Document 4400Q902 version 1.02 Page 8 of 18

CONTENTS

USE OF THIS DOCUMENT.......................................................................................................................................4

HAZARD AND OTHER INDICATORS.......................................................................................................................5

ESSENTIAL SAFETY INFORMATION......................................................................................................................6

RX2000 INSTALLATION AND OPERATIONAL REQUIREMENTS..........................................................................7

CONTENTS ...............................................................................................................................................................8

FIGURES...................................................................................................................................................................8

1 INTRODUCTION ....................................................................................................................................................9

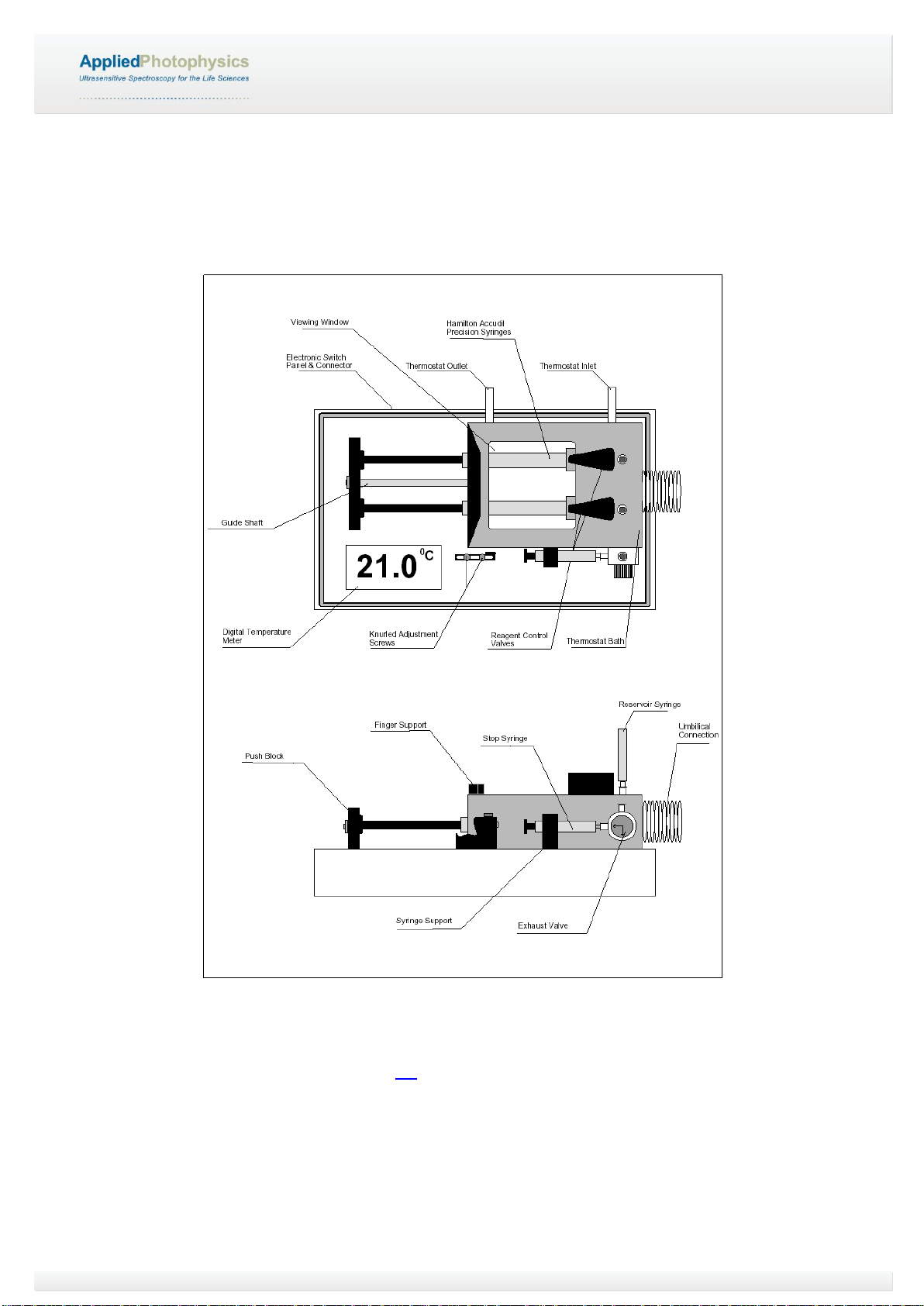

2 HARDWARE.........................................................................................................................................................10

2.1 Basic layout................................................................................................................................................10

2.2 The drive syringes......................................................................................................................................11

2.3 Reagent control valves...............................................................................................................................11

2.4 Waste control valve....................................................................................................................................12

2.5 The observation cell...................................................................................................................................13

2.6 Accessories................................................................................................................................................13

2.7 RX2000 specifications................................................................................................................................13

3 OPERATION.........................................................................................................................................................14

3.1 Instrument set-up .......................................................................................................................................14

3.1.1 Positioning the mixing unit and the DuoCell ............................................................................................. 14

3.1.2 Temperature control.................................................................................................................................. 14

3.1.3 Trigger signal.............................................................................................................................................. 14

3.2 Operation using the manual drive..............................................................................................................14

3.3 Operation using the pneumatic drive accessory........................................................................................15

3.4 Operation using the anaerobic accessory..................................................................................................16

3.4.1 Mounting the anaerobic accessory............................................................................................................ 16

3.4.2 Anaerobic operation .................................................................................................................................. 16

3.5 Operation using ratio mixing ......................................................................................................................17

3.6 Changing the drive syringe. .......................................................................................................................17

3.7 Selected test reactions...............................................................................................................................17

3.7.1 Formation of Iron (III) Thiocyante.............................................................................................................. 17

3.7.2 Fluorescence test reaction......................................................................................................................... 18

FIGURES

Figure 1.1: the RX2000.............................................................................................................................................9

Figure 2.1: schematic of the RX2000 .....................................................................................................................10

Figure 2.2: the valve positions in the Load (left) and Drive (right) positions...........................................................11

Figure 2.3: flow line closed (left) and open to waste reservoir (right).....................................................................12

Figure 2.4: flow line in its normal drive position (left) and normal empty position (right)........................................12