OPERATOR MANUAL

CONTENTS ez-Control for In Situ sterilizable Bioreactors

Project 310420; PS70 IST (AU)

TABLE OF CONTENTS

1GENERAL SAFETY .................................................................................................................................4

1.1 Safety Symbols..................................................................................................................................4

1.2 Safety Warnings ................................................................................................................................5

2GENERAL .................................................................................................................................................7

2.1 Introduction.......................................................................................................................................7

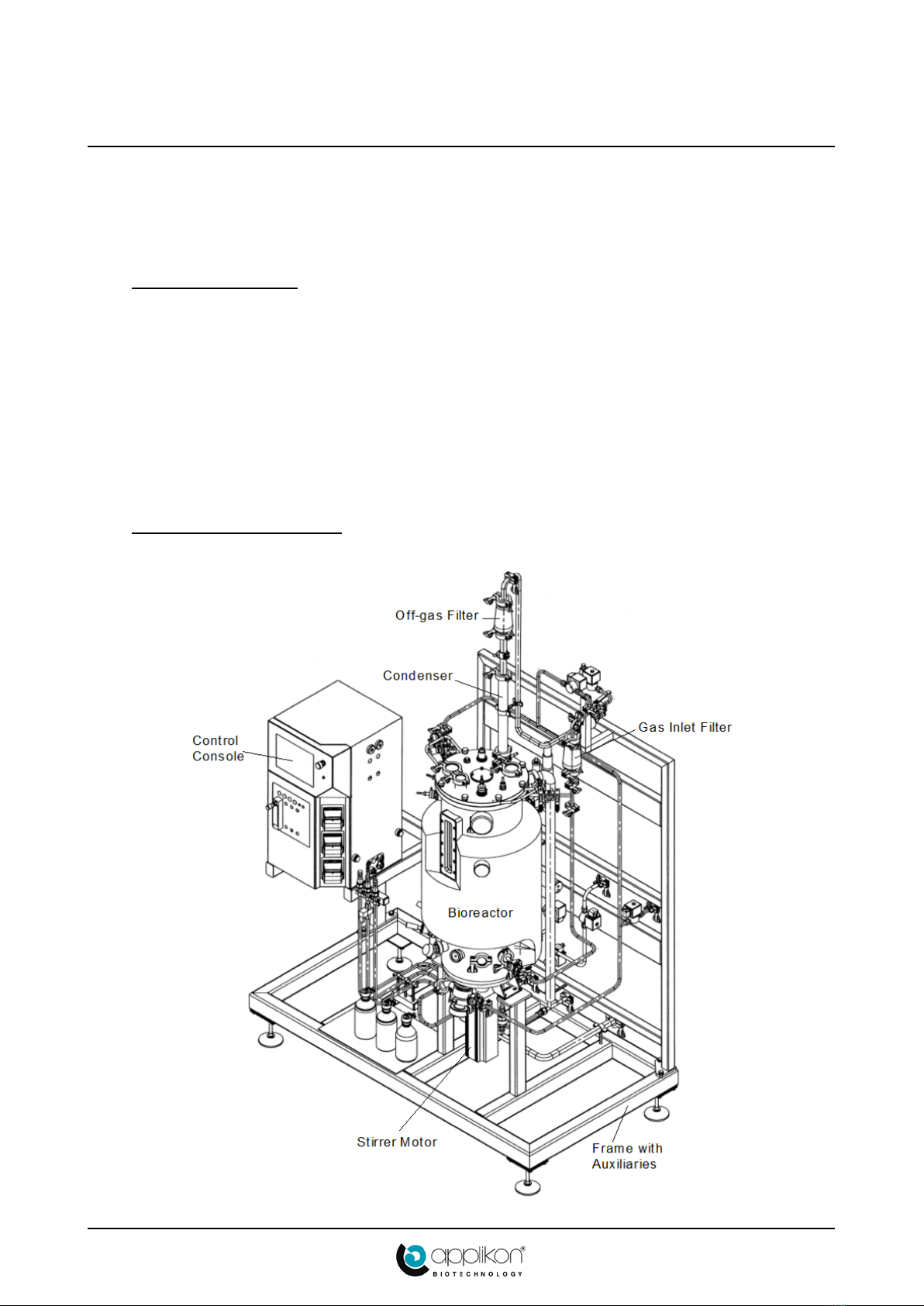

2.2 System Overview...............................................................................................................................7

2.3 Home Screen .....................................................................................................................................8

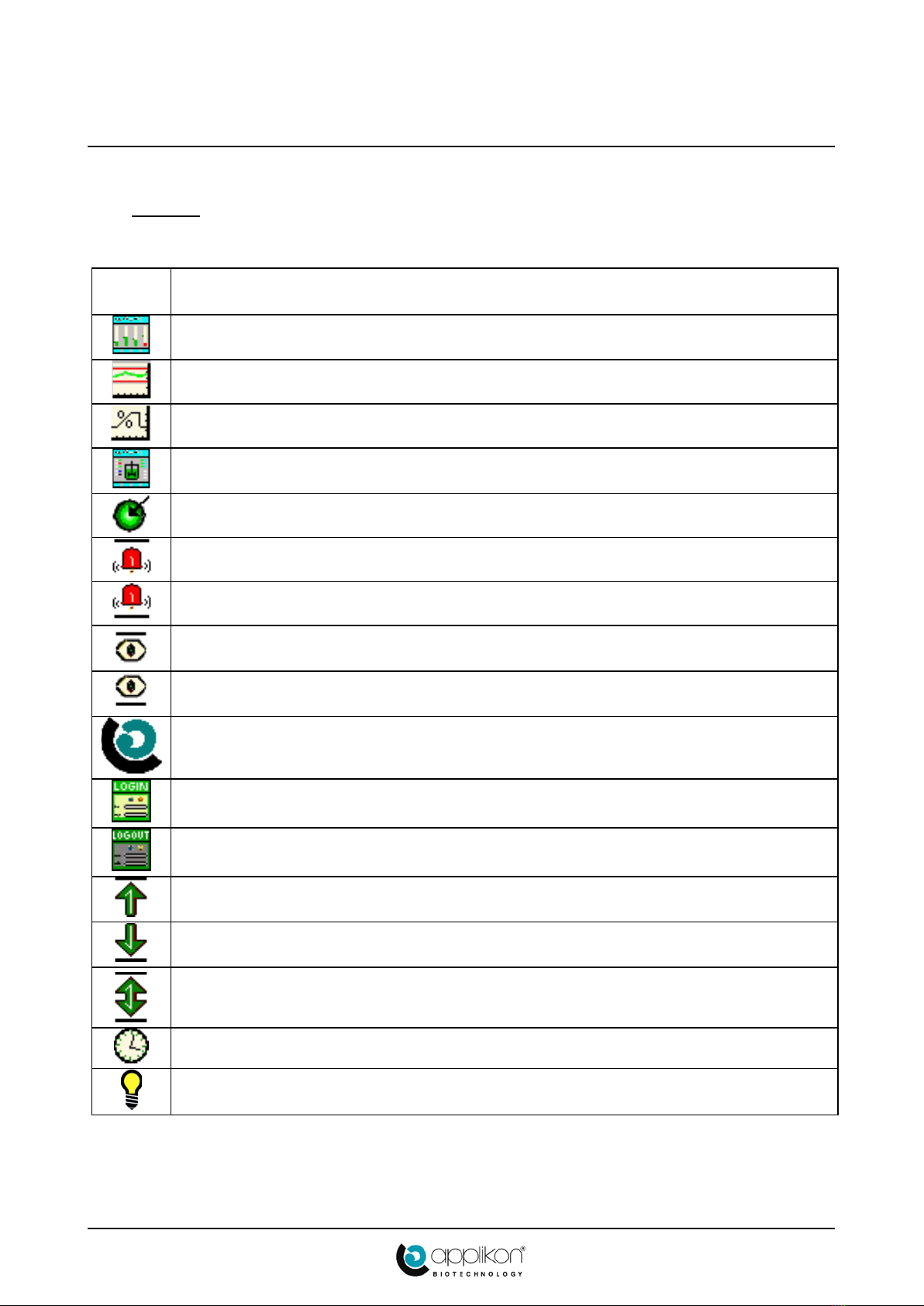

2.4 Icons................................................................................................................................................10

2.5 Keypad and Keyboard.....................................................................................................................11

2.6 Bar Graph and Trend View Screens................................................................................................12

2.7 Set-Points ........................................................................................................................................13

2.8 Configurable Outputs......................................................................................................................14

2.9 Related Manuals..............................................................................................................................14

3GENERAL PREPARATIONS.................................................................................................................15

3.1 General............................................................................................................................................15

3.2 Preparing for a New Process ...........................................................................................................15

3.2.1 Calibrate the pH Sensor.....................................................................................................15

3.2.2 Check the DO Sensor ........................................................................................................16

3.2.3 Other Sensors.....................................................................................................................16

3.2.4 Other Hardware .................................................................................................................16

3.2.5 Prepare Supplies................................................................................................................17

4PRESSURE TEST AND STERILIZATION............................................................................................18

4.1 Pressure Hold Test...........................................................................................................................18

4.2 Sterilization Routine........................................................................................................................18

4.3 Sterilization Settings........................................................................................................................26

4.4 Actuator Activity Matrix .................................................................................................................27

4.5 Execution of the Sterilization Routine.............................................................................................30

4.5.1 Start ...................................................................................................................................30

4.5.2 Initialization.......................................................................................................................30

4.5.3 Pressure Hold Test.............................................................................................................30

4.5.4 Phase 1...............................................................................................................................31

4.5.5 Preheating..........................................................................................................................31

4.5.6 Phase 2...............................................................................................................................31

4.5.7 Sterilization........................................................................................................................32

4.5.8 Natural Cooling .................................................................................................................32

4.5.9 Cooling 2...........................................................................................................................33

4.5.10 Cooling 3...........................................................................................................................33

4.5.11 End ....................................................................................................................................33

5CULTIVATION.......................................................................................................................................34

5.1 Preparing for Cultivation.................................................................................................................34

5.1.1 Prepare the Sensors............................................................................................................34

5.1.2Connect Addition Fluids....................................................................................................36

5.1.3 Activate the Control Loops................................................................................................37

5.2 Start Cultivation by adding Inoculum..............................................................................................38

5.3 Drain Valve.....................................................................................................................................39