Install according to this installation instructions strictly.

If installation is defective, it will cause water leakage,

electrical shock fire.

When installing the unit in a small room, take measures

against to keep refrigerant concentration from exceeding

allowable safety limits in the event of refrigerant leakage.

Contact the place of purchase for more information.

Excessive refrigerant in a closed ambient can lead to oxygen

deficiency.

Use the attached accessories parts and specified parts

for installation.

otherwise, it will cause the set to fall, water leakage,

electrical shock fire.

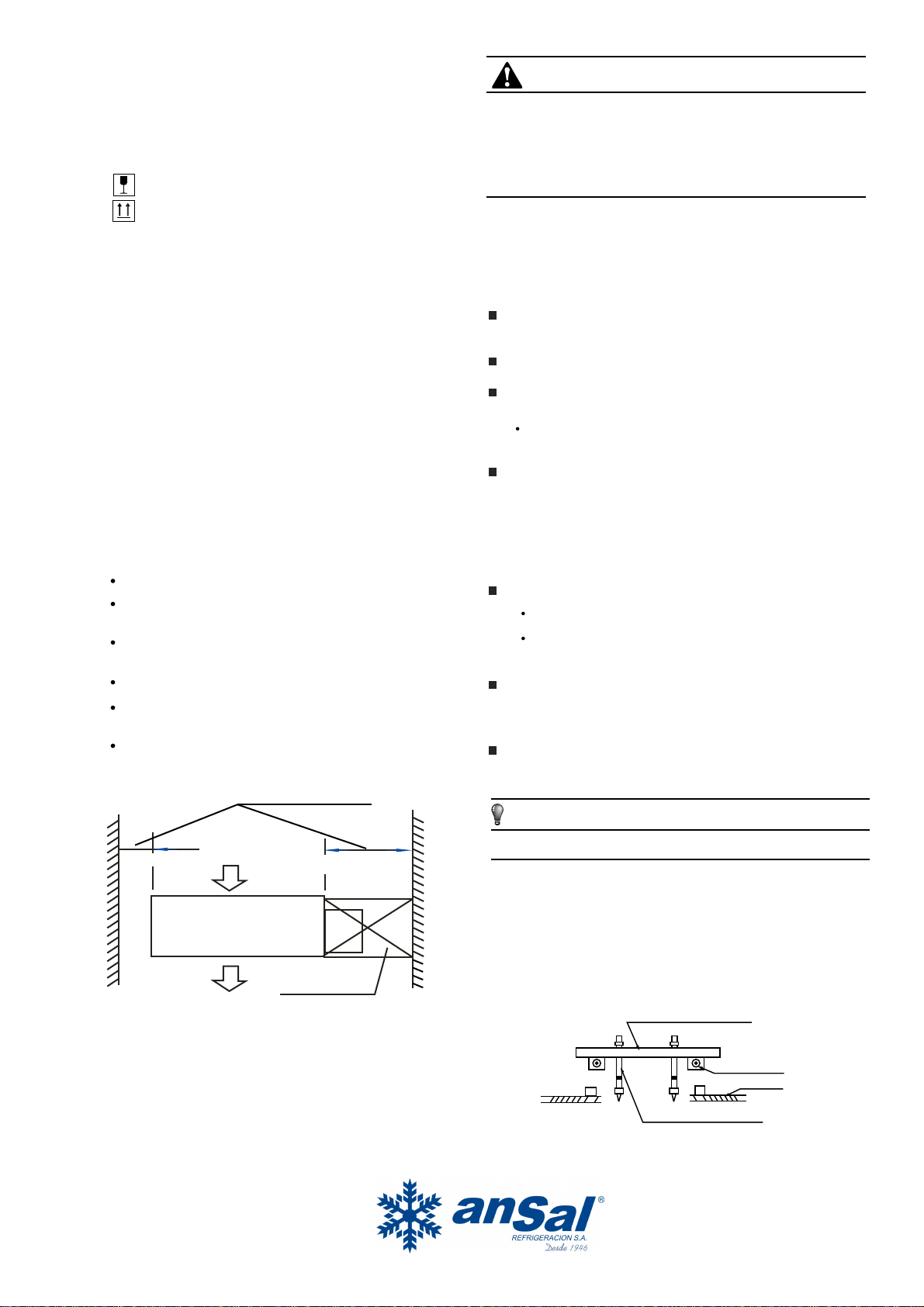

Install at a strong and firm location which is able to

withstand the set' s weight.

If the strength is not enough or installation is not properly

done, the set will drop to cause injury.

The appliance must be installed 2.5m above floor.

The appliance shall not be installed in the laundry.

Before obtaining access to terminals, all supply circuits

must be disconnected.

The appliance must be positioned so that the plug is

accessible.

The enclosure of the appliance shall be marked by word,

or by symbols, with the direction of the fluid flow.

For electrical work, follow the local national wiring

standard, regulation and this installation instructions. An

independent circuit and single outlet must be used.

If electrical circuit capacity is not enough or defect in

electrical work, it will cause electrical shock fire.

Use the specified cable and connect tightly and clamp

the cable so that no external force will be acted on the

terminal.

If connection or fixing is not perfect, it will cause heat-up or

fire at the connection.

Wiring routing must be properly arranged so that control

board cover is fixed properly.

If control board cover is not fixed perfectly, it will cause

heat-up at connection point of terminal, fire or electrical

shock.

If the supply cord is damaged, it must be replaced by the

manufacture or its service agent or similarly qualifued

person in order to avoid a hazard.

An all-pole disconnection device which has at least 3mm

separation distance in all pole and a residual current

device(RCD)with the rating of above 10mA shall be

incorporated in the fixed wiring according to the national

rule.

When carrying out piping connection, take care not to let

air substances go into refrigeration cycle.

Otherwise, it will cause lower capacity, abnormal high

pressure in the refrigeration cycle, explosion and injury.

Do not modify the length of the power supply cord or use

of extension cord, and do not share the single outlet with

other electrical appliances.

Otherwise, it will cause fire or electrical shock.

Carry out the specified installation work after taking into

account strong winds, typhoons or earthquakes.

Improper installation work may result in the equipment falling

and causing accidents.

Be sure to be in conformity with the local, national and

international laws and regulations.

Read "PRECAUTIONS" carefully before installation.

The following precautions include important safty items.

Observe them and never forget.

Keep this manual with the owner's manual in a handy place

for future reference.

1. PRECAUTIONS

WARNING

WARNING

The safty precautions listed here are divided into two categories. In

either case, important safty information is listed which must be read

carefully.

After completing the installation, make sure that the unit operates

properly during the start-up operation. Please instruct the customer

on how to operate the unit and keep it maintained.Also, inform

customers that they should store this installation manual along with

the owner's manual for future reference.

Be sure only trained and qualified service personnel to

install, repair or service the equipment.

Improper installation, repair, and maintenance may result in

electric shocks, short-circuit, leaks, fire or other damage to

the equipment.

Failure to observe a warning may result in death.

CAUTION

Failure to observe a caution may result in injury or damage

to the equipment.

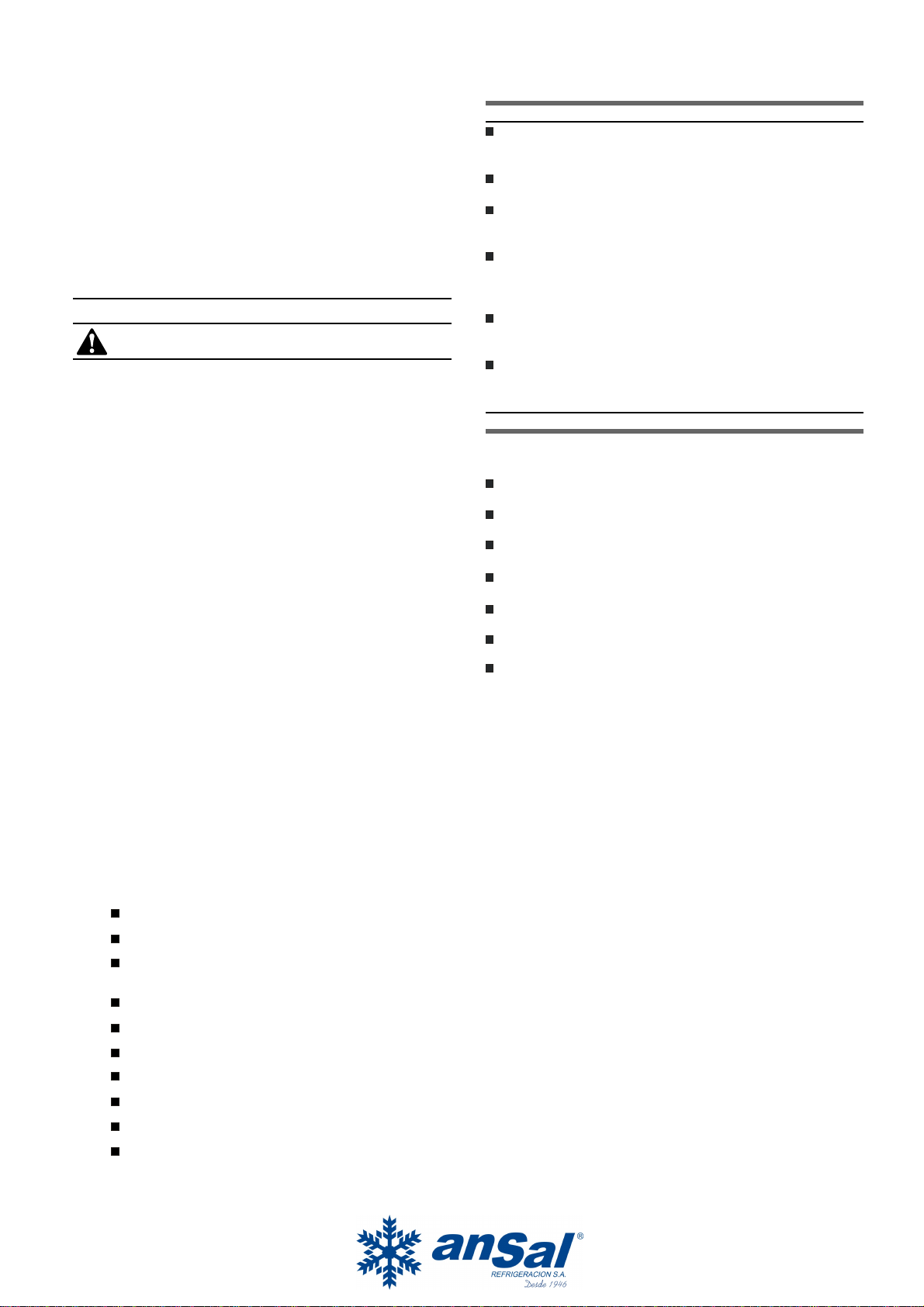

CONTENTS PAGE

PRECAUTIONS....................................................................................... 1

INSTALLATION INFORMATION................................................................ 2

ACCESSORIES....................................................................................... 3

INSPECTING AND HANDLING THE UNIT.................................................. 4

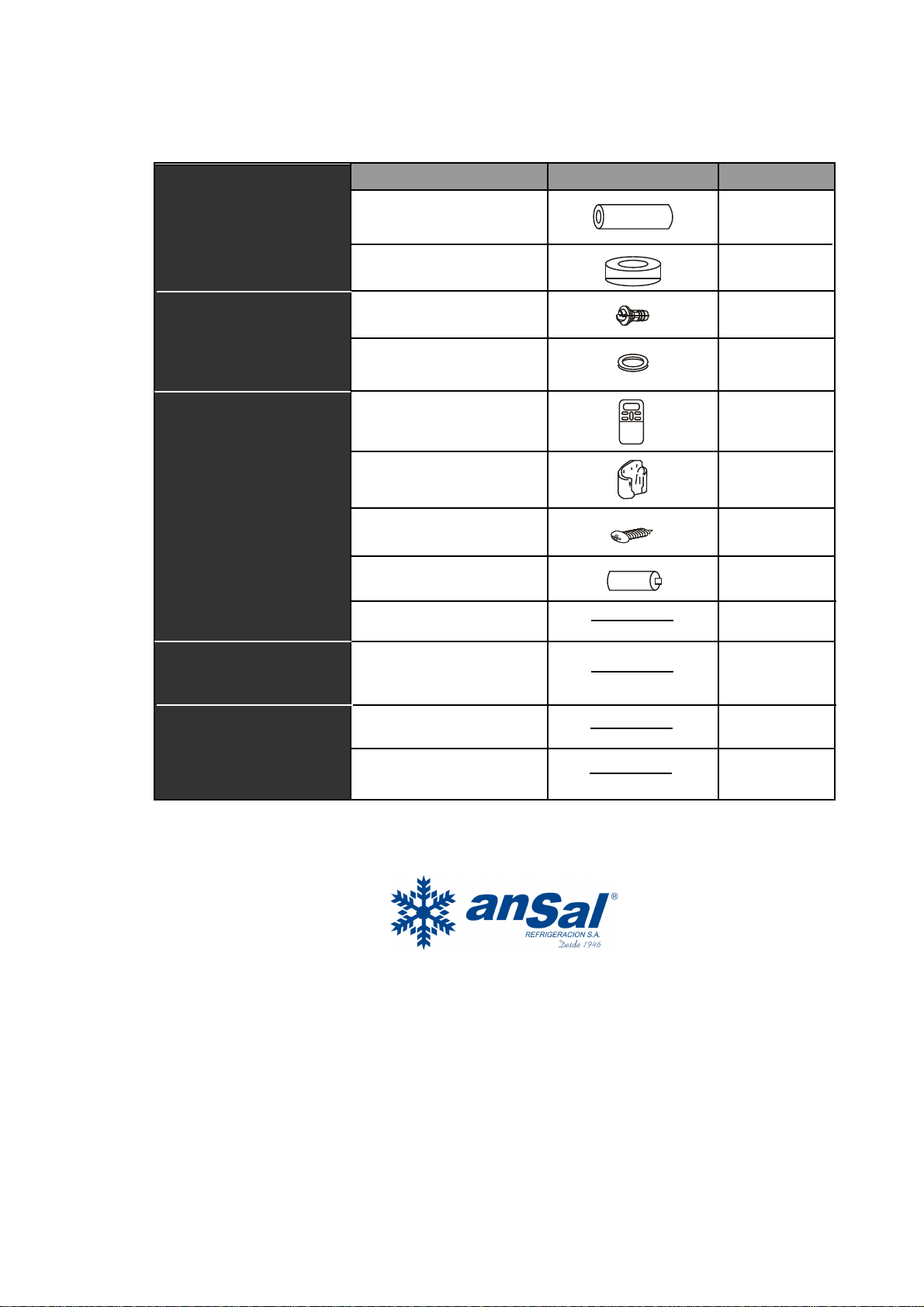

INDOOR UNIT INSTALLATION................................................................. 4

OUTDOOR UNIT INSTALLATION.............................................................13

INSTALL THE CONNECTING PIPE...........................................................17

CONNECT THE DRAIN PIPE....................................................................19

CONNECTIVE DIAGRAM........................................................................20

WIRING.................................................................................................20

TEST OPERATION..................................................................................21