LD/LJ Side Wall Vent Kit Instructions

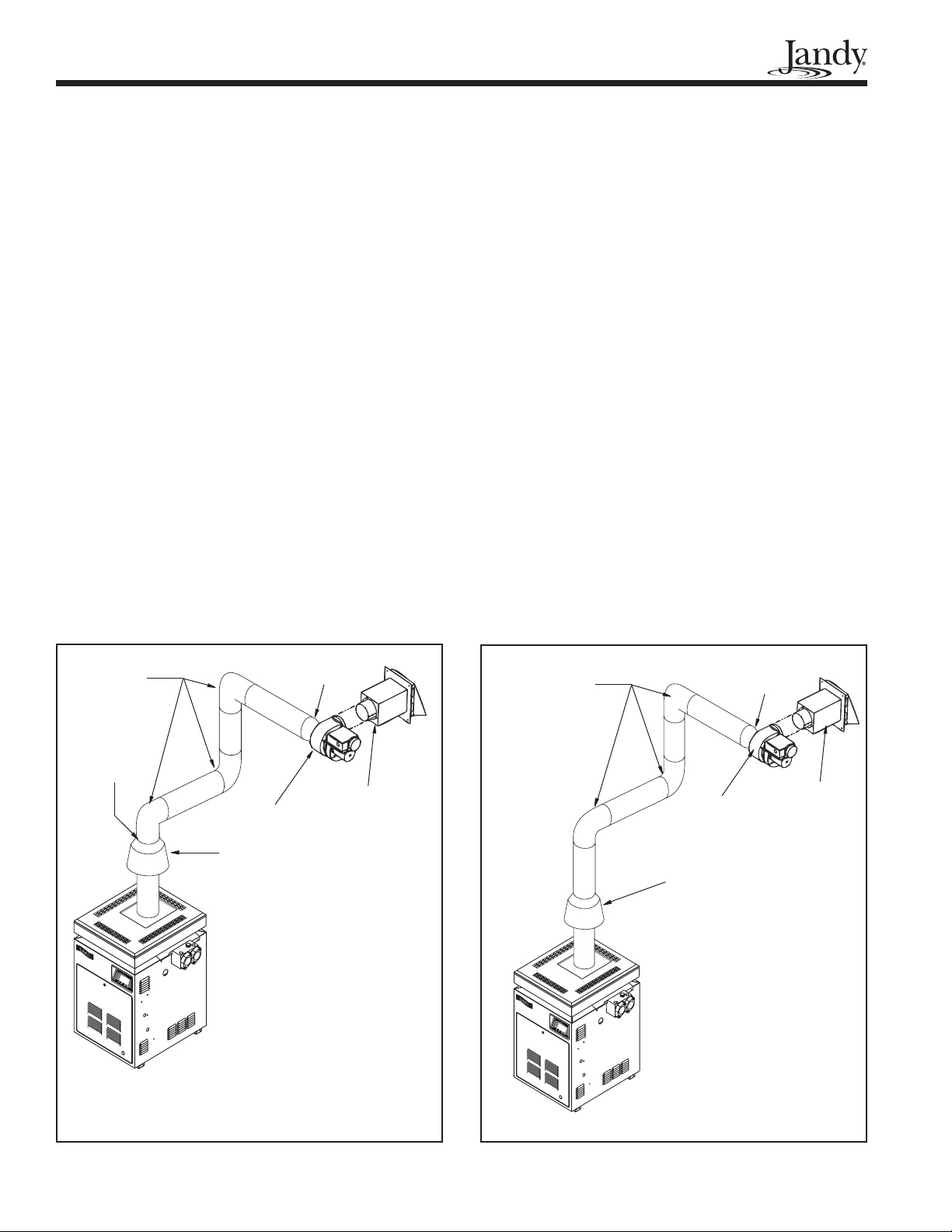

4. The vent pipe diameter is determined by the size

of the heater. The full length of the vent pipe must

be the diameter as stated in Table 1 on page 1. On

heater sizes 125, 175, 325, and 400, use the "bell"

reducer, enclosed in the kit to attach the vent pipe

to the power venter blower. On heater size 250,

use the "bell" reducer to attach the vent pipe to the

draft hood.

5. Horizontal sections of the vent pipe must have a

minimum 1/4 inch vertical rise per foot of pipe,

sloping upward, away from the heater.

6. There must not be any other appliance connected

to this venting system.

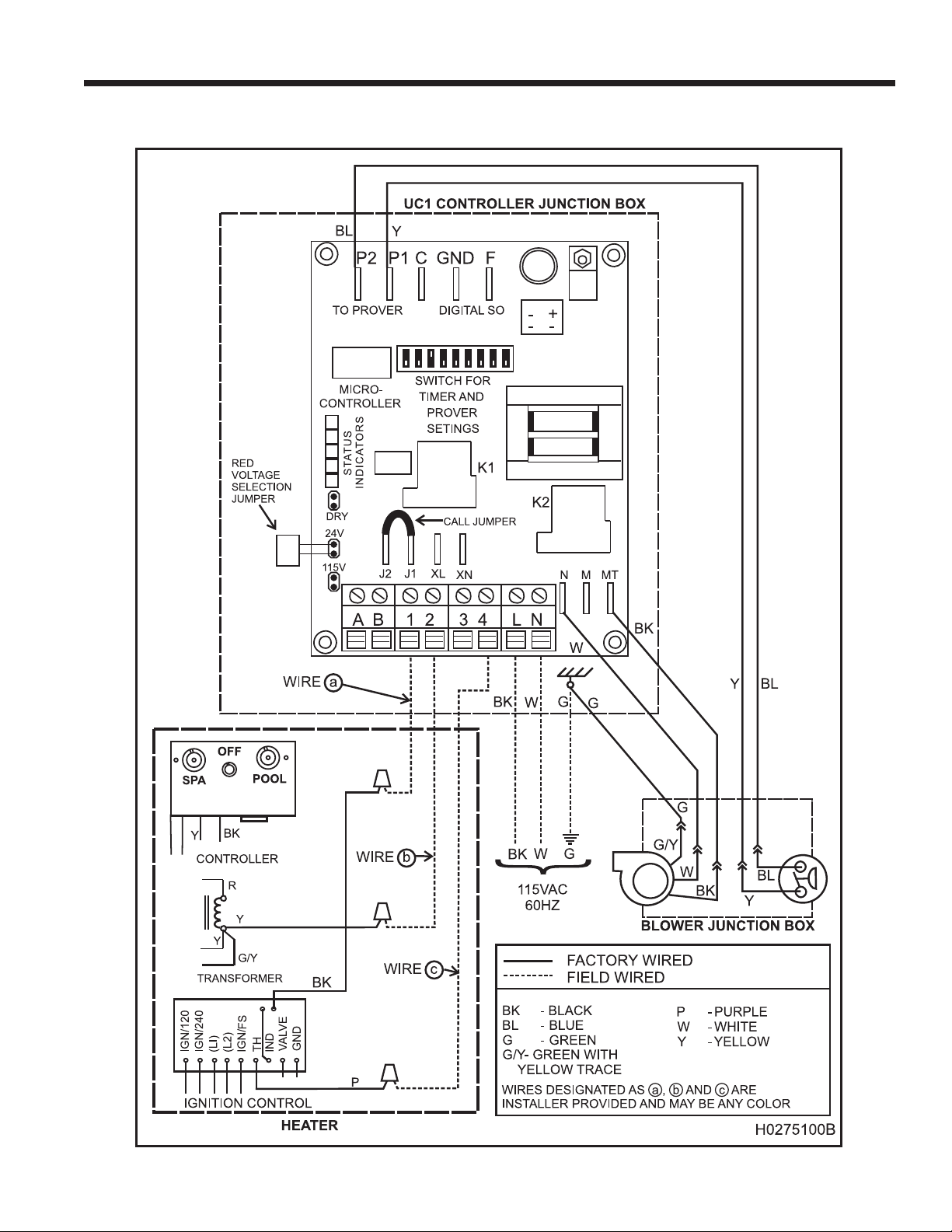

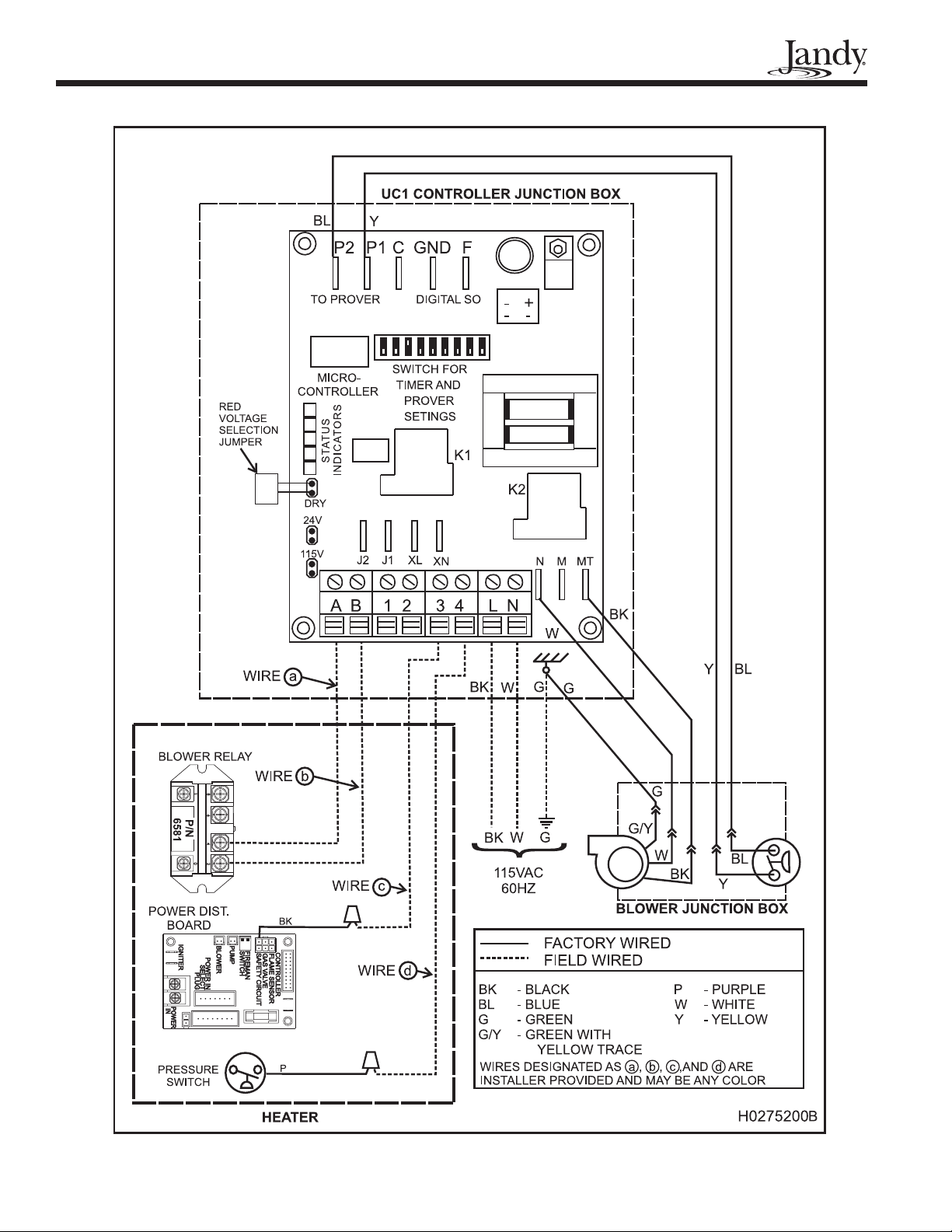

3. Electrical Connections

Please refer to the Tjernlund Products, Inc. "Side

Wall Vent Systems" installation manual for safety

information and detailed information on the Tjernlund

products.

The following instructions are specic to the wir-

ing and operation of the kit's blower and control panel

with the LD and LJ heaters. These instructions and the

wiring diagrams must be followed exactly in order for

the system to operate safely and efciently.

WARNING

SHOCK HAZARD!

3.1 Preparing The Heater

The internal 24 volt heater wiring must be slightly

modied to incorporate the side wall vent controller into

the safety circuit.

Section 3.1.1 describes the steps to modify the

model LD heater.

Section 3.1.2 describes the steps to modify the

model LJ heater.

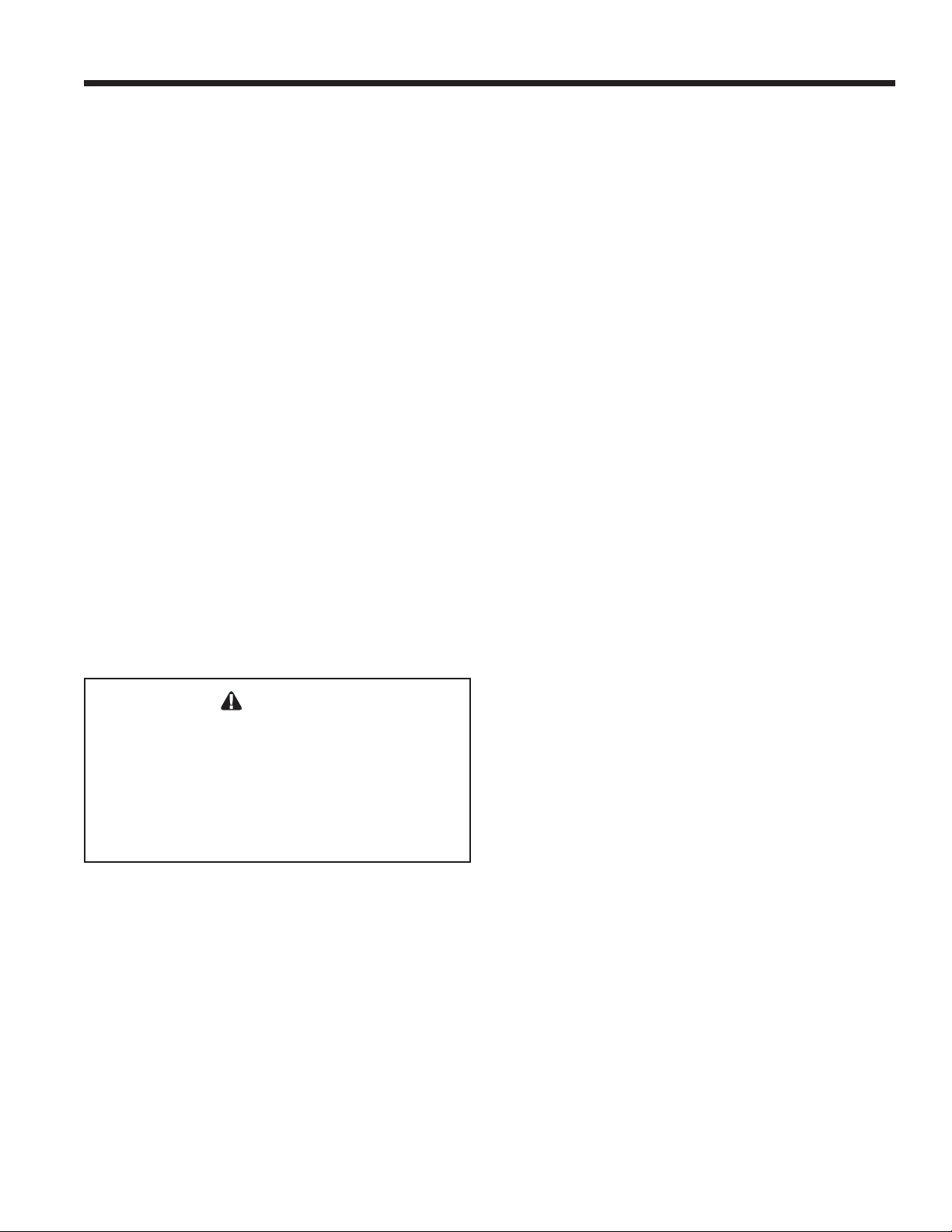

3.1.1. Modify the Model LD Heater

Wiring

1. Turn off the main breaker to the circuit that sup-

plies the heater with power.

2. Remove the heater door.

3. Locate the common terminal on the transformer.

There will be a yellow wire with a "piggy back"

terminal attached to the transformer and a green

wire with a yellow trace connected to the "piggy

back" terminal (refer to the heater's wiring di-

agram).

4. Disconnect the green wire with a yellow trace

from the "piggy back" terminal.

5. Plug the double male connector, included in the

kit, onto the "piggy back" terminal.

6. Reconnect the green wire with a yellow trace to

one (1) terminal of the double male connector.

7. Connect the yellow wire, supplied in the kit, to the

other terminal on the double male connector and

strip 1/2" of insulation off of the end of the wire.

8. Remove the black wire from the "TH" terminal of

the ignition control.

9. Cut the terminal off of the black wire and strip the

insulation back 1/2" from the end.

10. Connect the purple wire, supplied in the kit, to the

"TH" terminal of the ignition control.

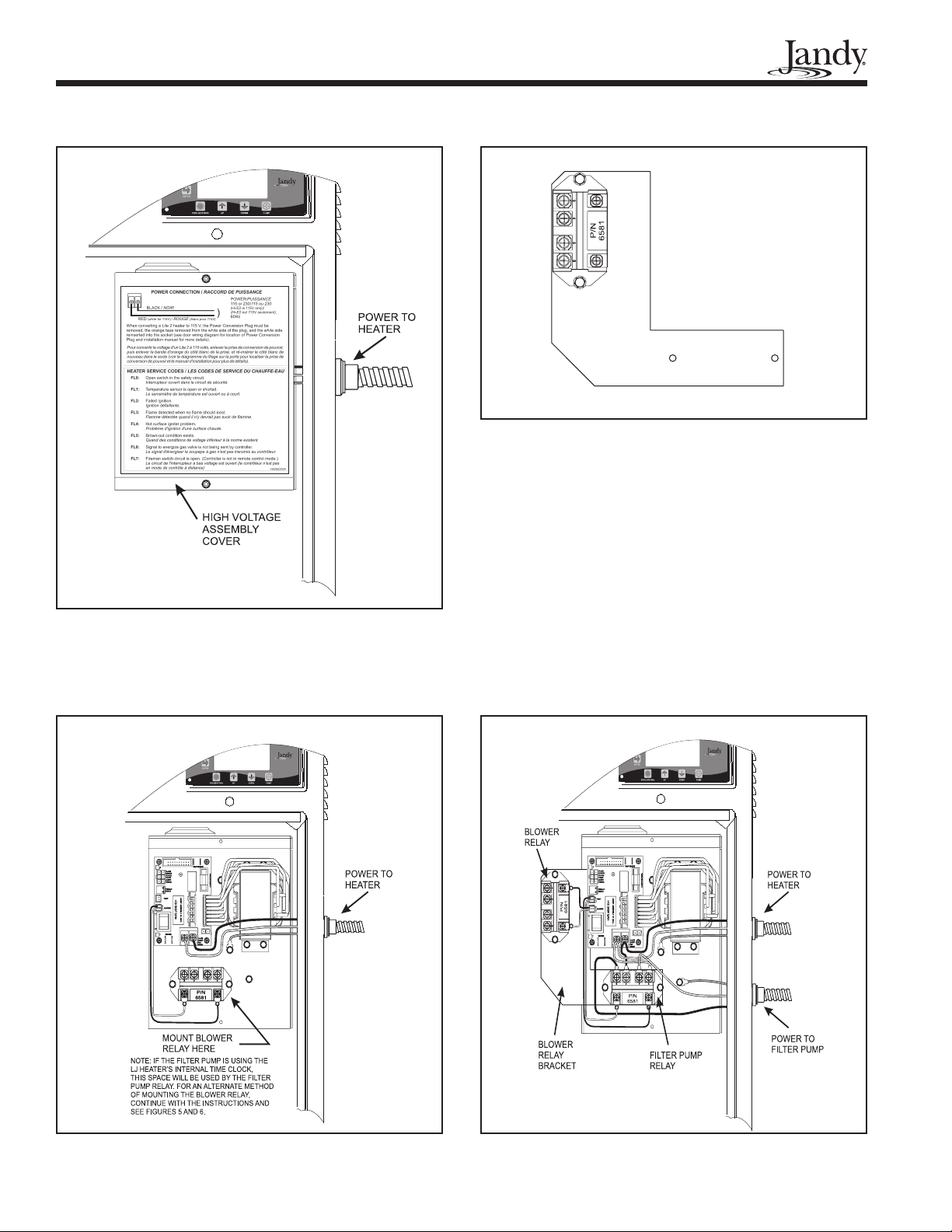

3.1.2. Modify the Model LJ Heater

Wiring

1. Turn off the main breaker to the circuit that sup-

plies the heater with power. If the pump is con-

nected to the heater's internal time clock, turn off

the breaker to the circuit that supplies power to the

pump.

2. Remove the heater door.

3. Remove the cover from the high voltage assembly

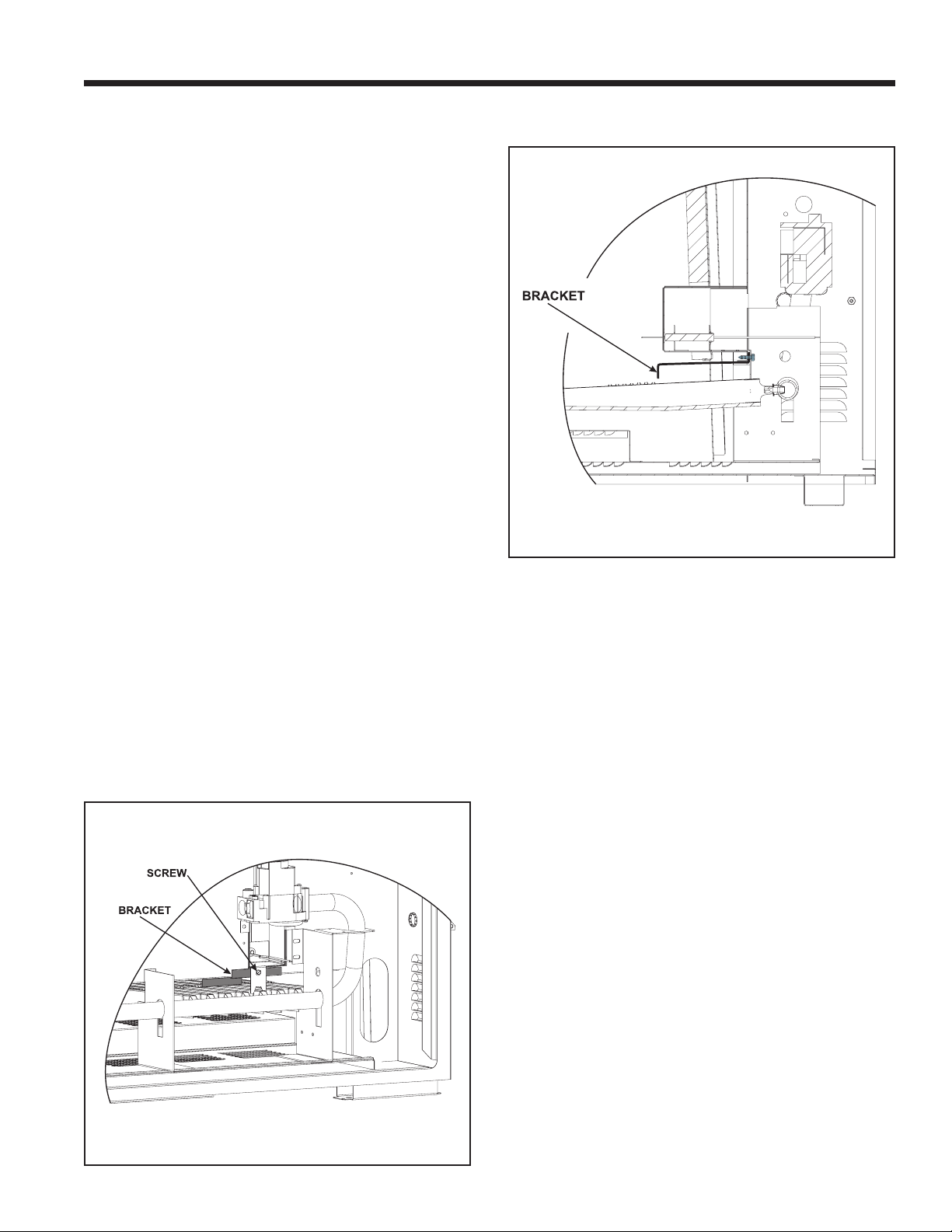

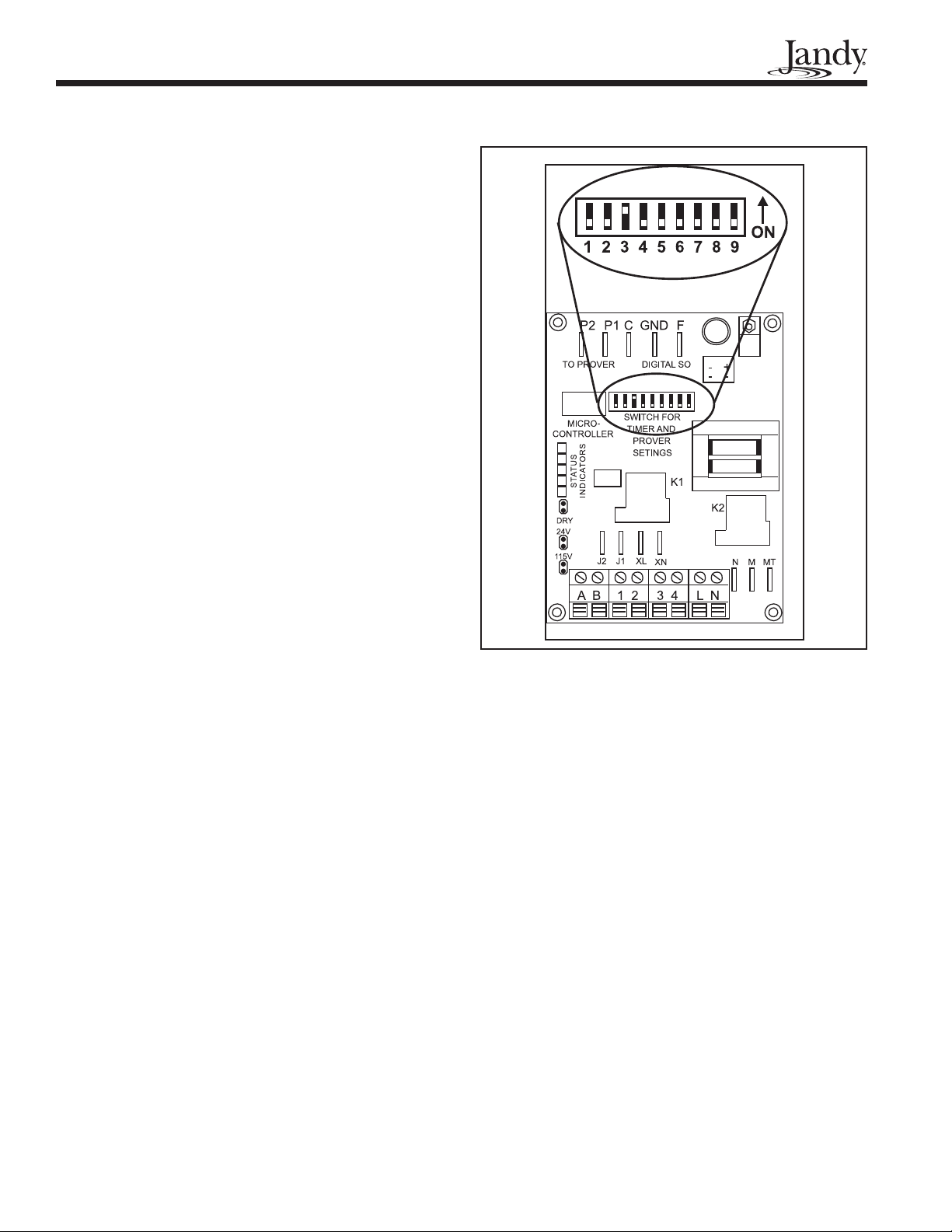

(see Figure 3).

4. Mount the blower relay to the back panel of the

high voltage assembly (see Figure 4). If the lter

pump is connected to the heater's internal time

clock, the pump relay will already be mounted in

this position. To mount the blower relay, do the

following:

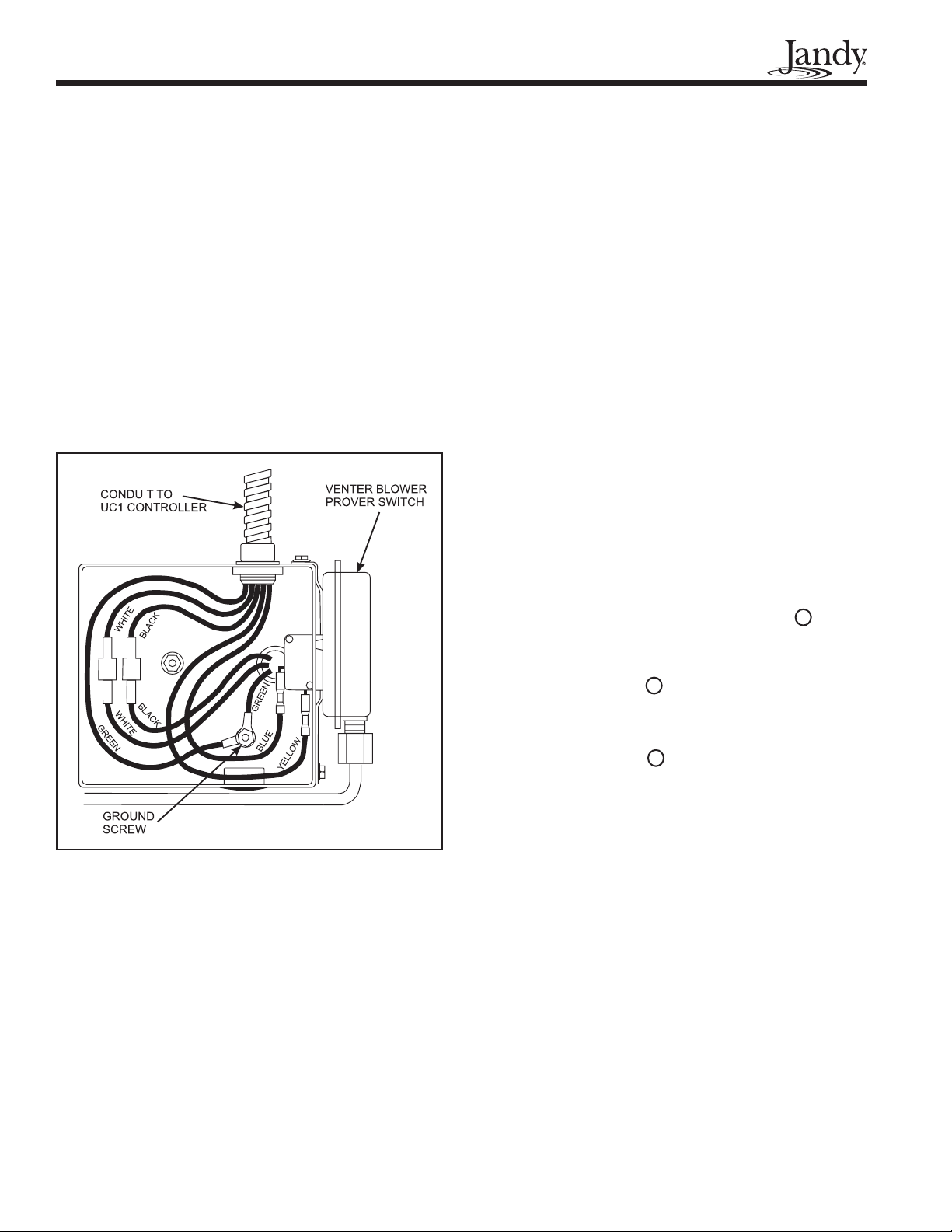

- Mount the blower relay to the relay bracket,

included in the kit, using the provided screws,

as shown in Figure 5, if a standard time clock

is controlling the lter pump.

- If a lter pump relay is controlling the lter

pump, remove the pump relay from the back

panel of the high voltage assembly. Do not dis-

connect any of the wires attached to the relay.