VWR VE2 User manual

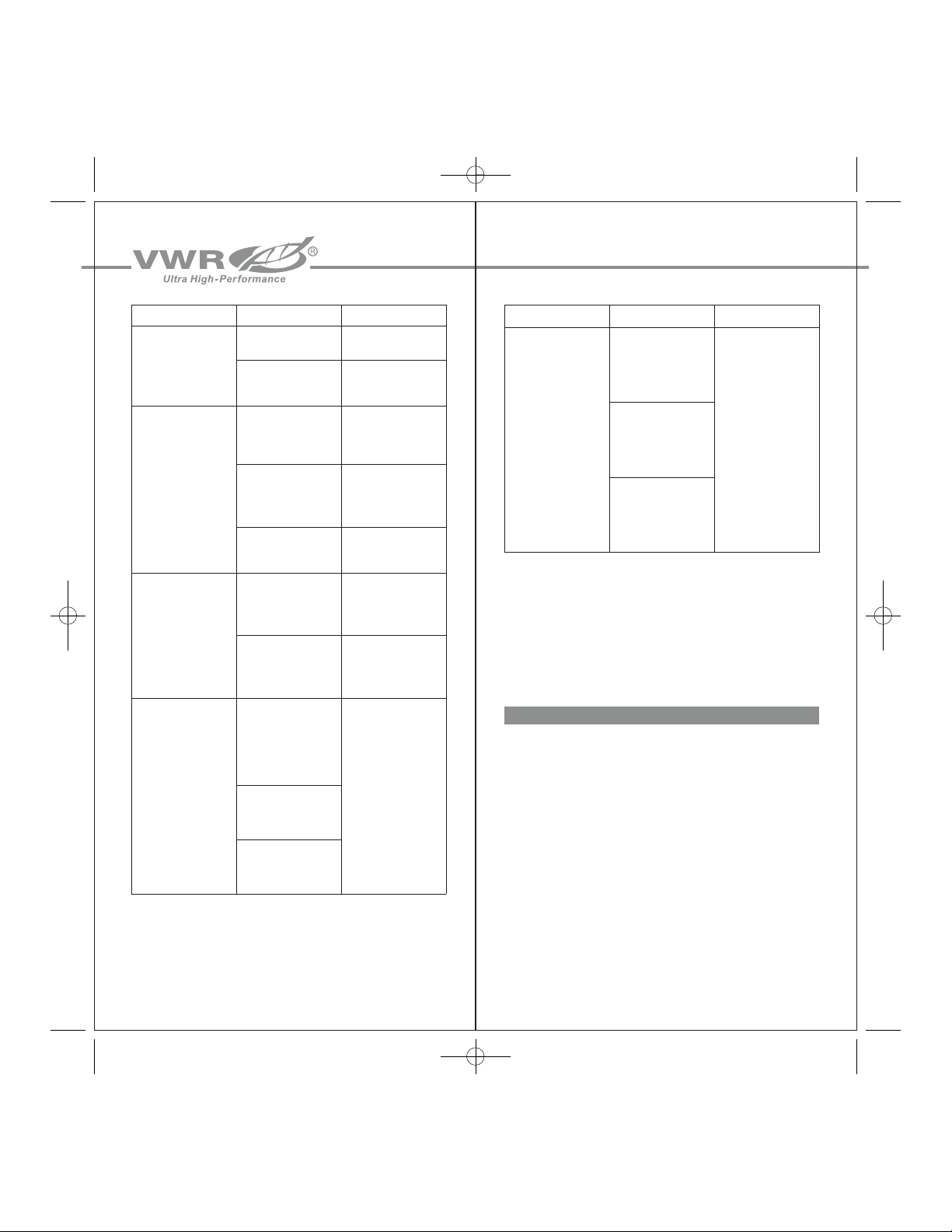

Other VWR Laboratory Equipment manuals

VWR

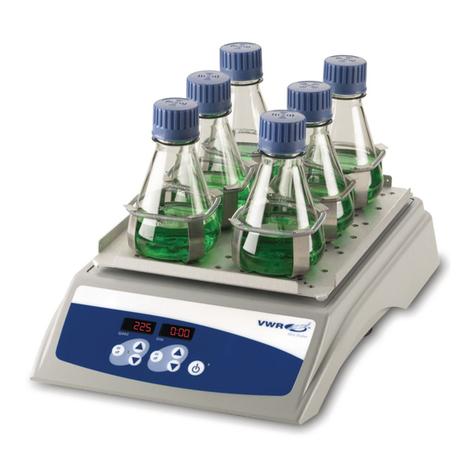

VWR Mini Shaker User manual

VWR

VWR ShiroGel 700-0250 User manual

VWR

VWR avantor UHP User manual

VWR

VWR Micro 1207 User manual

VWR

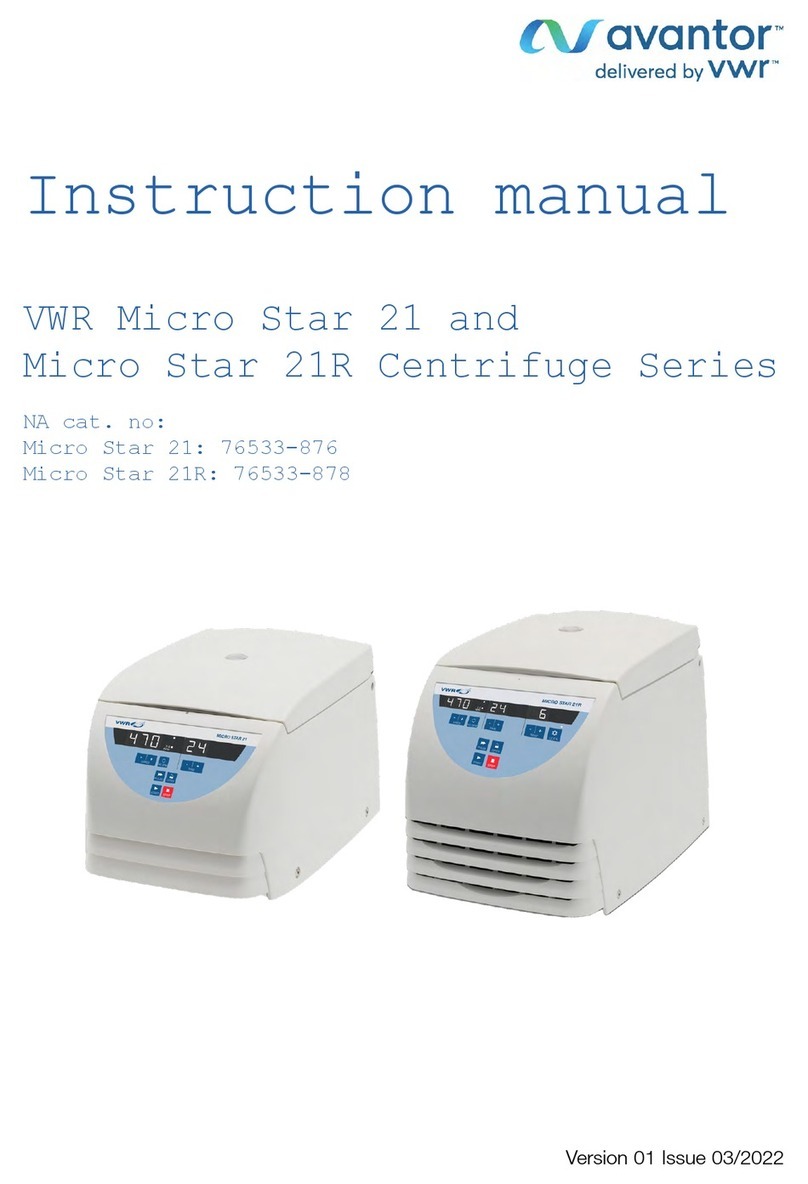

VWR 76533-876 User manual

VWR

VWR Signature ME50 User manual

VWR

VWR Bead Mill MAX User manual

VWR

VWR VWR Mega Star 600R User manual

VWR

VWR INCU-Line IL 56 User manual

VWR

VWR Signature VE2/V2 User manual

VWR

VWR Standard Series User manual

VWR

VWR Analog Vortex Mixer User manual

VWR

VWR avantor Chemi Premium User manual

VWR

VWR Advanced Mini Block Heaters User manual

VWR

VWR avantor User manual

VWR

VWR Peqlab PerfectBlue Mini S User manual

VWR

VWR 432-0367 User manual

VWR

VWR 5600 Series Operating instructions

VWR

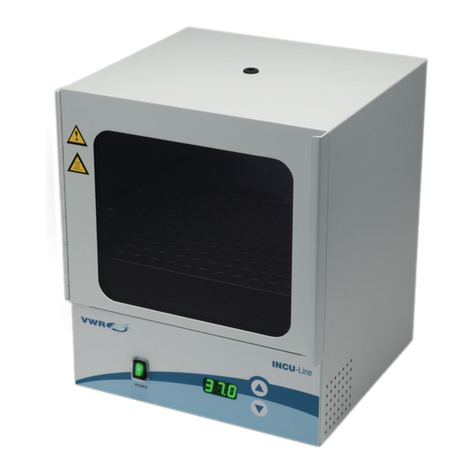

VWR VWR INCU-Line IL 10 User manual

VWR

VWR Mini Shaker User manual

Popular Laboratory Equipment manuals by other brands

Agilent Technologies

Agilent Technologies 5800 ICP-OES user guide

Endress+Hauser

Endress+Hauser Cleanfit CPA875 operating instructions

NI

NI PXI-5422 CALIBRATION PROCEDURE

Collomix

Collomix Aqix operating instructions

SPEX SamplePrep

SPEX SamplePrep 6875 Freezer/Mill Series operating manual

Ocean Insight

Ocean Insight FLAME-NIR+ Installation and operation manual

Parker

Parker ALIGN-MG-NA Installation, operation and maintenance manual

BD

BD 644787 user guide

DENTAURUM

DENTAURUM Compact Megaplus Instructions for use

Biuged Laboratory Instruments

Biuged Laboratory Instruments BGD 626 instruction manual

illumina

illumina MiSeqDx reference guide

Yamato

Yamato BM510 instruction manual