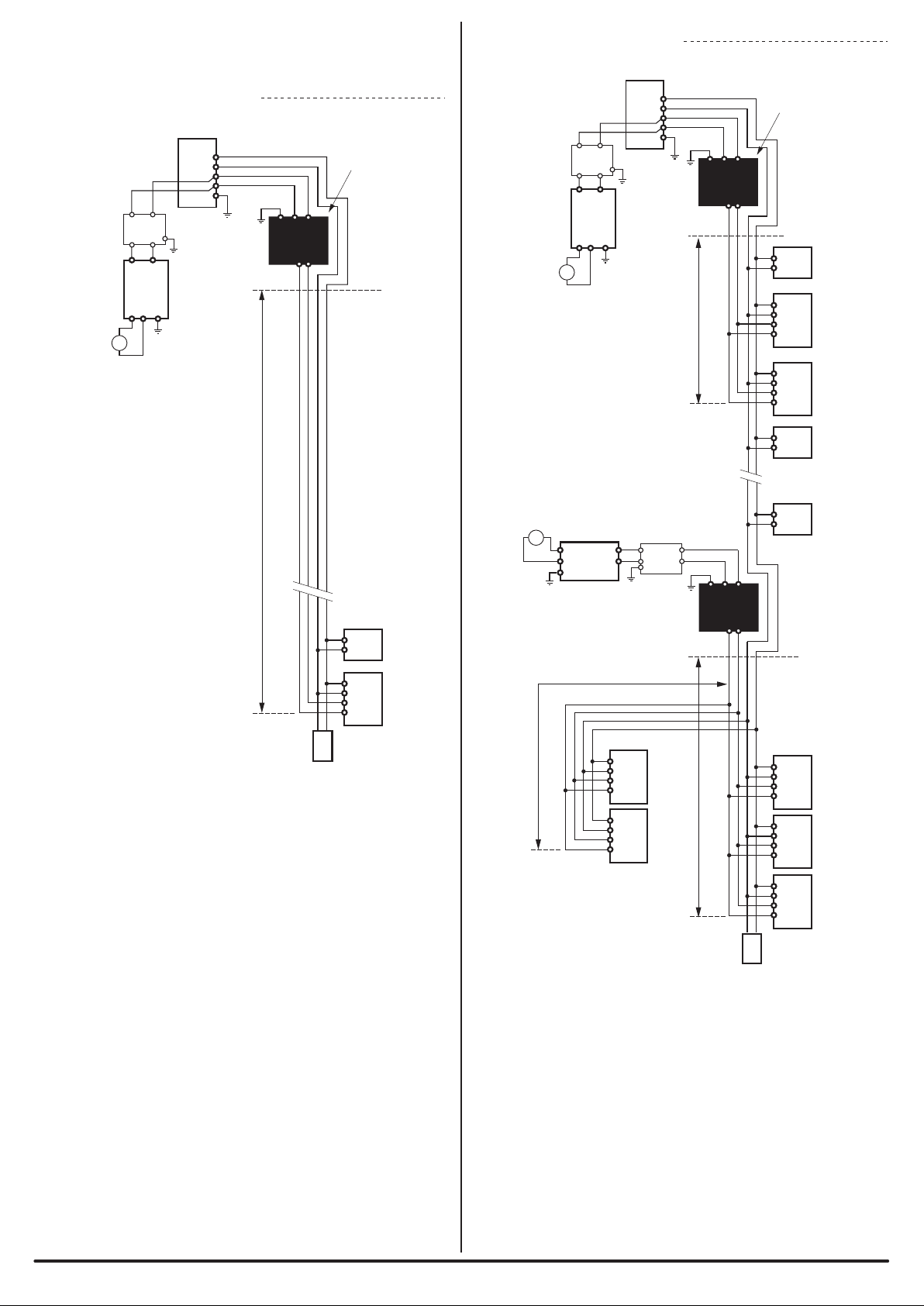

-BSK5217M**1K 8/9-

Parameters Factory

setting

Variable Description

【01.】M18: 5

M30: 6

M18: 6

M30: 7

0-100%

Threshold

【02.】

5

0-100%

Hysteresis

【03.】80

0-100%

Alarm Hi

【04.】0-100%

Alarm Lo

【05.】

50

3-255

【06.】

0

Normally open

Normally closed

0

NO/NC

【07.】

0

OFF

ON

0

Alarm feature

【10.】

0

Delay timer disabled

ON delay timer

Delay timer

ON/OFF

【11.】0-255 0

Delay

1

1

0

1

OFF delay timer

ON/OFF delay timer

2

3

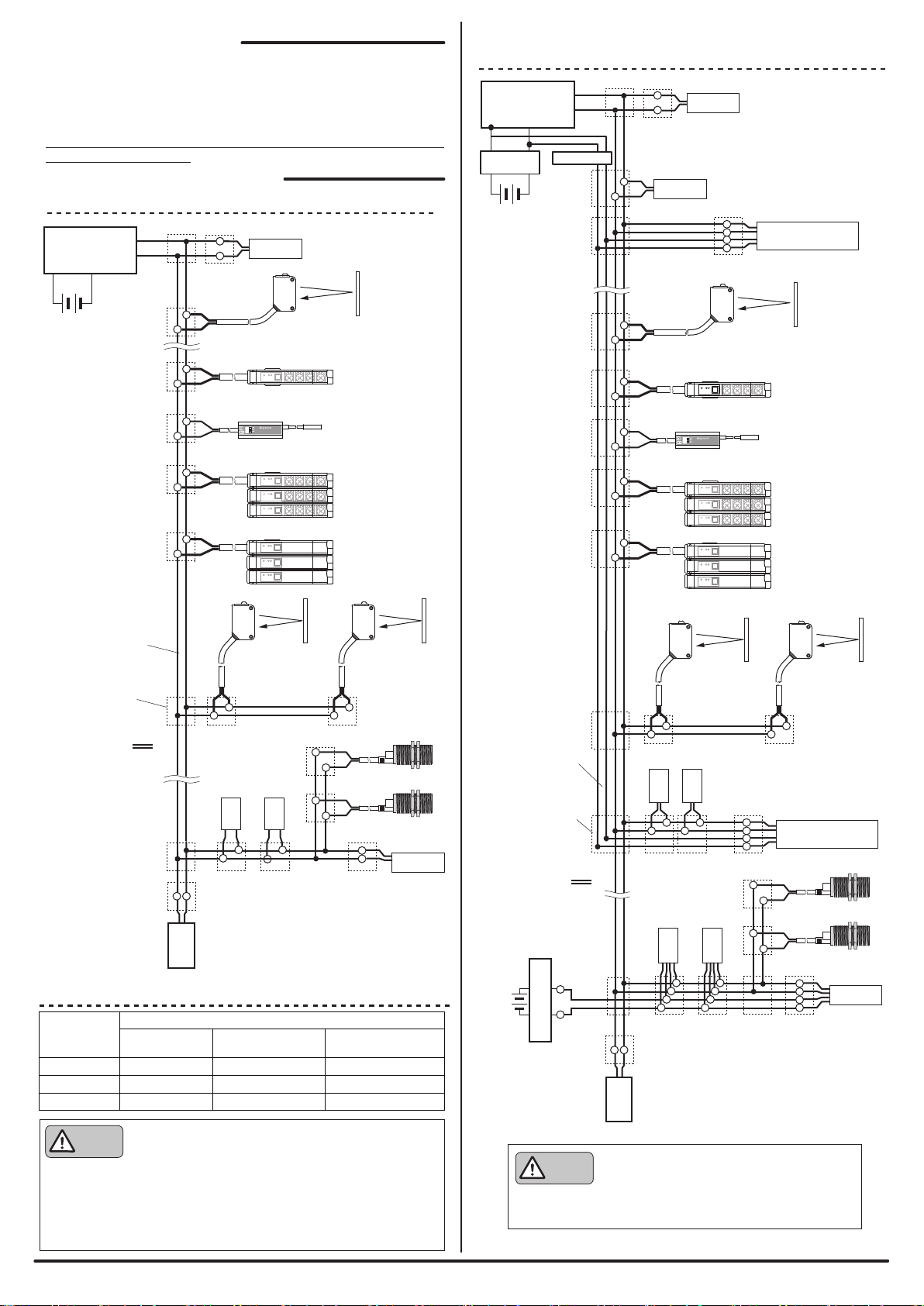

■General Specications

■Transmission Specications

■Individual Specications

<Ambient atmosphere>

Current consumption

Occupied number of points

Weight (Main unit, cable)

Detection target*3

Depends on the parameter setting

10ms max.

Detection distance

(at the ambient temperature of 23°C)

Hysteresis

A grounded metal piece of 50×50×1mm

Standard detection substance

Response time*4

The detection distance at 23°C

Inuence of temperature

Inuence of voltage

M18: Approx. 38g M30: Approx. 64g

Weight (Nut) M18: Approx. 2g M30: Approx. 3g

M18: 8mm(max.)M30: 15mm(max.)

Stable detection distance M18: 0 – 6.4mm M30: 0 – 12mm

M18: Within ±20% M30: Within ±20%

IP67

Protection class

Supplied by the AnyWireASLINK transmission signal (DP, DN)

Conductors/dielectrics

M18: 7.5mA M30: 7.6mA

1 input point

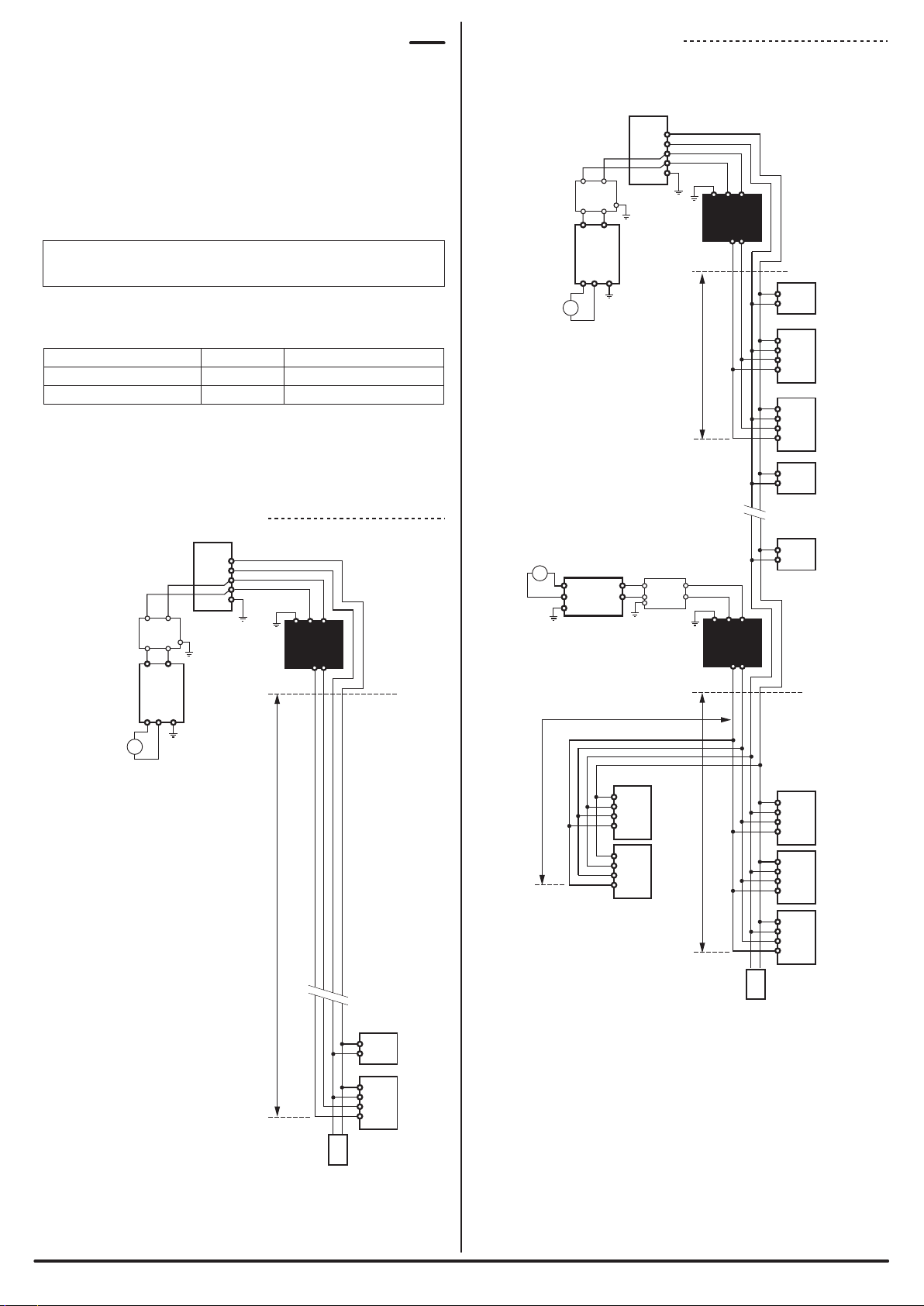

Should any of the following apply, take the following actions.

Symptom

Remedy

LINK IN ALM Cause Remedy

○○ ○

Unlit Unlit Unlit

●

Lit

○

Unlit

○

Unlit

◎

Flashing

○

Unlit

◎

Flashing

--◎

Flashing

◎-●

Flashing Lit

◎ -

Flashing

Display Cause

Remedy

【E-0303】

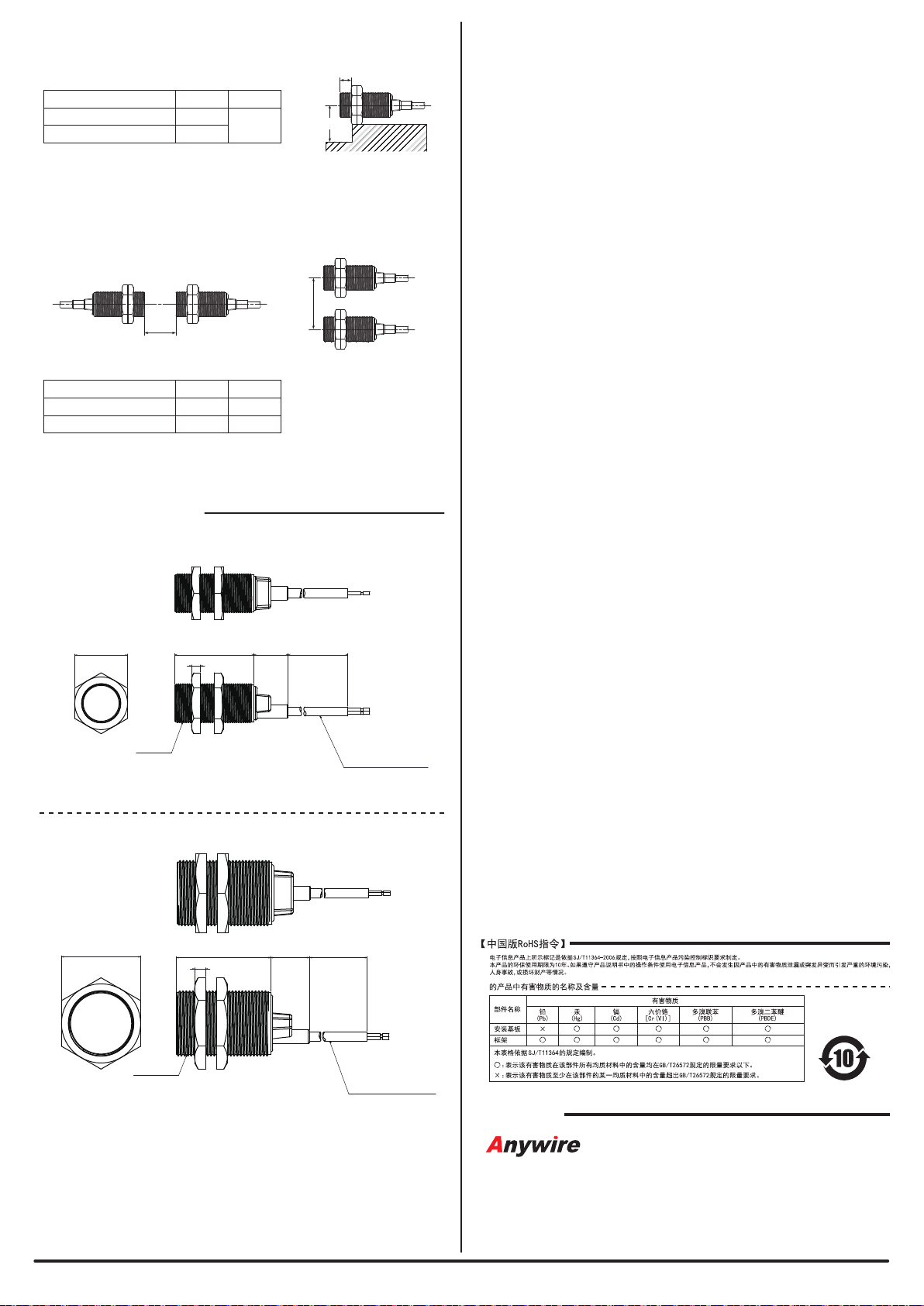

l

φ

d

m

n

l d m n

BS-K5217-M18-1K 15 40 10 60

(Unit: mm)

BS-K5217-M30-1K 10 60 20 60

*5Metal body

[Troubleshooting]

If the following statuses of the LEDs are indicated on the

ASLINKSENSOR, take the following actions.

If the following error is indicated on the Address Writer, take the

following action.

(alternates

with a 0.5 sec

interval)

(alternates

with a 0.5 sec

interval)

◎

Flashing

(alternates

with a 0.1 sec

interval)

(Lit for 0.2

sec, unlit for

1.0 sec)

-

The ASLINKSENSOR

is not connected to

the AnyWireASLINK

system.

-

The AnyWireASLINK

system is not turned

on.

- Check if there is a disconnection

between the ASLINKSENSOR and

AnyWireASLINK system and, if there

was a disconnection, restore the

connection.

- Check the power supply of

AnyWireASLINK system and turn ON

the power.

- Connected directly to

the 24-0V power supply.

- Reconnect the power to the

AnyWireASLINK system.

- The address of

ASLINKSENSOR

remains as “255”

(factory setting).

- The address of

ASLINKSENSOR is

duplicated.

- The transmission

signal level is

detected low.

- Assign an address other than 255.

- Look for a unit that has the same error

and assign an address different from

the address of that unit.

- Reduce the number of units connected

to the same AnyWireASLINK system.

- Reduce the length of transmission line

between ASLINKSENSOR and the

master unit.

- Check the condition of

ASLINKSENSOR, adjust its position

and clean the detection face.

- The sensing level is

low.

- Perform the teaching operation again.

- Teaching has not

been performed

properly.

The parameter setting is

incorrect.

Check the parameters and correct

them accordingly.

Detection cannot

be made

- Is the metal piece to be detected in an appropriate position?

→

Adjust the position of metal piece so that it will be in an

appropriate range from the detection face of

ASLINKSENSOR.

- Is the wiring correct?

→Ensure that the ASLINKSENSOR transmission line is

connected to the AnyWireASLINK system transmission line

(DP, DN) properly.

- Is there a power supply with a capacity appropriate for the

AnyWireASLINK master and slave units and turned ON?

→

Check the power supply.

- Has teaching been performed?

→

Perform teaching using the workpiece to be detected in the

operation.

- Is the sensor used in the specied detection range?

→

Use it within its rating.

Setting cannot be

made with the

Address Writer

- Is the wiring correct?

→

Check the connection of ASLINKSENSOR transmission

line once more.

- Is the power supplied to the AnyWireASLINK system?

→

Check the power supply.

- Are the parameters set correctly?

→

Check the parameters and correct them accordingly.

[Parameter and Setting Items]

The threshold of sensing level to

determine if a detection is made

The change in the sensing level required

for the detection status to change from

ON to OFF

The upper limit for alarm determination

The lower limit for alarm determination

The monitoring time for alarm

determination (1=100ms)

The delay for the delay timers

(1=100ms)

[Specifications]

Ambient temperature/humidity use -10 – 60°C, 10 – 90%RH No condensation

-25 – 75°C, 10 – 90%RH No condensation

No corrosive gas

Ambient temperature/humidity storage

Atmosphere use

Altitude use*1

Pollution level*2

0 – 2000m

2 or less

*1 Do not use or store AnyWireASLINK devices in an environment where the pressure exceeds

the atmospheric pressure at an altitude of 0 meters. Doing so may result in malfunction.

*2“Pollution level” is an index that indicates the degree of occurrence of conductive substances

in the environment where the device is used.

Pollution level 2 means the occurrence of only pollution by non-conductive substances.

In such an environment, however, electrical conduction could occur due to accidental condensation.

*3 The detection distance varies depending on the material.

*4The time from detecting the ON or OFF condition until the transmission signal is sent.

This time plus two transmission cycles will be the transmission delay.

*5 If the metal body is not grounded, the operation may be unstable. Always ground it.

Within ±1% of detection distance in the range of 27.6 to 21.6V

power supply voltage for the AnyWireASLINK master unit.

Avoid using the device with splashes of water, oil or chemicals on it or in an

atmosphere causing condensation as those fluids may be recognized as

detection targets and leading to erroneous detections.

The device is especially sensitive to dielectrics and can be influenced by

even a tiny drop of water.

<Influence of surrounding metals>

If the device is to be mounted in a metal body, ensure the distances listed in

the table below.

Also ensure the distances shown on this table for installations in materials

other than metals (such as resin) could have an influence on the detection.

Alarm

monitoring time

Service power supply

voltage

24V DC +15% to -10% (21.6 to 27.6V DC) with a ripple of

0.5Vp-p or less

Bus type (Multi-drop method, T-branch method,

Tree branch method)

DC power supply superimposed total frame/cyclic method

Transmission method

Frame/bit synchronization method

Synchronization method

Dedicated protocol

512 max. (IN: 256, OUT: 256)

Up to 128 units

Transmission procedure

Connection mode

RAS features

Number of connection

points

Number of units that can

be connected

Detection of transmission line disconnection, detection of

transmission line short circuit, detection of transmission power

drop, detection of duplicated/unregistered ID