CONTENTS

1 Safety Information ........................................................................................................................................................................................1

1.1 Markings and Symbols ........................................................................................................................................................................2

2 Technical Specification................................................................................................................................................................................3

2.1 Technical Data ......................................................................................................................................................................................3

2.2 Approvals Compliance and Exemptions............................................................................................................................................4

2.3 Materials of Construction ....................................................................................................................................................................5

2.4 Dimensions ...........................................................................................................................................................................................6

3.1 Receiving and Inspecting the Equipment ..........................................................................................................................................8

3.1.1 Storage.........................................................................................................................................................................................8

3.1.2 Unpacking ....................................................................................................................................................................................8

3.1.3 Lifting and Handling......................................................................................................................................................................8

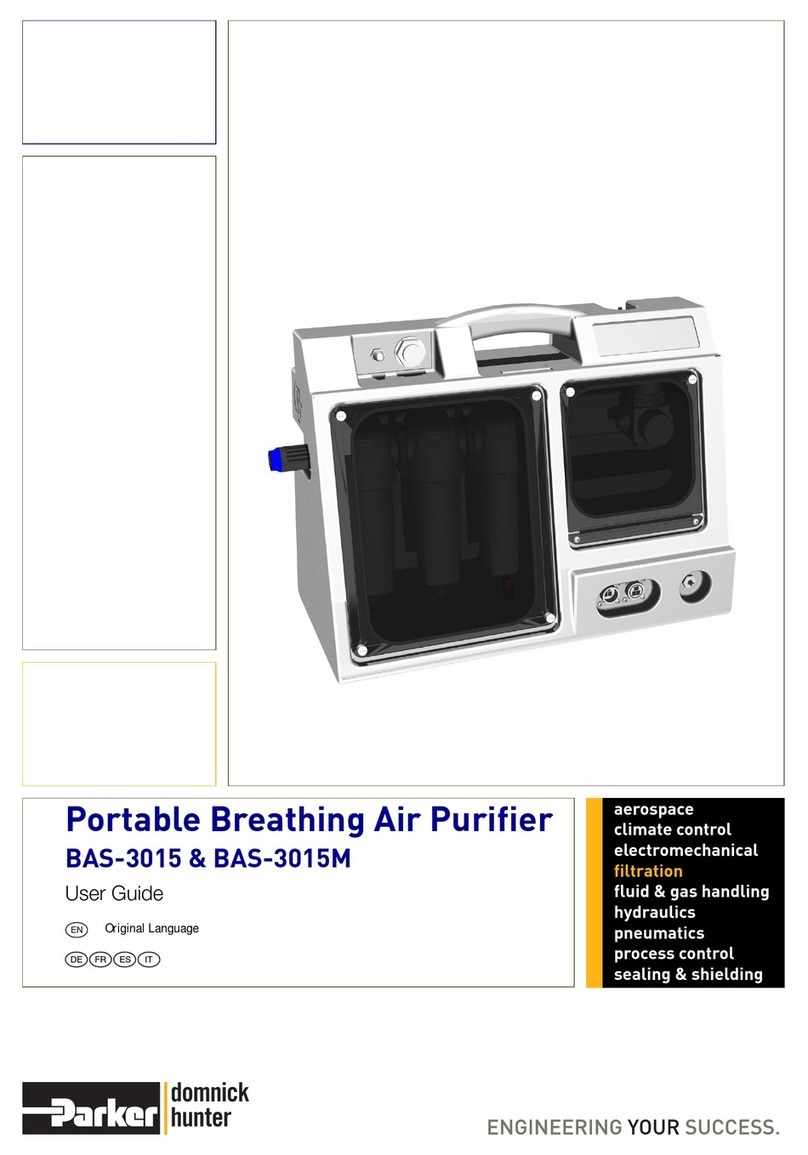

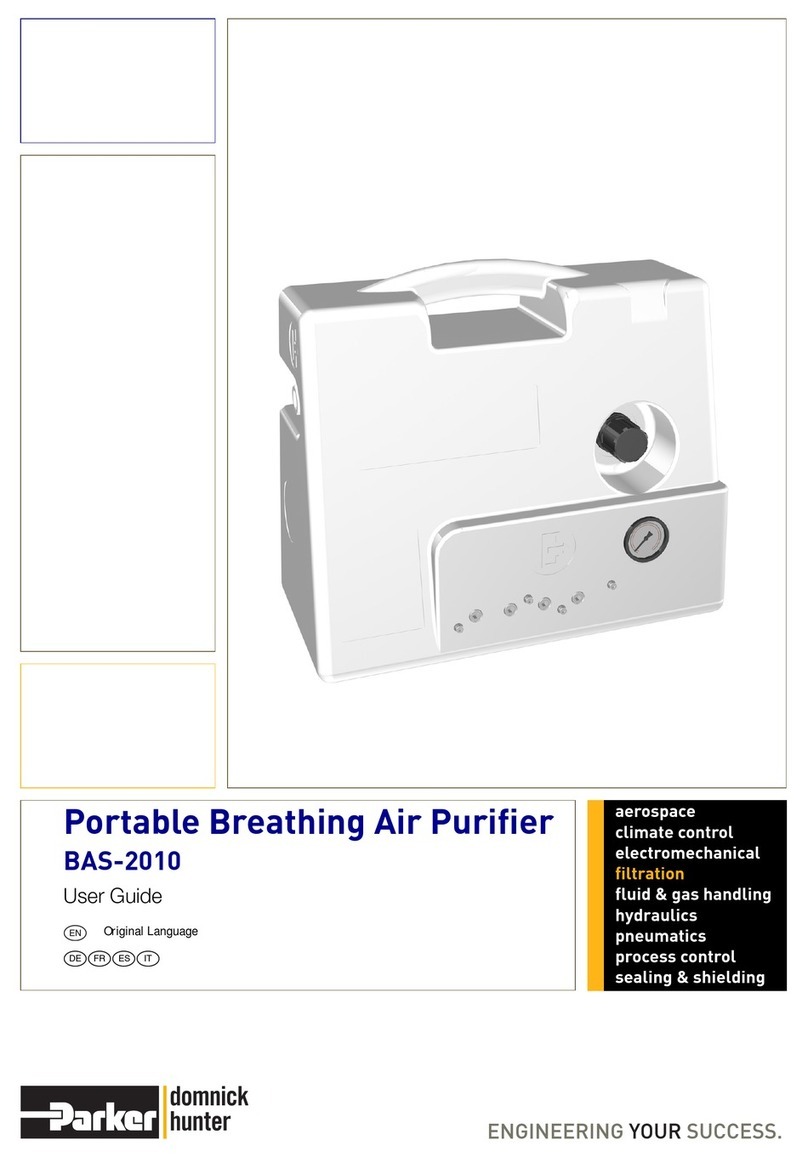

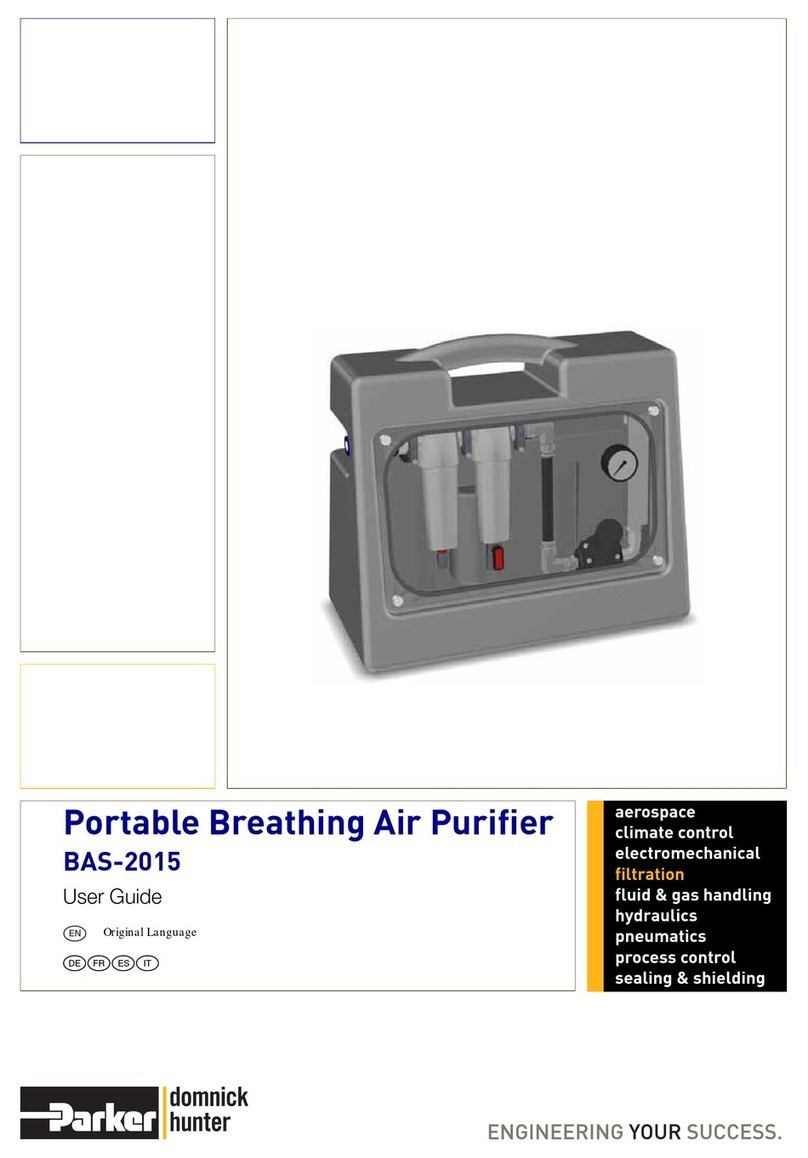

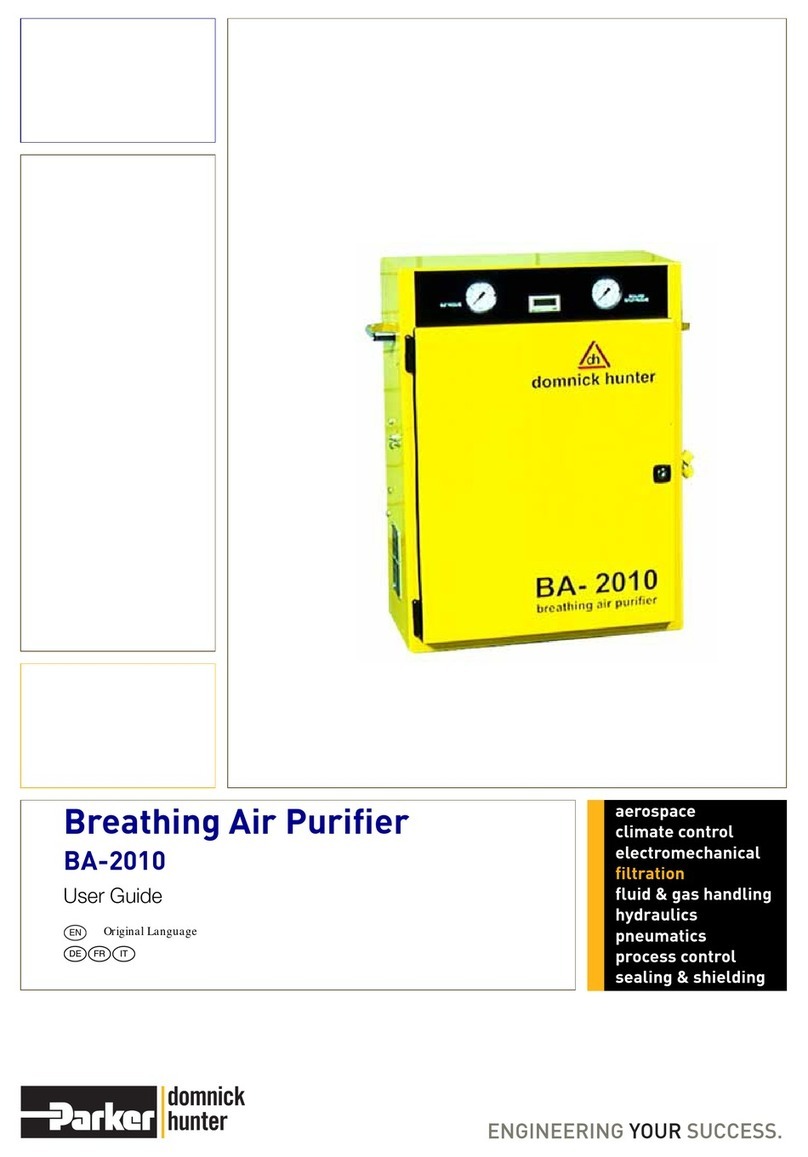

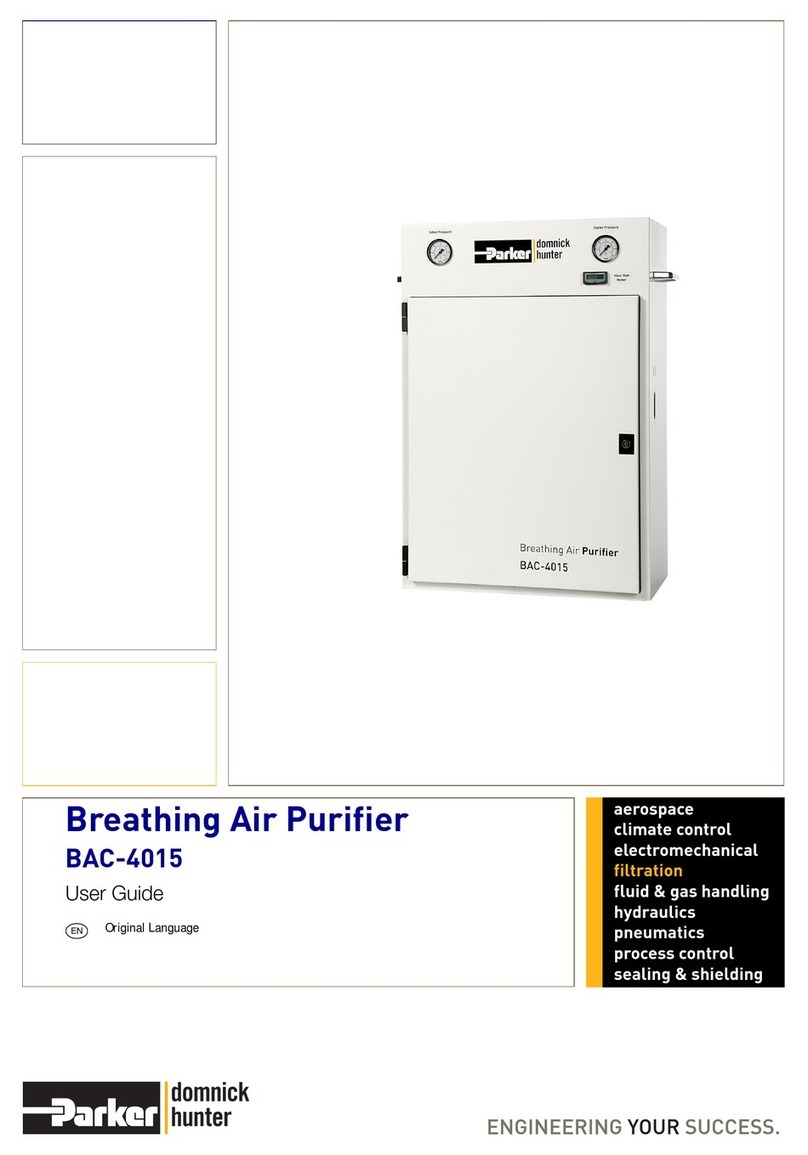

3.2 Overview of the Equipment .................................................................................................................................................................8

4 Installation and Commissioning..................................................................................................................................................................9

4.1 General ..................................................................................................................................................................................................9

4.1.1 Locating the Equipment................................................................................................................................................................9

4.1.2 Space Requirements....................................................................................................................................................................9

4.2 Mechanical Installation ........................................................................................................................................................................9

4.2.1 General Requirements .................................................................................................................................................................9

4.2.2 Securing the Dryer .......................................................................................................................................................................9

4.2.3 Piping Connections ......................................................................................................................................................................9

4.2.4 Purge Air Flow..............................................................................................................................................................................9

4.3 Electrical connections .......................................................................................................................................................................10

4.3.1 Connecting the electrical Supply............................................................................................................................................10

4.3.2 Auxiliary Connections.................................................................................................................................................................10

4.4 Initial Start Up .....................................................................................................................................................................................12

4.4.1 Getting Started ...........................................................................................................................................................................12

4.4.2 Start-Up ......................................................................................................................................................................................12

5 Operation.....................................................................................................................................................................................................13

5.1 Normal Operation ...............................................................................................................................................................................13

5.2 Dewpoint Dependent Switching (DDS).............................................................................................................................................13

5.3 Power Indicator and Fault Indicator Operation ...............................................................................................................................14

5.4 Shut-down ...........................................................................................................................................................................................14

6 Preventative Maintenance..........................................................................................................................................................................15

6.1 Service Intervals ................................................................................................................................................................................15

6.2 Preventative Maintenance Kits..........................................................................................................................................................16

8 Troubleshooting..........................................................................................................................................................................................19