Safety information:

• Read and understand all instructions in the operation

section of this manual before use.

• Do not substitute components as this may impair safety

and invalidate warranty.

• Observe all warnings and instructions marked on the

unit and within this manual.

• If this product is not working properly, read the trouble-

shooting guide or call Anton.

• Ensure qualified service personnel change sensors and

provide maintenance and calibration.

Additional information:

Sprint is designed to support the working practices defined

in British Standard BS7967 and the Design Standards

EN50379, BS7927 for flue gas analysers. It is highly

recommended that users are fully conversant with BS7967

when using a flue gas analyser for servicing or installing a

boiler system.

Sprint offers a timed let-by/tightness test in accordance

with the UK's Institute of Gas Engineers' procedure IGE/11/

UP/1B.

Performing CO measurements

When performing any CO measurements ensure the unit

is zeroed in clean air in accordance with British Standard

BS7967. A suitable location for sampling clean air will be

outside of the building where the boiler system is installed.

1. Repair of this equipment and gas sensor replacement

shall be carried out by the manufacturer or certified

service centre in accordance with the applicable code

of practice.

2. If the equipment is likely to come into contact with

aggressive substances, then it is the responsibility of the

user to take suitable precautions that prevent it from

being adversely affected.

3. The equipment is designed for use in ambient tempera-

tures in the range -10°C to +50°C and should not be

used outside this range

4. Use only charger(s) supplied by Telegan/Anton.

5. Use only the appropriate Telegan/Anton supplied cables

for connection to the sockets on the instrument.

© Copyright Telegan Gas Monitoring 2012.

All rights are reserved. No part of the document may be photo-

copied, reproduced, or translated to another language without the

prior written consent of Telegan Gas Monitoring

Publication number: M071021

First edition: July 2012

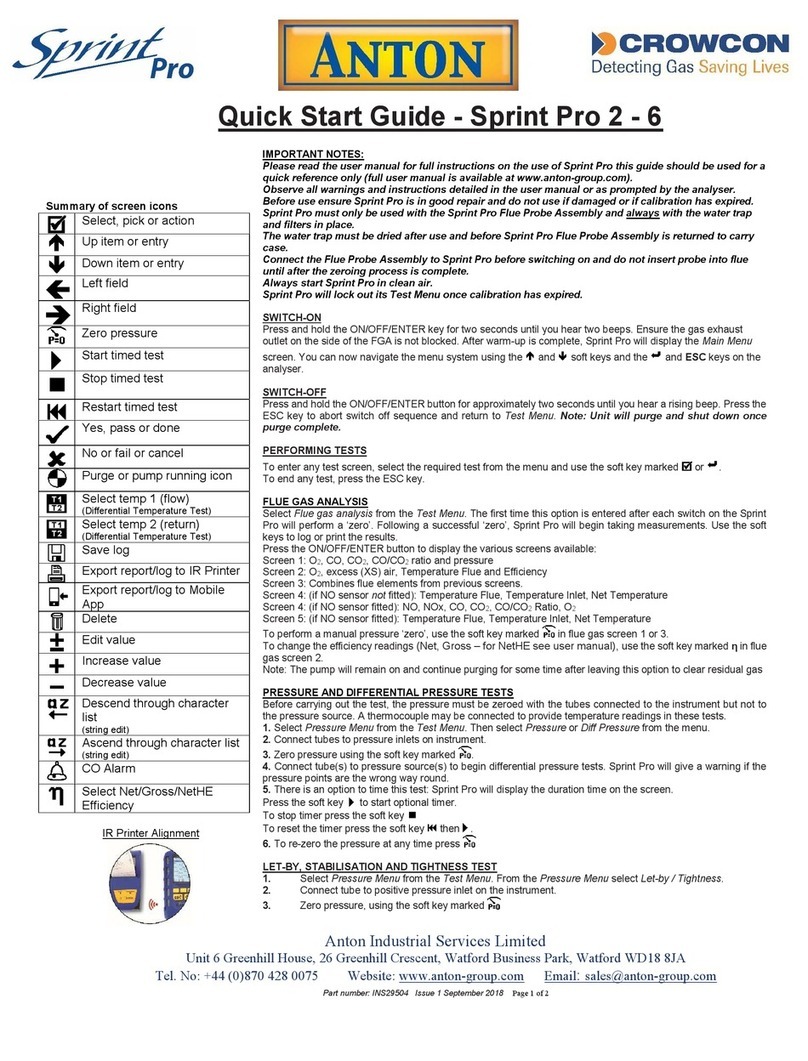

Summary of Screen Icons

þSelect, pick or action

éUp item or entry

êDown item or entry

çLeft field

èRight field

P=0 Zero pressure

u

Start

(Pressure & CO Room Safety tests)

Stop

(Pressure & CO Room Safety tests)

¢

tt

Restart

(Restart timer)

üYes, pass or done

ûNo or fail or cancel

Purge icon

Hold / pause readings

T2

T1 Select temp 1 (flow)

(Differential Temperature test)

T2

T1 Select temp 2 (return)

(Differential Temperature test)

<Save log

Print

Send XML report to Bluetooth®

(eVo3only)

Serial communications with PC in pro-

gress – please wait

Delete