HEADQUARTERS: AndersonPowerProducts®,13PrattsJunctionRoad,Sterling,MA01564-2305USA T:978-422-3600 F:978-422-3700

EUROPE: AndersonPowerProducts®Ltd.,Unit3,EuropaCourt,EuropaBoulevard,Westbrook,Warrington,Cheshire,WA57TNUnitedKingdom T:+44(0)1925428390 F:+44(0)1925428399

ASIA/PACIFIC:IDEALAndersonAsiaPacificLtd.,Unit922-928TopsailPlaza,11OnSumStreet,ShatinN.T.,HongKong T:+(852)26360836 F:+(852)26359036

CHINA:IDEALAndersonTechnologies(Shenzhen)Ltd.,BlockA8TantouWesternIndustrialPark,SonggangBaoanDistrict,Shenzhen,PR.China518105 T:+(86)75527682118 F:+(86)75527682218

TAIWAN:IDEALAndersonAsiaPacificLtd.,TaiwanBranch,4F.-2,No.116,Dadun20thSt.,SitunDistrict,TaichungCity407, Taiwan(R.O.C.) T:+(886)423106451 F:+(886)423106460

www.andersonpower.com

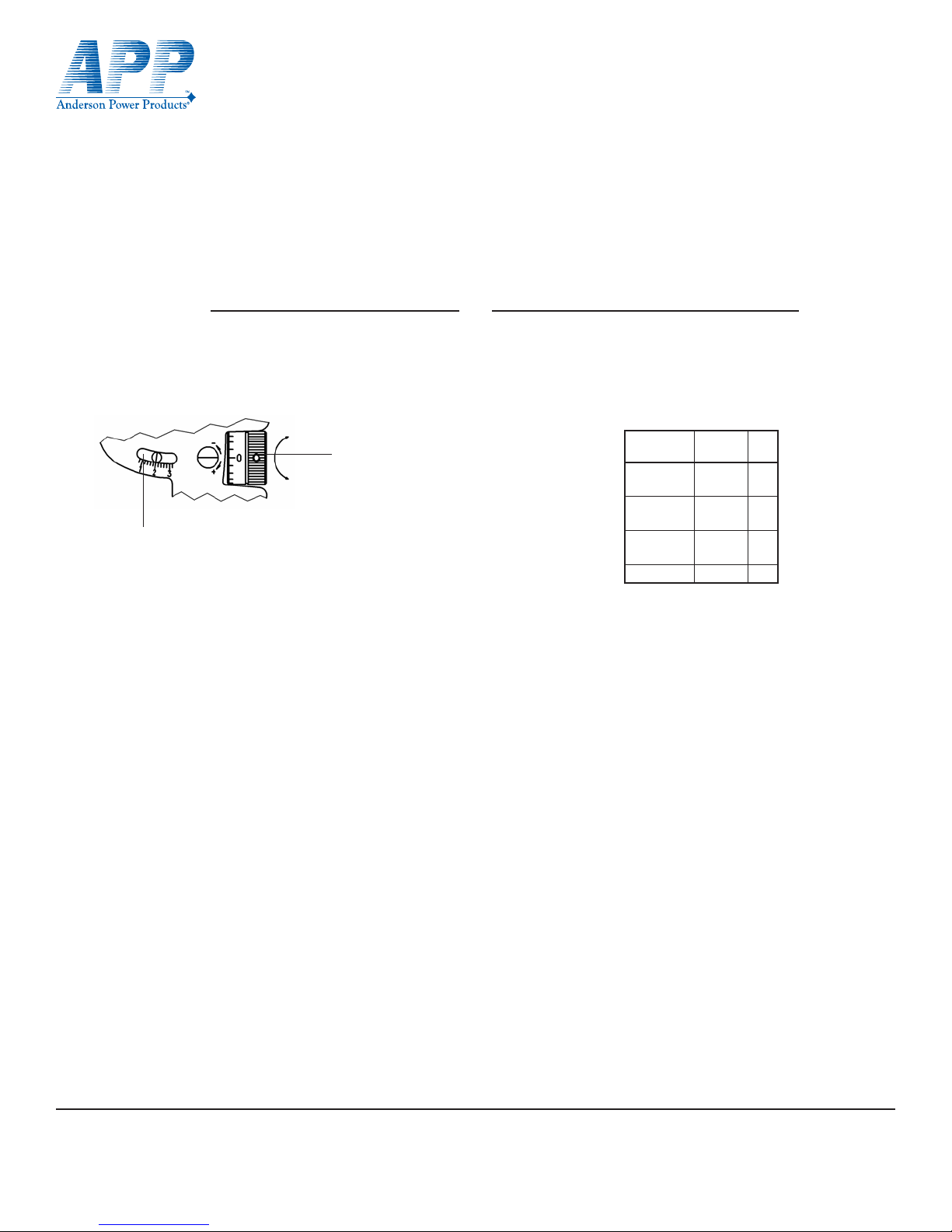

Crimp jaws

Adjusting screw with

0.01 mm tolerance

Scale indicating 0.2 mm

tolerance

Handles

(fixed & movable)

End stop

OperatingInstructions

4IndentCrimpTool

Designed and manufactured pursuant to state-of-the-art technical requirements and latest safety standards,

this four indent crimp tool PM1000G1 is to be used only when in good working order and in strict compliance

with existing safety rules.

The PM1000G1has been developed for crimping of both male and female turned contacts. The tool is only to

be used for the application described below.The manufacturer is not liable for damages caused by improper

use or unauthorized technical modifications of the tool. The tool consists of a movable handle with precision

ratchet mechanism, a fixed handle with a metric scale, an adjustment system by micro setting of 0.01 mm

tolerance, four indenter jaws and a 12 position locator, fully rotatable, for accurate positioning of contacts. A

reference table, marked onto the crimp tool’s surface, informs on the locator position and crimp depth to be

selected to match a particular contact. The tool can be adjusted to any crimp depths that might be requested

by the contact manufacturer.

PM1000G1

Manner of operation

The four indent crimp tool PM1000G1 has been developed for optimal crimping of turned contacts for wire ranges 0.14 to 6.0 mm² (26 through 10

AWG). The reference table indicates the correct locator position to be selected and the crimp depth to be adjusted for the contact to be crimped.

The contact is then inserted through the entry hole of the tool on the opposite side of the locator. The contact is fixed by closing the handles to the

first lock-in position thus preventing the contact falling out of the tool and facilitating insertion of cable into the contact. The precision ratchet

assures consistently accurate crimps every time by forcing the tool to be closed to its fullest extent, completing the crimping cycle before the

tool opens automatically.

12 Position

Position Contact Designation

1 PM16SxxxxS32

2 PM16PxxxxS30

3 PM16PxxxxA30

4 PM16PxxxxB30

5 PM16PxxxxC30 PC16SSN

6 SC20LGN

Position Contact Designation

7 PC20SGN

8 PC20FGN

9 SC20-GN

10 PC12LSN

11 PC12FSN PC12SSNSC16-SN

12 SC12-SN

LocatorContactPositions