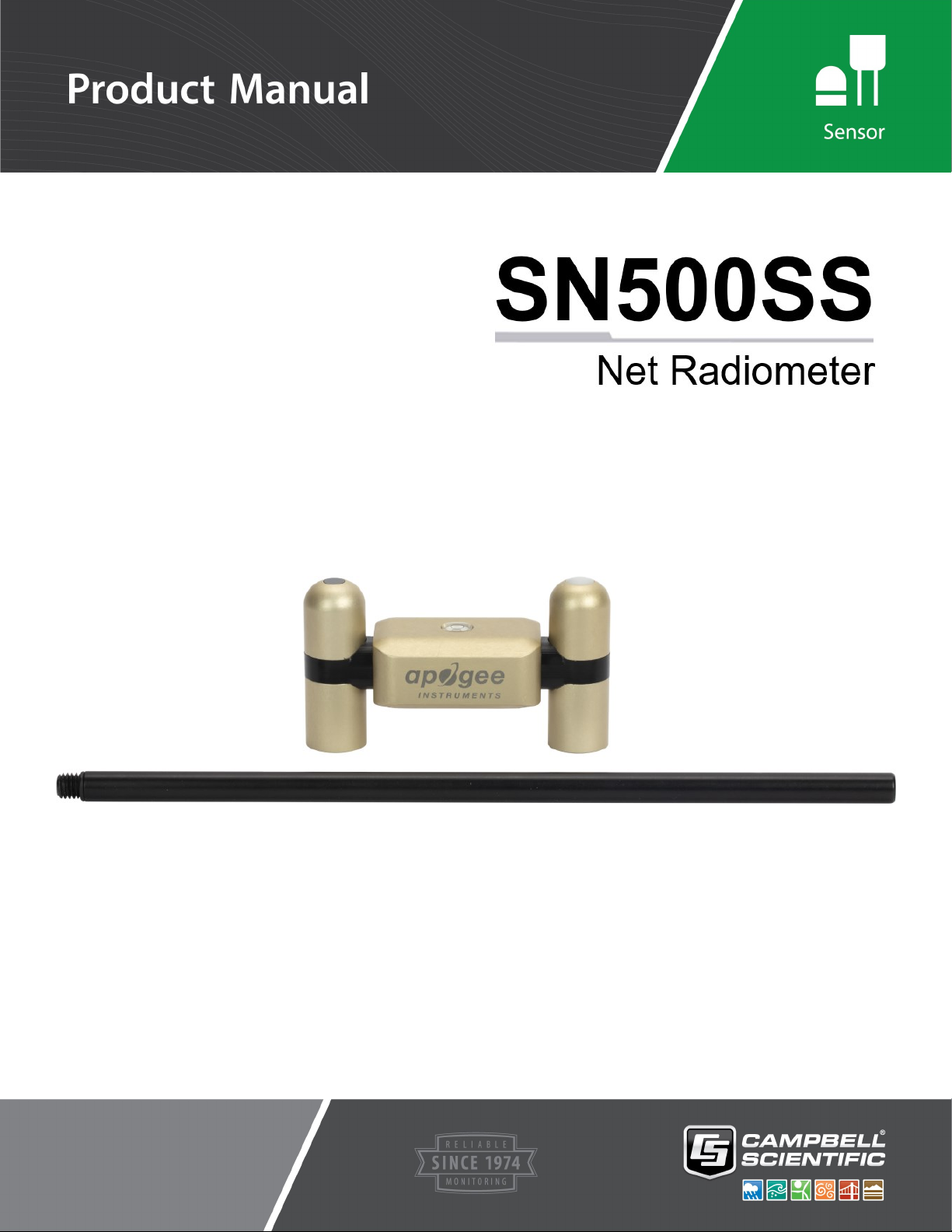

mounted in an anodized aluminum housing. Each radiometer is heated to minimize the effects of

dew, frost, snow, and ice on the filter and sensor head. Analog signals from each radiometer are

measured with an onboard voltmeter and converted to SDI-12 outputs, eliminating the need for

multiple analog data logger terminals to make the four-component measurement of net

radiation. The SN500SS is small and lightweight to facilitate mounting.

Net radiation at Earth surface is the source of available energy that drives key processes,

including surface and atmospheric heating, evaporation, sublimation, and transpiration.

Shortwave radiation (approximately 280 to 4000 nm) is emitted by the sun, and a fraction

incident at Earth’s surface is reflected. Longwave radiation (approximately 4000 to 100,000 nm) is

emitted by molecules in the atmosphere and land surfaces. Net radiation is the difference

between incoming (downwelling) and outgoing (upwelling) shortwave and longwave radiation.

Net radiation at Earth surface is spatially and temporally variable due to changes in position of

the sun with respect to Earth’s surface, changes in atmospheric conditions, and differences in

land surface conditions. Shortwave radiation accounts for a larger proportion of net radiation

during the day when the sun is shining. Longwave radiation contributes to net radiation during

the day and at night.

Net shortwave radiation is the difference between incoming shortwave (from sun, SWi) and

outgoing shortwave (reflected by surface, SWo). Net longwave radiation is the difference

between incoming longwave (emitted by molecules in the atmosphere, LWi) and outgoing

longwave (emitted by elements at the surface, LWo). Net radiation is the sum of net shortwave

and net longwave radiation. Net radiation changes with solar zenith angle, atmospheric

conditions (for example, degree of cloudiness), and surface conditions (for example, bare soil,

plant cover, snow).

Typical applications of net radiometers include measurement of net radiation on surface flux

towers and weather stations. Net radiation is a key variable in the surface energy balance and

influences turbulent fluxes, including evapotranspiration.

Features:

lIndividual measurement of four net radiation components

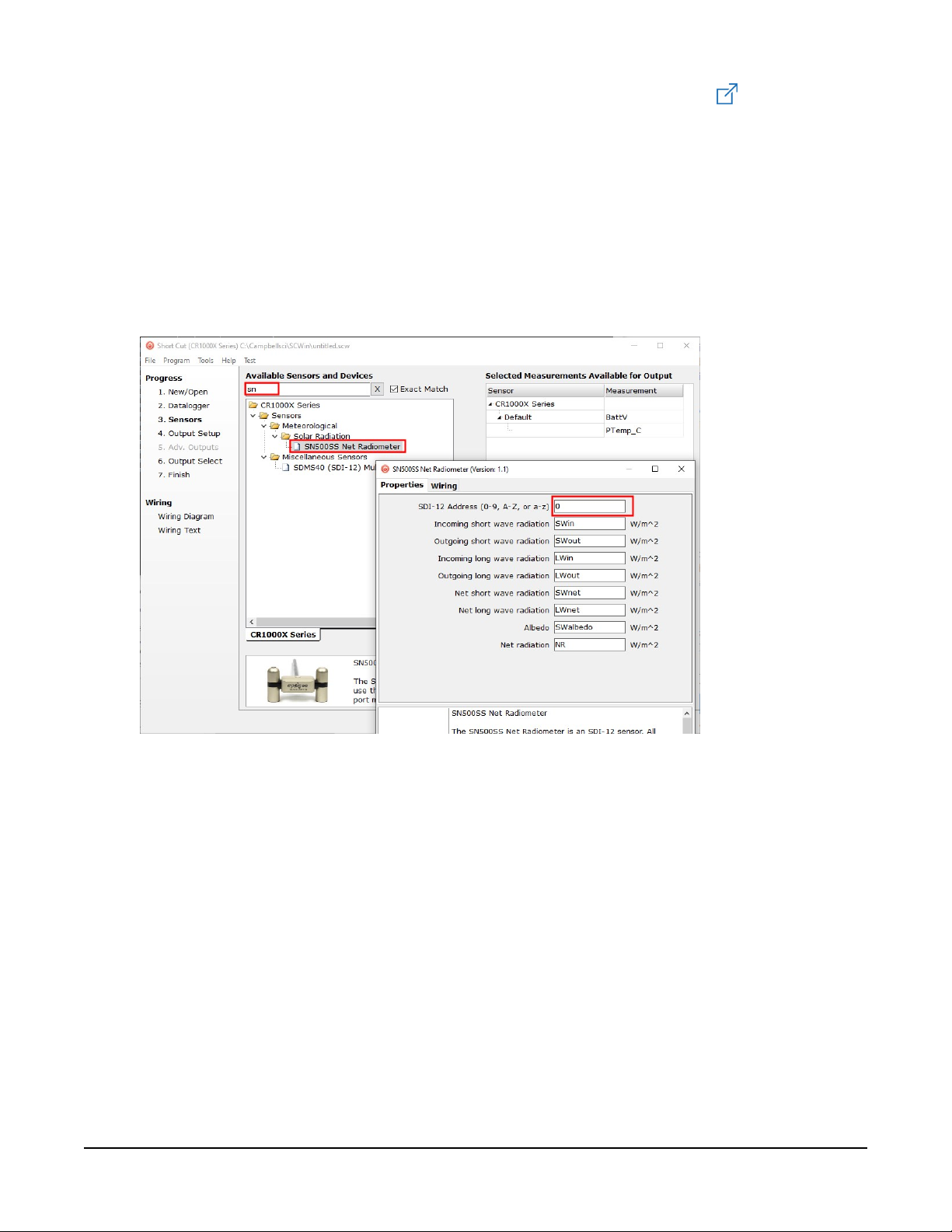

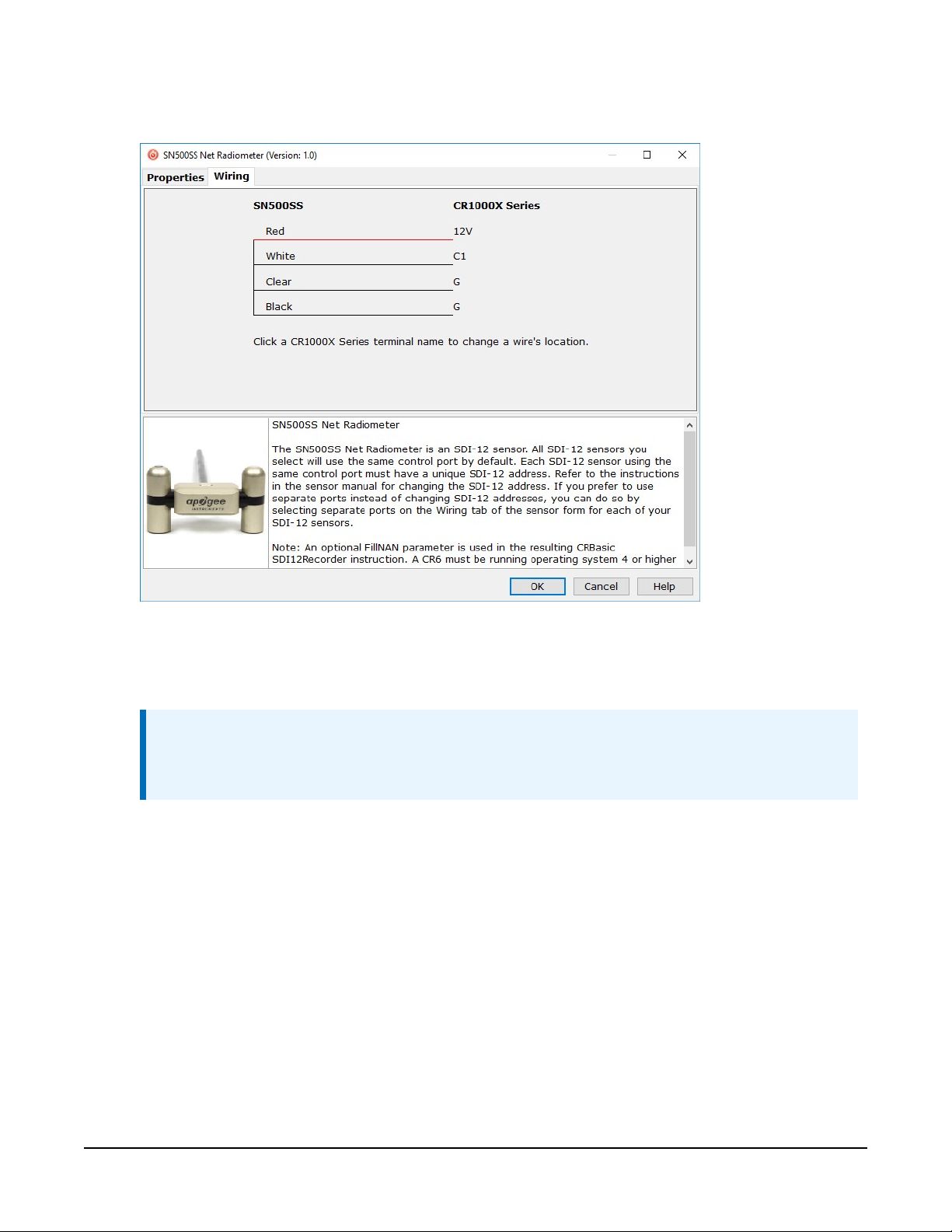

lSDI-12 output, eliminating the need for multiple analog terminals to measure the individual

components of net radiation

lComplete package that includes net radiometer, mounting rod, cable for data logger

interface, and carrying case

lCompatible with Campbell Scientific CRBasic data loggers: GRANITE-series, CR6, CR3000,

CR1000X, CR800-series, CR300-series, CR1000

SN500SS Net Radiometer 5