Novanta SYNRAD Pulstar p100 User manual

Other Novanta Measuring Instrument manuals

Novanta

Novanta ventus with mpc6000 User manual

Novanta

Novanta 32-1 Laser User manual

Novanta

Novanta JADAK FM-8 User manual

Novanta

Novanta i401 User manual

Novanta

Novanta v30 User manual

Novanta

Novanta ATI Axia80 User manual

Novanta

Novanta vi30 User manual

Novanta

Novanta gem with smd24 User manual

Novanta

Novanta v40 User manual

Novanta

Novanta f201 User manual

Popular Measuring Instrument manuals by other brands

Safety Vision

Safety Vision SV-IR-THRM user guide

Tektronix

Tektronix Keithley 4200A-SCS Setup and Maintenance

sauermann

sauermann Si-RM3 Simplified user manual

Seikom Electronic

Seikom Electronic NLSW 45-3 Ex SIL2 operating instructions

Escort

Escort iMiniPlus user manual

SSD

SSD SHOETESTER II instruction manual

TE Connectivity

TE Connectivity Integra Ri3 Installation and operating instructions

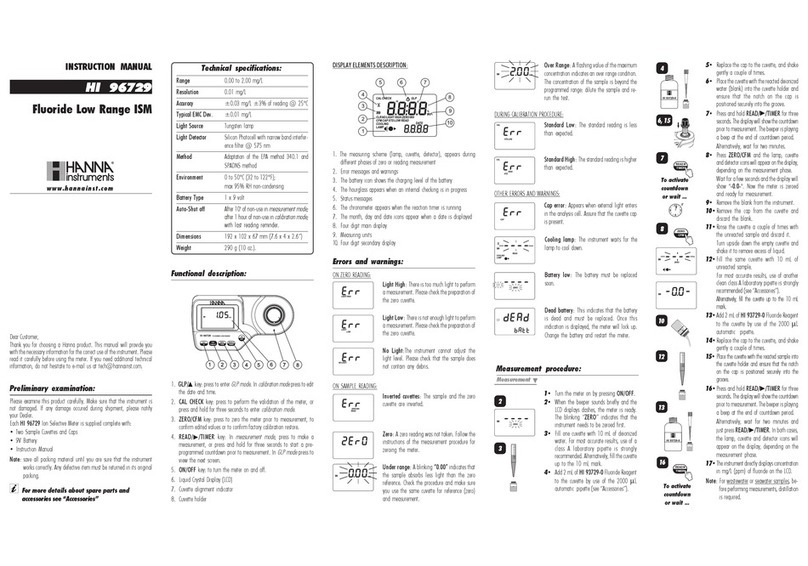

Hanna Instruments

Hanna Instruments HI96729 instruction manual

Newtons4th

Newtons4th PSM1700 Communications manual

Leuze

Leuze AMS 107i Original operating instructions

Omega

Omega DPG 1200 Series user guide

Pard

Pard TA Series Additional manual