AND AD-3255 User manual

Ultrasonic Thickness Gage

1WMPD4003292A

Note

No part of this publication may be reproduced, transmitted,

transcribed, or translated into any language in any form by any

means without the written permission of A&D Company, Limited.

The contents of this manual and the specifications of the

instrument covered by this manual are subject to change for

improvement without any notice and obligation on the part of the

manufacturer.

2017 All rights reserved.

ULTRAGEL II , HIGH Z and SONO are registered trademarks

of the Magnaflux company.

-1 -

Contents

1. Safety Information ....................................................................2

1-1-1. Meaning of Alert Indications ................................................2

1-1-2. Cautions Concerning Safety Indications..............................2

1-1-3. Cautions Concerning Performance .....................................3

2. Introduction ..............................................................................4

2-1. Features .................................................................................4

3. Overview "

Unpacking, Names, Operation & Response

".........................6

3-1. Unpacking ..............................................................................6

3-2. Names....................................................................................7

3-3. Operation and Response........................................................8

4. Measurements........................................................................ 11

4-1. Preparation........................................................................... 11

4-2. Basic Measurement..............................................................12

4-2-1. Primary Operation.............................................................12

4-2-2. Probe -Zero Function ......................................................14

4-2-3. Switching the Display Resolution ......................................15

4-2-4. Switching Measurement Modes ........................................15

4-3. Sound Velocity Calibration....................................................16

4-3-1. Use of Sound Velocity Calibration .....................................16

4-3-2. Calibration of Known Sound Velocities..............................17

4-3-3. Calibration of Unknown Sound Velocities..........................17

4-3-4. Two point calibration for Sound Velocities .........................18

4-3-5. Initialization of Sound Velocities ........................................19

4-3-6. Pre-installed Sound Velocities..........................................20

5. Information and Cautions .......................................................21

5-1. Battery..................................................................................21

5-2. Transducer ...........................................................................21

5-3. Measurement of the Tube & Pipe .........................................24

5-4. Couplant...............................................................................26

5-5. Measurement Principle.........................................................27

5-6. Reference Data of Sound Velocities .....................................28

6. Specifications .........................................................................29

-2 -

1.

Safety Information

This section describes information to use the AD-3255 safely and

to prevent injury.

1-1-1.

Meaning of Alert Indications

All safety messages are identified by the following of ANSI Z535.4.

Each alert indication has the following meaning.

Warning Definitions

Warning

A potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Caution

A potentially hazardous situation which, if not avoided,

may result in minor or moderate injury or damage to the

instrument.

This is a hazard alert mark.

Operation is prohibited.

Others

Caution

An important description for proper use of the instrument.

Note

The information that helps users operate the instrument.

1-1-2.

Cautions Concerning Safety Indications

Caution

Repair Only authorized individuals may open the case and repair the

AD-3255. Loss of data or malfunctions may result from

opening the case. Contact your local dealer or our service

department to resolve the issue.

Failure Should the AD-3255 experience a malfunction, stop usage

immediately, post a notice indicating "

Out of Order

" on the

AD-3255 and move it to place where it will not be used by

mistake. Continued usage of it in this state is very dangerous.

Contact your local dealer for repair.

-3 -

1-1-3.

Cautions Concerning Performance

Gently use the AD-3255 because of the precision instrument.

Strong impacts could result in a malfunction.

Use the accessory carrying case for transport.

The main unit and transducer are calibrated as pair in the factory.

Failure to use an authorized transducer may result in incorrect

thickness measurements. Always keep the main unit and transducer

as pair when asking for a repair.

The AD-3255 is not waterproof. Avoid water, moisture, oil and dust.

Avoid an extreme temperature change or impact. Do not immerse

the transducer in water or oil.

Avoid contaminating the transducer connector with water, oil and dust.

Use the accessory strap as needed.

Example: Tie the strap to the main unit to avoid losing the test piece.

Tie the strap to the main unit to prevent the set from

being stored in a piecemeal fashion.

Do not pull excessively on or sharply bend the transducer cable.

Clean the main unit using a lint free cloth that moistened with water

and neutral detergent. Clean the connectors and electrical

terminals using a dry lint free cloth.

Operating temperature range : 0 [°C] to 50 [°C]

Remove the batteries from the main unit when the AD-3255 is not

used for a long time.

-4 -

2.

Introduction

Congratulations on purchasing an ultrasonic thickness gage

AD-3255 of . We recommend that you read

through this manual carefully before using the AD-3255 for the first

time. Keep the manual nearby for reference.

2-1.

Features

The AD-3255 can measure the thickness of various materials using

a principle similar to sonar, displays the thickness value in 0.1 [mm]

or 0.01 [mm]units, and is equipped with a multimode feature.

The multimode feature

Pulse - Echo Mode

Use this mode for basic measurements or detection of flaws,

cracks and pits.

Echo - Echo Mode

When measuring the thickness, use this mode to eliminate

errors concerned with measuring coating and paint thickness.

Use the optional transducer, AD-3255-04.

The sampling mode

Single Point Mode

This mode can measure single point thickness where the

transducer is placed.

Sampling rate : 7[times/ second]

Scan Mode

This mode can display a minimum value from thickness in

areas where the transducer has been moved.

Sampling rate : 16 [times/ second]

-5 -

Probe-Zero Function

The AD-3255 is equipped with a probe-zero function to calibrate

the zero point of the transducer in the pulse -echo mode.

The sound velocity can be calibrated with a single point calibration,

two point calibration or numerical input.

The coupling state symbol indicates the state of the transducer

contacting the material surface.

The AD-3255 can store user settings and calibration data.

The battery indicator indicates the battery power.

The AD-3255 is equipped with an automatic power-off function:

When no operation is performed for approximately 5 minutes, the

display blinks for 20 seconds and then the power is turned off.

The AD-3255 can measure the thickness of other metal, plastic,

ceramics, composite materials, epoxy resin, glass and a variety of

other materials.

The range of sound velocity: 1000 to 9999 [m/s],

The range of thickness: 0.8 to 200 [mm],

Using the accessory transducer.

-6 -

3.

Overview "

Unpacking, Names, Operation & Response

"

3-1.

Unpacking

Upon receiving the product, inspect the main unit and accessories

contained in the package. Should anything be missing or damaged,

contact and consult your local dealer.

Use the carrying case for transport.

Packing list is as follows:

Main unit .......................................................................................................................... 1

Test piece "

is equivalent to the thickness of

4.00

mm

" AD-3255-01

.... 1

Transducer for the pulse -echo mode AD-3255-02 .... 1

Carrying case ............................................................................................................... 1

Empty bottle for the couplant .............................................................................. 1

Strap ................................................................................................................................... 1

Instruction manual "

This manual

" ........................................................................ 1

Main unit Test piece Bottle

Strap

Transducer for the

pulse -echo mode Carrying case This manual

-7 -

3-2.

Names

Coupling state

Battery indicator

Measurement mode

Units

Transducer connector "Transmitter"

Transducer connector "Receiver"

Battery cover

which covers the battery

box in which two

alkaline batteries, "LR6,

AA" can be installed.

Strap holes

Switches :

When pressed,

the buzzer sounds.

Display :

Thickness data and

settings are displayed.

References

Transducer for

the pulse - echo mode

Plugs

-8 -

3-3.

Operation and Response

Switches

Turns the AD-3255 on/off.

Turns the backlight on/off.

Changes the display resolution to 0.1 [mm]or 0.01 [mm].

Press the switch while pressing and holding the

switch after turning off the main unit.

Enters the sound velocity settings from the measurement.

Returns the measurement from the sound velocity

settings.

Starts the probe -zero function from the measurement.

Specifies a connected transducer in the probe -zero

function.

Increases the parameter in the setting mode.

Selects a measurement mode in the measurement.

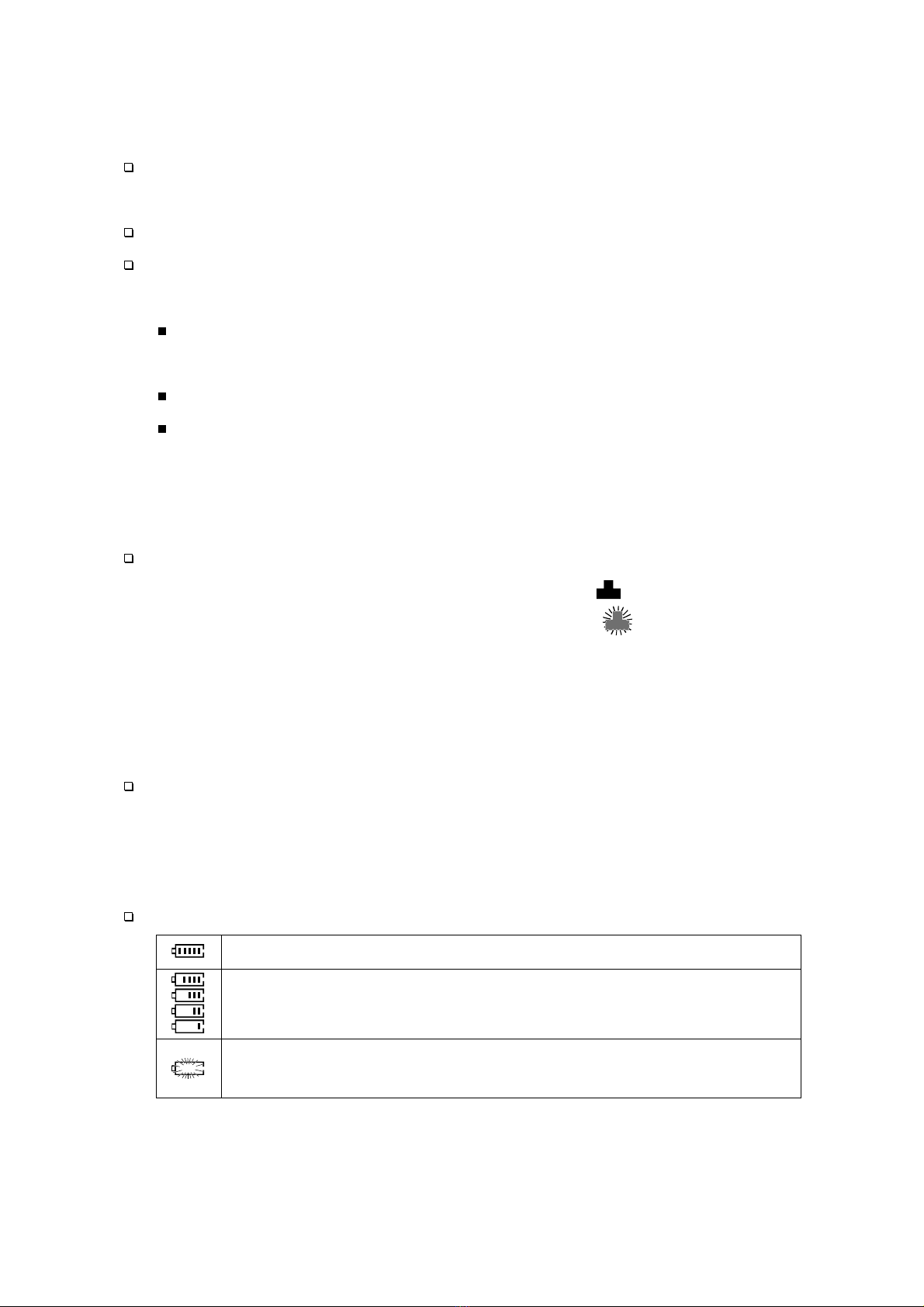

Single point mode....................... Indication

Measures the thickness in the space where the

transducer is placed on the material surface.

Sampling rate : 7[times/sec.]

Scan mode............................................ Indication

Displays a minimum thickness from the measured data

in the area where the transducer has been moved.

Sampling rate : 16 [times/sec.]

Decreases the parameter in the setting mode.

Selects the measurement mode.

Pulse - echo mode....................... Hide +, Indication

This mode is for major measurements and can be used

to detect a flaw or pit.

Echo - echo mode....................... Show +, Indication

This mode can be measure the thickness that is

eliminated errors concerned with measuring coating

and paint thickness.

-9 -

Cautions

Use the optional AD-3255-04 transducer if a thickness is

measured using the echo -echo mode.

The backlight consumes the battery power.

The AD-3255 can not perform in other modes while the current

mode is active or busy. For example :

During sound velocity calibrations, the probe-zero function can

not be performed.

During thickness measurements, numerical input is unavailable.

While setting information is displayed, switches cannot be

operated.

Coupling Indication

The AD-3255 can indicate the coupling state between the

transducer and material surface. The symbol indicates stable

and measurable contact. The blinking symbol indicates

unstable and weak contact. When the measurement is complete,

the buzzer sounds.

Units

The units of thickness [mm]or sound velocity [m/s]are displayed.

The unit [in]is not displayed.

Battery Indicator

The blocks indicate the state of to the battery.

Adequate battery power.

Blocks indicate changes in battery power levels.

The battery power has been consumed.

Replace with two new alkaline batteries, "LR6, AA".

-10 -

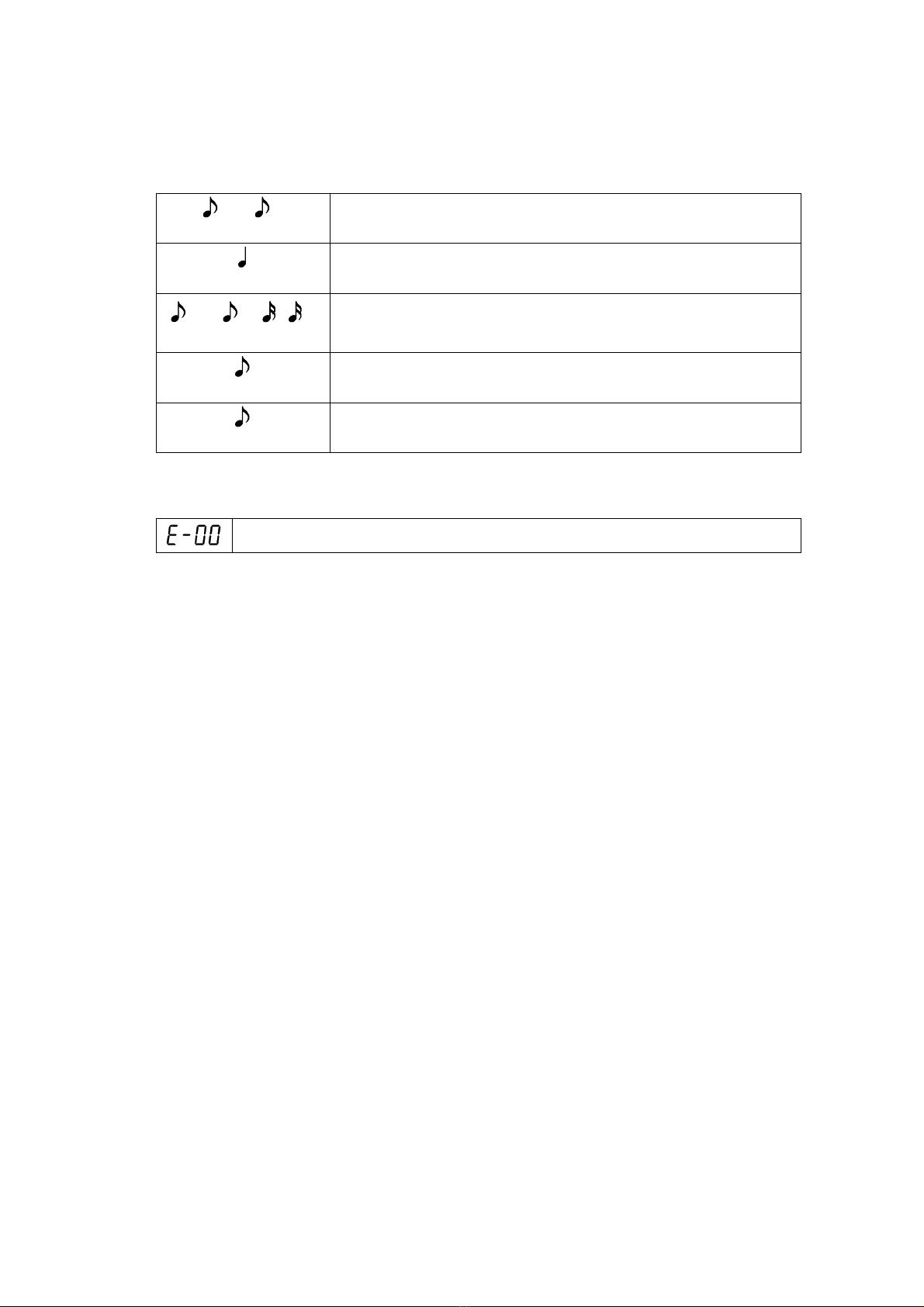

Buzzer

Different buzzer sound types indicate the following:

___ _

pitt pitt Turning on the AD-3255.

pii Turning off the AD-3255.

___ __ _ _

pitt pitt pitt pitt

Initializing sound velocity or when changing

display resolution.

pitt Switch response

pitt Measuring thickness.

Error Code

Battery power has been consumed.

Contact your local dealer for any error other than error code

displayed above.

-11 -

4.

Measurements

4-1.

Preparation

Step 1.

Install

"or Replace"

Batteries.

Open the battery cover.

Install two new alkaline batteries

matching polarities "+and -" with

those of the electrical terminals.

Close the battery cover.

Step 2.

Connect Plugs of the Transducer.

Connect the plugs of the transducer to the

connectors on the main unit.

The connector can connect either the

transmitter plug or receiver plug.

Clean the plug if couplant is present.

Step 3.

Prepare the Couplant.

Prepare the couplant using the bottle.

Step 4.

Prepare the Test Piece.

Prepare the accessory test piece with

an equivalent thickness of 4.00 mm.

Put the couplant on the surface of the

test piece.

Step 5.

Prepare a Material Sample Piece.

Prepare a sample piece to measure the thickness.

Apply couplant to the surface of the material.

Plug

Connecto

r

LR6 or AA

batteries

Battery cove

r

Battery box

Bottle

Couplant

Test piece

Couplant

-12 -

4-2.

Basic Measurement

4-2-1.

Primary Operation

Step 1.

Turn on the Main Unit.

Press the switch to turn on the main unit.

The buzzer sounds "pitt pitt".

The of the pulse -echo mode is displayed.

The of "the initial" sound velocity is displayed.

Step 2.

Confirm the Sound Velocity

"if necessary".

Press the switch twice.

Confirm the of the sound velocity for

the test piece. Select it using the switch

from pre-installed values "or using the

switch and switch", if necessary.

Press the switch to store it.

Step 3.

Specify the Transducer

"if necessary"

.

Press the switch to display the current

transducer. Specify the using the

switch and switch.

Step 4.

Calibrate the Zero Point.

Contact the transducer to the surface of

the test piece coated with couplant.

The calibration is finished when the

indicator is displayed, 4.00 [mm] is

measured and the buzzer sounds "pitt".

Test piece

Couplan

t

Resul

t

o

r

Twice

Select

-13 -

Step 5.

Measure the Material.

Contact the transducer to the surface of

the material. The indicator is

displayed and the thickness is

measured.

Step 6.

Turn off the Main Unit.

Press the switch to turn off the main

unit. The buzzer sounds "pii".

Thickness

Material

Transduce

r

Version

Turn off

-14 -

4-2-2.

Probe - Zero Function

Use this function to calibrate the zero point concerning the pulse -

echo mode. Don't use this function for the echo -echo mode.

Step 1.

Confirm the Sound Velocity

"if necessary".

Press the switch twice in the

measurement mode.

Confirm the of the sound

velocity for the test piece. Select it using

the switch from pre-installed

values "or using the switch and

switch", if necessary.

Press the switch to store it.

Step 2.

Specify the Transducer.

Press the switch to display the current transducer.

Specify the using the switch and switch.

AD-3255-02 Accessory

AD-3255-03 Option

AD-3255-04 Option

Not used

Step 3.

Calibrate the Zero Point.

Contact the transducer to the surface of the

test piece coated with couplant.

The calibration is finished when the indicator

is displayed, 4.00 [mm]is measured and

the buzzer sounds "pitt".

Twice

Selec

t

o

r

Test piece

Couplan

t

o

r

Transduce

r

-15 -

4-2-3.

Switching the Display Resolution

Press the switch to turn on the main unit while

pressing and holding the switch after turning

off the main unit. The display resolution is switched

to 0.1 [mm]or 0.01 [mm].

4-2-4.

Switching Measurement Modes

The following modes in the measurement can be selected.

Single Point Mode

The are displayed when the switch is

pressed in the measurement mode. This mode can measure

single point thickness where the transducer is placed.

Sampling rate : 7[times/sec.]

Scan Mode

The are displayed when the switch is pressed

in the measurement mode. This mode can display a minimum

value from the thickness in the area where the transducer has

been moved. Sampling rate : 16 [times/sec.]

In this mode, any brief interruptions "example: a week contact,

no couplant area, etc." less than 2 seconds in the signal will be

ignored.

When the "blinking symbol " is displayed, and the contact of

the transducer is lost for 2 seconds or more, the AD-3255 will

display the smallest measurement data.

The measurement value blinks 5 times when a minimum value

is displayed.

The AD-3255 doesn't store the scan mode settings. The single

point mode will run when restarting the AD-3255.

Turning off

Example:

The display resolution has been exchanged from 0.01 [

mm

] to 0.1 [

mm

].

-16 -

4-3.

Sound Velocity Calibration

Cautions

Confirm the [m/s]to the sound velocity when calibrating

the sound velocity using the accessory test piece. The settings are

not needed if the sound velocity has not changed.

Sample piece whose coating or paint has removed is required for

both the single point and the two point calibrations. If the sample

piece's coating or paint is not removed, a correct thickness value

can not be displayed.

In order to keep the accuracy of the measurement, use sample

pieces of known thickness.

4-3-1.

Use of Sound Velocity Calibration

"The single point calibration" is the simplest and is commonly

used as the calibration procedure that can optimize the linearity in

a wide range.

The method to input the sound velocity using numerical switches.

Refer to "

4-3-2

.

Calibration of Known Sound Velocities

".

The method to calculate the sound velocity based on known

thickness of sample piece.

Refer to "

4-3-3

.

Calibration of Unknown Sound Velocities

".

"The two point calibration" allows for greater accuracy over a small

range by calculating the probe-zero function and sound velocity

calibration.

Refer to "

4-3-4.

Two point calibration for Sound Velocities

".

The method to restore to the sound velocity of the test piece.

Refer to "

4-3-5

.

Initialization of Sound Velocities

".

The method select a sound velocity from pre-installed values.

Refer to "

4-3-6

.

Pre-installed Sound Velocities

".

-17 -

4-3-2.

Calibration of Known Sound Velocities

Step 1.

Numerical Input of the Sound Velocity.

Press the switch twice in the measurement mode.

Display the sound velocity using the

switch from pre-installed value

"or using the switch and switch".

Press the switch to store.

Refer to "

5-6

.Reference Data of Sound

Velocities" concerning principal sound velocities.

4-3-3.

Calibration of Unknown Sound Velocities

Prepare a sample piece that the thickness is known.

Step

1

.

Perform the Probe-Zero Function.

Perform the "

4-2-2

. Probe - Zero Function".

Step

2

.

Measure the Thickness of Sample Piece.

Apply couplant to the surface of the sample

piece. Press the transducer against it. The

thickness value is displayed.

Remove the transducer from the surface

after the measurement.

Step

3

.

Input the Thickness Value.

Press the switch. The mm blinks.

Input the thickness value using the

switch and switch.

Press the switch to store.

The sound velocity is calculated.

Press the switch to return to

the measurement.

Twice

Selec

t

o

r

o

r

Thickness Inpu

t

Calculated velocity

Thickness

Measure it and remove the transduce

r

Sample piece

Cou

p

lant

-18 -

Measure it and remove the

t

ransduce

r

Sample piece

Measured value

Couplant

4-3-4.

Two point calibration for Sound Velocities

Prepare a sample piece "or two pieces" whose thickness are

known.

Step

1

.

Perform the Probe-Zero Function.

Perform the "

4-2-2

. Probe - Zero Function".

Step 2.

Measure the Thickness of the First Point.

Apply couplant to the first point of the

sample piece. Press the transducer

against it. The thickness value of the

first point is displayed.

Remove the transducer from the

surface after the measurement.

Step 3.

Input the Value of the First Point.

Press the switch. The mm blinks.

Input the value of the first point using

the switch and switch.

Press the switch to display

of next step.

Step 4.

Measure the Thickness of the Second Point.

Apply couplant to the second point of

the sample piece. Press the transducer

against it. The thickness value of the

second point is displayed.

Remove the transducer from the

surface after the measurement.

o

r

Corrected value

Proceed next step

Measure it and remove the

t

ransduce

r

Measured value

Table of contents

Other AND Measuring Instrument manuals