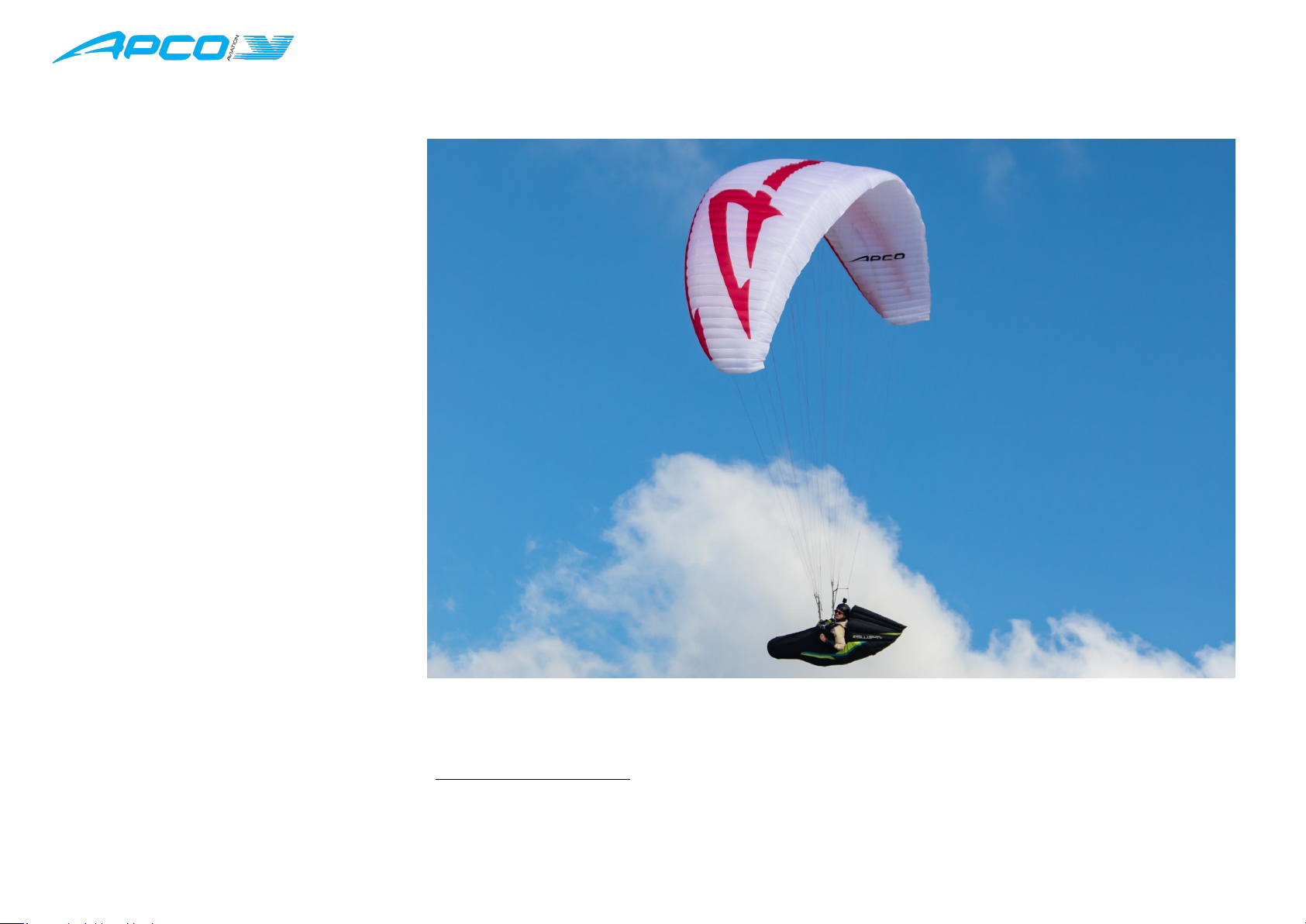

The NESTRA is APCO's all new high end EN-B.

A true cross country machine offering C level performance in

the EN-B category with real life B level safety for pilots looking for the

best that man can get!

No effort was spared to make it the best possible product,

which can be summed up with the following:

•True 2.5 liner - the only wing in the B category to date!

•Light weight –starting from 4.35 kg including standard risers.

•6.0 aspect ratio with impressive passive safety.

•Only 215m of lines - less than new generation EN-C 2-liners!

•APCO's embedded hook up points (link) for the cleanest, most

aerodynamic connection between line and canopy

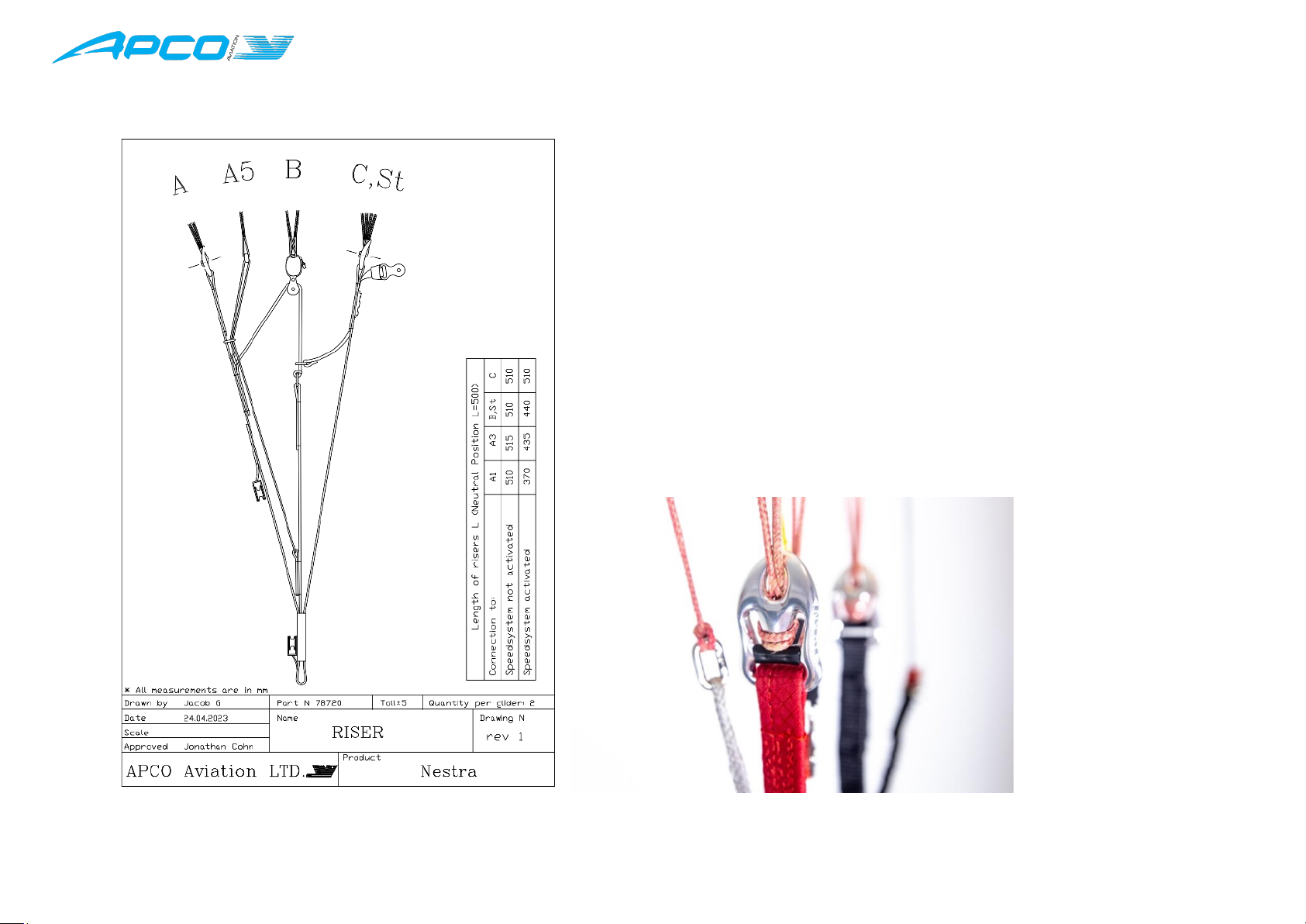

•Risers, including C steering, supported only by ball bearing pulleys

for amazing smoothness

•Flow aligned ribs (link to features page)

•Double diagonal ribs

•APCO's Flexon battens - memory free, do not require any special

care or folding technique

•3D shaping, butt holes, competition lines, shark nose, APCO V-

links, brake tensioners and more.

The Nestra is intended to pilots who has experience with EN-B

paragliders and flying at least 50h per year, and also recommended

for pilots that are already flying EN C wings but wants to move for a

lower class without sacrificing performance.