DELUXE FOOD WARMER

2P/N 1010678 Rev. F 09/04

DELUXE FOOD WARMER

3

P/N 1010678 Rev. F 09/04

General

The Deluxe Food Warmer (steamer) produces a steam

using plain tap water for quick heating and reconstitut-

ing of food items. Simple push-button action delivers

a shot of water which is immediately converted into

steam. Because the amount of steam is consistent, it

removes the guesswork and produces a uniform fin-

ished product from one operator to the next.

This manual provides the safety, installation and oper-

ating procedures for the Deluxe Food Warmer (steam-

er). We recommend that all information contained in

this manual be read prior to installing and operating the

unit.

Your Deluxe Food Warmer (steamer) is manufactured

from the finest materials available and is assembled to

Roundup’s strict quality standards. This unit has been

tested at the factory to ensure dependable trouble-free

operation.

OWNER INFORMATION

TABLE OF CONTENTS

IMPORTANT! Keep these instructions for future reference. If the unit changes ownership, be sure this

manual accompanies the equipment.

Warranty Information

Please read the full text of the Limited Warranty in this

manual.

If the unit arrives damaged, contact the carrier imme-

diately and file a damage claim with them. Save all

packing materials when filing a claim. Freight damage

claims are the responsibility of the purchaser and are

not covered under warranty. The warranty does not

extend to:

• Damages caused in shipment or damage as

result of improper use.

• Installation of electrical service.

• Normal maintenance as outlined in this manual.

• Malfunction resulting from improper maintenance.

• Damage caused by abuse or careless handling.

• Damage from moisture into electrical

components

• Damage from tampering with, removal of, or

changing any preset control or safety device.

Owner Information .....................................................2

General......................................................................2

Warranty Information .................................................2

Service/Technical Assistance ....................................3

Important Safety Information ....................................4

Specifications .............................................................6

Electrical Ratings.......................................................6

Electrical Cord & Plug Configurations .......................6

Model Designation.....................................................6

Dimensions................................................................7

Shipping Weight ........................................................7

Capacities..................................................................7

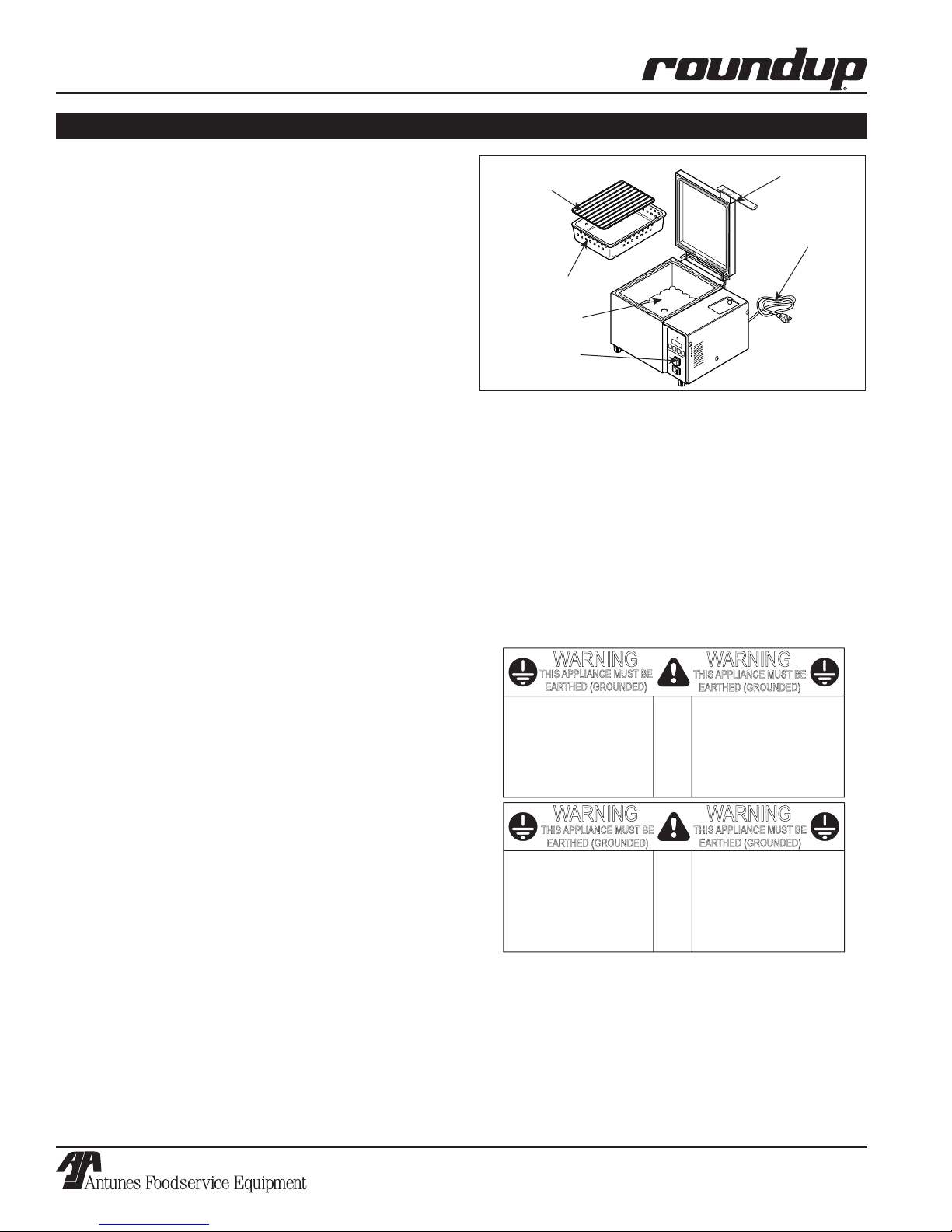

Installation...................................................................8

Unpacking..................................................................8

Equipment Setup.......................................................8

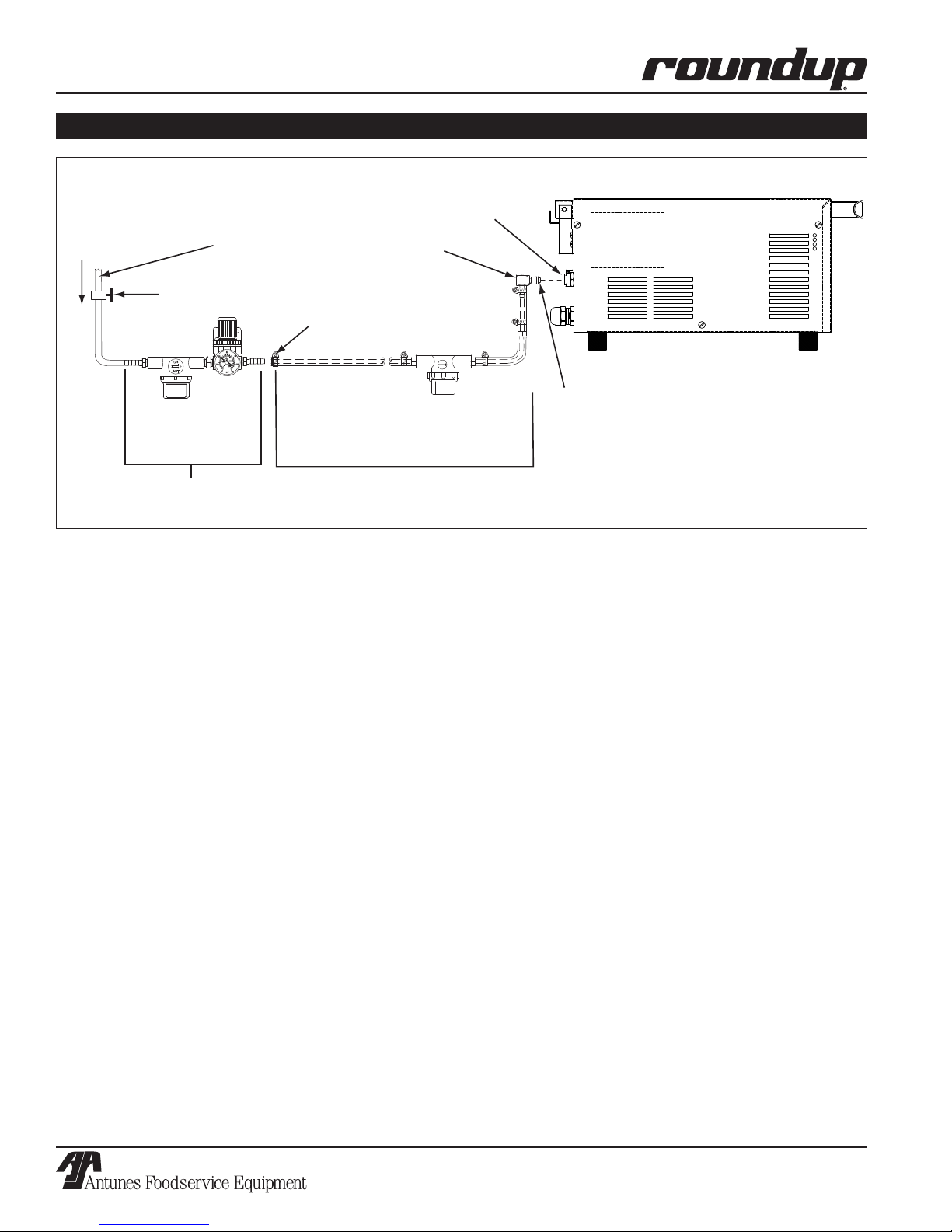

Models DFW/DFWT-100/150 ....................................9

Models DFW/DFWT/DFWF-200/250.........................9

Operation................................................................... 11

General Information.................................................11

Operating Instructions For (Non-Timer) Models......11

Operating Instructions For Timer Models .............. 12

Programming - Timer Models ................................. 12

Steaming Tips......................................................... 14

Hi-Limit Reset Button ............................................. 14

Diagnostic LEDs (Non-Timer Models) Only ........... 14

Diagnostic LEDs (Timer Models) Only ................... 14

Maintenance..............................................................15

Daily Maintenance.................................................. 15

Monthly Maintenance ............................................. 15

Cleaning the Spray Tube and Steam Generator.... 16

Water Tank Filter

(Models DFW/DFWT-100/150 Only) ...................... 17

Checking and Cleaning the Water Strainer

(Monthly) DFW/DFWT/DFWF-200/250 Only.......... 17

Technical Theory of Operation

(Timer Models Only) ............................................... 19

Technical Theory of Operation

(Non-Timer Models Only) ....................................... 19

Troubleshooting .......................................................22

Replacement Parts ...................................................25

Wiring Diagram.........................................................33

LIMITED WARRANTY ...............................Back Cover