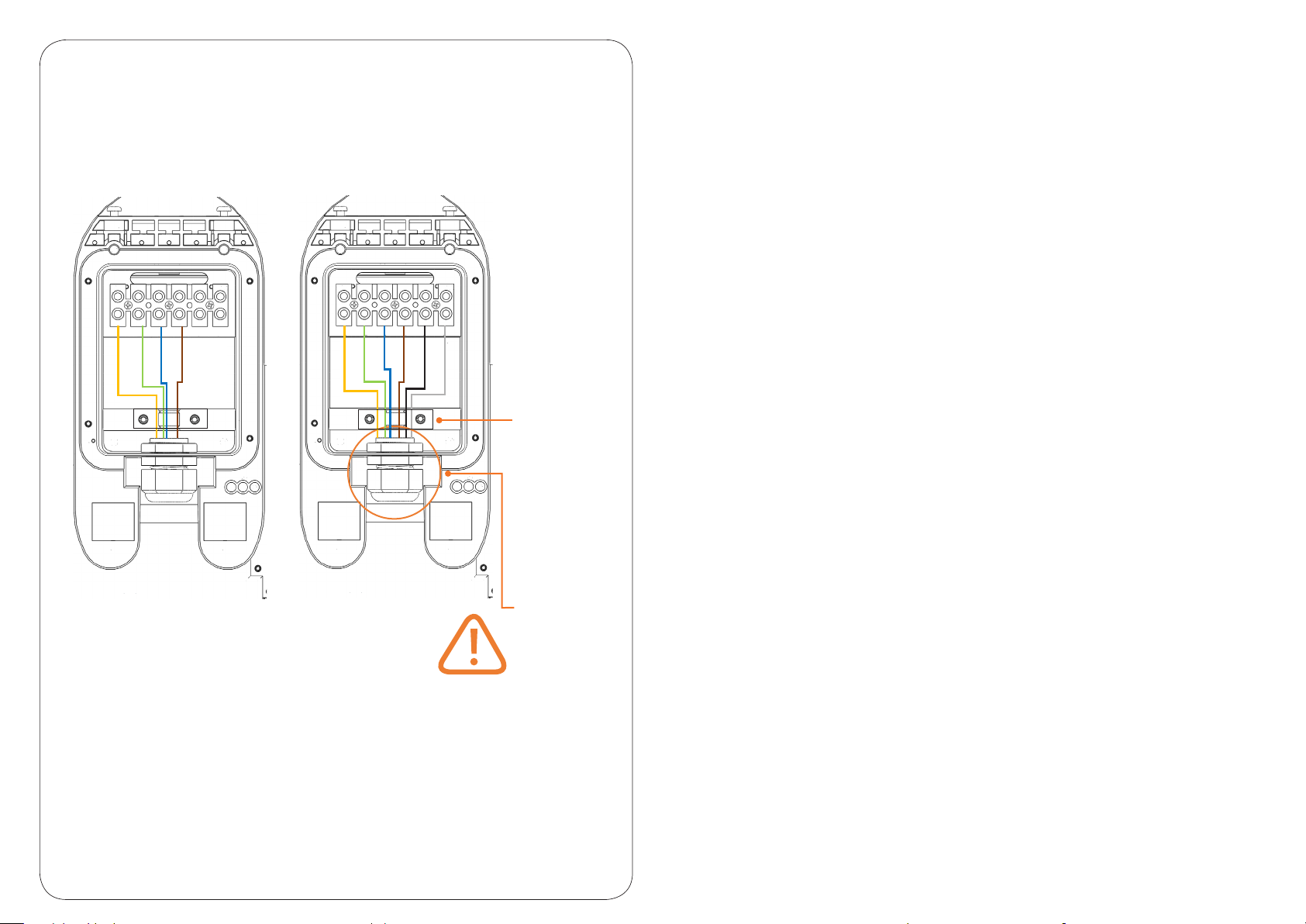

2mm and 3mm

alan key

screwdriver

philips head

(cross head)

x29

M3 x 16mm

long screw

x4

M5 x 8mm

counter

sunk screw

x2

6mm

washer

x2

6mm

penny

washer

ANDERSEN A2

x2

M5 x 12mm

long screw

OPERATION LED STATUS

System powering up. Red, Amber, Green

LED flash together twice a second

Standby State (solid green)

Vehicle connected state (solid green & solid

amber)

Vehicle charging state (solid amber)

Charge point locked or awaiting scheduled

charge (solid green & solid red)

ERROR & UPDATE LED STATUS

Disconnected from network/cloud (green

LED flash every 5 seconds)

RCM or charge error (blip red every sec-

ond)

Firmware upgrade (sequence of green,

amber, red for duration of upgrade)

SETUP LED STATUS

Wifi Setup (Amber LED flash once per second)

Reset warning. Red, Amber, Green LED flash

4 times per second.

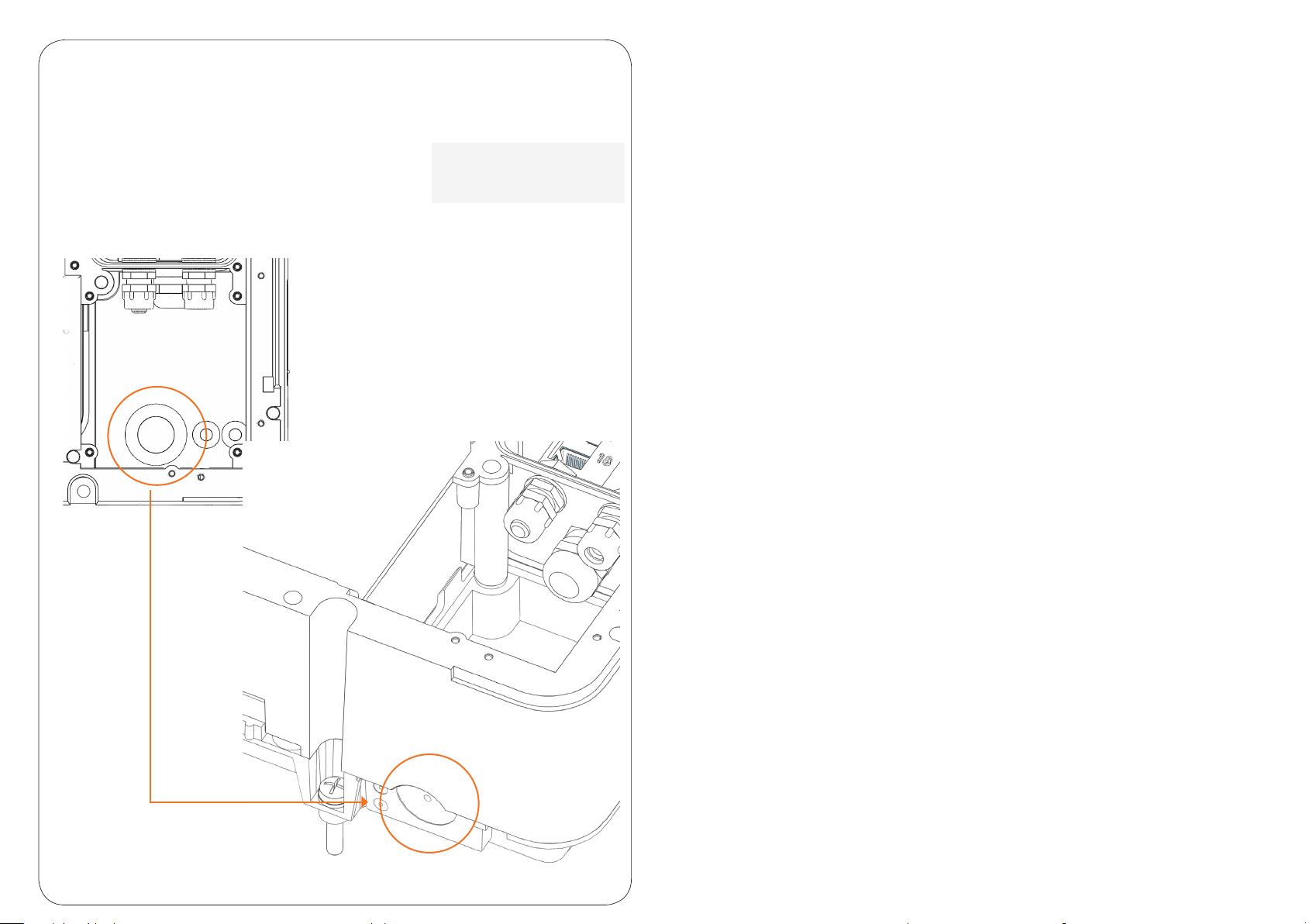

SETUP MULTI FUNCTION OPERATION

Reset RCM (Two button presses)

Enter Network setup mode (Three button

presses)

Exit Network setup mode

(One button press)

Enter unit reset mode (Five button presses)

+ Exit Timeout 30 secs

x2

x3

x1

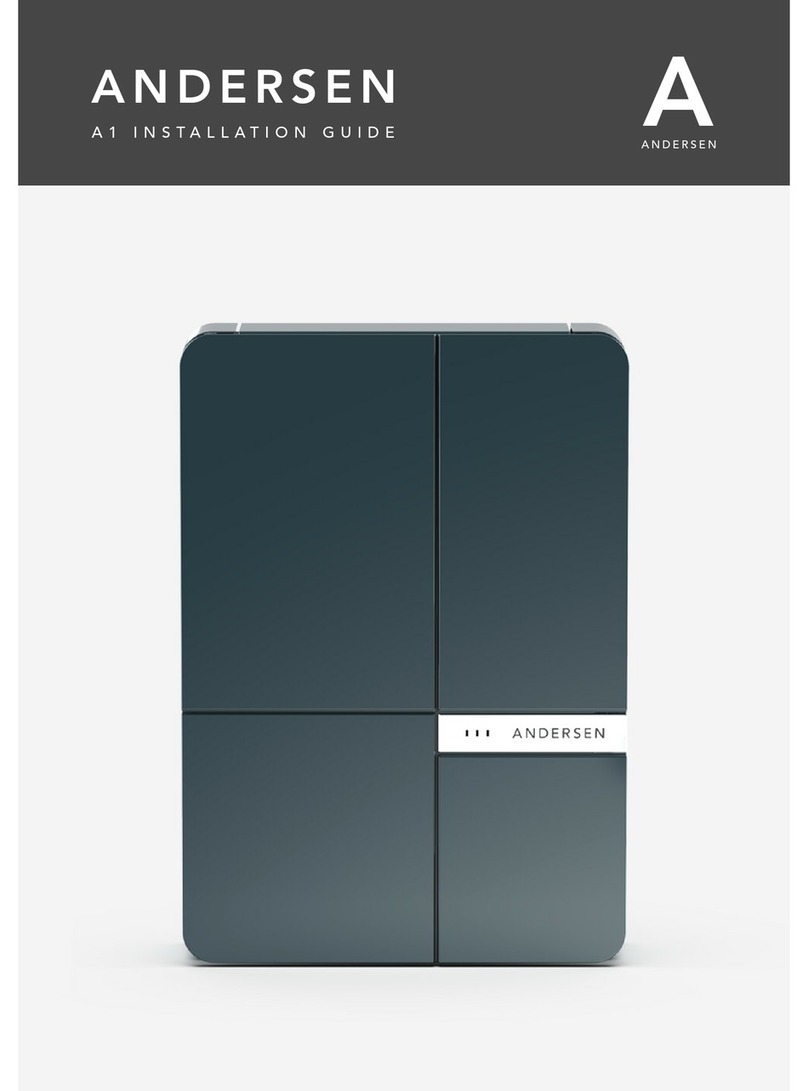

Multi function

button located

at the bottom

left inside the

cable slot

x5