REMOTE MANUAL PULL STATION INSTALLATION

(CABLE TYPE) (Continued)

FIGURE 6

001800

WIRING THE “ANSUL AUTOMAN” II-C RELEASE

TheANSULAUTOMAN II-C is designed for use with the sep-

arately listed or approved fire detection and releasing control

unit which will initiate the electrical signal to operate the

release. Accordingly, conduit and wiring connections

between the release and the detection/alarm control system

should be made by or under the supervision of the detec-

tion/control system manufacturer’s technician.

Installation of Wiring

Aterminal strip is provided inside the ANSUL AUTOMAN

II-C enclosure for making field terminations. It is to be con-

nected to a nominal 12 VDC or 24 VDC releasing circuit. The

activation current is 450 mA at 12 VDC or 750 mA at 24 VDC

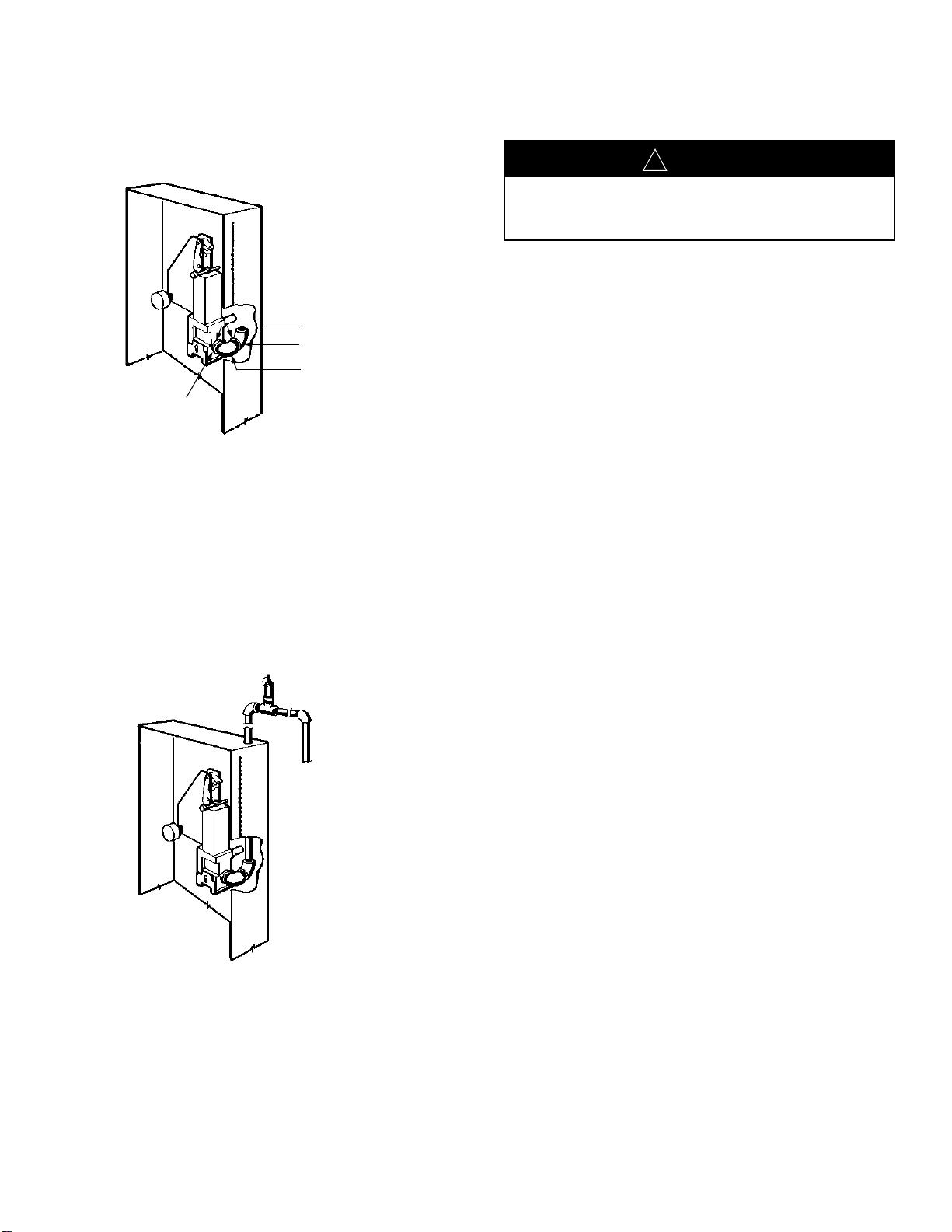

for approximately 55 milliseconds. The wiring diagram shown

in Figure 7 provides the details for making the field wiring

connections.

All interconnecting wiring to the solenoid is to be a minimum

of 18 AWG. All wiring should be done in accordance with the

National Electric Code and/or local codes and standards.

The circuit connections from the output of the Releasing

Control Unit are made to Terminals 4 and 8 of the ANSUL

AUTOMAN II-C release. The release is shipped with a

jumper (J2) installed across Terminals 4 and 5. If the releas-

ing control unit that is to be connected to the release requires

an in-line supervisory device to maintain proper circuit super-

vision, jumper J2should be removed and the appropriate in-

line supervisory device installed in its place. Refer to the

installation instructions from the manufacturer of the releas-

ing control unit for polarity requirements when installing an

in-line supervisory device.

Install the in-line supervisory device (SDxin Figure 7) across

terminals 4 and 5. Refer to the releasing control unit installa-

tion instructions for supervisory device requirements. If an in-

line supervisory device is not required, install jumper J2

across terminals 4 and 5.

Terminals 1 through 3 are provided for auxiliary device con-

nections. Auxiliary equipment is controlled through the action

of switch S1. Refer to the following ELECTRICAL DATA

SECTION for the contact ratings of S1.

Replace the protective cover over the terminal strip upon

completion of field wiring. Test the system by following the

procedures on the following pages.

ELECTRICAL DATA

Input Current: 750 mAat 24 VDC for 50 milliseconds

450 mAat 12 VDC for 50 milliseconds

Input Voltage: 12.5 – 30 VDC

Polarization: Polarization will result only by installation of

a polarized in-line supervisory device (SDx).

Observe polarity when connected to a

release circuit; terminal 4 positive, terminal 8

negative.

Contact Ratings: S1and S2contact ratings are 15A, 1/3

HP, 125 or 250 VAC resistive; 1/2A, 125

VDC; 1/4A, 250 VDC; 5A, 120 VAC

inductive

SOL1Coil Resistance: 28 ohms ± 10% at 77 °F (25 °C)

Operating Sequence

With solenoid cut-off switch (S2), in the normal position (the

release reset lever in the armed position), an electrical circuit

is formed between terminals 4 and 8. As the supervisory

release circuit of the control unit is activated, power is

applied between terminals 4 and 8 of TB1causing solenoid

SOL1to operate the ANSUL AUTOMAN II-C release. As the

release operates, S1and S2will change positions with S2

cutting power to the solenoid, which opens the release cir-

cuit. S1, being a condition switch, provides an isolated set of

form “C” contacts for auxiliary functions at terminals 1, 2 and

3 of TB1.

FIGURE 7

004302

INSTALLATION INSTRUCTIONS

UL R5998 6-16-95 Page 4

CAUTION

!

Do not install cartridge until all testing has been completed

and the system is ready to be armed as instructed on the

following pages.

1/2 IN.

(13 mm)

SEE

DETAIL “A”

DETAIL “A”

THESE SWITCH CONTACTS

TRANSFER UPON ACTUATION

OF RELEASE

“ANSULAUTOMAN” II-C

VOLTAGE TRANSIENT SUPPRESSOR

OR

IN-LINE

SUPERVISORY

DEVICE

UL LISTED

SUPERVISED

RELEASING

CONTROL

UNIT

TB1

J1

TZ1

J2

S1

(+)

(+)

(–)

(–)

S2

SDx

SOL1

NC

NC

ACCESSORY

POWER

SOURCE

*AUXILIARYALARMING DEVICES, SEE S1RATINGS

** FUEL SHUT-OFF VALVE, BLOWER MOTOR, DOOR CLOSER, ETC., SEE S1RATINGS

HIGH

LOW