VSH SUPER

Compression Fittings

Metallic Sealed

Technical Information |Installation Instructions

EN

Areas of application

■Suitable for domestic water systems according to

DVGW W 534 and DIN 1988, pipe materials:

Copperpipe DIN EN 1057 and stainless steel pipe

DINEN 10312, DVGW GW 541 dimensions 12 to 42 mm,

certification no. DW-8511AQ2006

■Suitable for gas installations according to DVGW

worksheet G 260/I the 2nd gas type, according to

DIN3387 (removable pipe connections for metal gas

pipes / smooth pipe connectors) and in accordance

with DVGW G 600, TRGI 2008, pipe material: Copper

pipe according to DIN EN 1057 and DVGW GW 392,

semi-hard (R250), dimensions 12 to 22 mm,

certification no. NG-4502BL6101 (use support sleeve)

■According to DIN 1988 and DVGW worksheet G 600,

TRGI 2008 VSH SUPER compression fitting made of

brass may be installed under plaster.

Under certain conditions brass components (including

nuts, clamp rings of VSH SUPER compression fittings) can

be aected by stress corrosion cracking. This special type

of corrosion leads to component failure.

To prevent this, such systems must not be exposed to

ammoniac or chlorinated environments (e.g. stables,

swimming pools). Furthermore, no condensate should

form on the fittings. Particularly in the areas where fittings

and pipes are continuously cold must be fully and non-

diusively equipped with closed cell insulation to reliably

prevent condensation. The insulation used and all other

adhesives, additives and coatings have to be absolutely

free of chlorine, ammoniac and nitrite.

If in doubt, a clearance certificate must be obtained from

the manufacturer.

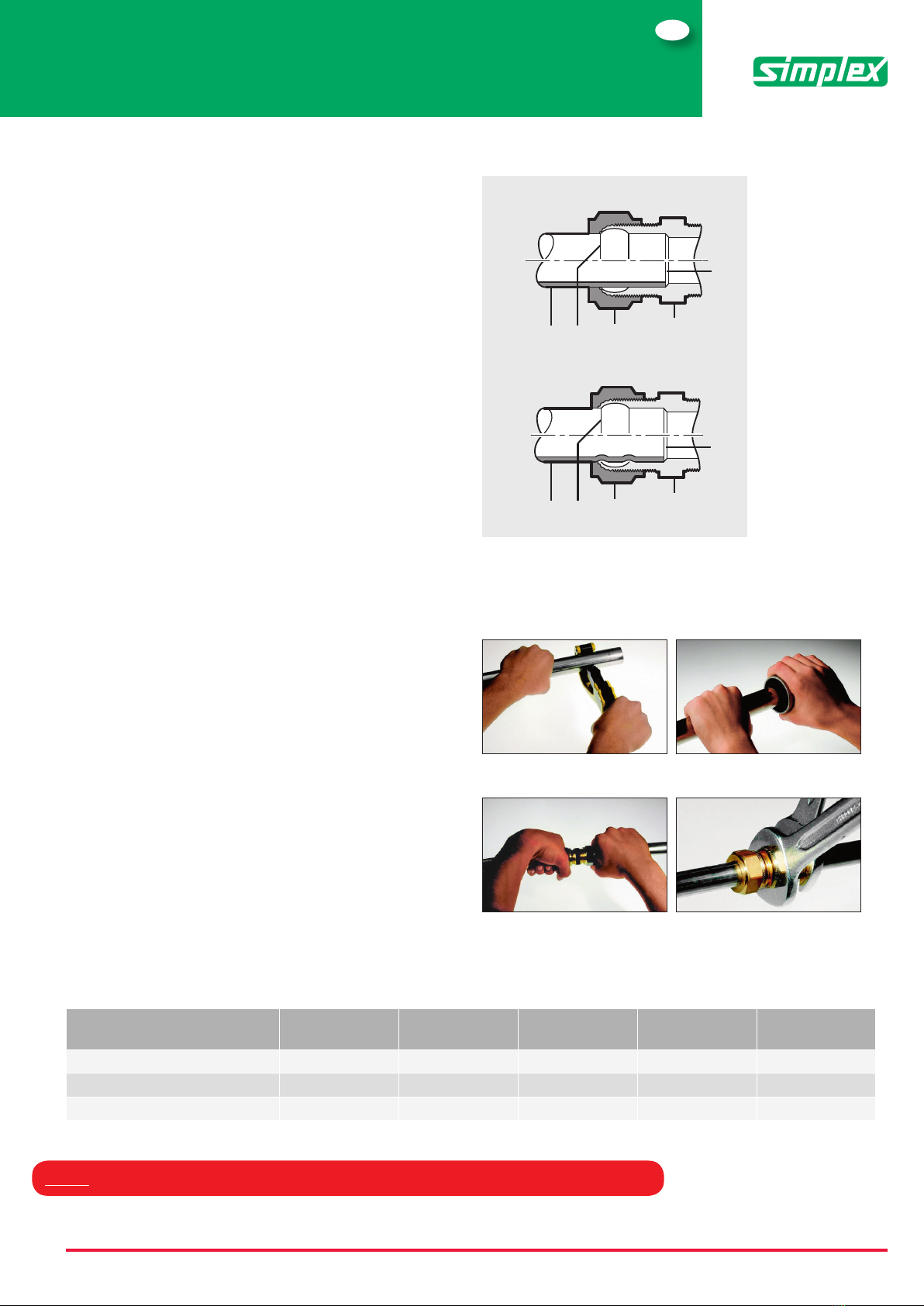

The prescribed processing instructions with information

concerning the correct installation of the union nuts must

be observed.

When using VSH SUPER compression fittings in gas systems,

no oil or grease may be used to facilitate assembly.

Danger of explosion! Only aids authorized in accordance

with the relevant DVGW guidelines and with appropriate

DVGW registration are permitted.

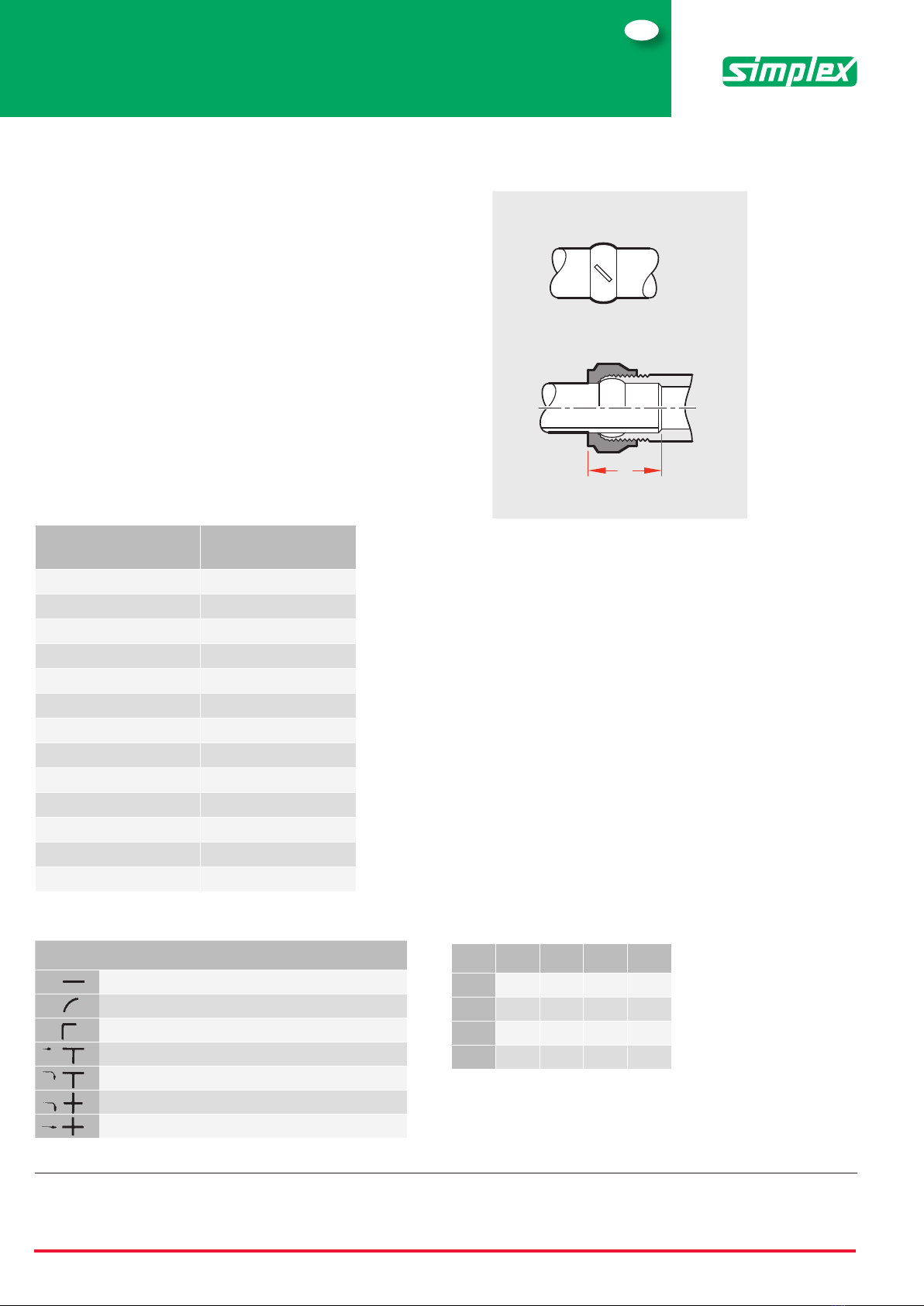

The reuse of a previously used fittings is only permitted

with a new seal set.

Important Installation Notice!