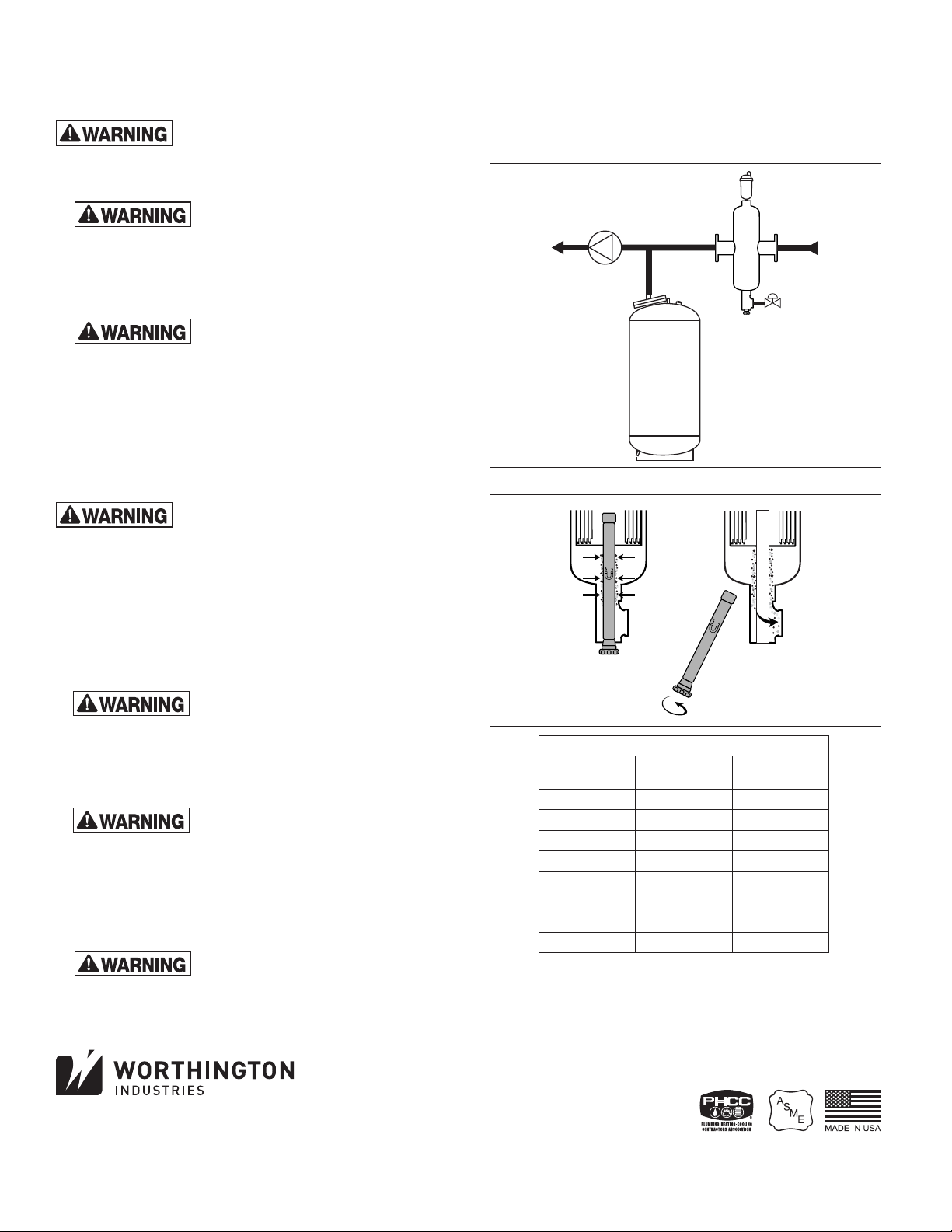

Suggested Piping Diagrams

Figure 1

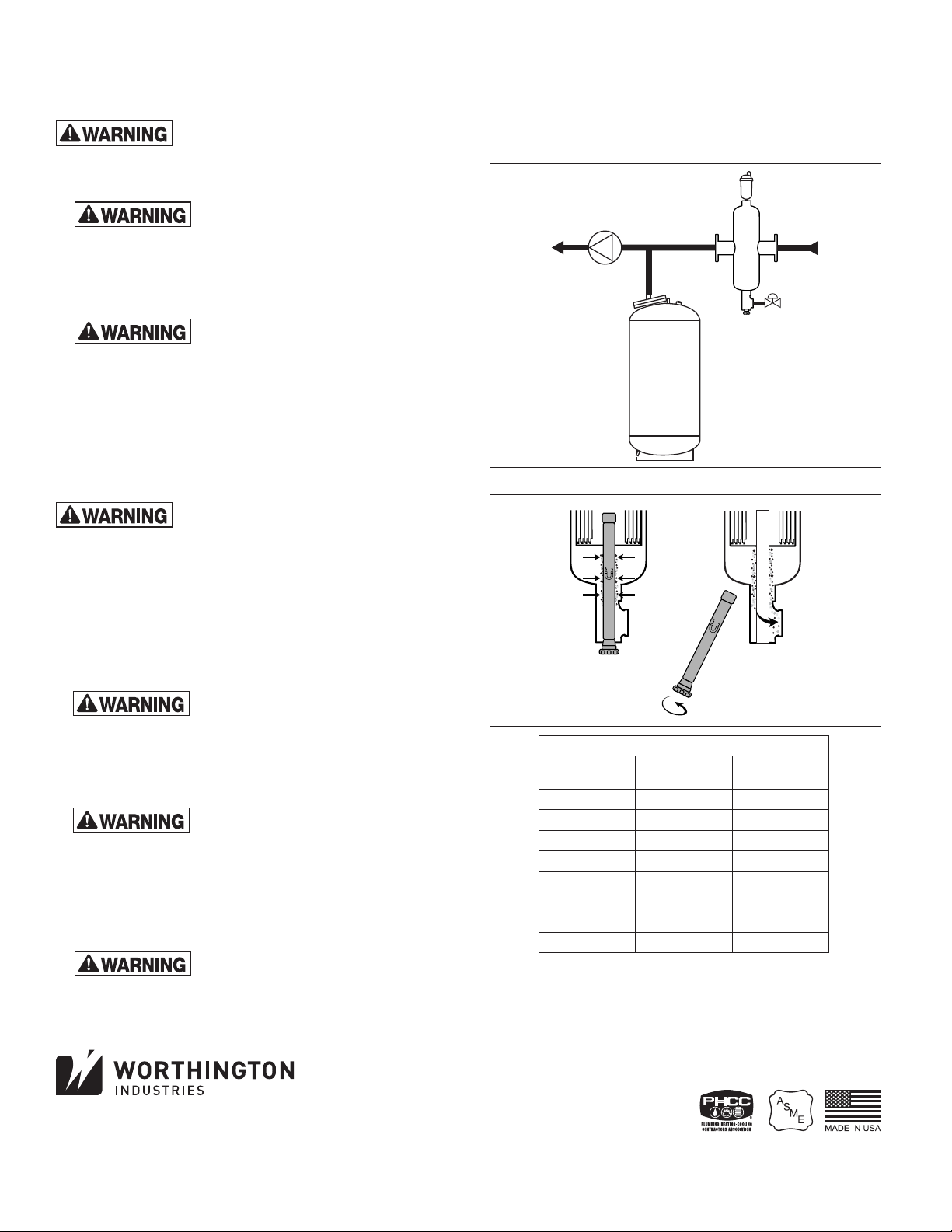

Figure 2

PLEASE READ THE FOLLOWING INSTRUCTIONS CAREFULLY

IMPORTANT GENERAL SAFETY INFORMATION - ADDITIONAL SPECIFIC SAFETY ALERTS APPEAR IN THE FOLLOWING INSTRUCTIONS.

THIS PRODUCT MUST BE INSTALLED BY A

LICENSED PROFESSIONAL.

Installation

1. Refer to Figure 1 for proper installation of the Amtrol ADS.

Wet weight of the separator can exceed strength

of supports. Make sure provisions are made to

support the wet weight and not just the dry weight (see weight chart

below). Failure to follow these instructions may result in serious or

fatal personal injury and/or property damage.

2. ADS Series Separators can be supported in the piping system as long

as pipe hangers are attached to the nozzles as close to the unit’s shell

as possible.

Welding to the pressure vessel boundary will

void the ASME rating.

3. A blowdown valve should be added to the blowdown connection at the

bottom of the tank. The function of the blowdown valve is to facilitate the

purging of sediment from the vessel.

An automatic, float-type air vent needs to be installed on the top con-

nection of the separator. Install with at least 30” of clearance below unit.

Maintenance

A licensed professional should check the complete system, including

the air separator, yearly and more frequently as the system ages.

Leakage, corrosion or indications of damage are

signs of an impending serious failure of the air

separator. Periodically inspect for damage and, if noted, the separator

must be serviced or replaced immediately. Failure to follow these

instructions may result in serious or fatal personal injury and/or

property damage.

Sediment should be purged from the vessel periodically. This is

particularly true during the initial start-up period. During each purge

cycle, note the condition of the water to determine a regular blowdown

interval. The need to purge sediment from the vessel may be evidenced

by a high pressure drop across the separator or by pump cavitation

problems. To clean the separator:

1. Allow the system water temperature to cool below 100°F.

Water temperature above 100°F can be very

hazardous. Allow system water temperature

to cool down below 100°F before blowing down the separator.

Failure to follow these instructions may result in serious or fatal

personal injury and/or property damage.

2. Magnetic Option only: (Figure 2) Unscrew and remove the Magnetic

rod. Place rod on a nonmetallic surface, away from dirt and

metal objects.

Can be harmful to pacemaker and ICD wearers.

Stay at least 12” away. Magnet exerts strong

forces on metallic objects. Tools, magnets and metal objects can

cut, pinch and entrap hands and fingers. HANDLE WITH CAUTION!

3. Operate the blowdown valve for a few seconds. This should dislodge

accumulated dirt from the vessel. Start by closing the isolation valve to

isolate the separator from the system. Open the blowdown valve on the

bottom of the separator to drain the unit. Make sure that all of the flow

from the blowdown valve has stopped. If water continues to flow, the

isolation valve must be repaired or replaced before proceeding.

System fluid under pressure and/or high

temperature can be very hazardous. Before

proceeding, reduce system pressure to zero and isolate the

separator from the system. Allow system temperature to cool

below 100°F. Failure to follow these instructions may result in

serious or fatal personal injury and/or property damage.

Weight Chart (150 PSI)

Model

Number

Dry Weight

(lbs)

Wet Weight

(lbs)

2-ADS 65 90

3-ADS 97 152

4-ADS 110 170

5-ADS 154 324

6-ADS 159 334

8-ADS 270 630

10-ADS 395 995

12-ADS 550 1745

System

Supply

ECM Circulator

Pump

Manual Drain or

Automatic Blowdown

Valve (ABV)

Amtrol Air Vent

EXTROL®

Expansion

Tank

Inlet

Amtrol

ADS

Warranty

ADS Series Models: One (1) Year Limited Warranty

Visit www.amtrol.com for complete warranty details.

© 2019 Worthington Industries Inc. Part #: 9017-158 (03/19)

One or more features of this product are covered by U.S. patents, visit www.amtrol.com/patents for more information.

1400 Division Road, West Warwick, RI USA 02893

T: 800.426.8765 www.amtrol.com

Magnetic option adds 10 lbs. (5kg.)