-BSK4117M**1K 8/9-

[Specications]

-10 - 60°C, 10 - 90%RH (No condensation)

Ambient temperature/humidity for use

-25 - 75°C, 10 - 90%RH (No condensation)

Ambient temperature/humidity for storage

No corrosive gas

■General Specications

Atmosphere for use

0 to 2000m

Altitude of use *1

2 or less

Pollution level *2

■Transmission specications

Frame/bit synchronization method

Synchronization method

DC power supply superimposed total frame/cyclic method

Transmission method

Voltage 24V DC +15% to -10% (21.6 to 27.6V DC

Ripple of 0.5Vp-p max.

Power supply voltage

for use

Dedicated protocol

Transmission procedure

Bus type

(Multi-drop method, T-branch method, Tree branch method)

Connection mode

512 max. (IN: 256, OUT: 256)

Number of connection points

Up to 128 units

Number of units connected

RAS feature

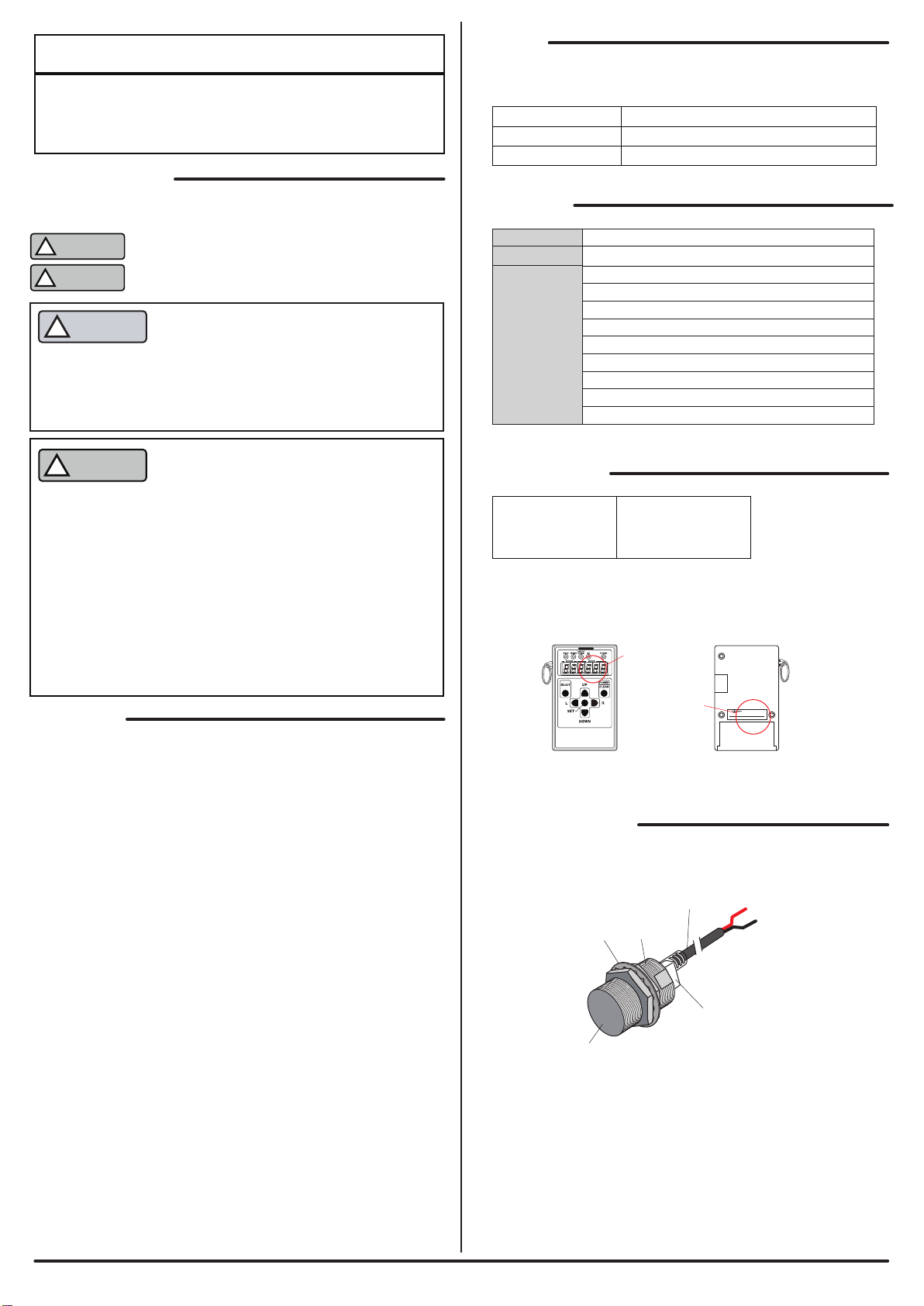

■Individual specications

Consumption current

Number of occupied points

Mass

(This product/Cable)

Electromagnetic induction detection

Detection method

Shield type

Shield presence/absence

Non-magnetic metal/Magnetic metal

Detection target *3

Standard detection objects

Depends on parameter setting

Max. 10ms

Detection distance

Hysteresis

Response time *4

Detection distance at 23°C

Impact from

temperature

Impact from voltage

(At ambient temperature

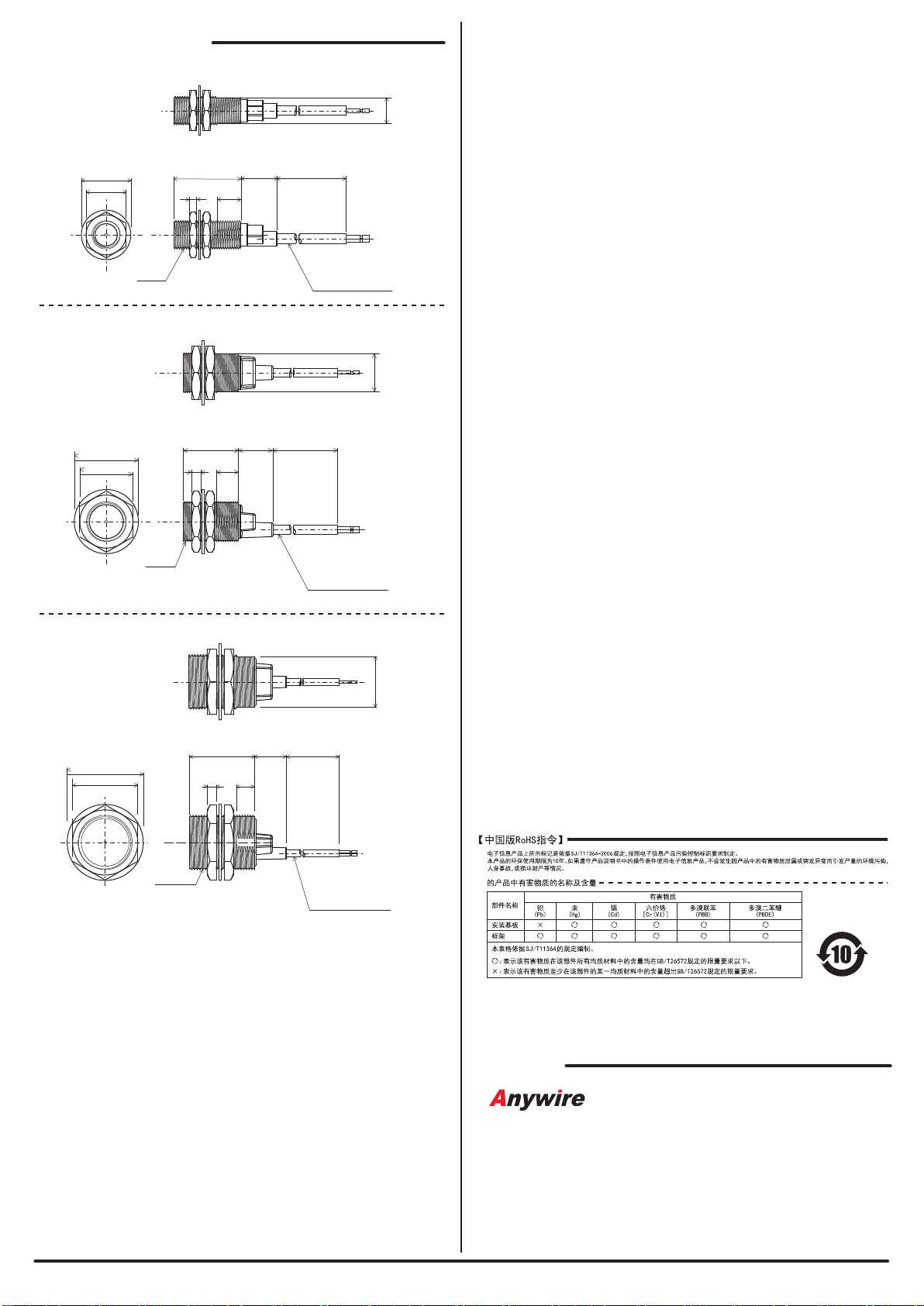

of 23°C) M18: 5mm (max.)

M18: Aluminum 18×18×3mm

M12: Approx. 37g

M18: Approx. 49g

M30: Approx. 105g

Mass

(Nuts/Washer)

M12: Approx. 8g

M18: Approx. 19g

M30: Approx. 41g

M12: Aluminum 12×12×3mm M30: Aluminum 30×30×3mm

M12: 2mm (max.) M30: 10mm (max.)

Stable detection

distance M18: 0 to 4.5mm

M12: 0 to 1.6mm M30: 0 to 9.0mm

M12: Within ±20%

M18: Within ±10%

M30: Within ±10%

IP67

Protective structure

Supplied via AnyWireASLINK transmission signal (DP, DN)

M12: 13mA

M18: 13mA

M30: 13mA

One-point input

*1 Do not use or store the AnyWireASLINK device in an environment pressurized equal to

or higher than the atmospheric pressure at an altitude of 0m. Doing so could cause a

malfunction.

*2 Index that indicates the occurrence of conductive material in the environment where

the device is used.

Contamination level 2 indicates that only non-conductive contamination occurs.

However, incidental condensation could create temporary conductivity in this

environment.

*3 The detection distance depends on the material.

*4 Time from when ON or OFF is detected until the transmission signal is transmitted.

The time combining this time and the transmission 2 cycle time is the transmission

delay time.

Transmission line disconnection detection,

transmission line short-circuit detection,

transmission power supply reduction detection,

ID redundancy, ID not set detection

Within ±1% of the detection distance with the

AnyWireASLINK master supplied power voltage

within range of 27.6 to 21.6V

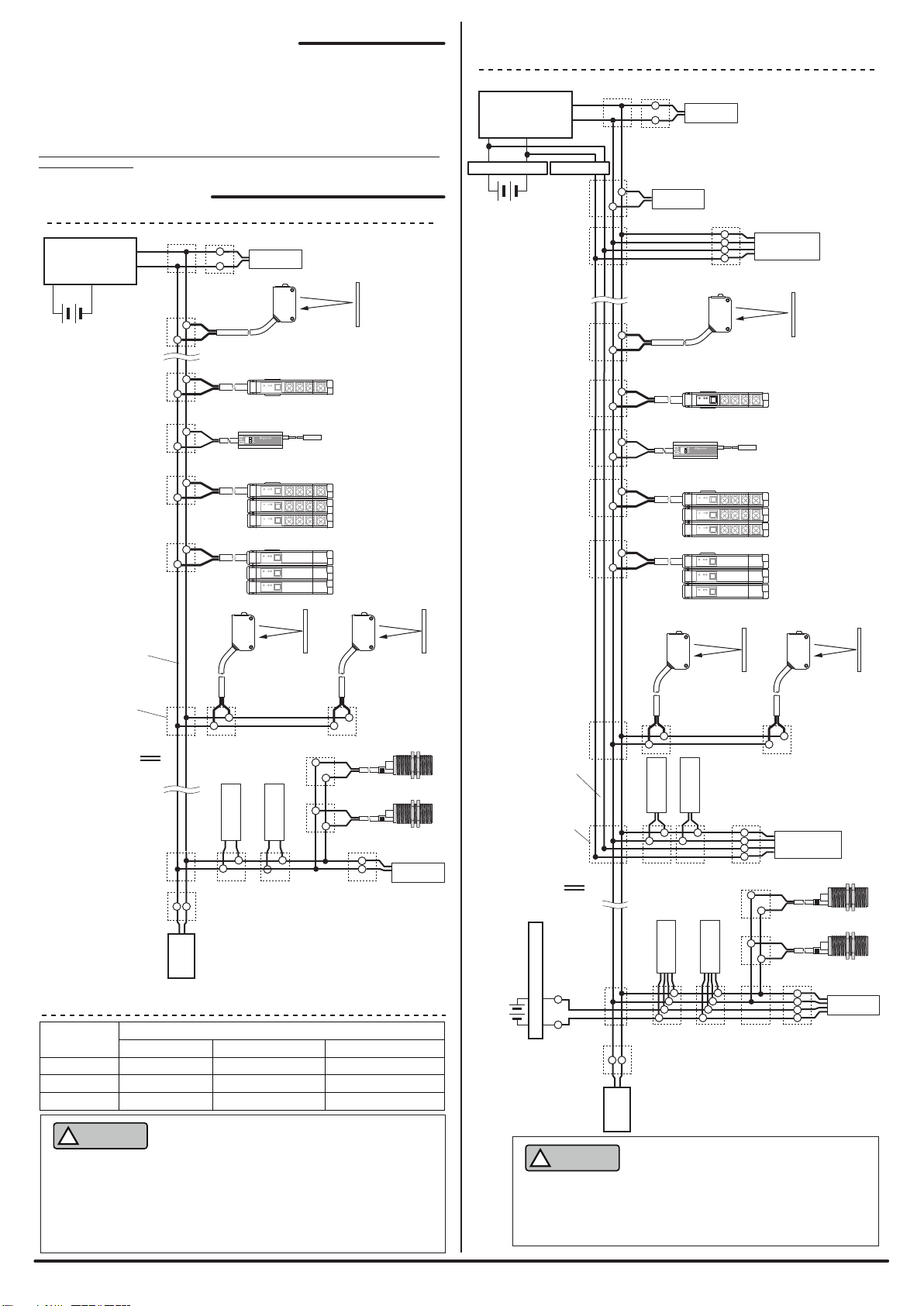

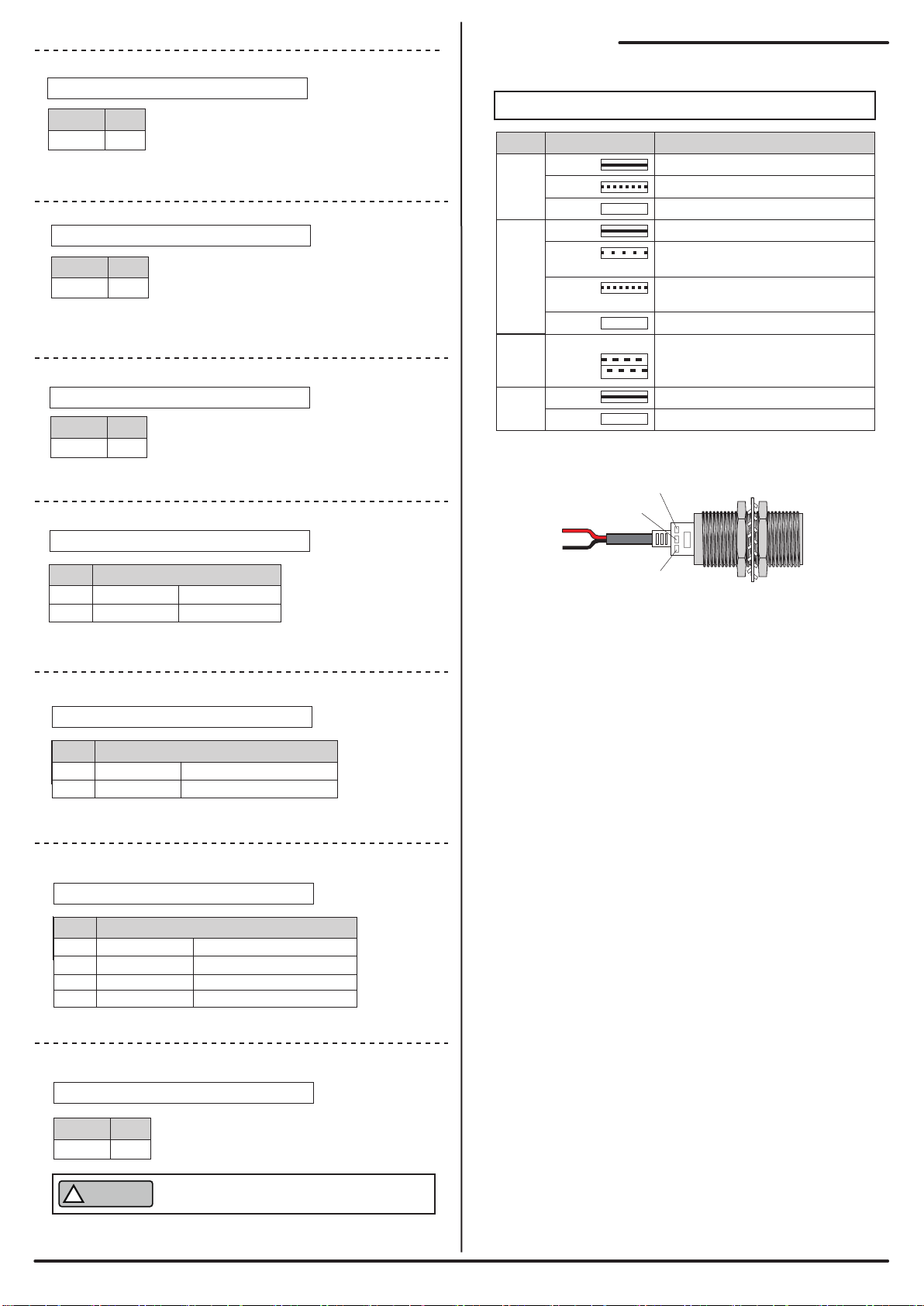

LINK IN ALM Cause Measures

○ ○ ○

Off Off Off

●

On

○

Off

○

Off

◎

Flashing

(0.5 seconds

alternately)

○

Off

◎

Flashing

(0.5 seconds

alternately)

- - ◎

Flashing

(On for

0.2 seconds,

off for

1.0 seconds)

◎ - ●

Flashing On

[Troubleshooting]

If the followings are displayed on the LEDs of this product, take

measures as shown below.

- ASLINKSENSOR is

not connected to an

AnyWireASLINK

system.

- Power supply for the

AnyWireASLINK

system itself is not

turned on.

-

Directly connected to

24-0V power supply.

- The ASLINKSENSOR

maintains the

address number 255

(default setting).

- The ASLINKSENSOR

has an address

redundant with

another unit.

- Transmission signal

level reduction has

been detected.

- The sensing level

has been reduced.

- Conrm that there is no

disconnection between the

ASLINKSENSOR and the

AnyWireASLINK system, and recover

the connection.

- Conrm the power status of the

AnyWireASLINK system, and turn on

the power.

- Re-connect to the AnyWireASLINK

system.

- Set any address number other than

255.

- Look for the other unit which has the

same error indication, and set any

address number different from it.

- Decrease the number of units

connected to the same

AnyWireASLINK system.

- Shorten the transmission line

between the ASLINKSENSOR and

the master unit.

- Conrm the ASLINKSENSOR status,

adjust the position, and clean the

detection surface.

◎ - ◎

Flashing

(0.1 seconds

alternately)

Flashing

- Teaching is not

normally operated.

- Make sure to perform teaching

operation again.

Take measures as follows in the following case.

Symptom Measures

Detection cannot be

performed.

Setting cannot be

performed with

the address writer.

Indication Cause Measures

[E-0303]

When the following error is indicated on the address writer, take

measures as shown below.

The set parameter is incorrect. Check the parameter and set the correct

parameter.

- Is the detected metal in the appropriate location?

→Make adjustments so that the detected metal is within an appropriate range

from the ASLINKSENSOR detection surface.

- Is wiring correct?

→Conrm that the ASLINKSENSOR transmission line is correctly connected

to the AnyWireASLINK transmission line (DP, DN).

- Are the AnyWireASLINK master unit and slave unit powered by a power supply

with the appropriate capacity?

→Conrm the power supply.

- Did you perform teaching?

→Perform teaching settings with the work that is actually detected.

- Are you using within the rated detection range?

→Use within the rated range.

- Is wiring correct?

→Reconrm the ASLINKSENSOR transmission line connection.

- Is power fed to the AnyWireASLINK system?

→Conrm the power supply.

- Is the set parameter correct?

→Check the parameter and set the correct parameter.

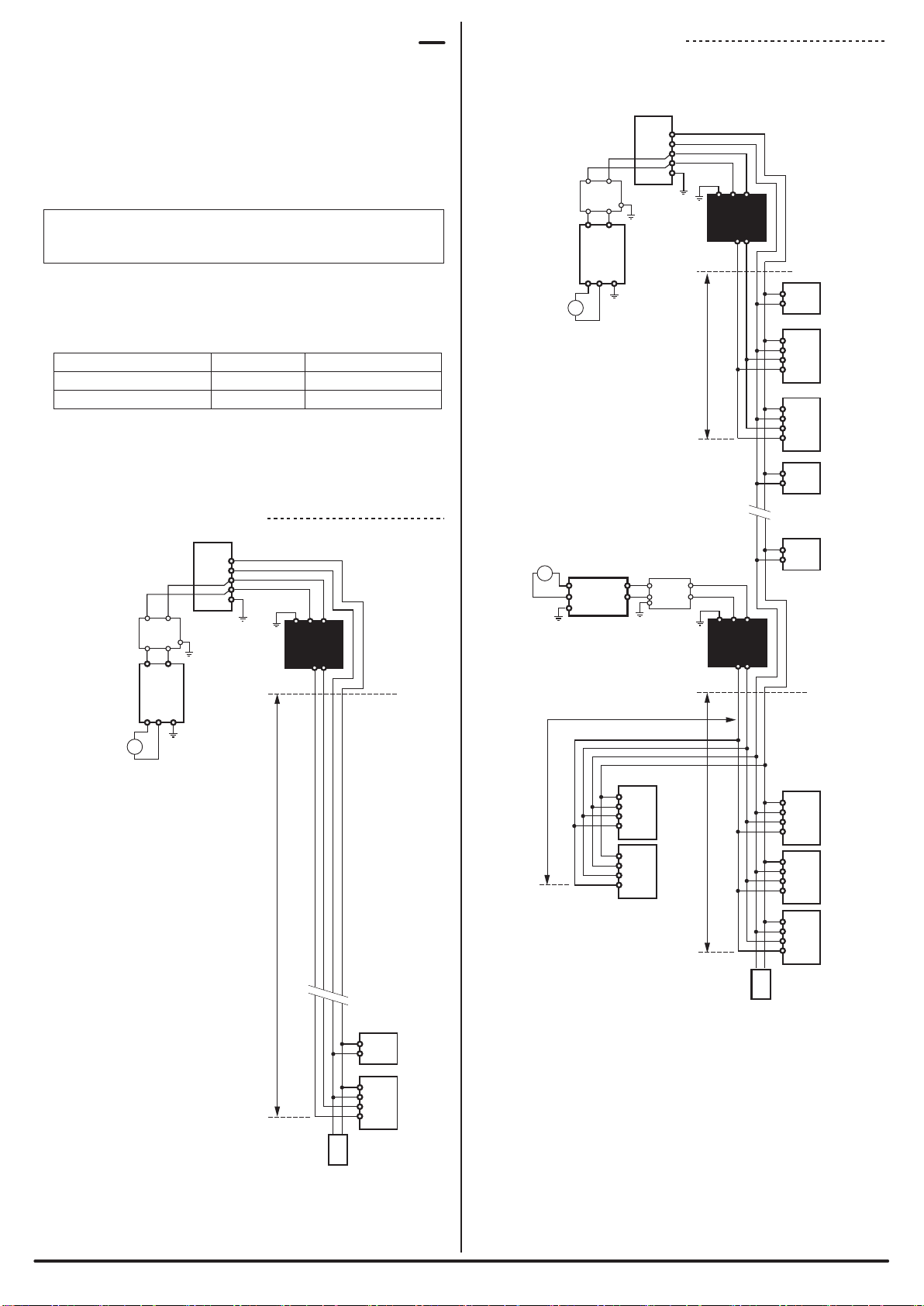

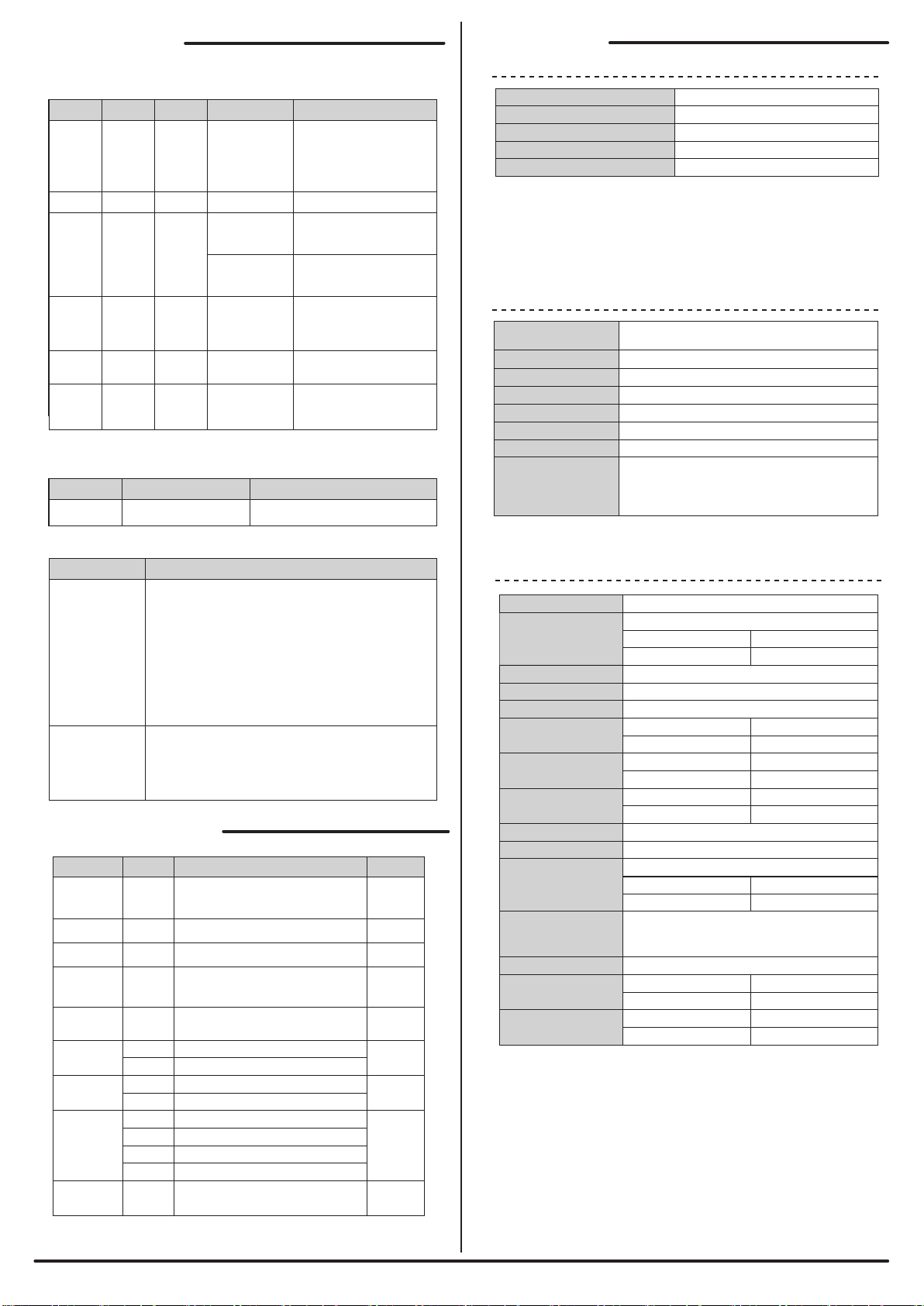

[Parameters and items]

Parameter Default

variable

Variable Details

[01.] M12 : 18

M18 : 24

M30 : 26

M12 : 19

M18 : 25

M30 : 27

Set the threshold of the sensing level

to judge presence/absence of detection.

0 - 100%

Threshold

[02.] 5

Set change amount of sensing level

required to turn detection state ON to OFF.

0 - 100%

Hysteresis

[03.] 80

Set an upper limit for the alarm

judgment value.

0 - 100%

Alarm value Hi

[04.]

Set a lower limit for the alarm

judgment value.

0 - 100%

Alarm value Lo

[05.]

50

Set a monitor time for the alarm

judgment value. (1 = 100ms)

3-255

Alarm value

monitor time

[06.]

0

Normally open

Normally close

0

Normally open/

Normally close

[07.]

0

Simple mode

Normal mode

0

Operation

mode

[10.]

0

Delay timer disabled

ON delay timer

Delay timer

ON/OFF

[11.]

0 - 255 Set the delay time. (1 = 10ms) 0

Delay timer

value

1

1

0

1

OFF delay timer

ON/OFF delay timer

2

3