E3 1 DTR.SG...05(ENG)

CONTENTS

I. APPENDIX EX.03 (SGE–25.SMART, SGE–25S.SMART, SGE–25C.SMART) ................................2

II. APPENDIX EX.04 (SGE–25, SGE–25S, SGE–25C).........................................................................5

1. INTRODUCTION..............................................................................................................................8

2. USER MATERIALS..........................................................................................................................8

3. APPLICATIONS OF PROBES.........................................................................................................8

4. IDENTIFYING MARKS. ORDERING PROCEDURE.........................................................................8

5. TECHNICAL DATA..........................................................................................................................9

5.1. TECHNICAL DATA.SGE-25.SMART, SGE-25S.SMART, SGE-25C.SMART, SGE-25S.SMART/TITAN

PROBES ...................................................................................................................................................... 9

5.2. TECHNICAL PARAMETERS OF THE SGE-25............................................................................................. 10

5.3. TECHNICAL PARAMETERS OF THE SGE-25S, SGE-25C.......................................................................... 11

5.4. TECHNICAL PARAMETERS OF THE SGE-16............................................................................................. 11

5.5. SGE-25, SGE-16, SGE-25S, SGE-25C. ELECTRICAL PARAMETERS....................................................... 12

5.6. CONSTRUCTION MATERIALS:(FOR WHOLE PROBES)................................................................................ 12

5.7. INGRESS PROTECTION RATING .............................................................................................................. 12

6. TECHNICAL DESCRIPTION..........................................................................................................13

6.1. PRINCIPLES OF OPERATION.................................................................................................................. 13

6.2. CONSTRUCTION .................................................................................................................................. 13

6.3. ELECTRONIC CIRCUIT OF THE PROBES.................................................................................................... 13

7. PLACE OF INSTALLATION ..........................................................................................................13

7.2. HIGH AND LOW AMBIENT TEMPERATURES AND MEDIUM TEMPERATURES................................................... 13

8. INSTALLATION AND CONNECTION............................................................................................14

8.1. MECHANICAL INSTALLATION.................................................................................................................. 14

8.2. ELECTRICAL CONNECTION.................................................................................................................... 14

9. SETTINGS AND REGULATION.....................................................................................................14

9.1. SETTINGS OF SGE-25,SGE-16, SG-25C, SGE-25S PROBES................................................................ 14

9.2. SETTINGS OF SGE-25.SMART, SGE-25S.SMART, SGE-25S.SMART/TITAN PROBES.......................... 14

9.3. SGE-25.SMART, SGE-25S.SMART, SGE-25S.SMART/TITAN. MEASUREMENT RANGES.DEFINITIONS. 14

9.4. CONFIGURATION AND CALIBRATION....................................................................................................... 15

10. INSPECTIONS, REPAIRS AND SPARE PARTS...........................................................................15

10.1. REGULAR INSPECTIONS...................................................................................................................... 15

10.2. ADDITIONAL INSPECTIONS .................................................................................................................. 15

10.3. SPARE PARTS................................................................................................................................... 17

11. PACKING, STORAGE AND TRANSPORT....................................................................................17

11.1. PACKING,TRANSPORT....................................................................................................................... 17

11.2. STORAGE ......................................................................................................................................... 17

12. GUARANTEE.................................................................................................................................17

13. SCRAPPING, DISPOSAL ..............................................................................................................17

14. ADDITIONAL INFORMATION........................................................................................................17

15. LEVEL PROBE WITH INTERNAL TEMPERATURE SENSOR PT100...........................................17

16. FIGURES .......................................................................................................................................18

FIGURE 1. SGE-25.SMART AND SGE-25S.SMART PROBES –DIMENSIONS .................................................. 18

FIGURE 2. SGE-25.SMART AND SGE-25S.SMART PROBES –CONNECTION METHOD .................................... 18

FIGURE 3. SGE-25, SGE-16, SGE-25C AND SGE-25SPROBES –DIMENSIONS.............................................. 19

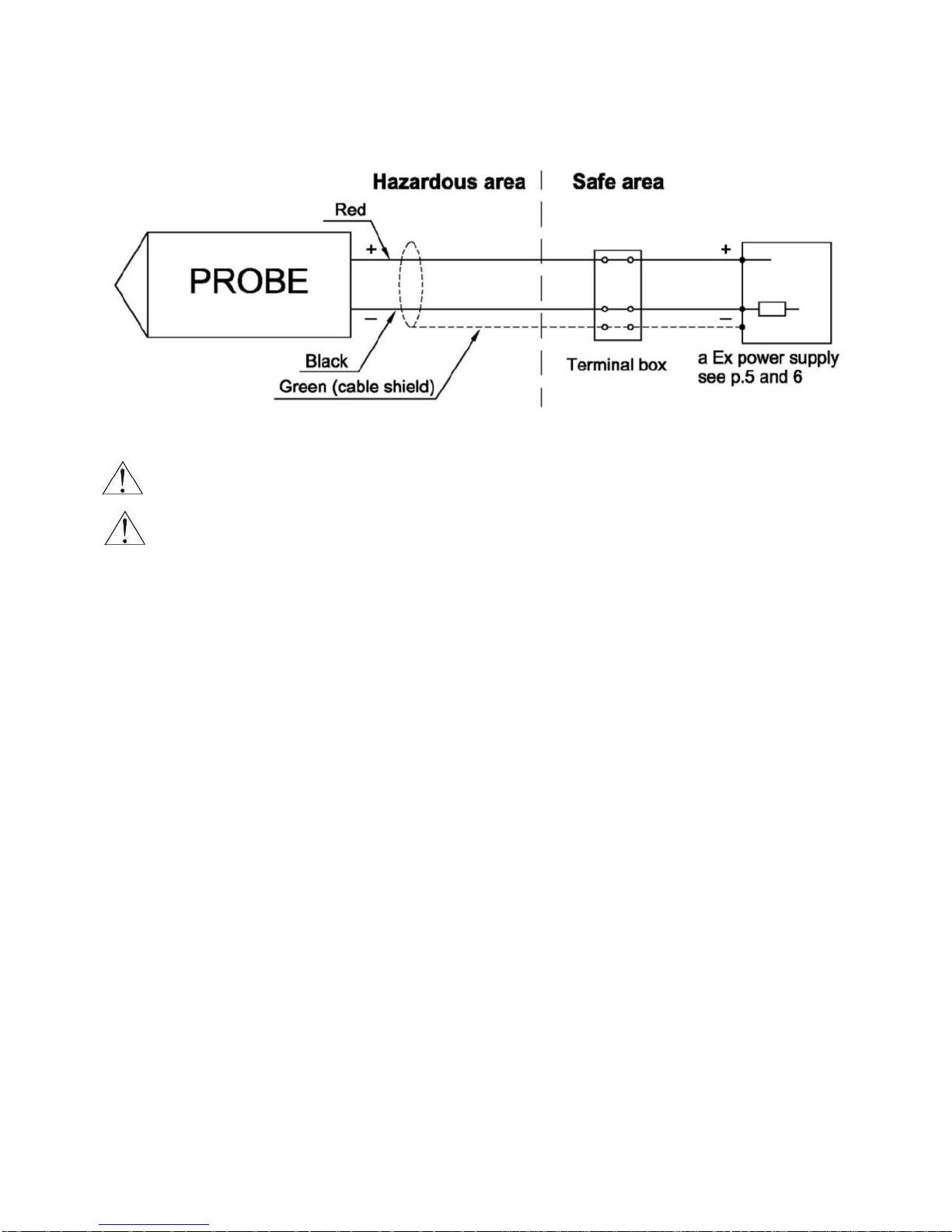

FIGURE 3A. CONNECTION OF SGE-25,SGE-16, SGE-25S AND SGE-25C IN A TWO-WIRE SYSTEM (4…20MA

OUTPUT SIGNAL)........................................................................................................................................ 19

FIGURE 4. SGE-25, SGE-16, SGE-25C PROBES IN LOW VOLTAGE VERSIONS –DIMENSIONS ............................ 20

FIGURE 4A. CONNECTION OF SGE-25, SGE-25S AND SGE-25C IN A THREE-WIRE SYSTEM (0…10V OUTPUT

SIGNAL) .................................................................................................................................................... 20

FIGURE 5. THE PROBE IN EX-VERSION WITH A CABLE WITH TEFLON SHIELD....................................................... 21