POWERED FLIGHT GROUND TRAINING

We recommend doing all the initial ground schooling with a ground handling harness, which will reduce fatigue. Only progress onto inflation with the frame and

motor once all the needed ground handling skills have been mastered.

• Never place the power unit downwind of the paraglider during preparation.

• Never start the motor for ground schooling.

12 PACKING

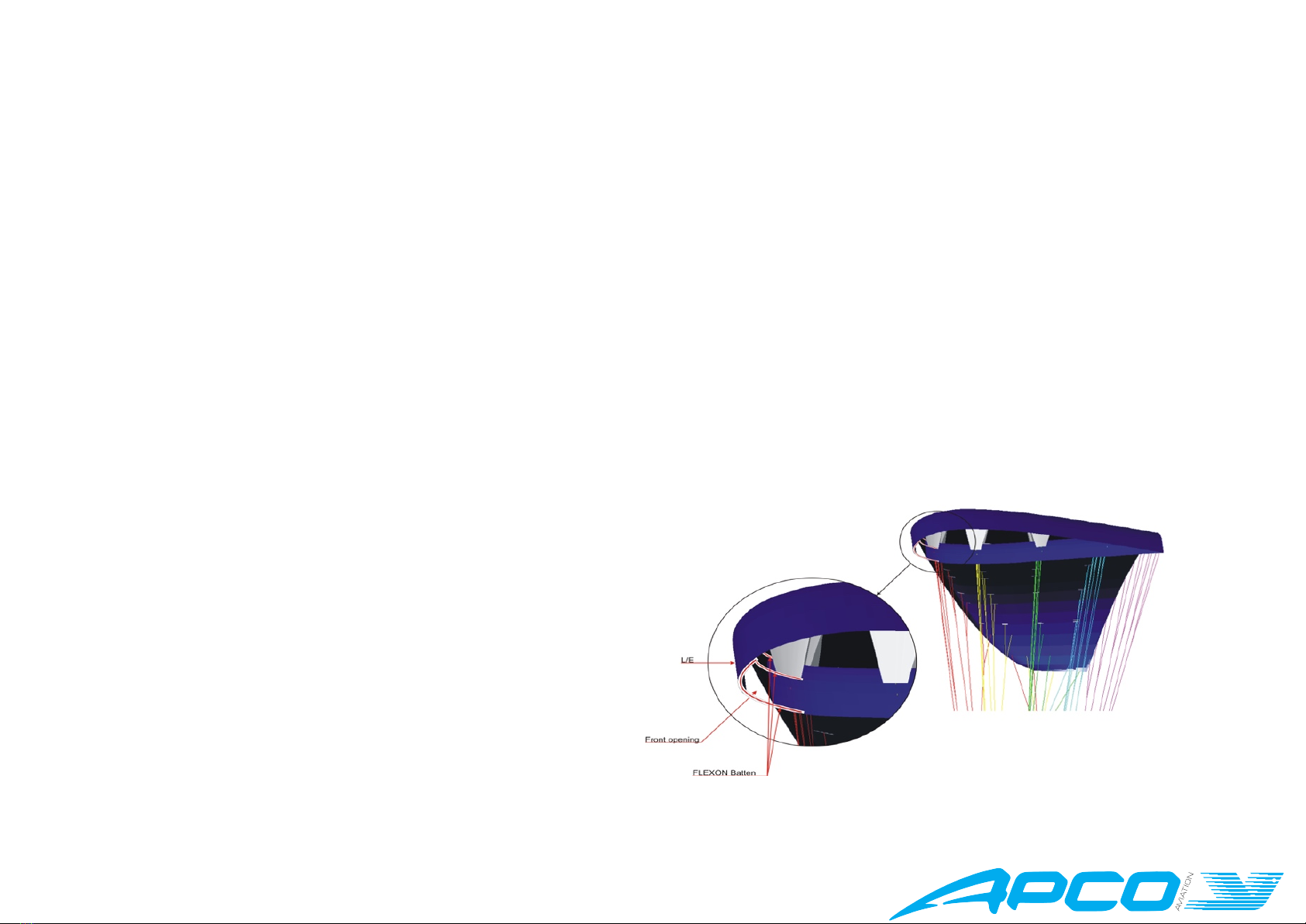

No special needs to be taken with the Flexon battens (Leading Edge Stiffeners) – the wing can be folded “old school” and does not need concertina folding. Spread

the wing completely out on the ground. Separate the lines to the left and the right side of the glider. If the risers are disconnected from the harness, join the two

risers together by passing one carabiner loop through the other. This keeps them neatly together and helps to stop line tangles.

Fold the canopy from the right and left sides, working towards the centre, press out the air, working from the rear towards the front. Place the risers at the trailing

edge of the folded canopy and use them to finally fold the canopy from trailing edge to leading edge.

13 MAINTENANCE & CLEANING

Cleaning should be carried-out with a damp cloth and if necessary, gentle soap. Baby wipes also do

a good job, but be sure to wipe any residue of with a clean cloth. If the glider comes in contact with

salt water, rinse it thoroughly with fresh water. Do not use solvents of any kind, as this may remove

the protective coatings and destroy the fabric.

14 BUTT HOLE II (Auto Debris release valves)

The Adama is equipped with Butt-hole II, which automatically clears smaller particles such as sand,

grass and stones from the wing. If anything too large to pass is seen inside the wing, it should be

removed through the cell openings.

15 STORAGE

When the glider is not in use, it should be stored in a cool, dry place. A wet glider should first be dried (out of direct sunlight). Protect the glider against sunlight (UV

radiation). When on the hill keep the glider covered or in the bag. Never store or transport the glider near paint, petrol or any other chemicals.

Do not leave your paraglider in the trunk of a car or exposed to the sun.

Temperatures on a hot summer’s day in a closed environment: car, etc. can easily reach over 60ºC

At these temperatures Nylon permanently changes its characteristics which may alter the behaviour and shape of the wing.

It will cause permanent damage to the paraglider, rendering it non-airworthy. APCO’s warranty will not be applicable.