3

Subject to change without notice | 83053600fUK – Translation of the original operating manual | ait-deutschland GmbH

Contents

INFORMATION FOR USERS AND

QUALIFIED TECHNICIANS

Please read rst ........................................................ 2

Symbols..................................................................... 2

Intended use.............................................................. 4

Disclaimer.................................................................. 4

Safety ........................................................................ 4

Customer service ...................................................... 5

Warranty / Guarantee................................................ 5

Disposal..................................................................... 5

Heat metering............................................................ 5

Operation................................................................... 5

Care of the unit.......................................................... 5

Maintenance of the unit............................................. 6

Malfunctions .............................................................. 6

INSTRUCTIONS FOR QUALIFIED

TECHNICIANS

Scope of delivery....................................................... 7

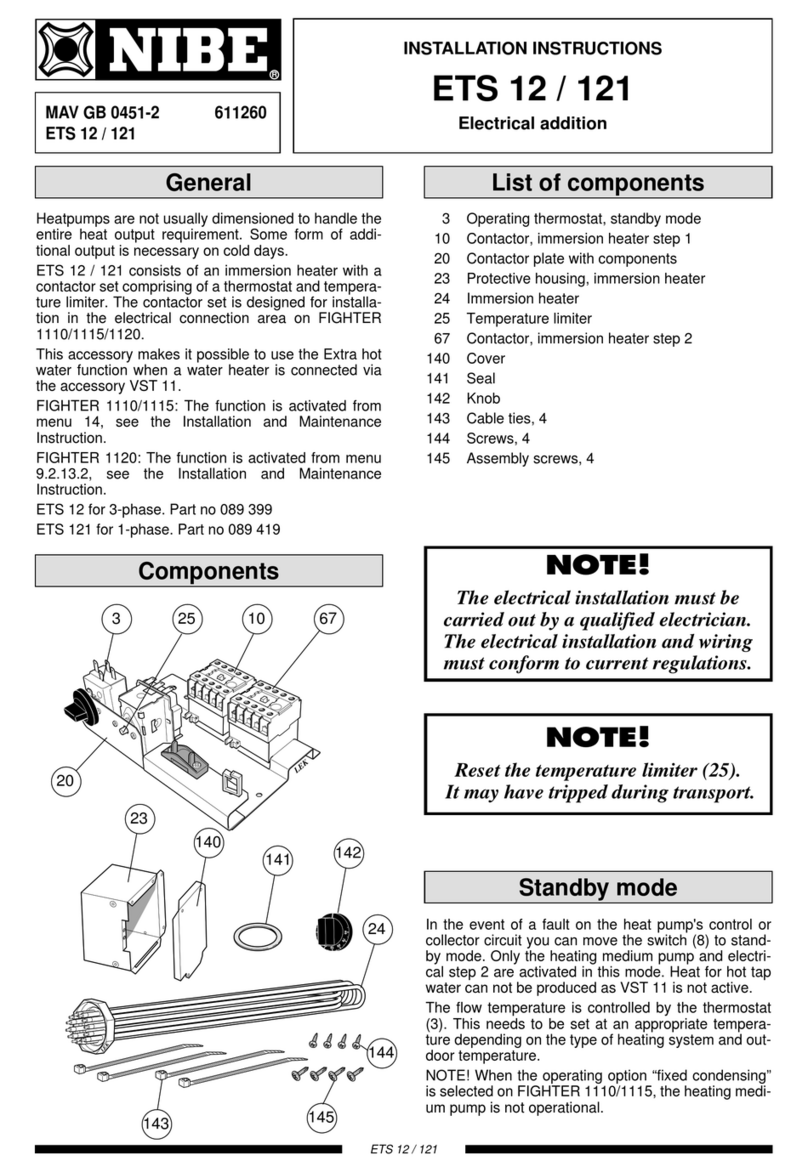

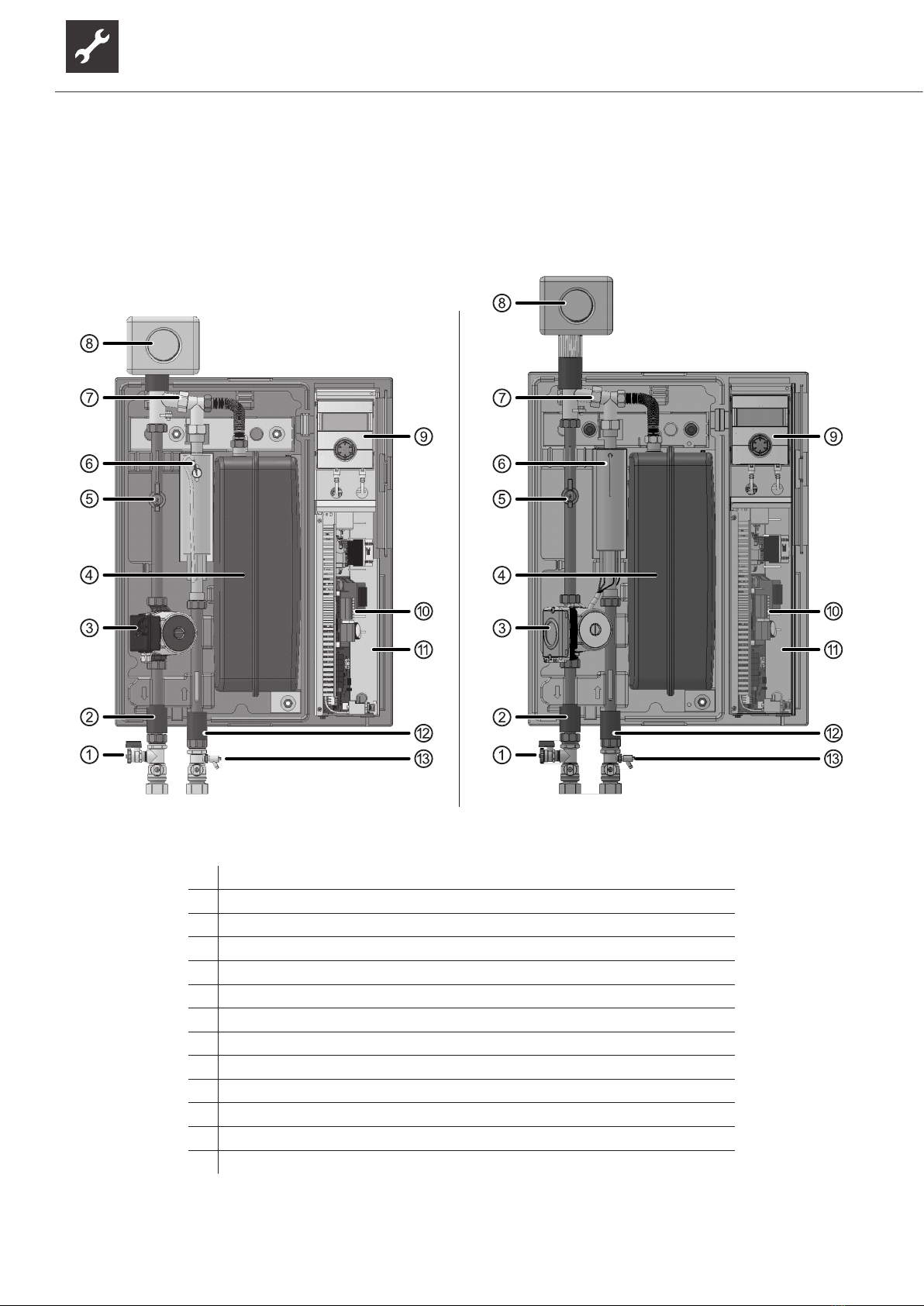

Components of the unit ........................................ 8

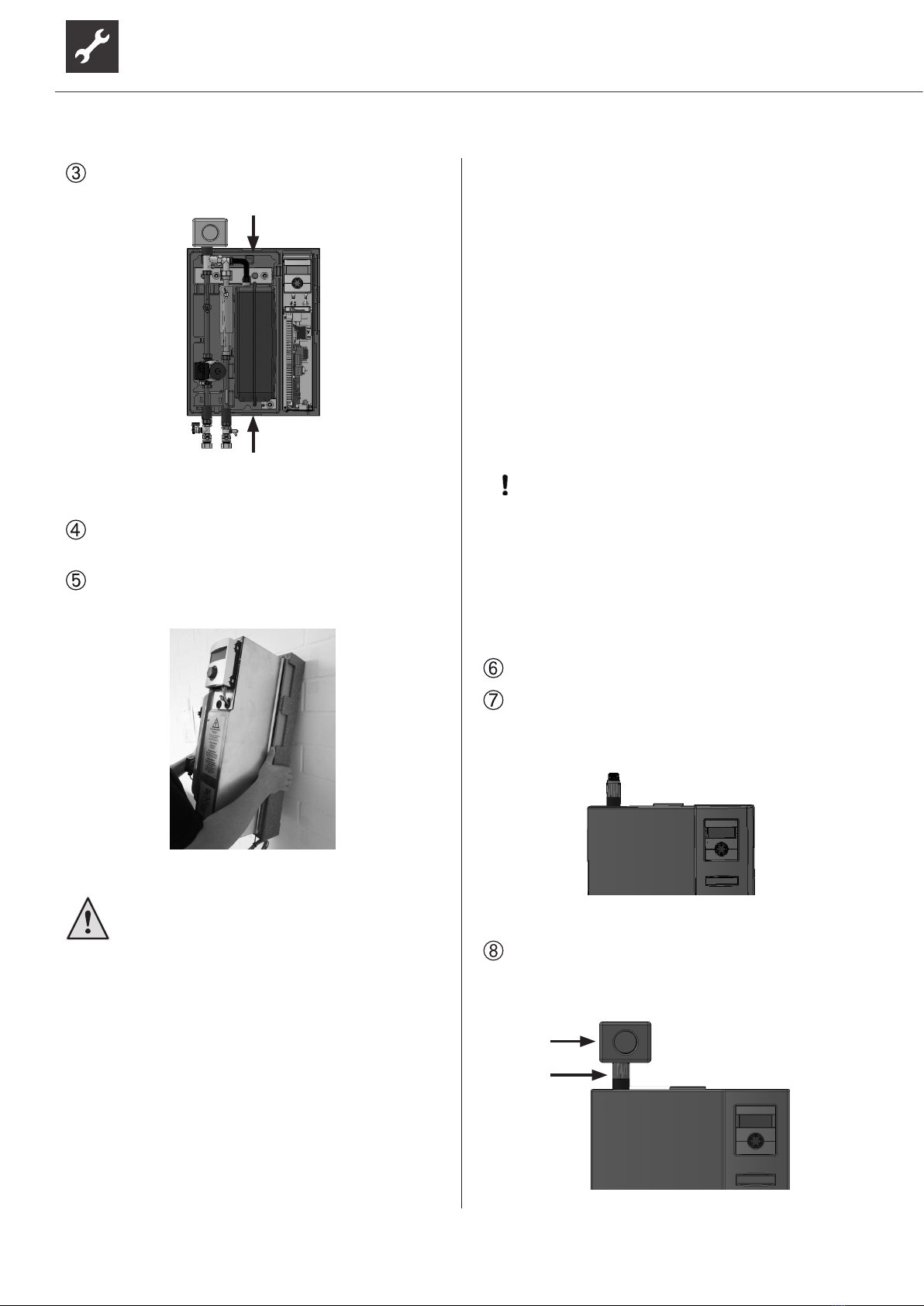

Installation ................................................................. 9

Installation location............................................... 9

Transport to installation location .......................... 9

Installation ............................................................ 9

Installation / Hydraulic connection

to heating circuit .............................................11

Safety assembly..................................................11

Expansion vessels ..............................................11

Electrical connections ............................................. 12

Connect BUS cable............................................ 13

Flushing, lling and bleeding the system................. 14

Flushing, lling and bleeding

the heating circuit.......................................... 14

Insulating the hydraulic connections ....................... 15

Set the overow valve ............................................. 15

Control element....................................................... 16

Commissioning........................................................ 17

Safety temperature limiter .................................. 17

Dismantling.............................................................. 17

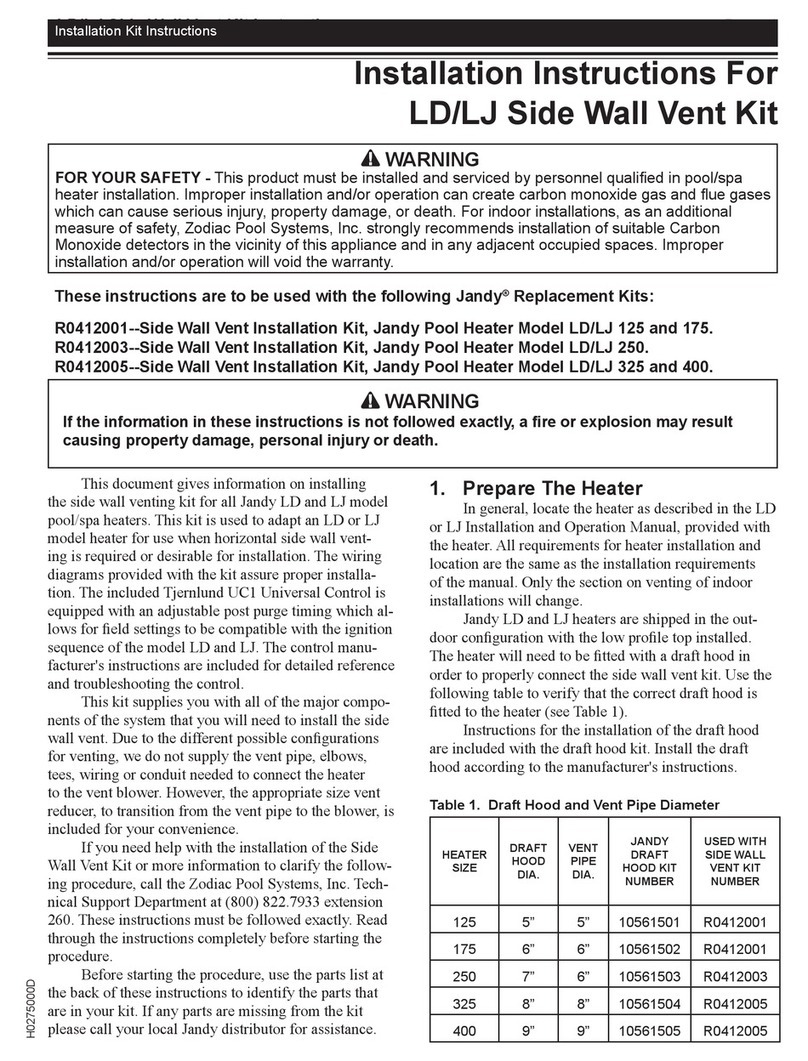

Technical data / scope of delivery ............................ 18

HMD 1/E............................................................. 18

HMD 1/RE .......................................................... 19

Free compression.................................................... 20

Dimensional drawings

HMD 1/E............................................................. 21

HMD 1/RE .......................................................... 22

Drilling pattern ......................................................... 23

Installation plans

HMD 1/E............................................................. 24

HMD 1/RE .......................................................... 25

Hydraulic integration

Row tank ............................................................ 26

Separate buer tank........................................... 27

Unit variant R (cooling)....................................... 28

Legend Hydraulic integration.............................. 29

Terminal diagram..................................................... 30

Circuit diagrams

HMD 1/E............................................................. 31

HMD 1/RE .......................................................... 33

EC declaration of conformity ................................... 35