CP295MRS CP305MRS CP405MRS Technical reference - Rev. K 2

Advanced Printing Systems

1. TABLE OF CONTENTS

CP 295 MRS........................................................................................................................................................... 1

CP 305 MRS........................................................................................................................................................... 1

CP 405 MRS........................................................................................................................................................... 1

1. Table of contents ........................................................................................................................................ 2

2. General features.......................................................................................................................................... 3

3. Revision history.......................................................................................................................................... 4

4. General specifications ................................................................................................................................ 5

5. Printer Device Interconnection................................................................................................................... 6

5.1 Power supply connector ..................................................................................................................... 6

5.2 Serial communication connector ........................................................................................................ 6

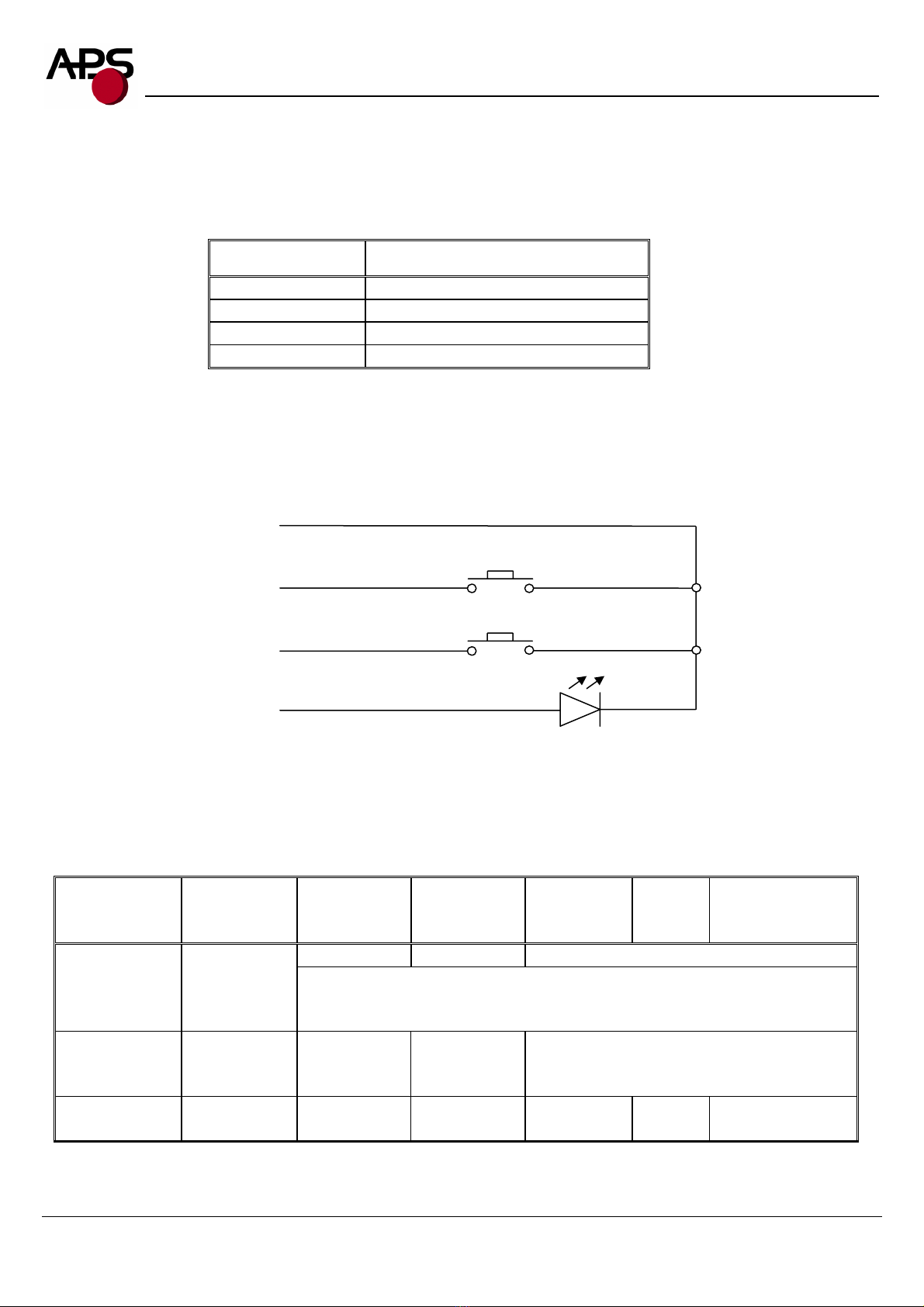

5.3 Switch/Led connector......................................................................................................................... 7

5.4 Parallel communication connector ..................................................................................................... 8

5.5 Sleep mode disable connector ............................................................................................................ 8

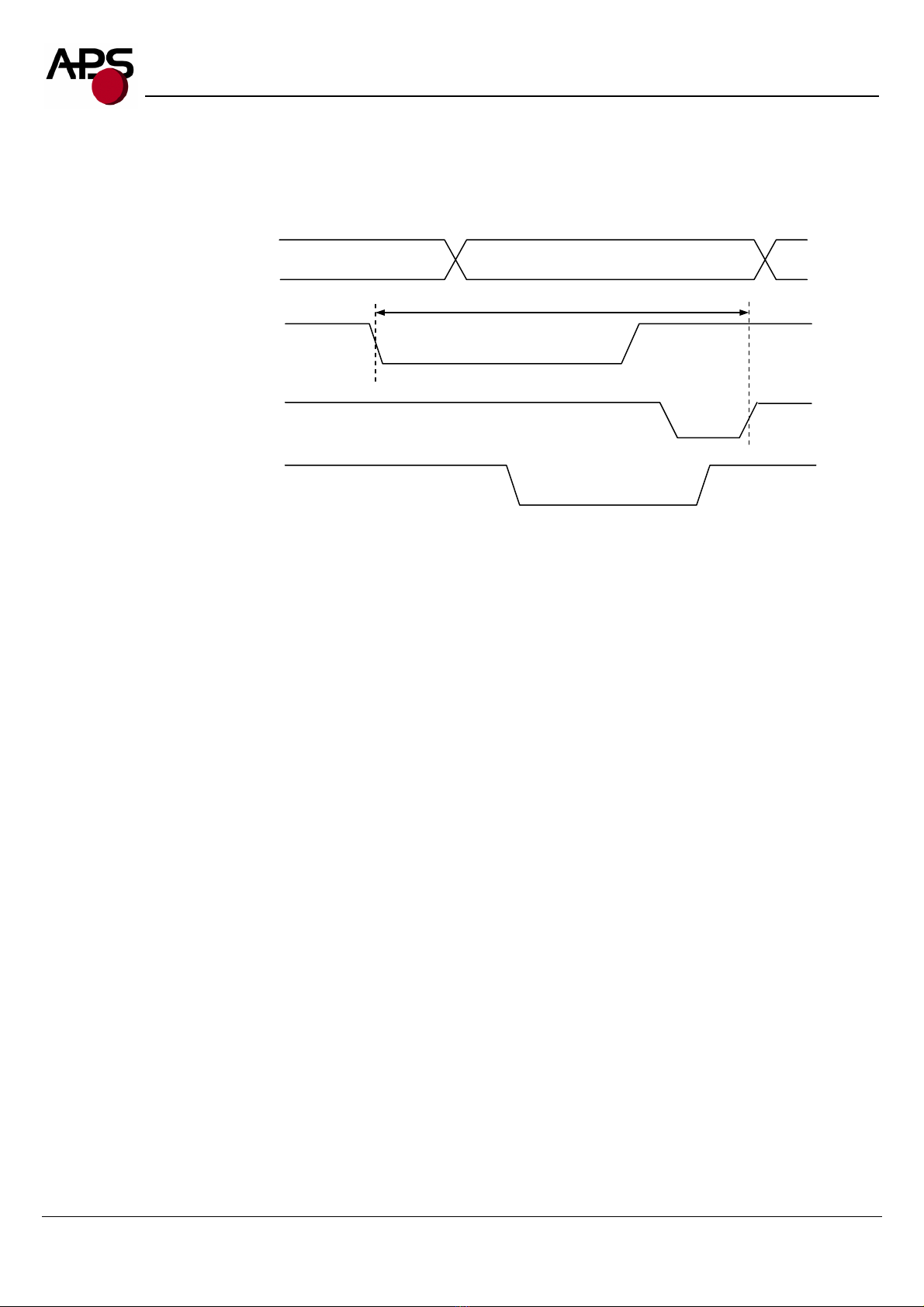

5.6 Timing for parallel communication.................................................................................................... 9

5.7 Serial / Parallel mode selection ........................................................................................................ 10

5.8 Near end of paper sensor .................................................................................................................. 11

6. Printer Device Operations ........................................................................................................................ 12

6.1 Self test Mode................................................................................................................................... 12

6.2 Paper loading.................................................................................................................................... 13

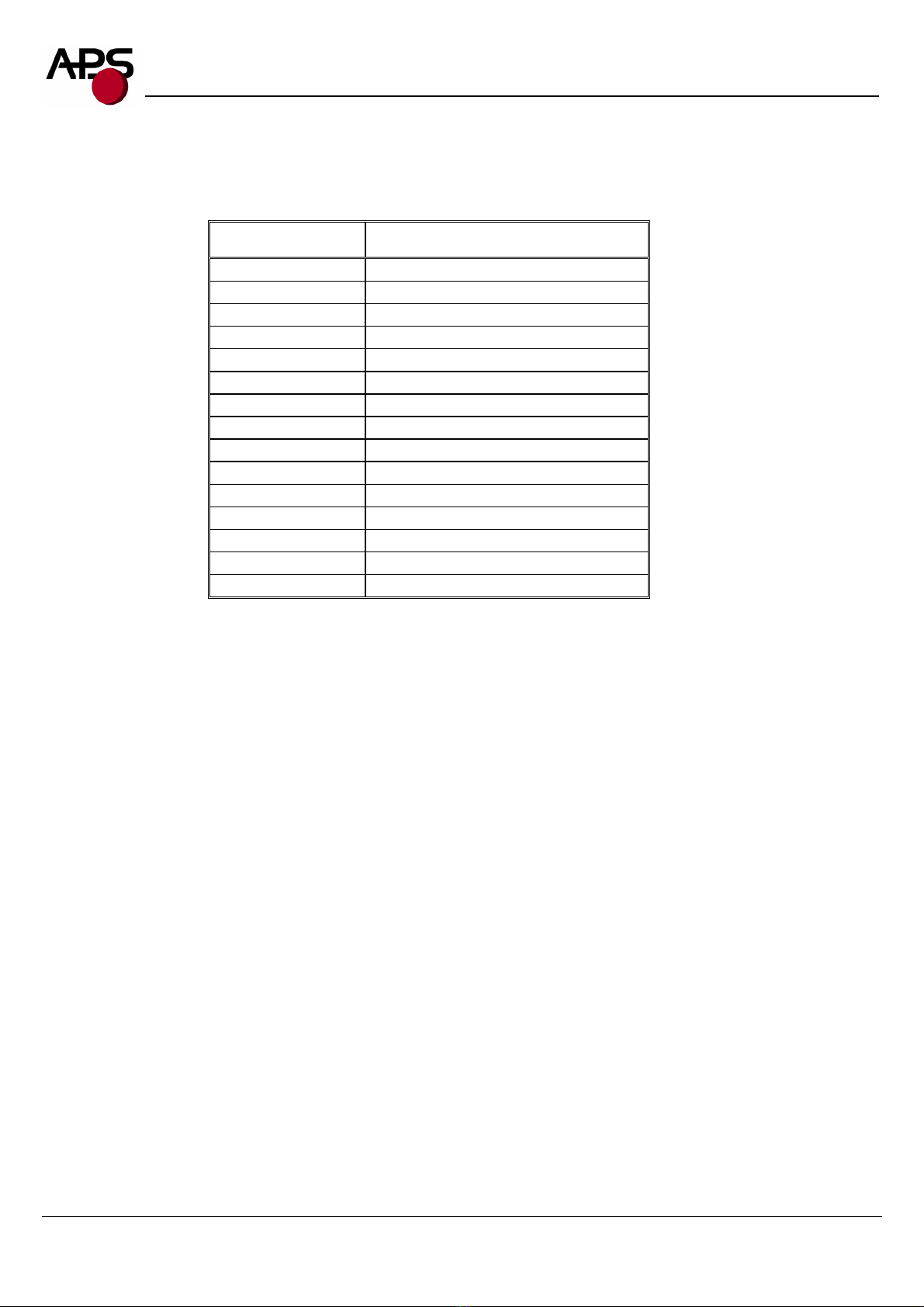

6.3 Text Printing Format ........................................................................................................................ 14

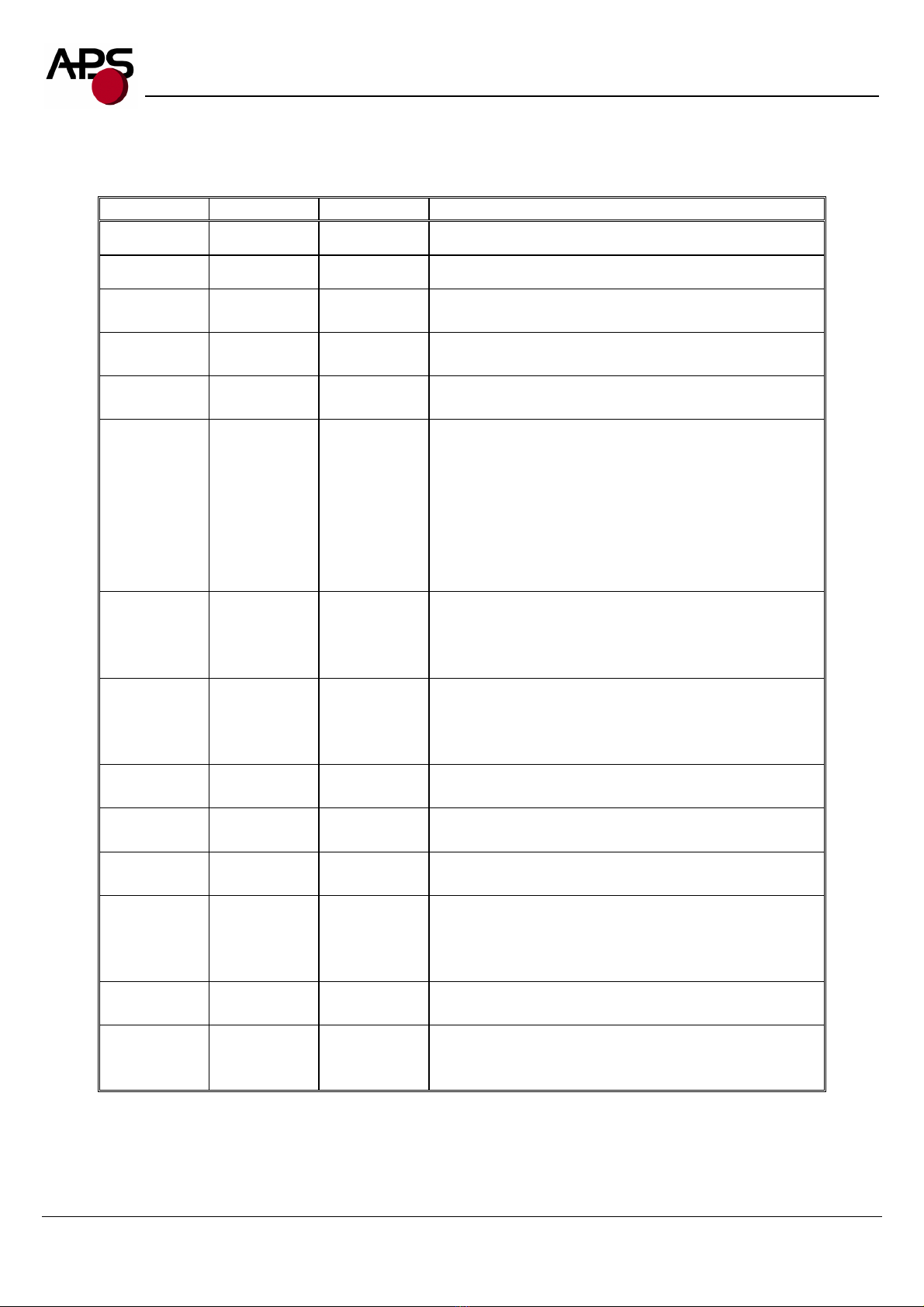

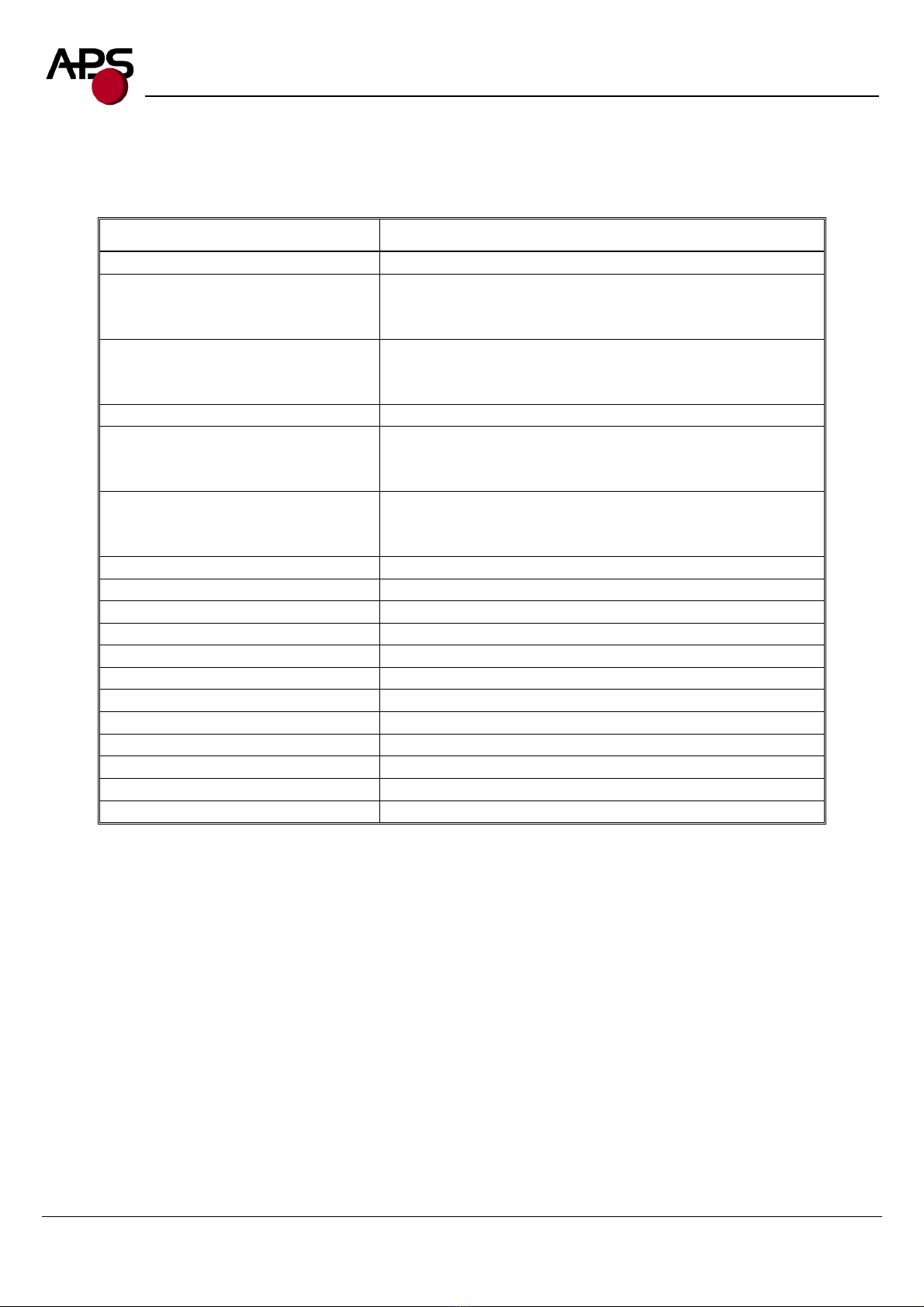

6.4 Operating Control codes................................................................................................................... 16

7. Ordering code ........................................................................................................................................... 38

http://www.aps-printers.com/

This manual provides complete information about APS CP295MRS, CP305MRS, CP405MRS printer.

A.P.S. reserves the right to make changes without notice to the product to improve reliability, function or design.

A.P.S. does not assume any liability arising out of the application or use of the product or circuit described herein.