TROUBLESHOOTING

DISPLAY IS BLANK

If Power LED is not illuminated at the equipment

control module check the following:

• Check circuit breaker and reset if necessary.

• Make sure power switch at heating & cooling

system is on.

• Make sure furnace door is closed securely.

HEATING SYSTEM DOES NOT RESPOND

(“HEATING” APPEARS ON SCREEN)

• Check for 24VAC at the equipment on the secondary

side of the transformer between power and

common. If voltage is not present, check the heating

equipment to find the cause of the problem.

• Check for 24VAC between the heat terminal (W)

and the transformer common. If 24VAC is present,

the thermostat is functional. Check the heating

equipment to find the cause of the problem.

• Check for loose or broken wires between the

thermostat and the heating equipment.

COOLING SYSTEM DOES NOT RESPOND

(“COOLING” APPEARS ON SCREEN)

• Check for 24VAC at the equipment on the secondary

side of the transformer between power and

common. If voltage is not present, check the cooling

equipment to find the cause of the problem

• Check for 24VAC between the cooling terminal (Y)

and the transformer common. If 24VAC is present,

the thermostat is functional. Check the cooling

system to find the cause of the problem.

• Check for loose or broken wires between the

thermostat and the cooling equipment.

FAN DOES NOT TURN ON IN A CALL FOR HEAT

• Check Installer Setting Fan Control In Heating /

Heat Pump Auxiliary Type, to make sure the fan

control is properly set to match the type of system.

HEAT PUMP ISSUES COOL AIR IN HEAT MODE,

OR WARM AIR IN COOL MODE

• Check wiring at the terminal block to confirm the

reversing valve is connected to the proper terminal.

O is active in cooling and B is active in heating.

HEAT/COOL BOTH ON AT SAME TIME

• Check Installer Setting Equipment Type, to make

sure it is set to match the installed heating/cooling

equipment.

• Check to make sure heating and cooling wires are

not shorted together.

HEATING EQUIPMENT IS RUNNING IN

COOL MODE

• Check Installer Setting Equipment Type, to make

sure it is set to match the installed heating/cooling

equipment.

“HEATING” IS NOT DISPLAYED

• Check Installer Setting Control Setup is set

correctly.

• Change the System Mode to Heat, and set

the temperature level above the current room

temperature.

“COOLING” IS NOT DISPLAYED

• Check Installer Setting Control Setup is set

correctly.

• Change the System Mode to Cool, and set

the temperature level below the current room

temperature.

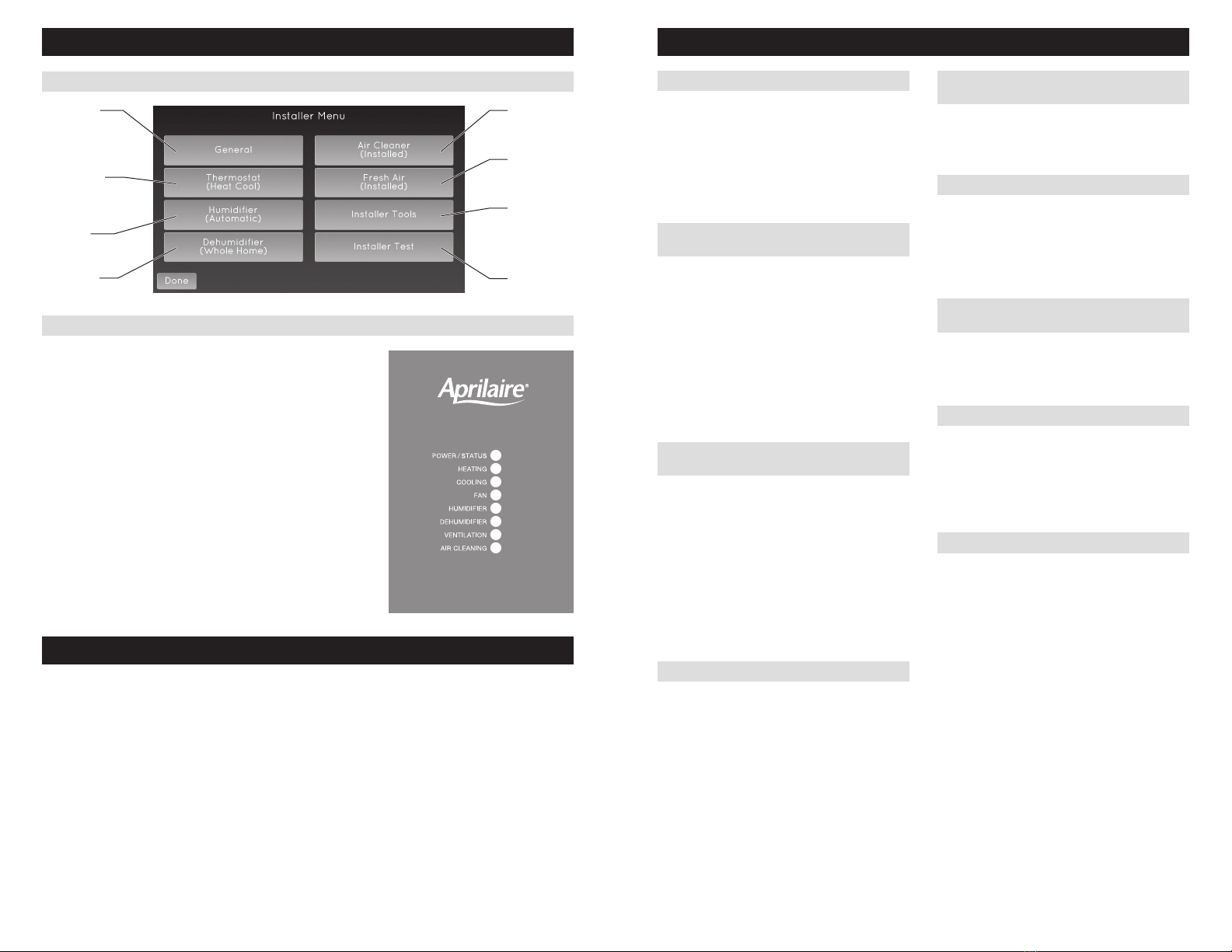

INSTALLER MENU

USB SETTINGS

FILE IMPORT, ETC

THERMOSTAT &

HVAC SYSTEM

CONFIGURATION

HUMIDIFIER

CONFIGURATION

DEHUMIDIFIER

CONFIGURATION

EQUIPMENT

OUTPUT TESTS

IMPORT/EXPORT

USB INSTALLER

SETTINGS FILES,

FACTORY RESET

VENTILATION

CONFIGURATION

AIR CLEANER

CONFIGURATION

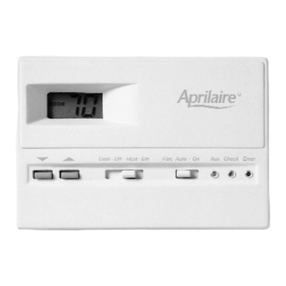

QUICK REFERENCE TO CONTROLS & DISPLAY

POWER/STATUS – On solid during normal operation. Flashes

when connection to the thermostat is lost and at power-up while

the thermostat connection is being established.

HEATING – On when heating outputs are active.

COOLING – On when cooling outputs are active.

FAN – On when fan output is active.

HUMIDIFIER – On when humidifier output is active.

DEHUMIDIFIER – On when dehumidifier output is active.

VENTILATION – On when ventilation output is active.

AIR CLEANING – On when air cleaner output is active.

EQUIPMENT CONTROL MODULE LEDs

THERMOSTAT FEATURES

• Remote access and control over Wi-Fi.

• Indoor air quality control.

– Humidification automatic or manual control.

– Dehumidification.

– Event-Based™air cleaning.

– Ventilation with temperature and humidity limits.

• Temperature control.

• Heat Blast®raises the room temperature 3°F to 5°F.

• One touch Away.

• Support for optional wireless outdoor temperature

sensor.

• Large touch screen with adjustable backlight.

• 7 day programmability.

• Displays room temperature, room humidity,

temperature setting, and optional outdoor temperature.

• Air filter, humidifier, dehumidifier, and HVAC service

reminders.

• Programmable fan control with fan circulation mode.

• Easy to use temperature control can override program

schedule at any time.

• Progressive recovery ensures proper temperature at

the start of a program event.

• Built in compressor protection prevents damage to

your equipment.

• System test mode.

English 1918 English