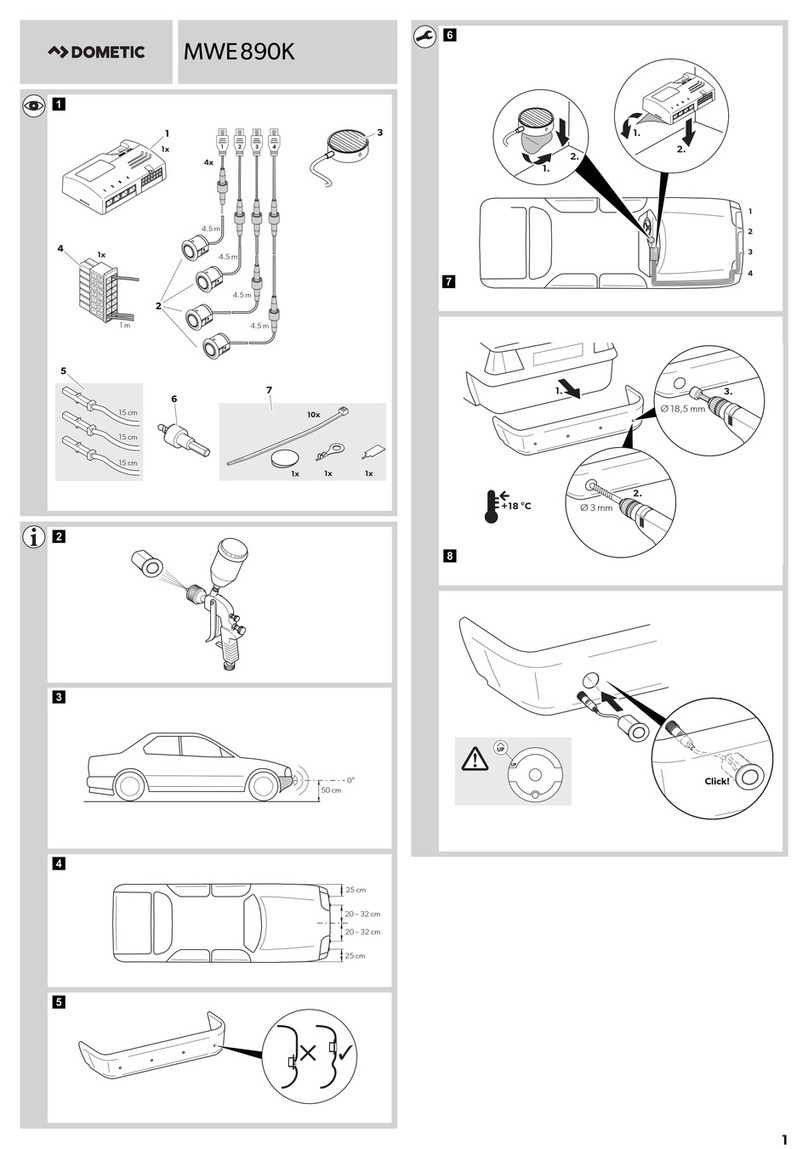

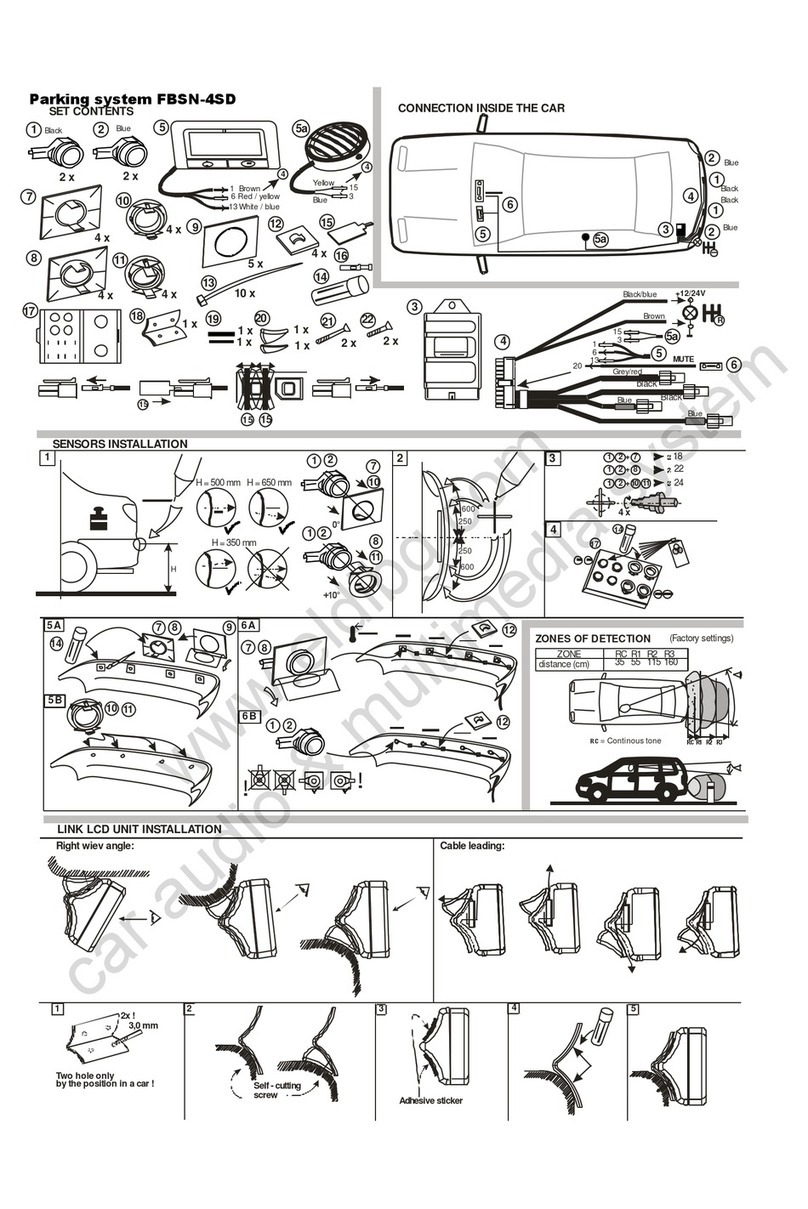

Functional description

Parking assistant

After switching the ignition ON, front sensors are activated. Detection of obstacles and their signaling is launched

immediately. After shifting into reverse gear you can hear control signal. Now, both front and rear sensors are activated.

Obstacles are signaled audibly by speaker inside the display unit and visually on LCD display. The faster beeping the closer

obstacle is. Consequently restricted zone segments appear on the display and displayed value means distance to the nearest

obstacle (front or rear).

There are 3 rear zones distinguished by the height of the warning tone. The front zone warning tone is also different from

the rear tones. Continuous tone means STOP zone (STOP icon appears on the display and obstacle distance disappear).

Range of separate zones can be adjusted to vehicle geometry (see chapter Parameters adjustment).

Volume of the speaker can be adjusted as well as the color of the display illumination (see chapter Parameters adjustment).

Vehicle speed can be displayed when there is no need to display parking situation (drive forward in speed > 15 km/h). To

do so, attach speed signal to the display unit and set parameter No. 14 value to 2. Now you can also activate speed limit

warning by pressing right pushbutton when driving just the limit speed. To deactivate this warning press the left pushbutton

during drive > 15 km/h (“SET 250 km/h” appears on the display).

To avoid undesirable signaling, utilize possibilities of front sensors deactivation:

•Automatic deactivation of the front sensors, if vehicle speed exceeds approximately 15km/h.

•Deactivation by Push-button on the display unit. It is possible to deactivate front and rear sensors

independently. Deactivation is valid only until next reverse gear or ignition ON.

•Time window - if signal of vehicle speed is not at disposal (see chapter Parameters adjustment – parameter No.13).

Front sensors are then active only after ignition ON or after reverse gear. Deactivation is done automatically after

certain time (time window) since ignition ON or reverse gear rejection (if there is no front obstacle indicated). It is

also possible to activate front sensors for next period of time window by pressing left pushbutton of Display unit.

Rem.: If you don´t use for deactivate front sensors default function „Time window“ and in the vehicle isn´t available analog

speed signal, we recommend using one of the external units „Universal CAN-Bus Interface“ or „GPS SPEED MODULE“

which aren´t included in the kit.

Rem1.:

Time window deactivation of front sensors is in play every time after switching ignition ON. When vehicle speed

signal is detected after vehicle start up, automatic deactivation of front sensors comes in play. If no speed signal is

connected (to the display unit or to the front ECU), time window deactivation remains in play.

Rem2.:

If no TPM option is active, nothing can be seen on the display after speed increases over and subsequently

decreases under 15 km/h and no obstacles are detected. But system remains active – picture and illumination appears

immediately after an obstacle detection or after reverse gear. Some short pushbutton pushes are also deactivated when no

picture is on the display.

Rem3.:

In case of wireless communication problems between ECUs (electronic disturbances, insufficient placement of

ECUs inside the vehicle etc.) antenna icon with exclamation sign turns on and warning ticks will sound (ticks can be quiet

by pressing any pushbutton). After communication recovery the icon turns off.

WARNINGS:

Even with electronic parking system installed it is necessary to watch surroundings of the vehicle carefully during

maneuvering. Small obstacles and items with low reflectance do not have to be captured by the system. Strong frost

may also decrease sensitivity of the parking system.

It is possible to switch off the speaker sound using this parking system. A crossed speaker icon appears on the

display in this case. Don’t rely on the speaker sound during maneuvering with this icon on the display!