Step 2-12

Step 2-14

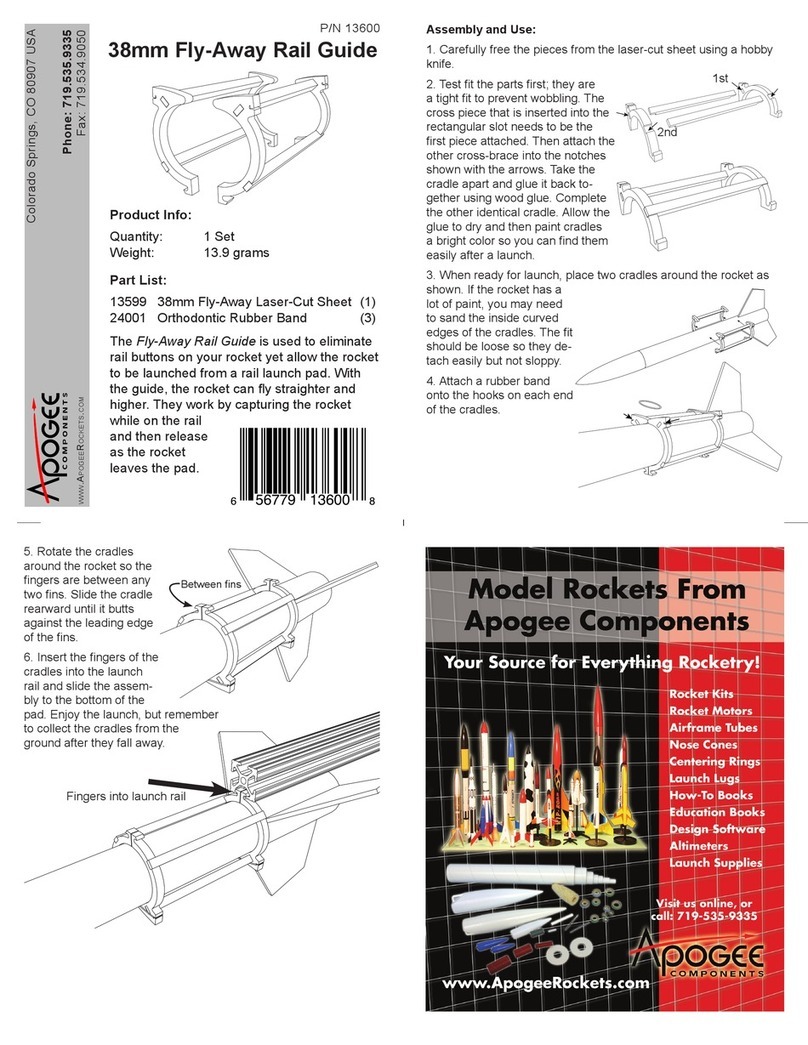

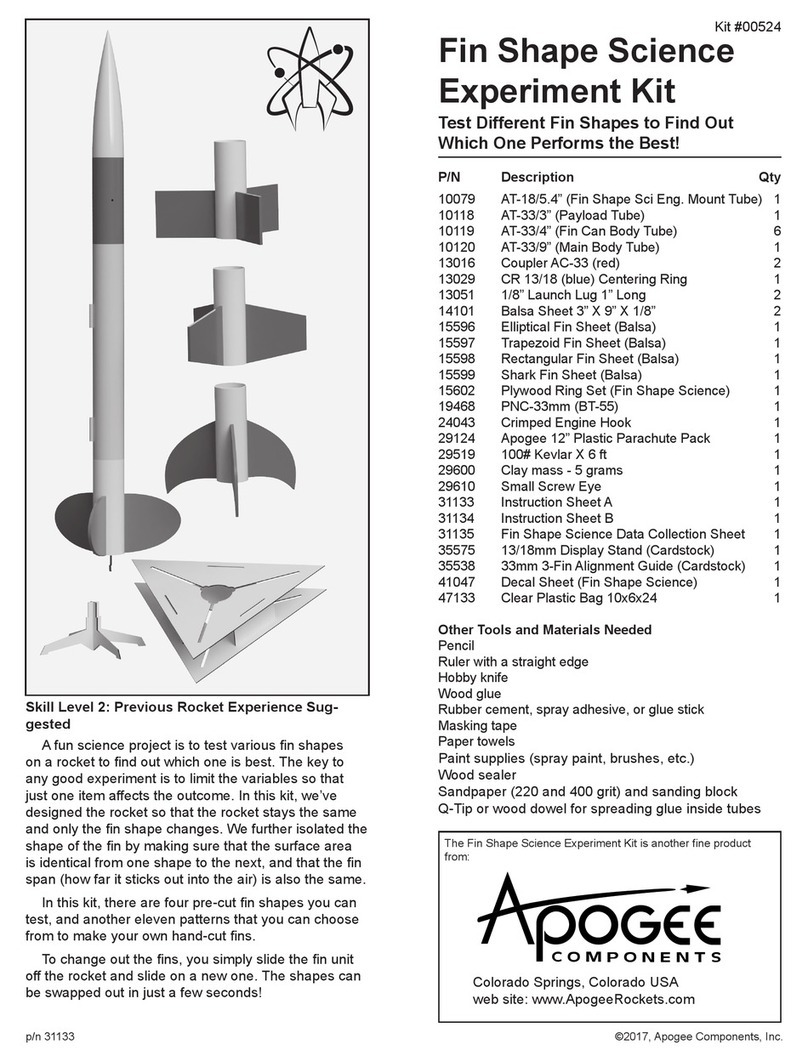

2-11. DO NOT GLUE - Slide the aft centering ring (ring F)

over all three motor tubes, and rotate the tubes so that

the engine hooks align with the notches in the aft ring,

and are all facing the same direction.

2-12. Rotate the latch assembly, so the latch is facing

away from you. Apply glue to the interior of the three

holes. Quickly install the front of the motor mount tubes

in the latch assembly centering ring, Press the tubes all

the way into the front centering ring and get the tubes as

square as possible.

2-13. Once the tubes are secure at the latch assembly,

apply glue at the 5/8" (16mm) marks of all tubes and slide

the aft centering ring into place.

2-14. Apply wood glue to the joints between the centering

rings and motor tubes, then form llets with a nger tip.

Allow the removable mount to dry entirely before install-

ing in a rocket.

Adjusting Mounts for Correct Fit

To adjust the t of the removable mount, the tabs may

need to be led down somewhat. This compensates for

slight inaccuracies in both the xed mount and remov-

able mounts. To test, insert the removable mount into the

rocket and rotate it until the tabs on the latch drop into

the slots in the xed mount. Rotate the removable mount

clockwise to latch. If the removable mount refuses to

rotate or is overly stiff, take the mount out and use a at

needle le to remove material from the aft side of each

of the tabs (as shown here with the 3x24mm mount).

Repeat this process of testing and removing material until

the mount rotates and latches without binding

Remove materials

from backside of tabs

Slide centering ring

into position

5/8”

(16mm)

Step 2-13

Slide centering ring

into position

5/8"

16mm

Page 10

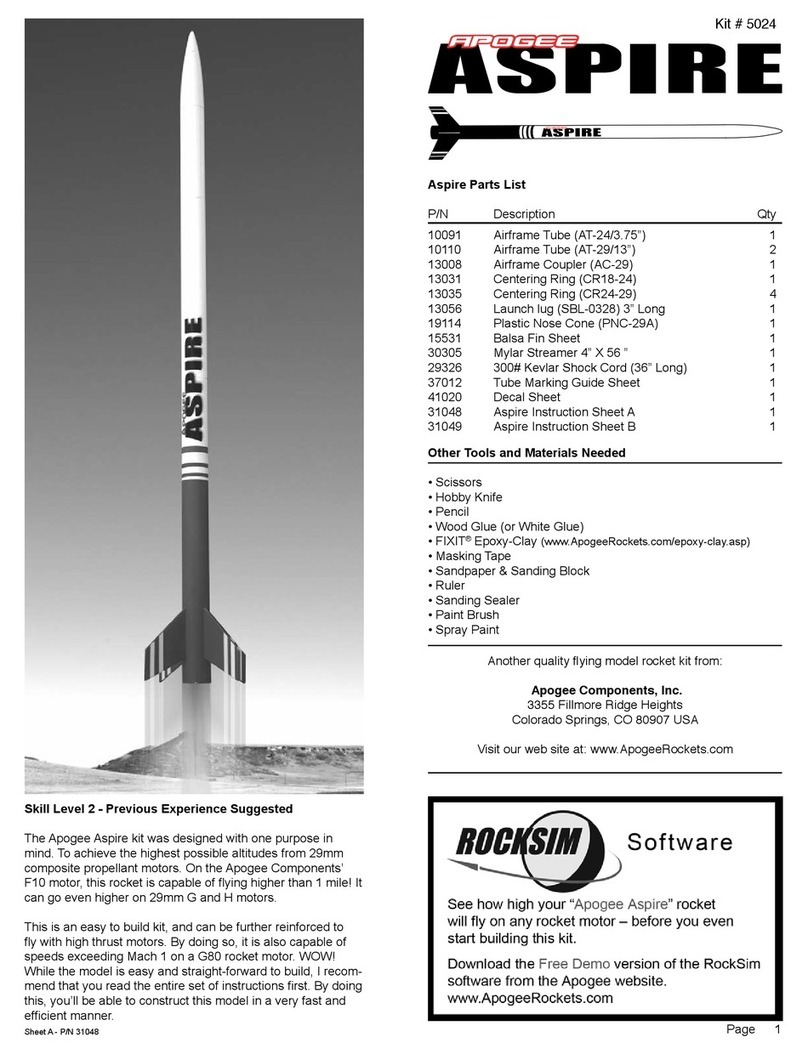

*Quick Draw Suggested Motor Charts*Quick Draw Suggested Motor Charts

1x29mm Motor Mount:1x29mm Motor Mount:

Manufac-

turer

Engine

Loaded Motor Type Est. Altitude

Ft m

Estes E16-4 Single Use 548 167

Cesaroni F36SS-6 Reloadable 792 241

AeroTech F27R-4 Single Use 1008 307

Cesaroni F31CL-6 Reloadable 1075 328

AeroTech F25W-6 Single Use 1538 469

Cesaroni G88SS-8 Reloadable 1695 517

AeroTech G25W-6 Reloadable 2551 778

Manufac-

turer

Engine

Loaded Motor Type Est. Altitude

Ft m

Estes 2 x E16-4 Single Use 1186 362

Cesaroni 2 x F36SS-8 Reloadable 1601 488

Estes 2 x F15-6 Single Use 1952 595

Cesaroni 2 x F29IM-8 Reloadable 2101 641

AeroTech 2 x F25W-9 Single Use 2734 834

2x29mm Motor Mount (Sold Separately):2x29mm Motor Mount (Sold Separately):

Step 2-11 Ring F

Manufac-

turer

Engine

Loaded Motor Type Est. Altitude

Ft m

Estes 3 x C11-5 Single Use 390 119

Estes 3 x D12-5 Single Use 965 294

Quest 3 x D22W-7 Single Use 1177 359

Estes 3 x E12-6 Single Use 1613 492

3x24mm Motor Mount:3x24mm Motor Mount: