TPC ERN Series User manual

COIL WINDING MACHINE ERN T-VERSION

OPERATING INSTRUCTIONS

ERN 22, 32, 32S, 42, 52

TPC s.r.o

Pálenica 53/79

03301 Liptovský Hrádok

SLOVAKIA

Tel.: +421-44-5221366

Fax: +421-44-5222088

E-mail: [email protected]

www.tpc.sk

Version: 1.3

Date: December 21, 2018

1. Introduction

1.1 Characteristic features

2. Technical data

2.1 Climatic conditions

3. Description of machine

3.1 Description of controls

3.2 Description PC display

4. Installation and preparation of working equipment

4.1 Connection to the power

5. Winding operation

5.1 Switching the machine ON and gear setting

5.2 Backup of winding data in case of an electricity drop

5.3 Winding and programming window

5.4 Explanation of concepts STANDSTILL, START, STOP

5.5 Winding programme selection

5.6 Start and Stop of winding cycle

5.7 Foot pedal

5.8 Protection shield

5.9 Winding corrections

5.9.1 Spindle reference position setting

5.9.2 Wire guide relative position setting

5.9.3 Number of turns correction

5.9.4 Total counter

5.9.5 Wire guide correction

5.9.6 Wire guide direction change

5.9.7 Abort step

5.9.8 Back winding

5.9.9 Deceleration ramp for the STOP - button

5.9.10 Spindle zero position

6. Joystick

7. Programming

7.1 Basis of programming

7.2 Step parameters programming

7.2.1 Basic step types

7.2.2 Wire guide shift

7.2.3 Winding step

7.2.4 Wire guide jump

7.2.5 Delay

7.3 Display and assignment of the layer

7.4 Programming corrections

7.4.1 Insert empty step

7.4.2 Delete step

7.4.3 Copy step

7.4.4 Global change

7.4.5 Coordinate offset

1

1

2

2

2

3

6

7

7

8

8

10

11

11

12

12

13

14

15

15

16

17

17

18

18

19

19

20

20

21

23

24

25

25

25

27

31

32

33

34

34

35

35

36

37

7.5 Special functions

7.5.1 Layer-stop

7.5.2 Layer end

7.5.3 Warnings

7.5.4 Automatic correction

7.5.5 Automatic switch to manual regime

7.5.6 Trapezoidal winding

7.6 Auxiliary inputs and outputs

7.6.1 Window for inputs and outputs

7.6.2 Digital inputs programming

7.6.3 Digital outputs programming

8. Steps list

9. Programme saving and opening

9.1 Programme opening

9.2 Programme saving

9.3 Programme copy

10. Menu

10.1 Programme locking

10.2 Error messages

10.3 Model selection

10.4 Display language

10.5 Winding machine number

10.6 Access PIN code setting

10.7 Zero spindle position mode

11. Firmware and upgrade

11.1 Upgrade of the application programme

11.2 Upgrade of the control board

12. Creation and modification of the operator list

13. Production log settings

13.1 Production log

13.2 Terminal mode

14. Software GRAPHIC

15. Gear change

16. Package contents

17. Fuse change

18. Maintenance

19. Warranty period and service

38

38

39

39

40

42

43

44

44

45

45

47

51

51

53

54

55

55

56

57

58

58

58

59

60

60

60

61

62

62

63

64

65

66

66

66

66

1. INTRODUCTION

Bench-type universal coil winding machine ERN is designed for winding the coils,

transformers, chokes, resistors etc with wire up to diameter of - see technical data.

1.1 Characteristic features:

- 15" industrial capacitive touch screen for data display and programming

- wide range of application for winding simple or complicated coils, multi-chamber coils,

trapezoidal or asymetric windings

- AC servo, that is used like a spindle drive assures excellent dynamical parameters,

constant torque and accurate positioning

- wire guide on ball bearings with a separate stepping motor

- accurate reversible turn counting

- microprocessor-controlled winding cycle without time waste

- wide programming options

- special functions Layer-stop, Automatic guide correction, Manual regime

- 4 programmable digital outputs

- 4 programmable digital inputs

- 40 GB programme store

-connection : 2x USB 2.0

1x USB 3.0

1x LAN

1 / ERN T / V 1.3

2. TECHNICAL DATA

Wire diameter (mm):

Pitch range (mm/rev):

Winding width (mm):

Winding speed / torque [rpm/Nm]:

Accuracy of spindle stop [rev]:

Spindle position pre-set [rev]:

Wire guide position pre-set [mm]:

Max.speed of wire guide - shift [mm/s]:

- winding

Acceleration/deceleration:

Max.coil diameter [mm]:

Distance between centres [mm]:

Dimensions (mm):

Weight [kg]:

Power supply [V/Hz]:

Power consumption [kVA]:

Noise [dB]:

3. DESCRIPTION OF MACHINE

Coil winding machine ERN consists of the following parts:

- controller containing control electronics

- industrial PC with 15" touch screen

- drive unit containing servomotor with gears, pitch control unit with stepping motor,

power electronics and control elements

- base plate

- protection shield

- support with spool holders and dereelers (optional accessories)

- tailstock (optional accessories)

- wire guides (optional accessories)

Winding cycle (linear acceleration, max.speed, linear deceleration and stop) is running automatically

after pressing the START-button. Deceleration is controlled by microprocessor to ensure

accurate stopping and spindle positioning.

rpm MAX.SPEED

NUMBER OF TURNS

DECELERATION

LINEAR ACCELER.

2.1 Climatic conditions

Machine is designed for normal workshop conditions with relative air moisture

70% and temperature in the range of +15 up to +30 C.

ERN22

0,02 - 1,7

0,008 - 40

0,01 - 210

12000 / 0,7

6000 / 1,5

3000 / 3

0,01

0,01

0,01

100

75

table

180

250

780 x 420

85

230 / 50-60

1

74

ERN32

0,02 - 2,5

0,008 - 40

0,01 - 300

6000 / 1,5

1500 / 6

750 / 12

0,01

0,01

0,01

100

75

table

250

340

870 x 460

120

230 / 50-60

1,2

74

ERN32S

0,02 - 3,0

0,008 - 40

0,01 - 300

4000 / 3,5

1000 / 15

500 / 30

0,01

0,01

0,01

100

75

table

250

340

870 x 460

120

3x 400/50-60

1,5

74

ERN42

0,02 - 5,0

0,008 - 40

0,01 - 300

4000 / 3,5

1000 / 15

500 / 30

0,01

0,01

0,01

100

75

table

450

330

910 x 530

140

3x 400/50-60

1,5

74

ERN52

0,02 - 5,0

0,008 - 40

0,01 - 450

4000 / 3,5

1000 / 15

500 / 30

0,01

0,01

0.01

100

75

table

450

650

1235 x 530

180

3x 400/50-60

1,5

74

2 / ERN T / V 1.3

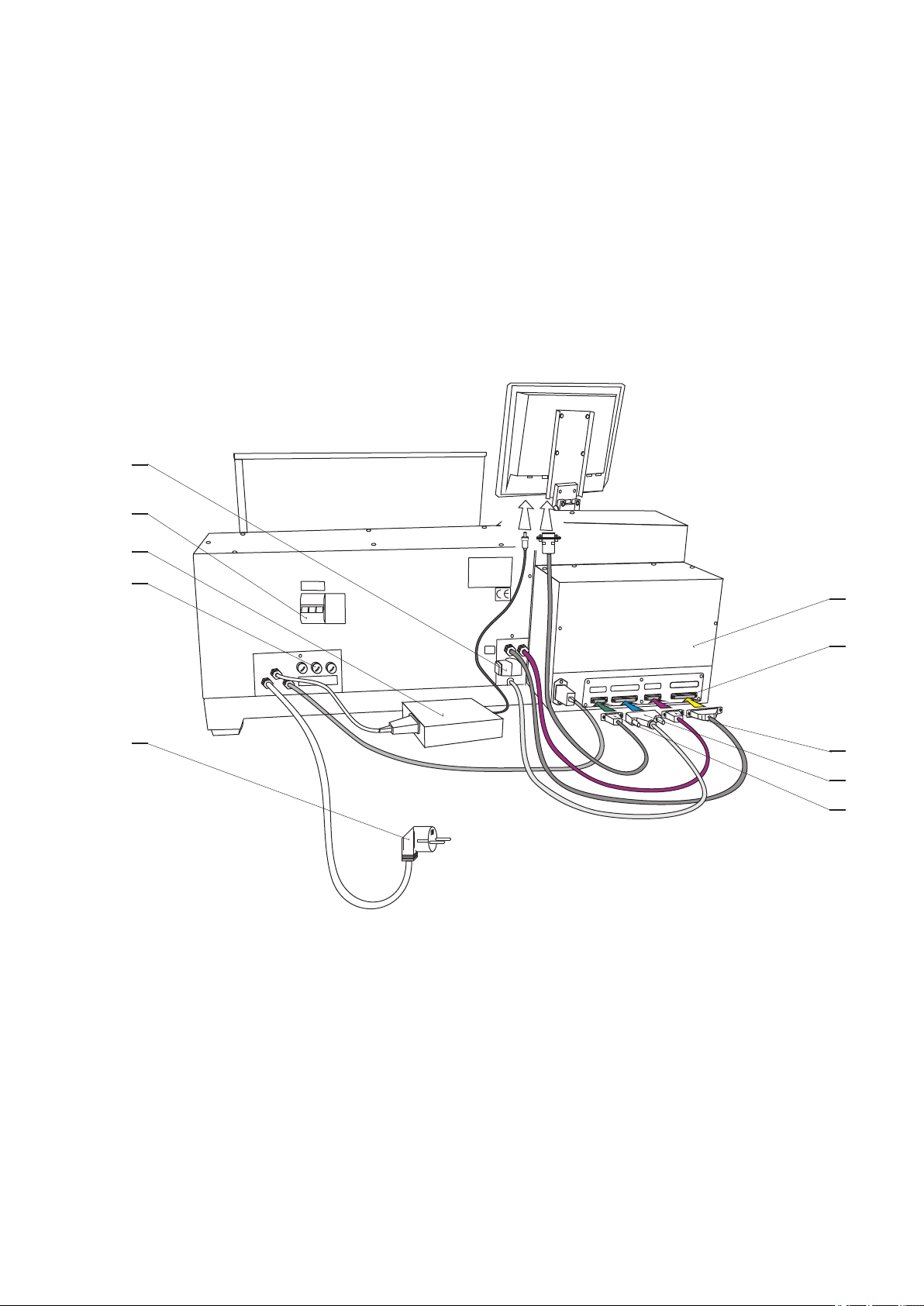

3.1 Description of controls

1 - POWER ON / OFF switch

2 - EMERGENCY STOP - disconnects power in emergency

3 - POWER ON indicator

4 - START button - starts the winding cycle

5 - STOP button - interrupts the winding cycle

6 - BRAKE ON / OFF - switches on/off the electromagnetic brake

7 - JOYSTICK

8 - Fixing screws

9 - Gear cover with timing belt

10 - Industrial PC

11 - Controller

12 - Serial interface between Controller and PC

13 - Connectors for joystick, inputs and outputs

14 - Power plug

15 - AC circuit breaker (only for ERN 32S,42,52)

16 - Fuses

17 - PC power supply

18 - CAN-BUS cable

19 - Control unit cable

20 - Connector for foot pedal

3 / ERN T / V 1.3

4 / ERN T / V 1.3

6

10

3

7

8

16

2 1 5

11

15

9

ENTER

ERN-22

GEAR

6000

REMEMBER

POSITION

OF

4

I

0

EMERGENCY STOP

BRAKE

POWER

WINDING

CORRECTIONS

STEP +

15

16

13

10

18

19

12

17

20

14

5 / ERN T / V 1.3

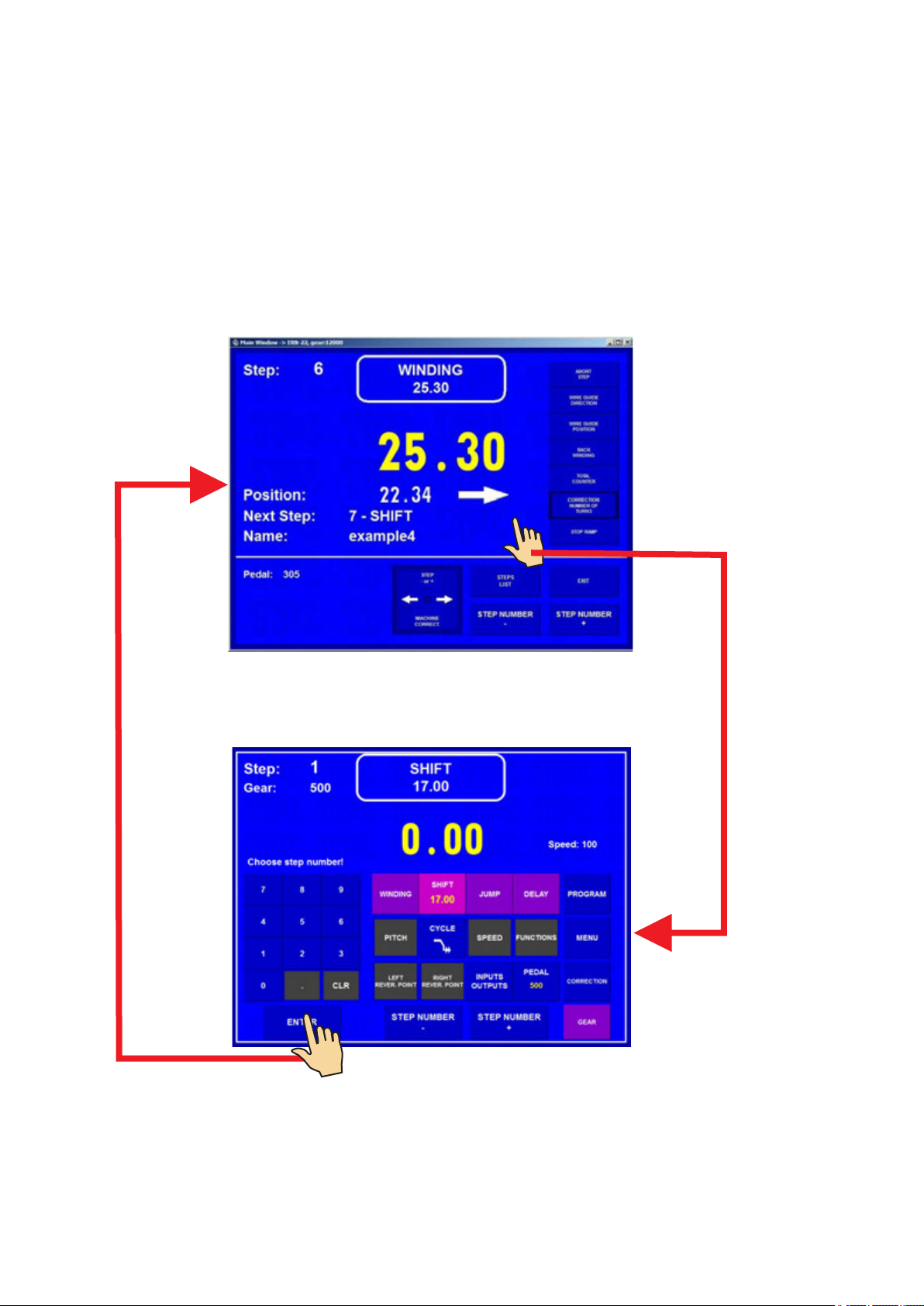

3.2 Description of PC display

Display provides two basic views for standard information during winding:

Winding window and Programming window.

Switching from Winding to Programming window it is necessary to touch central display place.

Switching back - touch ENTER button.

6 / ERN T / V 1.3

Winding window

Programming window

In order to work with a PC we can use the supplied mouse, which we plug into the USB port .

Some advanced computer operations can be performed only with the mouse and keyboard.

4. INSTALLATION AND PREPARATION OF WORKING EQUIPMENT

The machine should be operated by a skilled person who is acquainted with operating manual

and safety formulars. The training is provided by manufacturer or qualified person.

The machine is delivered partly disassembled for easier packing and transport.

Before you switch the machine ON for the first time, assemble it as follows:

a) Mount the controller and display on the drive unit. Connect cables in accordance with the picture - page 5

b) Check and fasten the fuse cartridges on the back panel of the drive unit

c) Assemble support with spool holders and dereelers

d) Connect the foot pedal to the connector (20)

Assembly is now complete and the machine is ready for use.

4.1 Connection to the power

The machine must be powered:

ERN 22,32 - by N/PE 230V/50 Hz AC with tolerance + - 5% and max. power consumption 1,2 k VA.

ERN 32S,42,52 - by 3N/PE 400V/50 Hz AC , tolerance + - 5%, max.power consumption 1,5 kVA.

Before plugging in the connection cable make sure that electric power is in accordance with conforms

to technical requirements. Only professional staff who are qualified in electrical engineering are allowed

to install the power connection to the machine.

Since the leakage current to PE is more than 3,5 mA, in compliance with IEC 61800-5-1

the PE connection must be doubled.

USE THE PE TERMINAL ON THE BACK OF THE MACHINE FOR THIS PARALLER PE CONNECTION.

If a residual current protective device is used, we recommend that each winding machine

be protected individually using a 30 mA RCD.

There is no guarantee for damages caused by wrong or out of range connection

to the power supply.

7 / ERN T / V 1.3

8 / ERN T / V 1.3

After pressing "OPERATOR" it is possible to choose operator name and continue by pressing START.

This window appears only if you choose operator login (see chap. 13.)

OPERATOR

LOGIN

20.4.2011 8:30

OPERATOR : operator 1

OPERATOR

1

4

7

0

START

2

5

8

3

6

9

5. WINDING OPERATION

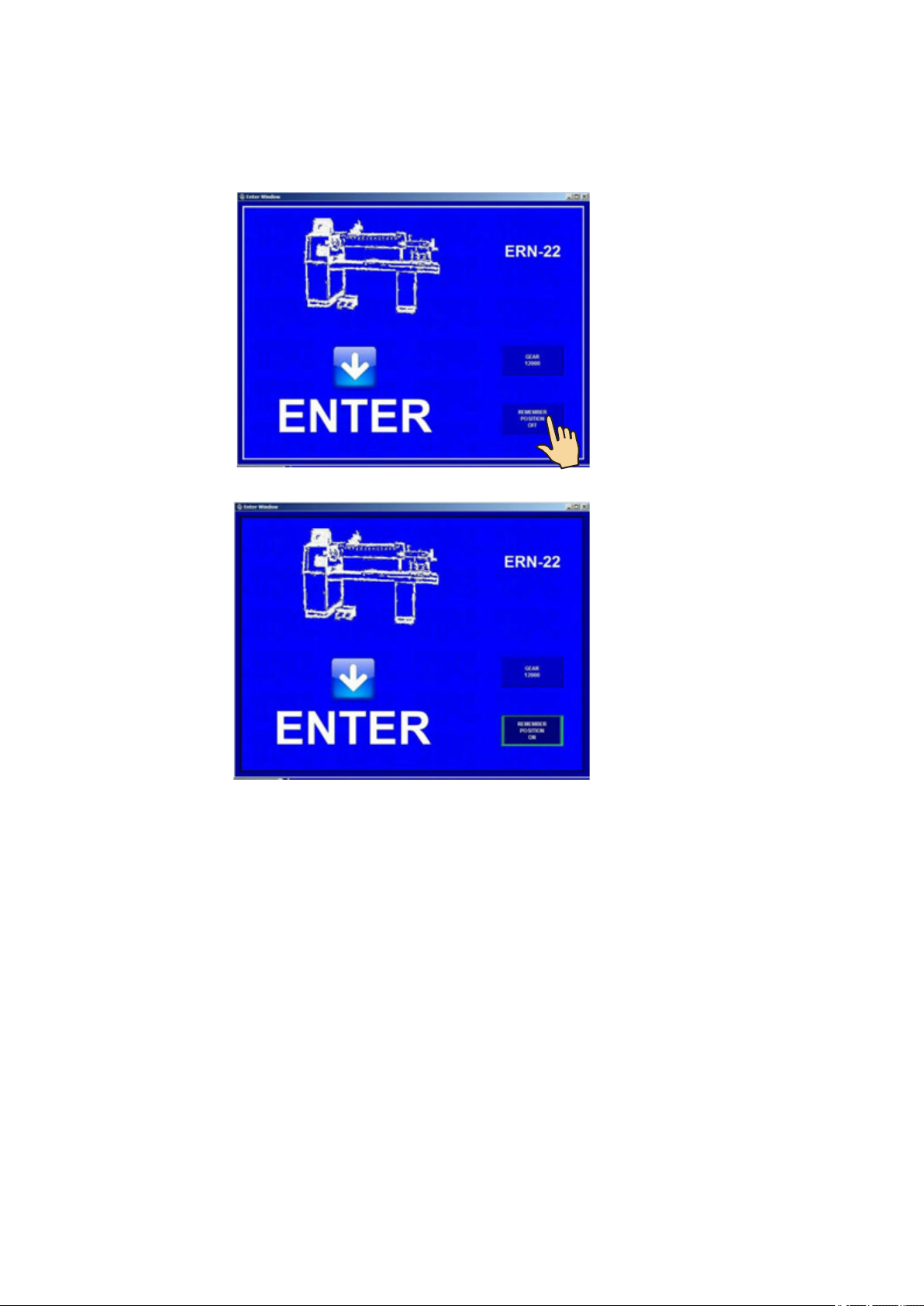

5.1 Switching the machine on and gear setting

After switching on (1) the start window appears

Display provides information about the type of machine the controller is set for.

In this window the set gear can be changed. This must be in ABSOLUTE ACCORDANCE with how

the mechanical gear is set.

28.5. 2015 11:45

After pressing ENTER the initial setup is complete. This means that the wire guide is shifted

to left home (zero) position - zero number of turns, step 0 and the last programme is set.

9 / ERN T / V 1.3

1

2

The gear change requires the use of password - Master code (listed in the warranty card)

as a confirmation that the change is done by an authorized person.

5.2 Backup of winding data in case of an electricity drop

In this window the initial setting of the machine (wire guide position, number of turns and step)

can be activated.

After the activation of this function (MEM.POS.ON) will be updated with values as they were

before the electricity drop.

IN ORDER TO USE THIS FUNCTION THE MACHINE MUST BE EQUIPPED WITH

THE UNINTERRUPTIBLE POWER SUPPLY UNIT (UPS) AND THE REPORT OF

ELECTRICITY DROP (relay for POWER) MUST BE INSTALLED.

IF THE MACHINE IS NOT EQUIPPED WITH THIS, THE INITIAL SETTINGS WILL BE SET TO

ZERO VALUES.

10 / ERN T / V 1.3

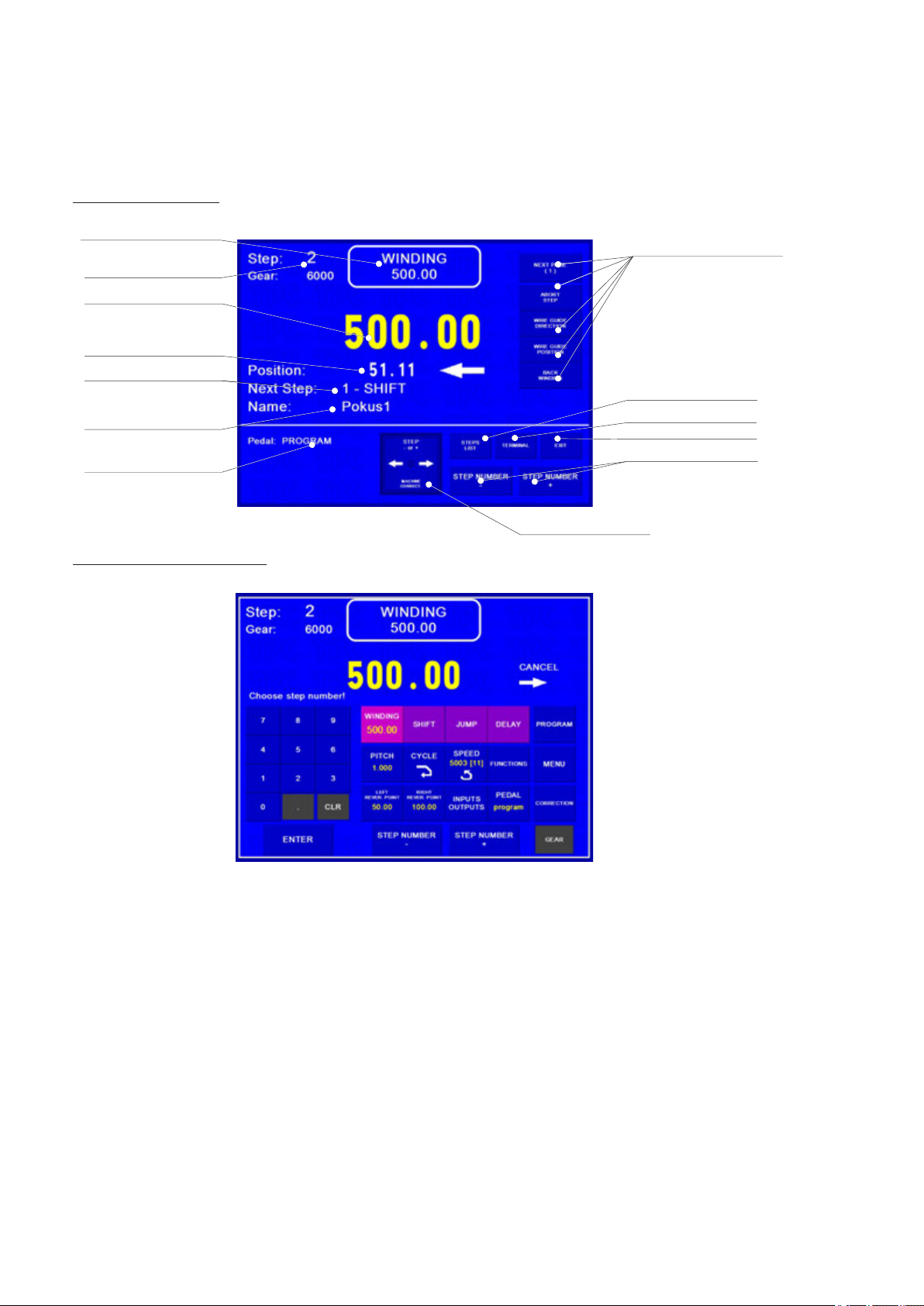

5.3 Winding and programming window

There are two basic windows.

Winding window - provides actual information about the winding process

Programming window - displays the view of programmed step parameters

Winding is possible only in these two windows and STEPS LIST window .

If any other window is opened, the cycle start is blocked.

5.4 Explanation of concepts STANDSTILL, START, STOP

STANDSTILL: State after switching on the machine and pressing ENTER, or after a step

finished. Starting from this state will shift the programme one step forward.

Eg.: If we are in the step 0, after pressing START, step 1 will be running.

START: Active run of some step type (winding, shift, jump and pause).

STOP: State after pressing the STOP-button (cycle interruption).

Pressing the START-button again will reactivate the interrupted cycle. There is no step shifting.

11 / ERN T / V 1.3

Wire guide position

and direction

Actual state

Step

Number of turns

Next step

Coil name

Pedal speed

Winding corrections

Steps list

Terminal

Exit

Step change

Joystick

12 / ERN T / V 1.3

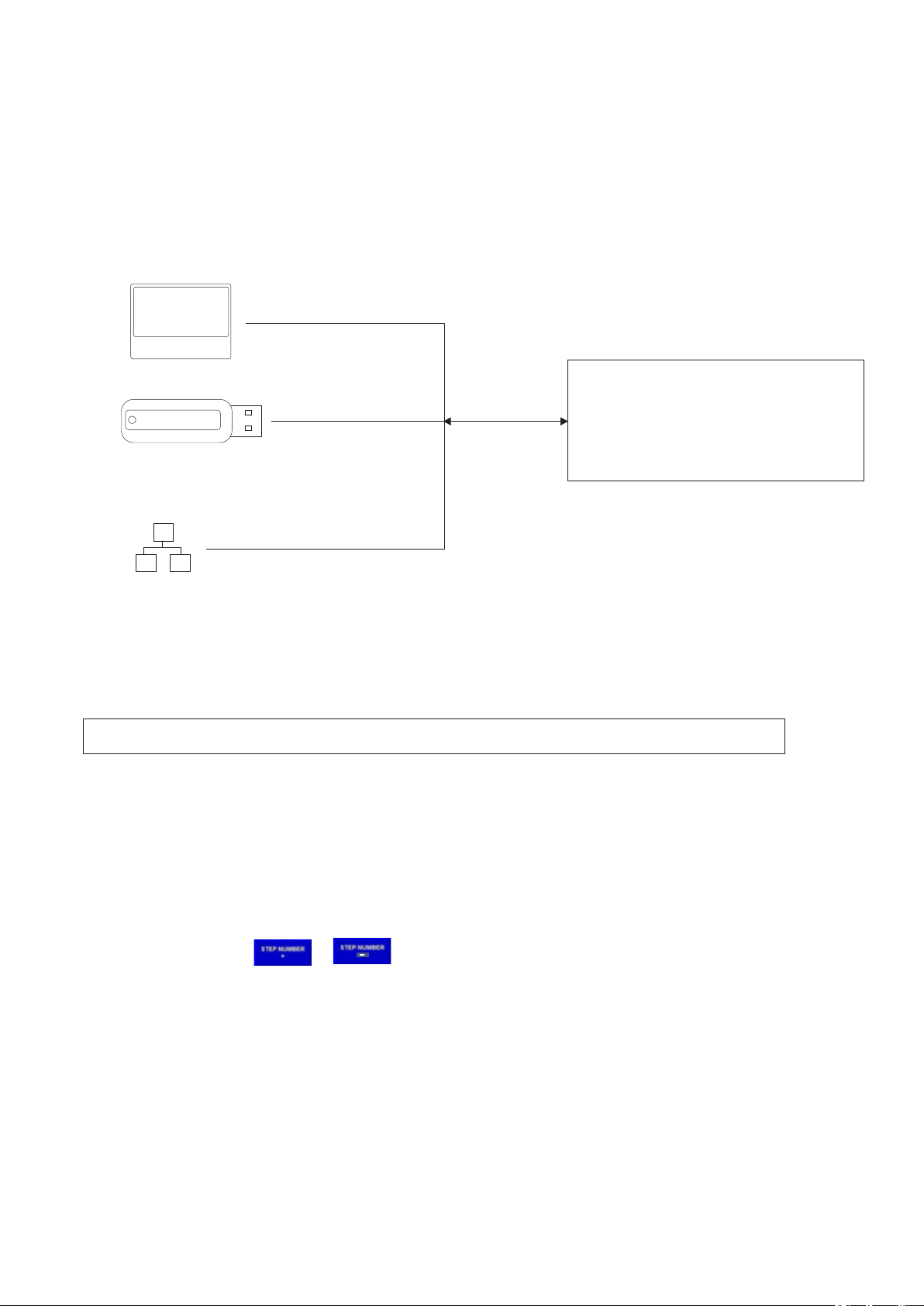

5.5 Winding programme selection

The winding programme we are currently using with (winding or programme creation can be performed)

is called ACTUAL PROGRAMME. Actual programme is located in so-called working part of memory.

Desired winding programme can be loaded to the working part of memory either from PC memory,

USB flash drive or a LAN network.

USB

Proceeding with programme selection: see section 9.

Working part of memory

ACTUAL PROGRAMME

NONVOLATILE MEMORY

Data store in the working part of memory will remain there even if power is disconnected!

PC SSD disc

PART D

LAN

5.6 Start and Stop of winding cycle (programme)

Winding cycle is initiated by pressing START-button (4), or foot pedal.

It is possible to start programme from each step. Required step is set up

by the touch buttons , numeric keyboard or joystick.

STOP-button (5) interrupts the winding cycle. It is the priority button, which means, that the cycle

interruption at incorrect time (while deceleration), may cause inaccurate stopping and

positioning of the spindle.

Cycle interruption at the step "Winding" allows almost all corrections and adjustments.

-

5.7 Foot pedal

Winding machine may be equipped with the following types of foot pedal:

Double foot pedal controls START, BRAKE RELEASE

- left pedal releases the spindle brake

- right pedal works in parallel with the START-button

Double foot pedal controls SPEED, BRAKE RELEASE

- left pedal releases the spindle brake

- right foot pedal controls spindle speed depending how hard the pedal is pressed.

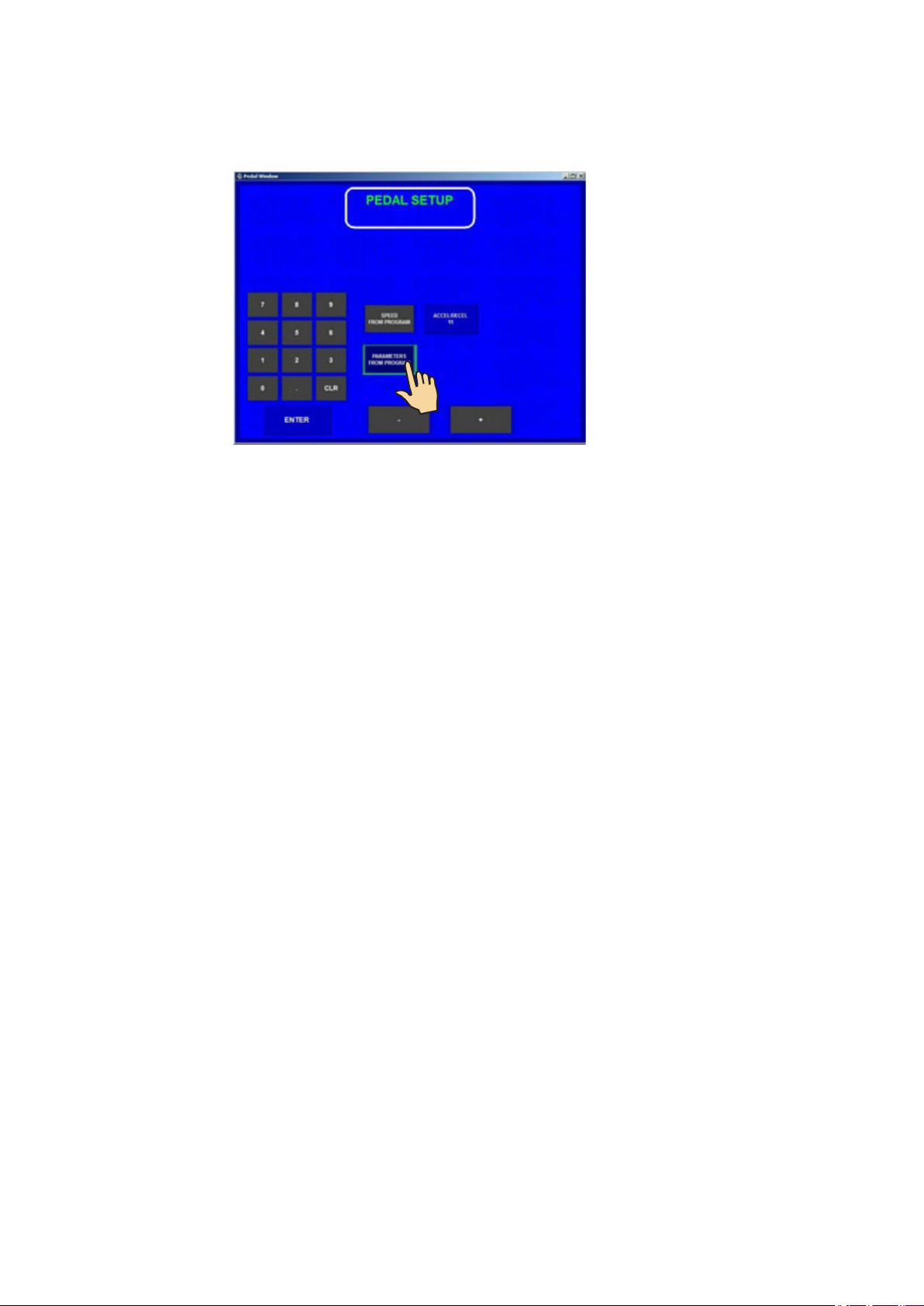

Maximum speed, acceleration and deceleration ramp can be set up by PEDAL button.

Speed set up in this way is applicable only for the current programme. It is independent of the

speed programmed in a specific programme step. Eg.: maximum speed set up by START

pedal may be differ to maximum speed set up by START button.

There is a time delay 0,5 sec between repeated presses for safety work to prevent

unintended start of the next step.

13 / ERN T / V 1.3

Acceleration and deceleration ramp values are always taken from window PEDAL SETUP.

CODE

1

2

3

4

5

6

7

8

ACC.TIME DEC.TIME

1,0

1,6

2,4

3,0

4,0

5,0

6,0

8,0

0,5

0,8

1,2

1,5

2,0

2,5

3,0

4,0

( sec ) ( sec )

Accel. and dec. ramp for pedal

21

3

14 / ERN T / V 1.3

5.8 Protection shield

Protection shield may be programmed as:

CLOSED

It is possible for winding to only work if the protection shield is closed.

If the shield is opened, the cycle is interrupted.

OPENED

It is possible for winding to work whilst the protection shield is open but in such case the spindle speed

will be automatically limited to only work up to pre-set safety values.

When the shield is closed during the winding, the cycle continues with the programmed speed values.

If we require the same maximum pedal speed as speed programmed in the current programme step,

we need to press the PARAMETERS FROM PROGRAM button.

Max. pedal speed is controlled by values programmed in individual programme steps.

Winding cycle start continuity

This option is utilized during winding start. Wire application and winding of the first turns is done by

pedal and then by pressing START button (4) cycle continues. Winding cycle can continue seamlesly

without interruption.

5.9 Winding corrections

Program corrections and adjustments are allowed only in the state "STANDSTILL" or "Winding STOP".

Keys are blocked in other states.

5.9.1 Spindle reference position setting

The spindle can be positioned in the range + - a few degrees and exact position is kept for any

amount of windings.

Reference (zero) spindle position is set up as follows:

- switch the brake off by the switch (6)

- turn the spindle manually to the required position and return the switch (6) to the former position

- press EXIT and then RESET

OR

- press correction button ZERO SPINDLE POSITION 5.9.10 (new spindle position was changed without

machine reset)

Note: When you switch the machine ON (by switch POWER or EMERGENCY STOP),

RESET is running automatically and the spindle position is taken as reference position.

15 / ERN T / V 1.3

5.9.2. Wire guide relative position setting

This correction shifts zero coordinate of the wire guide (relative zero position). It allows you to correct

the wire guide position to be in accordance with the bobbin or winding tool.

Default: 5 mm

rel. pos. 9mm

rel. pos. 5mm

rel. pos. 1mm

the same wire guide coordinate depending on relative position

relative zero

0 0 0

16 / ERN T / V 1.3

Holding any of the buttons pressed (cca 0,5 s) moves the wire guide continuously.

1

2

17 / ERN T / V 1.3

5.9.3. Number of turns correction

It is possible to change the number of turns actually counted.

Correction of decimal and hundredths turn number e.g. XX.36 to XX.30 without adequate spindle

turn, leads to the loss of reference position.

Pressing the RESET button will change the actual number count to zero.

1

2

5.9.4 Total counter

We can switch between TOTAL COUNTER and COUNTER. TOTAL COUNTER counts all spindle turns

until it is set to zero by RESET, or is set differently by numeric keyboard.

Both counters are independent. By switching is only displayed one of it !

This manual suits for next models

5

Table of contents

Other TPC Industrial Equipment manuals