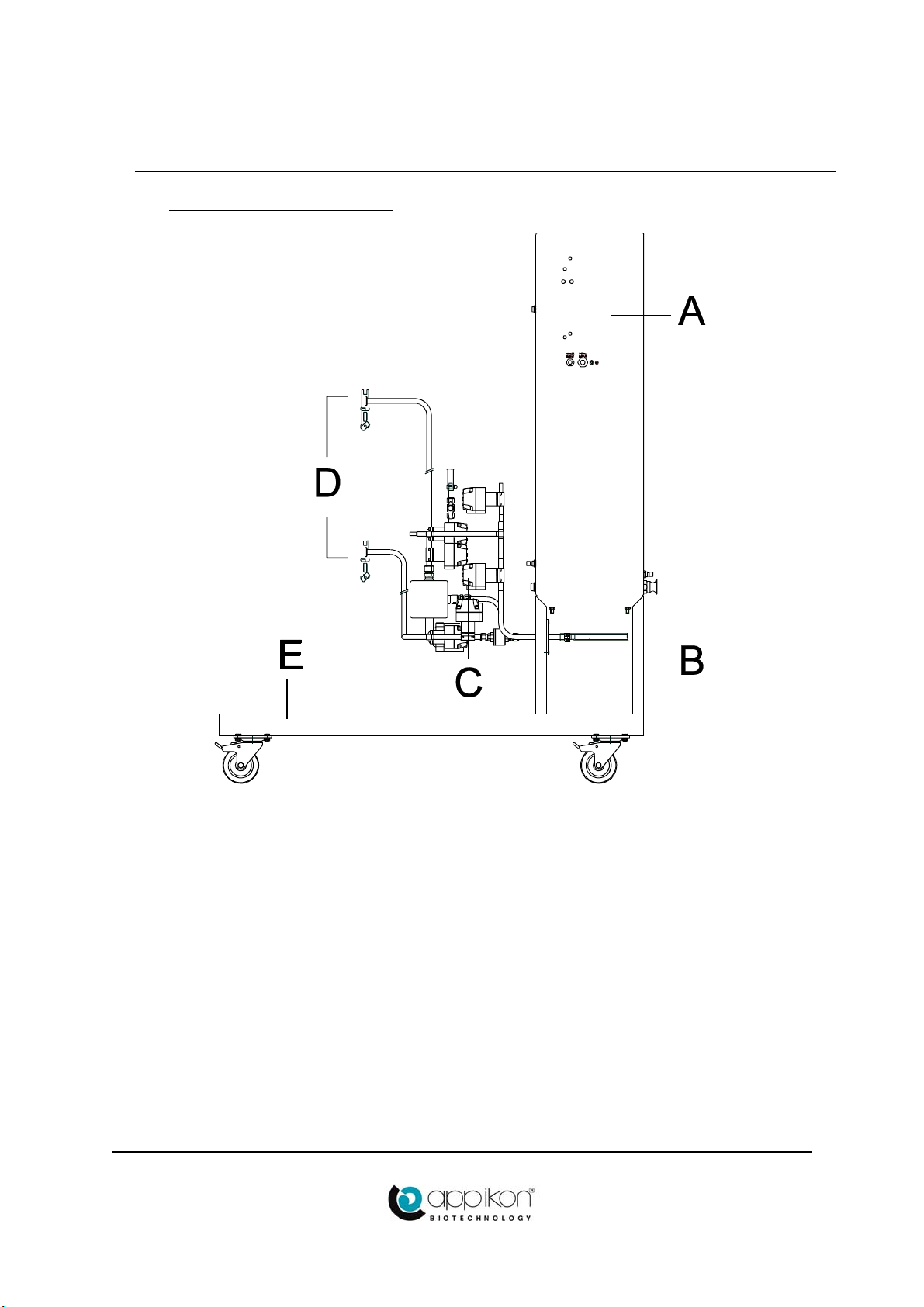

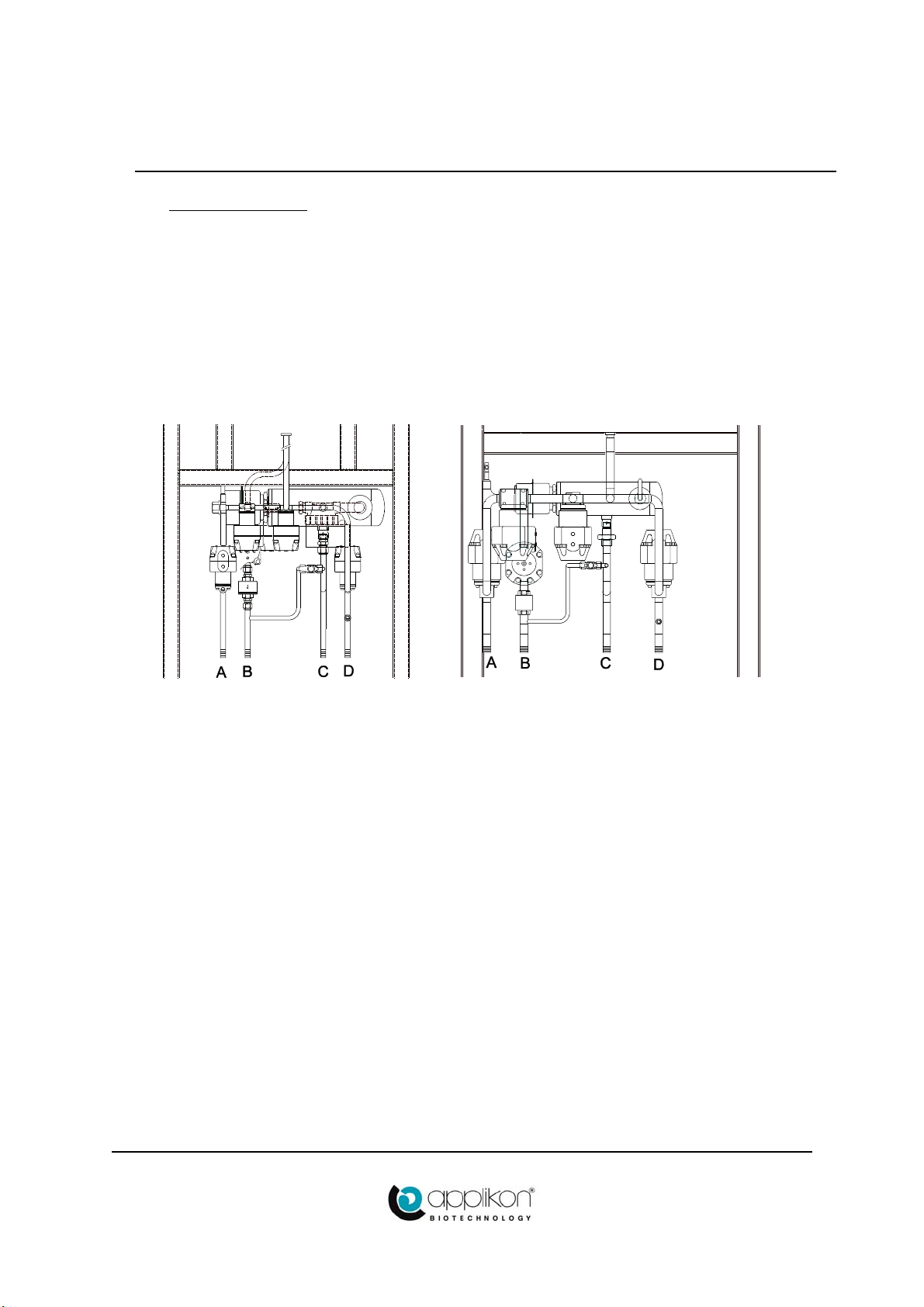

ADI 1075 Pilot System

December 2002

SAFETY CLASS I APPARATUS

This apparatus has been designed in accordance with

IEC1010-1 "Safety Requirements for Electrical Equipment

for Measurement, Control and Laboratory Use", and has

been supplied in a safe condition. The installation manual

contains information and warnings which have to be

followed by the user to ensure safe operation and to retain

the apparatus in safe condition.

Before switching the apparatus on, make sure that it is set

to the line voltage.

This apparatus is designed as an actuator console for bio-

process control; it must not be used for other purposes!

Caution:

Any interruption of the protective conductor inside or

outside the apparatus or disconnection of the protective

conductor terminal will make the apparatus dangerous.

Intentional interruption is prohibited.

Capacitors inside the apparatus may still be charged,

even if the apparatus has been disconnected from all

voltage sources.

Any adjustment, maintenance and repair of the opened

apparatus under voltage shall be avoided as far as

possible and, if inevitable, must only be carried out by

qualified personnel.

Make sure that only fuses with the required rated current

and of the specified type (IEC 127) are used for

replacement. The use of makeshift fuses and the short-

circuiting of fuse holders are prohibited.