &Parts List PC-MM

Chassis Schematic Diagram

Keyboard Schematic Diagram &P.C.B. Layout

Keyboard Exploded View

Chassis Schematic Diagram PC-MM

Chassis Schematic Diagram

Chassis Schematic Diagram

Chassis Schematic Diagram PC-MM Monitor

Chassis Schematic Diagram

PC-CM Power Supply

PC-CM Main PCB Component Layout

PC-CM Main PCB Component Layout

CRT PC Board, Colour Monitor

Schematic Diagram FD-3 CPU

Page

2

2

3

3

4-6

7- 14

15

16& 17

18-20

21

22 &23

24

25

26

27

28

29

30-33

34&35

36

37

38

39

40

41

42

43

43

44

TECHNICAL SPECIFICATION

51 2K system unit with all circuitry on asingle motherboard.

8MHz 8086 processor.

Memory expandable on motherboard to 640K.

Integral colour graphics adaptor with special 16 colour hi-res

mode.

Three full-size compatible expansion slots with power available

in the standard unit to supply a hard disc and controller.

Choice of one or two 360K 51A" floppy discs or one floppy with a

1or 20 megabyte hard disc drive.

HARD DISC VERSIONS ARE SUPPLIED WITH AN EXTRA

FLOPPY DISC AND MANUAL WITH BACKUP, RESTORE AND

FORMAT UTILITIES.

Motherboard includes an RS232c serial and parallel interface

with standard connectors.

Loudspeaker with volume control.

Battery-backed real time clock and configuratioon RAM.

Socket for 8087 maths co-processor.

Connector for light pen.

Complete with Colour Monitor or Monochrome (Grey Level)

Monitor.

The standard built-in colour adaptor provides all the following

modes.

Medium resolution Alpha; 16 colours, 40x45 characters.

High resolution Alpha; 16 colours, 80x25 characters. .^

Medium resolution Graphics; 2colour, Three 4-colour pallettes,

320x200 pixels.

High resolution Graphics; 2colour, 640x200 pixels.

-FSpecial high-res Graphics; 16 colours, 640x200 pixels.

Full size QWERTY keyboard.

Illuminated Numlock and Capslock.

Keyboard joystock port.

Extra DEL-» and ENTER keys.

Two button Mouse with

Dedicated port on system unit.

Microsoft compatible MOUSE.COM plus special text operation.

DIMENSIONS (all in mm)

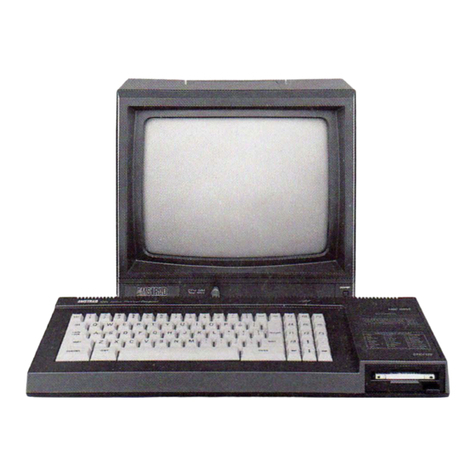

PC1 51 2SD System unit 372(w) x384(d) x135(h) 6.05Kg

PC1512DD System unit 372(w) x384(d) x135(h) 7.75Kg

Keyboard Unit inc feet 465(w) x160(d) x58(h) 1 .1 75Kg

PC-MM Monochrome Monitor 350(w) x300(d) x31 5(h) 7.43Kg

PC-CM Colour Monitor 372(w) x365(d) x330(h) 11.6Kg

SAFETY TEST

All monitors are safety tested to the following specifications.

1). Flash Test

Test at 3kV between the live and neutral of the mains lead joined together and

and ALL accessible metal points on the exterior of the set.

2). Insulation Resistance Test

Test between the live and neutral of the mains lead joined together and ALL

accessible metal points on the exterior of the set to show aresistance of at

least 4Mohm.

If after servicing there is any doubt about continued electrical safety the above

tests should be carried out.

AMSTRAD pic

BRENTWOOD HOUSE, 169 KINGS ROAD, BRENTWOOD, ESSEX CM14 4EF.

TELEPHONE; 0277 230222. TELEX: 995417 AMSELE G.