ANTTI PLUG&DRY ................................................................................................................................................ 4

SELECTING LOCATION FOR THE DRYER.......................................................................................................... 4

FOUNDATION ........................................................................................................................................................ 4

THE SPACE REQUIRED FOR THE INSTALLATION............................................................................................. 5

PRESENTATION OF THE MACHINE .................................................................................................................... 5

SAFETY.................................................................................................................................................................. 6

INSTALLATION OF THE ANTTI PLUG&DRY ........................................................................................................ 6

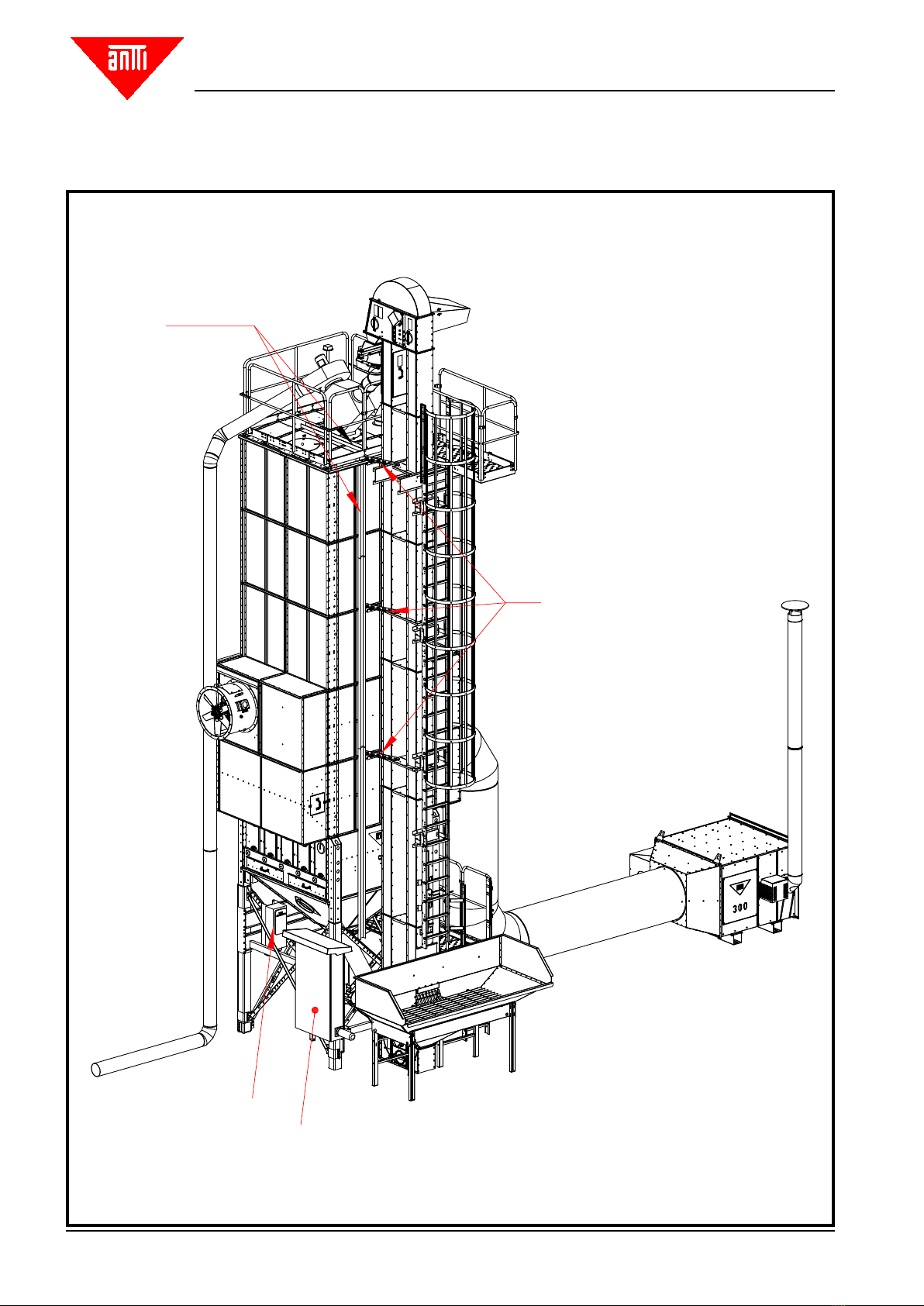

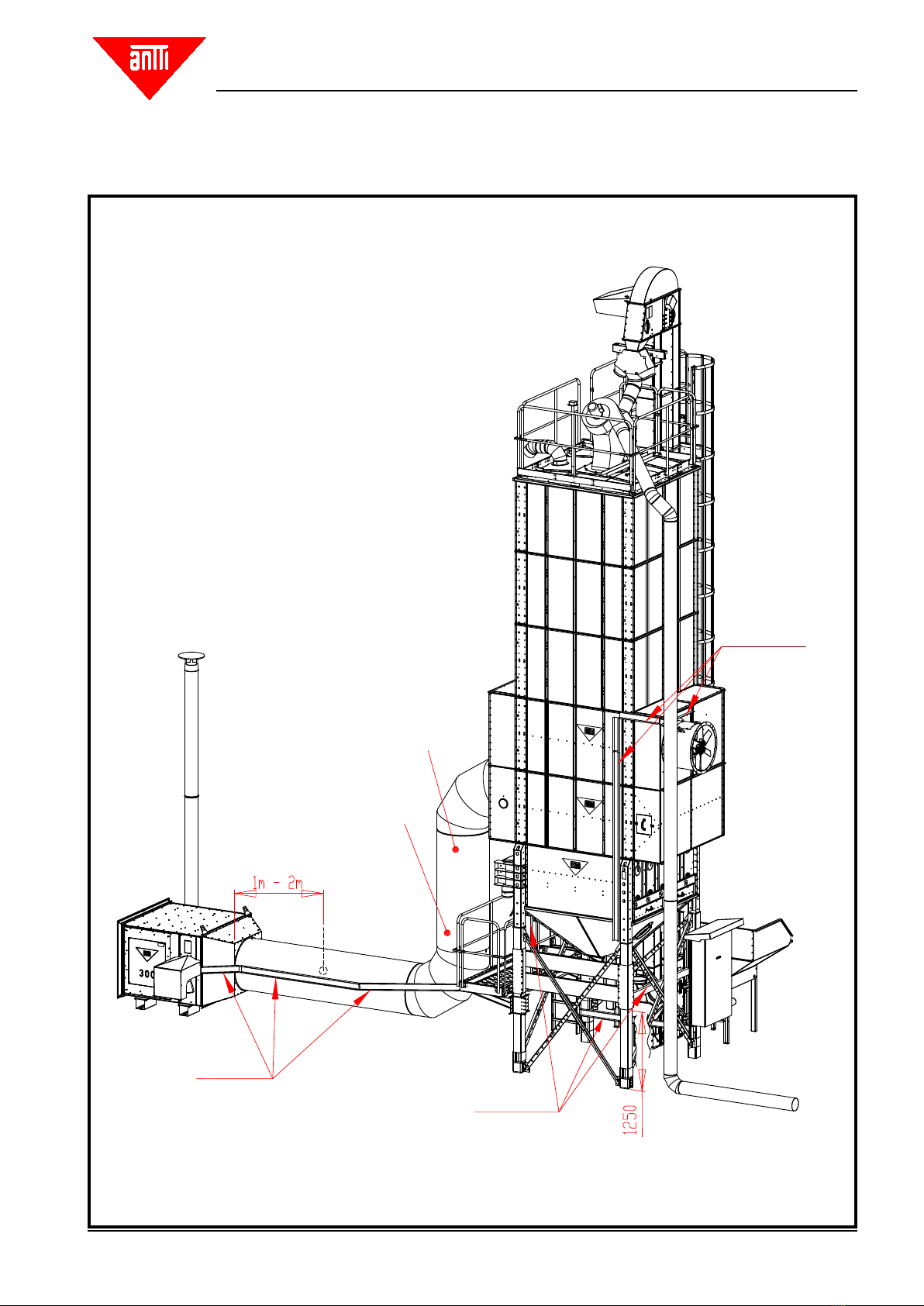

Principle drawings of dierent dryer types with accessories .................................................................................. 8

Installing the electric cabinet and the bracket for the frequency transformer ...................................................... 11

Principle drawing of the cable routing................................................................................................................... 12

Unit-specic cabling ............................................................................................................................................. 13

Example of connector IDs .................................................................................................................................... 14

Electric installations.............................................................................................................................................. 15

Installation ............................................................................................................................................................ 16

Installing the LTM thermostat ............................................................................................................................... 16

Installing the temperature transmitter and the re thermostat in the axial blower ................................................ 17

Installing the vacuum sensor................................................................................................................................ 19

Installing the upper limit sensor (Capacitive, adjustable) ..................................................................................... 20

Installing the temperature transmitter in the duct ................................................................................................. 21

Installing the re thermostat in the duct................................................................................................................ 23

Piping the heaters with a grain pocket.................................................................................................................. 31

Dimensioning of the basic parts viewed from the side ......................................................................................... 32

Dimensioning of the basic parts with a small intake pit viewed from above......................................................... 33

Principle dimensioning drawings for the 10 m³ and 17m³ intake pits ................................................................... 34

Dimensioning of the intake pit to be used with a chain conveyor......................................................................... 35

Installing the base and the legs............................................................................................................................ 36

Sections, air channel ends ................................................................................................................................... 36

Top tanks and cover with handrails ...................................................................................................................... 36

Installing the elevator and the ladder.................................................................................................................... 37

Bolt-assembled hopper 10m³ / 17m³ .................................................................................................................... 37

The intake pit with Skandia conveyor................................................................................................................... 37

Wire control of the 3-way divider .......................................................................................................................... 38

Fuel pipes............................................................................................................................................................. 47

Installing the debris piping for the pre-cleaner...................................................................................................... 47

STARTING UP...................................................................................................................................................... 48

Elevator ................................................................................................................................................................ 48

Pre-cleaner........................................................................................................................................................... 48

Feeder ................................................................................................................................................................. 49

Blower................................................................................................................................................................... 49

Burner................................................................................................................................................................... 49

LTM thermostat..................................................................................................................................................... 49

CONTENTS

Translation of original