1. Installing Rear Panel Cables (MS464xA VNA)

QSG-2 PN: 10410-00732 Rev. C VectorStar ME7838D/G QSG

High Performance Modular Broadband/Banded Millimeter-Wave

Vector Network Analyzer (VNA) Measurement System,

70 kHz to 145 GHz or 220 GHz

This guide provides quick setup instructions for the ME7838D/G Broadband/Banded mm-Wave VNA System

assembly. For additional safety and compliance information, and for more details about the assembly,

configuration, setup, and test of the equipment, refer to the VectorStar™ ME7838 Series

Broadband/Millimeter-Wave System Installation Guide – 10410-00293.

This and all other documentation that supports the ME7838D/G is available on the VectorStar product web

page:

http://www.anritsu.com/en-us/products-solutions/products/ms4640b-series.aspx

On this web page, you can select various tabs for more information about your instrument. Included is a

“Library” tab which contains links to all the latest technical documentation related to this instrument.

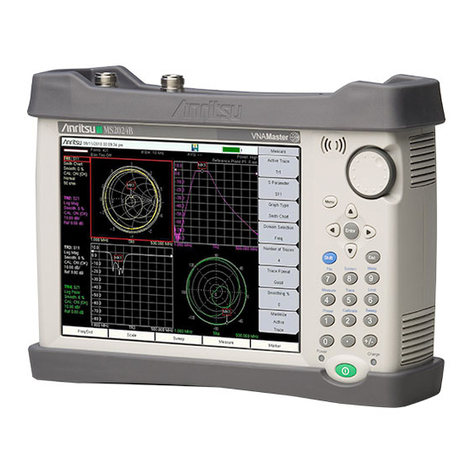

The ME7838D/G Broadband system consists of the MS4647B VNA with Option 007 (Receiver Offset),

Option 08x (Modular Broadband Connection Capability), the 3739C Broadband Test Set, two MA25300A or

two MA25400A Millimeter-Wave Modules, and the necessary front and rear panel cables. A fully configured

system is shown below.

The ME7838D/G Banded Millimeter-Wave system consists of an MS464xA/B VNA with Option 08x, the 3739C

Broadband Test Set, and two 3744A-EE, 3744A-EW, or two OML/VDI Millimeter-Wave Modules.

1. Installing Rear Panel Cables (MS464xA VNA)

The MS4647A VNA can be used in the ME7838D-based systems only.

This section focuses on installing cables when using a MS464xA VNA. Start the ME7838D assembly by placing

the 3739C Broadband Test Set so you can access the rear panel for cable connection.

Warning To avoid injury, use two or more people to lift the MS464xA VNA to the top of the 3739C Test Set.

Caution

To avoid connector damage or inaccurate measurements, before making any connections, review

the 10100-00060-Connector Care Instruction Sheet. Observe connector torque requirements where

indicated in this guide.

Note The MS4647A software does not support the ME7838G system.