CONTENTS

Technical Specification

Safety Tests

FD-3 Maintenance

Flow Charts

Hard Disc Installation Instructions

Switch Settings

Understanding bad sectors on ahard disc

Notes

Keyboard Exploded Diagram

Keyboard Control PCB Layout

Keyboard Schematic Diagram

PC1640 Electrical Parts List

PC1 640/SD/DD/HD20 Cabinet Drawing &Parts List

PC1640/SD/DD/HD20 CPU P.C. Board

PC1 640/SD/DD/HD20 CPU P.C. Board (Bottom View)

PC1640/SD/DD/HD20 Chassis Schematic Diagram

PC1 640/SD/DD/HD20 Chassis Schematic Diagram

PC1640/SD/DD/HD20 Chassis Schematic Diagram

PC1640/SD/DD/HD20 Chassis Schematic Diagram

PC1640/SD/DD/HD20 Chassis Schematic Diagram

PC1 640/SD/DD/HD20 Chassis Schematic Diagram

PC-MD Electrical Parts List

PC-MD Cabinet &Parts List

PC/MD Main/CRT/Volume P.C. Board

PC/MD Chassis Schematic Diagram -Power Supply

PC-MD Chassis Schematic Diagram

PC-MD Alignment Instructions

PC-CD Electrical Parts List

PC-CD Electrical Parts List

PC-CD Alignment Instructions

PC/CD Chassis Schematic Diagram •

PC/CD Chassis Schematic Diagram

PC/CD Main P.C. Board

PC/ECD Cabinet &Parts List

PC-ECD Electrical Parts List

PC-ECD Alignment Instructions

PC-ECD RGB P.C. Board

PC/ECD CRT P.C. Board

PC-ECD Relay P.C. Board

PC/ECD Main P.C. Board

PC/ECD Chassis Schematic Diagram

PC/ECD Chassis Schematic Diagram -

PC/ECD Chassis Schematic Diagram

Monitor

Power Supply

Monitor

-TTL Decoder

Power Supply

Monitor

Page

2

2

3- 14

15- 17

18

19

20

21 &22

23

24

24&25

26

27

28

29

30

31

32

33

34

35

35

36

37

38

39

40

40

41

41

42

43

44

45

46

47

48

48

48

49

50

51

52

TECHNICAL SPECIFICATION

Internal Graphics Adaptor, fully compatible

640K system unit with all circuitry on asingle motherboard

8MHz 8086 processor

Three full-size compatible expansion slots (even with hard disc

option)

One or two 360K 5'A" floppy disks or one floppy with a20

Megabyte hard disk drive.

RS232 serial and parallel interface with standard connectors.

Loudspeaker with volume control.

Battery back-up real time clock and configuration RAM.

Socket for 8087 maths co-processor

Connector for light pen and/or joystick.

Full sized keyboard.

Numlock and Capslock.

Keyboard joystick port.

Two-button mouse with dedicated port on system unit.

Choice of one of three displays (paper-white mono, colour,

enhanced colour) with standard video connector.

ECD monitor has .31 mm pitch shadow mask.

CD monitor has .42mm pitch shadow mask.

Internal Graphics Adaptor provides:

Mono(MD):

80 column high resolution text with 9x14 dot characters.

EGA compatible Monochrome graphics 640 x350 lines.

Colour (CD):

(for use with CGA and 200-line EGA software)

40/80 column text with 8x8 dot characters in 16colours.

Medium resolution graphics 320 x200 lines in 4colours.

High resolution colour graphics 640 x200 lines in 2or 16col^

Enhanced Colour (ECD):

40/80 column text with 8x14 or 8x8dot characters in 16

colours.

High resolution colour graphics 640 x200 lines in 2or 16

colours.

Extra-high resolution graphics 640 x350 lines in 16 out of 64

colours.

oIum^

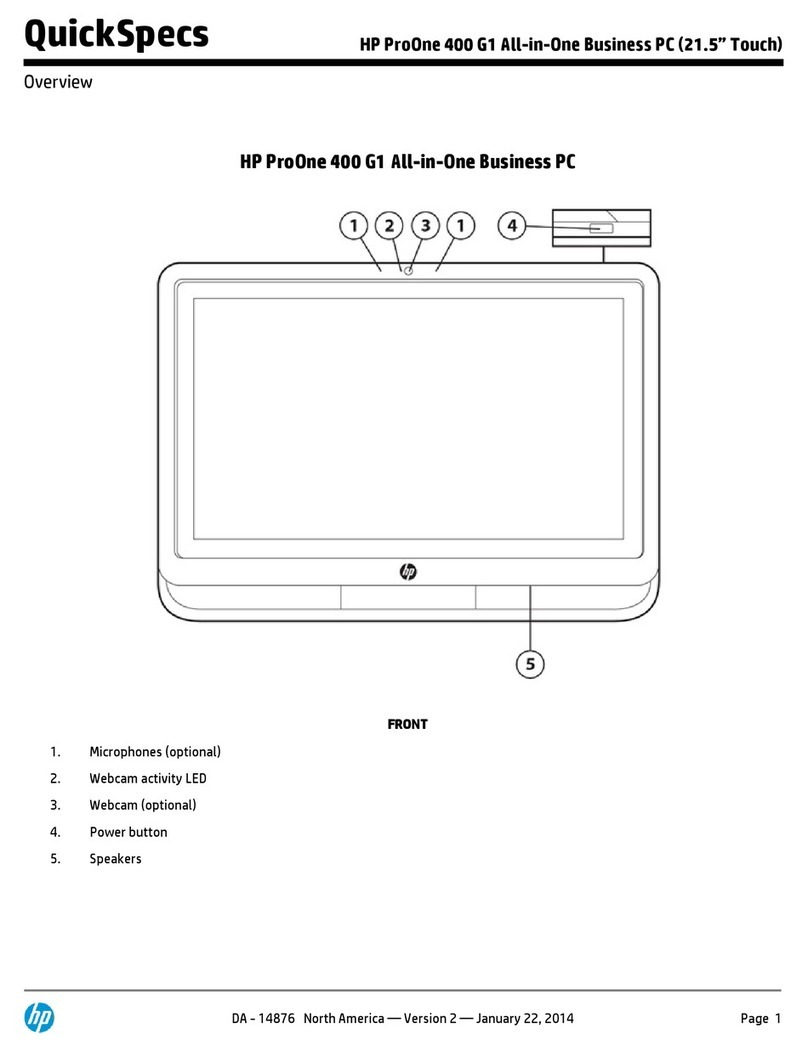

Dimensions (approx):

Monitors (Unboxed)

PC-MD

PC-CD

PC-ECD

System Unit

Gross Weights (approx):

Monitors

PC-MD

PC-CD

PC-ECD

System Unit

PC-SD

PC-DD

PC-HD

WIDTH

350mm

370mm

370mm

370mm

HEIGHT

315mm

320mm

320mm

135mm

(Boxed) 9.0Kg

13.5 Kg

13.5 Kg

DEPTH

300mm

360mm

360mm

384mm

(Unboxed)

8.0Kg

11.5Kg

11.5Kg

(Boxed) (Unboxed)

8.9Kg

10.5 Kg

11.0Kg

Keyboard (Boxed with

system unit)

5.0Kg

5. 8Kg

e^QKg

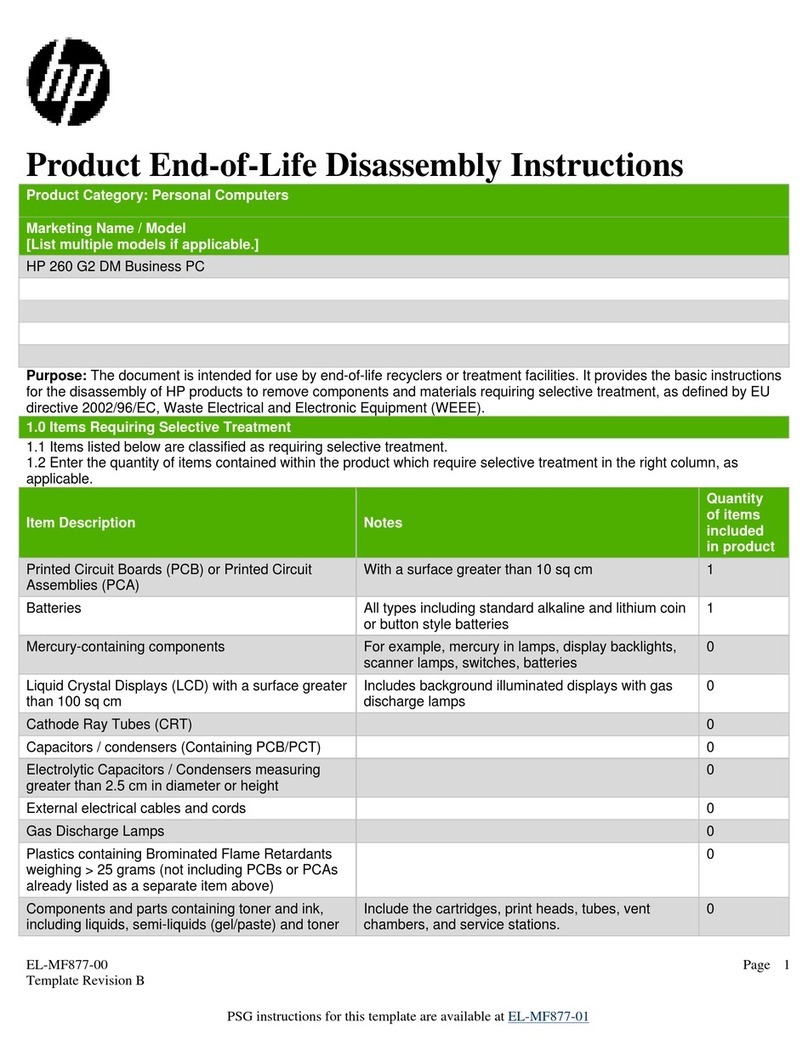

SAFETY TEST

All monitors are tested to the following specifications.

1.Flash Test: Test at 1.5kV RMS /3sec between the live and neutral poles of the mains lead and

all accessible metal points on the exterior of the set.

2. Insulation Resistance Test: Test at 1.5kV RMS /3sec between the live and neutral poles of the

mains lead and all accessible metal points on the exterior of the set to show aresistance greater

than 4Mohms.

3. Earth Continuity Test: The resistance of the mains lead shall not exceed 0.5ohms.

PLEASE NOTE: When any work is completed on this unit, correct safety tests must be carried out

to ensure continued electrical safety.

PLEASE NOTE: All parts shown with the part number prefix /'\ are Safety Items and must be

replaced with similar items having an identical safety specification.

All those items may be purchased direct from AMSTRAD pic.

AMSTRAD PLC

BRENTWOOD HOUSE, 169 KINGS ROAD, BRENTWOOD, ESSEX CM14 4EF.

TELEPHONE: 0277 230222. TELEGRAMS: AMSELEC BRENTWOOD. TELEX: 995417 AMSELE G.

In keeping with our policy of continually improving our service, and the technical quality of our products, we reserve the right to change component types,

manufacturers, sources of supply or technical specification at any time.