Document No. D106-009 Page 2 of 76

Revision 1.15

CONTENTS

1. Preface ............................................................................................................................... 5

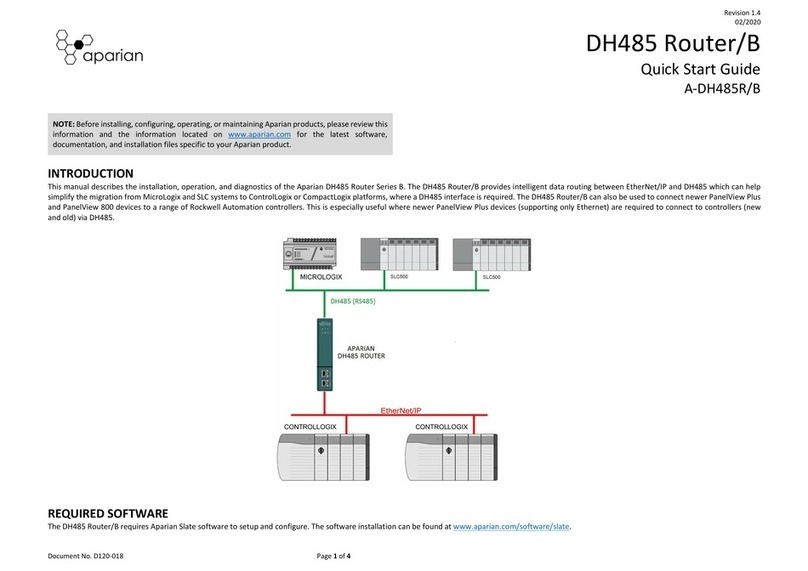

1.1. Introduction to the Modbus Router ........................................................................... 5

1.2. Features ....................................................................................................................... 5

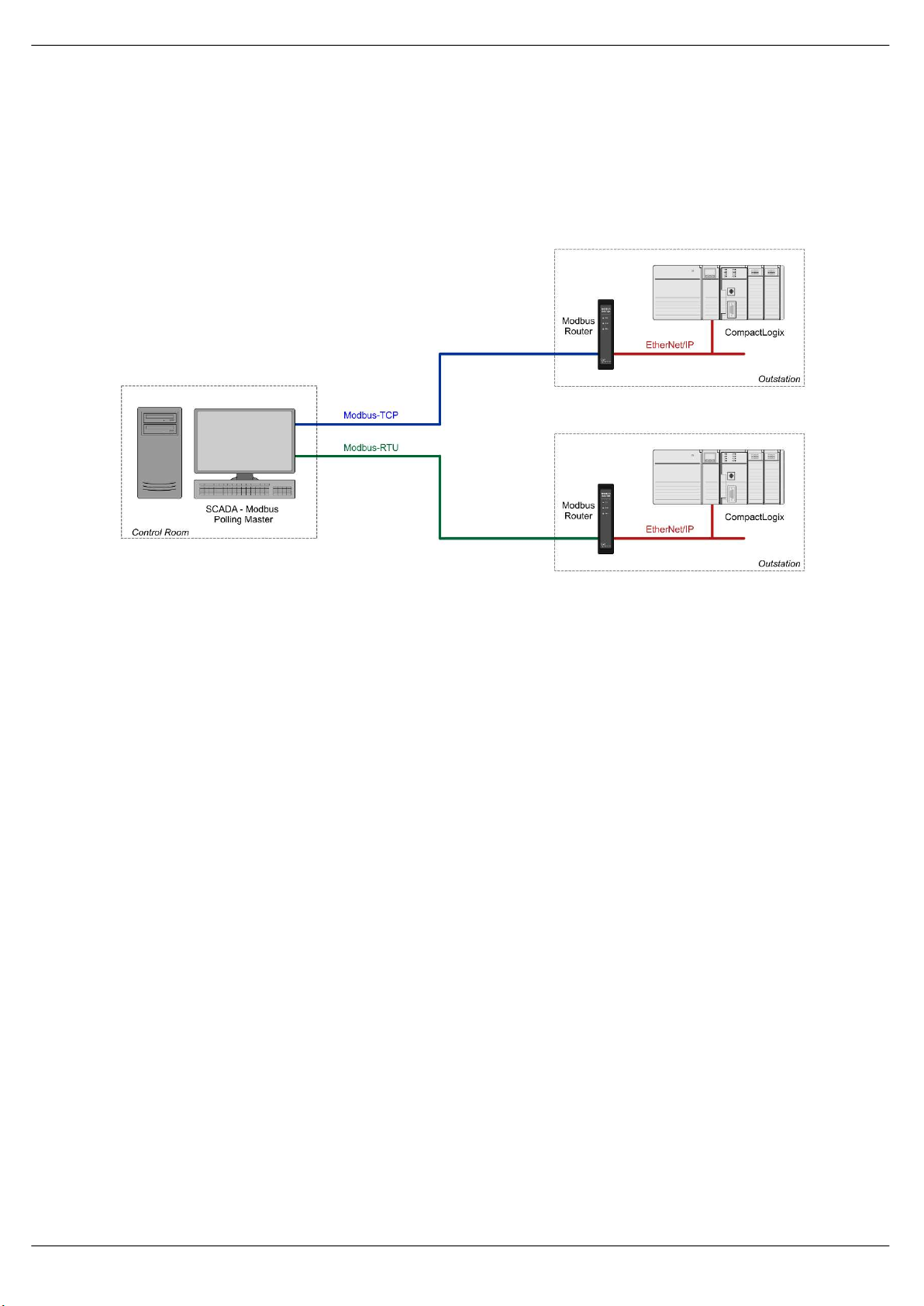

1.3. Architecture ................................................................................................................. 7

1.4. Additional Information ................................................................................................ 9

1.5. Support ........................................................................................................................ 9

2. Installation ....................................................................................................................... 10

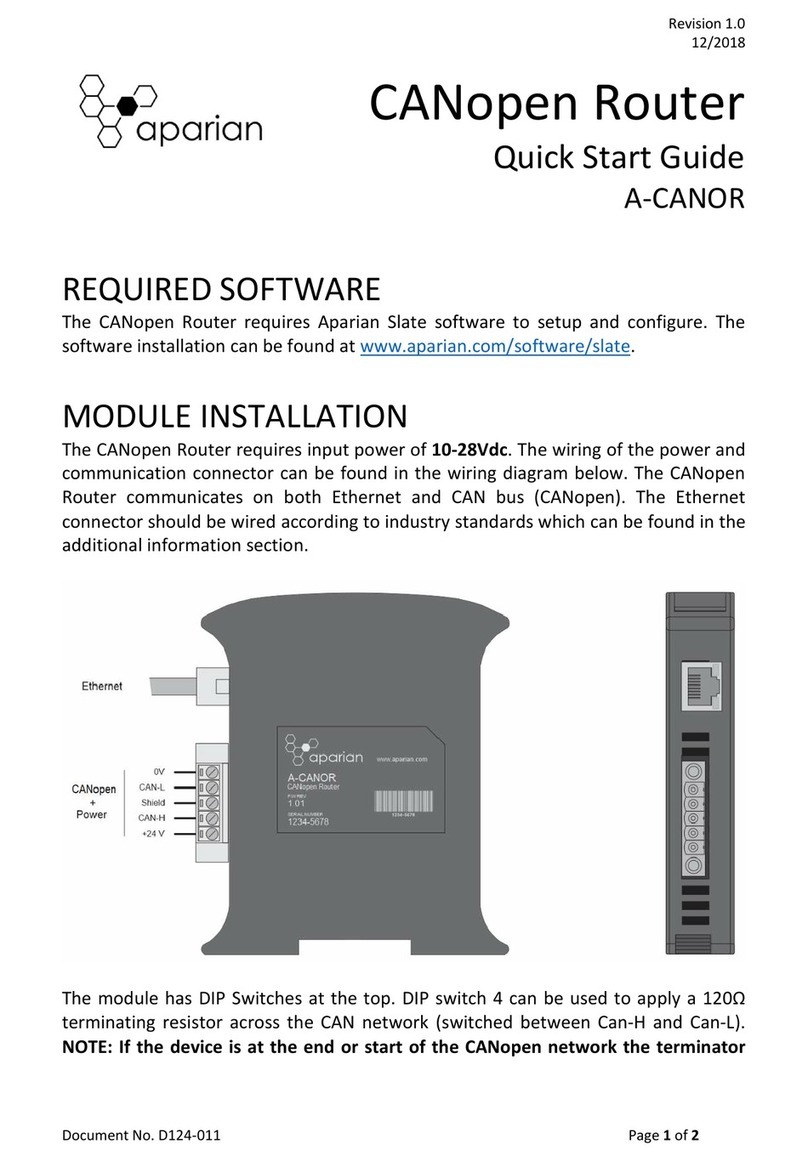

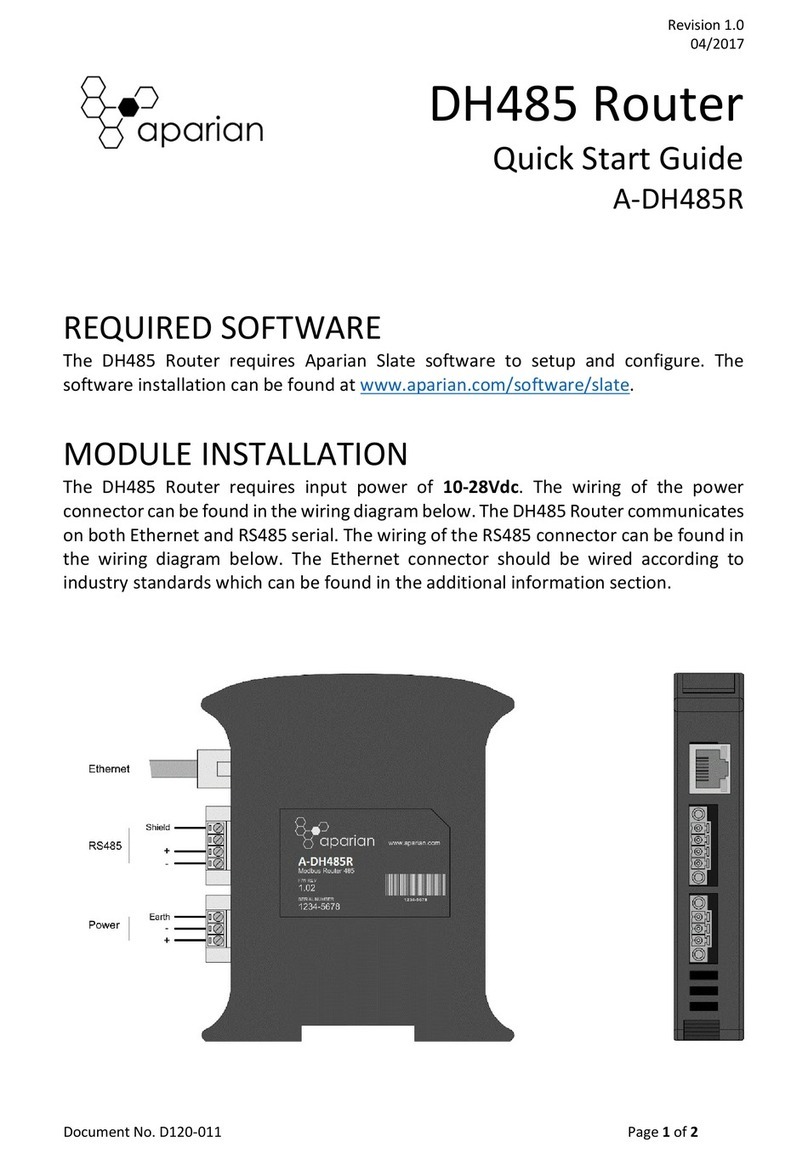

2.1. Module Layout .......................................................................................................... 10

2.2. Module Mounting ..................................................................................................... 13

2.3. Power ........................................................................................................................ 14

2.4. RS232 Port ................................................................................................................. 14

2.5. RS485 Port ................................................................................................................. 15

2.6. RS485 Termination .................................................................................................... 15

2.7. Ethernet Port ............................................................................................................. 16

3. Setup ................................................................................................................................ 17

3.1. Install Configuration Software .................................................................................. 17

3.2. Network Parameters ................................................................................................. 17

3.3. Creating a New Project .............................................................................................. 22

3.4. Modbus parameters .................................................................................................. 24

3.5. Message Routing ....................................................................................................... 27

3.5.1. Reactive Tag Mode............................................................................................. 27

3.5.2. Scheduled Tag Mode.......................................................................................... 34

3.5.3. Unscheduled Mode ............................................................................................ 39

3.6. Module Download ..................................................................................................... 40

3.7. RSLogix 5000 Configuration ...................................................................................... 42

3.7.1. Studio 5000 Configuration (Version 20+) .......................................................... 42

3.7.2. RSLogix 5000 Configuration (Pre-Version 20) .................................................... 46

4. Operation ......................................................................................................................... 50

4.1. Message Routing ....................................................................................................... 50

4.2. RSLogix 5000 assemblies ........................................................................................... 50

1.1.1. Input Assembly................................................................................................... 51