9 1-13-2022

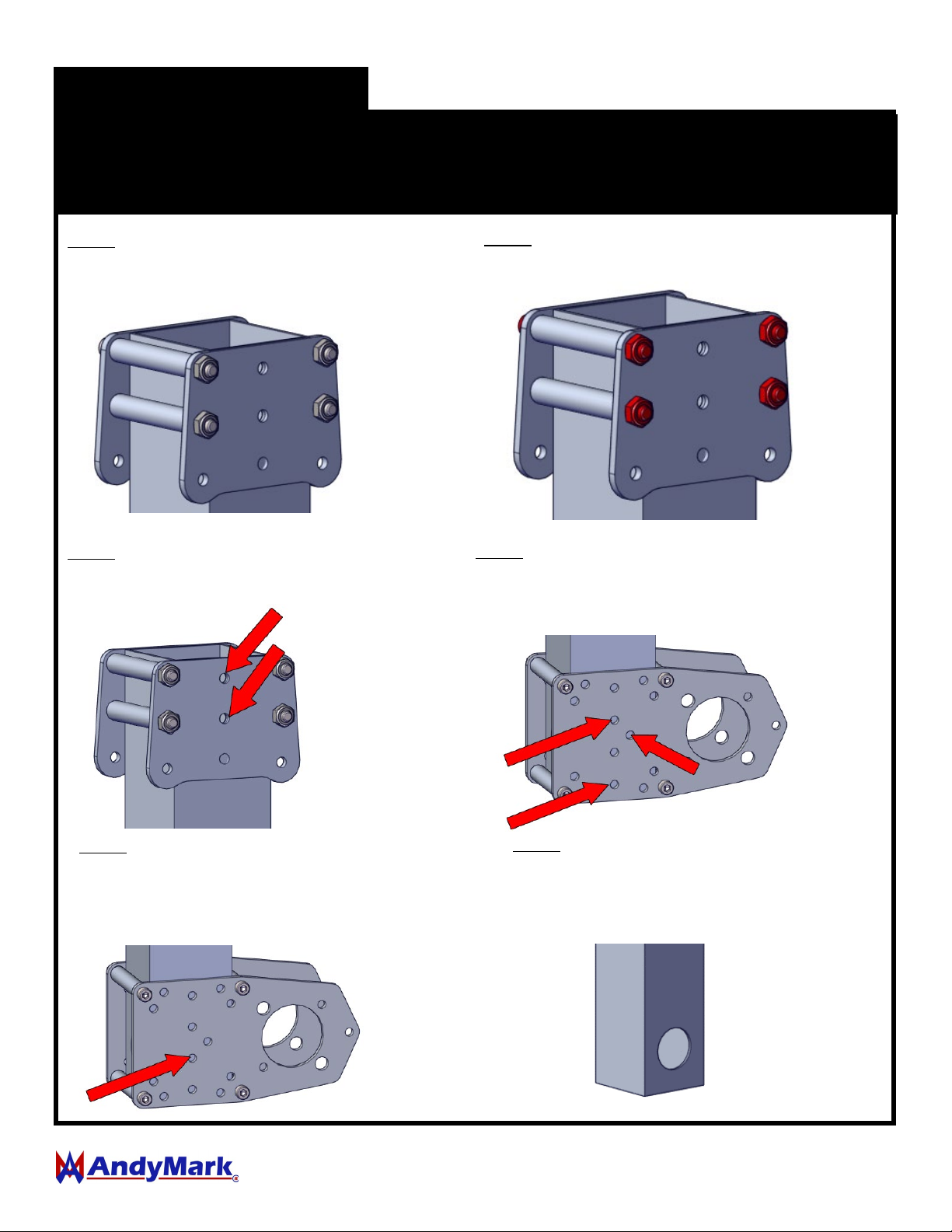

Tips for drilling: Keep drill bit straight and perpendicular to the tube surface.

Make sure not to push to hard and bend the tube surface.

Ensure all chips and burrs are removed from the inside and outside of the tube after drilling.

Step 1: Align the flat edge of the

bearing plate with the edge of the

Box Tube.

Step 2: Tighten screws to secure

assembly.

Step 3: Use a #7 .201" drill bit and

drill two holes on both sides.

Step 4a: Move the bearing plate assembly to the other

end of tube and other face 90 degrees opposed to the

faces with the holes drilled in the previous step. Use a

#7 .201" drill bit and drill three holes on both sides.

For 2-Stage Climbers drill the following additional holes in the 1.5” Box Tubes

Step 4b: Align the winch plate

assembly to the other end of the tube.

Use a #7 .201" drill bit and drill three

holes on both sides. Ensure the offset

hole aligns across the tube.

For 1-Stage Climbers drill the following additional holes in the 1.5” Box Tubes

Step 5b: Move the winch plate

assembly to the face 90 degrees

opposed to the faces with the holes

drilled in the previous step. Use a

#7 .201” drill bit and drill in the

center hole on ONE side.

Step 5c: Using a step drill bit, open

up the hole in the tube to

approximately 1.125” in diameter.

The rope will pass through this

hole so make sure the edges are

deburred and smooth.