Anritsu MS462 Series User manual

Other Anritsu Measuring Instrument manuals

Anritsu

Anritsu IQ Fiber Master User manual

Anritsu

Anritsu MP1570A User manual

Anritsu

Anritsu MP1800A User manual

Anritsu

Anritsu VectorStar ME7838 Series User manual

Anritsu

Anritsu MW9076 Series User manual

Anritsu

Anritsu MT8820A User manual

Anritsu

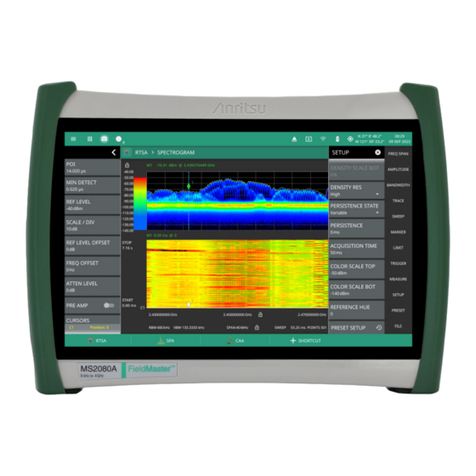

Anritsu Field Master MS2080A User manual

Anritsu

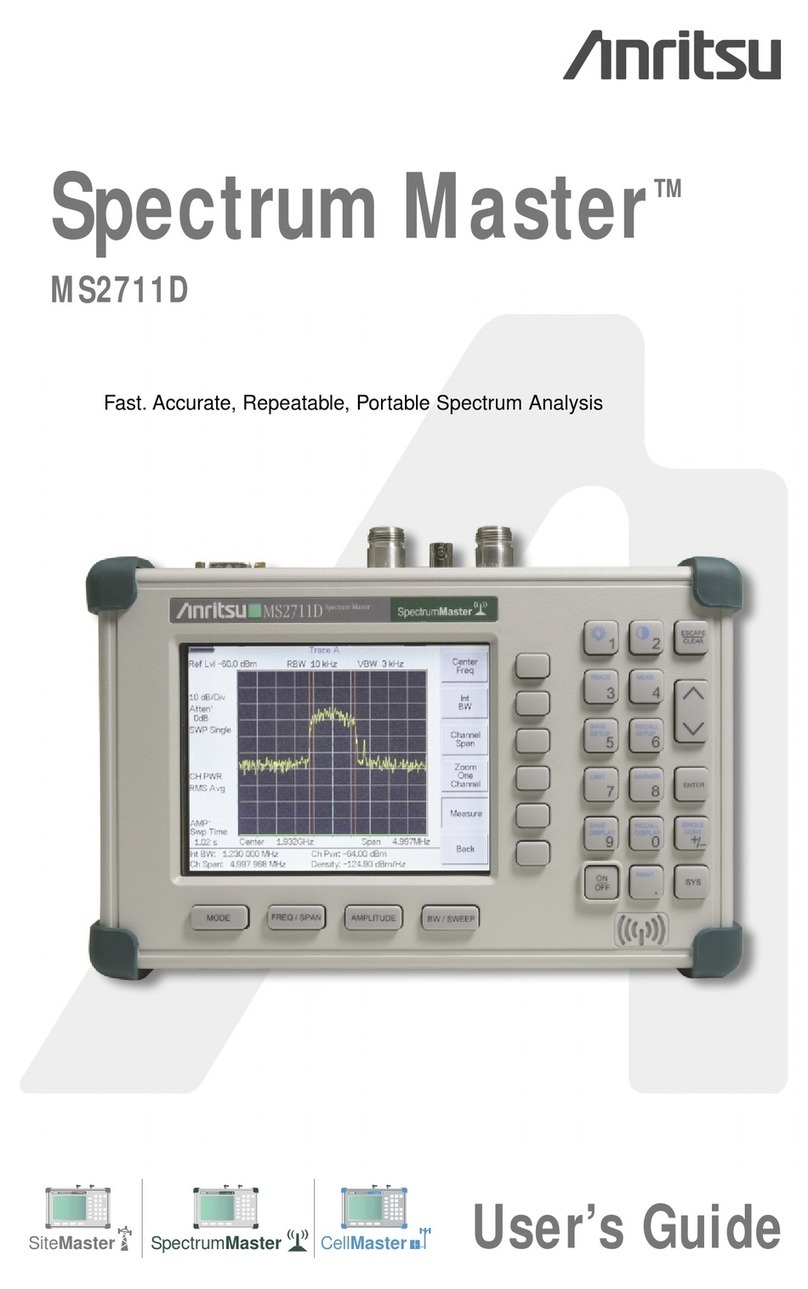

Anritsu Spectrum Master MS2711D User manual

Anritsu

Anritsu VectorStar ME7838D User manual

Anritsu

Anritsu MS9740A User manual

Anritsu

Anritsu SM/PL Series Use and care manual

Anritsu

Anritsu ML2480B Series User manual

Anritsu

Anritsu MT8220A User manual

Anritsu

Anritsu VectorStar MS4640A Series User manual

Anritsu

Anritsu VectorStar ME7848A-0272 User manual

Anritsu

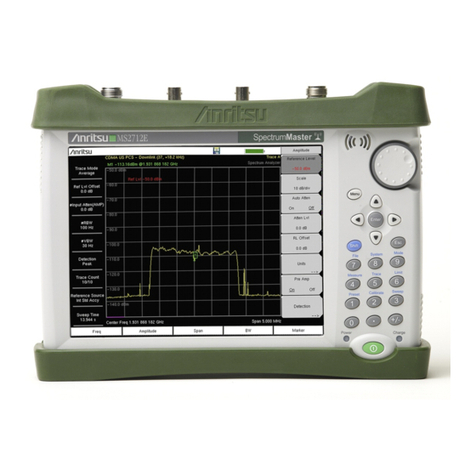

Anritsu Spectrum Master MS2712E User manual

Anritsu

Anritsu MW9076 Series User manual

Anritsu

Anritsu MX269018A User manual

Anritsu

Anritsu Field Master MS2070A-703 User manual

Anritsu

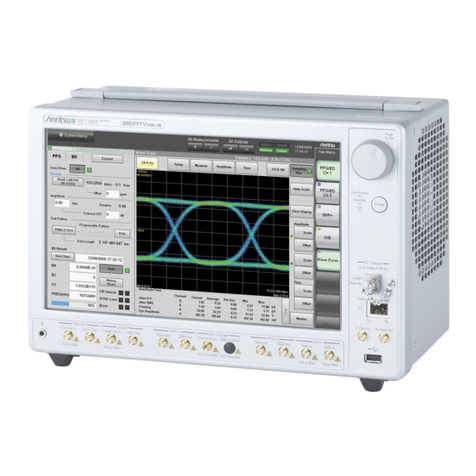

Anritsu MP2100A BERTWave User manual