Installation Manual

High Efficiency Half-Cell Module

1

www.aptossolar.com | info@aptossolar.com All Rights Reserved. DNA-120/144

Version: AS-IM-001

Introduction

This manual contains information about electrical and

mechanical installation of the solar panels: DNA-120 and

DNA-144 Series

Disclaimer of Liability

Installation techniques and methods of this product is

beyond Aptos Solar Technology’s control. AST doesnot

assume responsibility of loss or damage resulting from

improper installation, handling or use. AST disclaims liability

for damage, loss, expense arising out of, or in any way

connected with installation, use or maintenance by using this

manual.

Regulation Information

This certified product meets the UL61730 standard for

maximum system voltage of 1000V with maximum

overcurrent protection rating of 20A. The installer or system

integrator is assumed the responsibility to ensure compliance

with all local electrical codes which may be applicable.

Warnings & Safety

Solar panels generate electricity when exposed to light,

which can cause lethal shock and burn hazards.

Only authorized, qualified and trained installers should

handle these solar panels. Do not touch live terminals

with bare hands. Work only in dry weather with dry solar

panels and tools.

Do not make connections while under load. Do not

disconnect under load. Use insulated tools for electrical

connections. Do not step or stand on the solar panel.

Do not disassemble the solar panel or junction box.

Carry panel with two or more person. Do not carry by its

wires or junction box. Wear non-slip, suitable gloves

and protective clothing.

Do not install the solar panel where flammable vapors

or gases are present. Do not install in corrosive

environment.

Do not direct artificially concentrated sunlight on solar

panel.

Under normal conditions, a photovoltaic module is likely

to experience conditions that produce higher current

and/or voltage than reported at standard test conditions.

Accordingly, the values of Isc and Voc marked on this

PV module should be multiplied by a factor of 1.25

when determining component voltage ratings, conductor

current ratings, and size of controls (e.g., inverter)

connected to the PV output.

The module is considered to be in compliance with this

standard only when the module is either mounted in the

manner specified by the mounting instructions, or when

the mounting means has been evaluated with this PV

module to UL 2703. A module with exposed conductive

parts is considered to be in compliance with this

standard only when it is either electrically grounded in

accordance with the manufacturer’s instructions and the

requirements of the National Electrical Code,

ANSI/NFPA 70 (2014-2017), or when the bonding

means has been evaluated with this PV module to UL

2703.

Fire Rating

If mounted over a roof, the solar panel shall be mounted

over a fire-resistant roof covering rated for the

application. Refer to local authority for guidelines and

regulations for building fire protection and required

slope. The module fire performance rating is Type I.

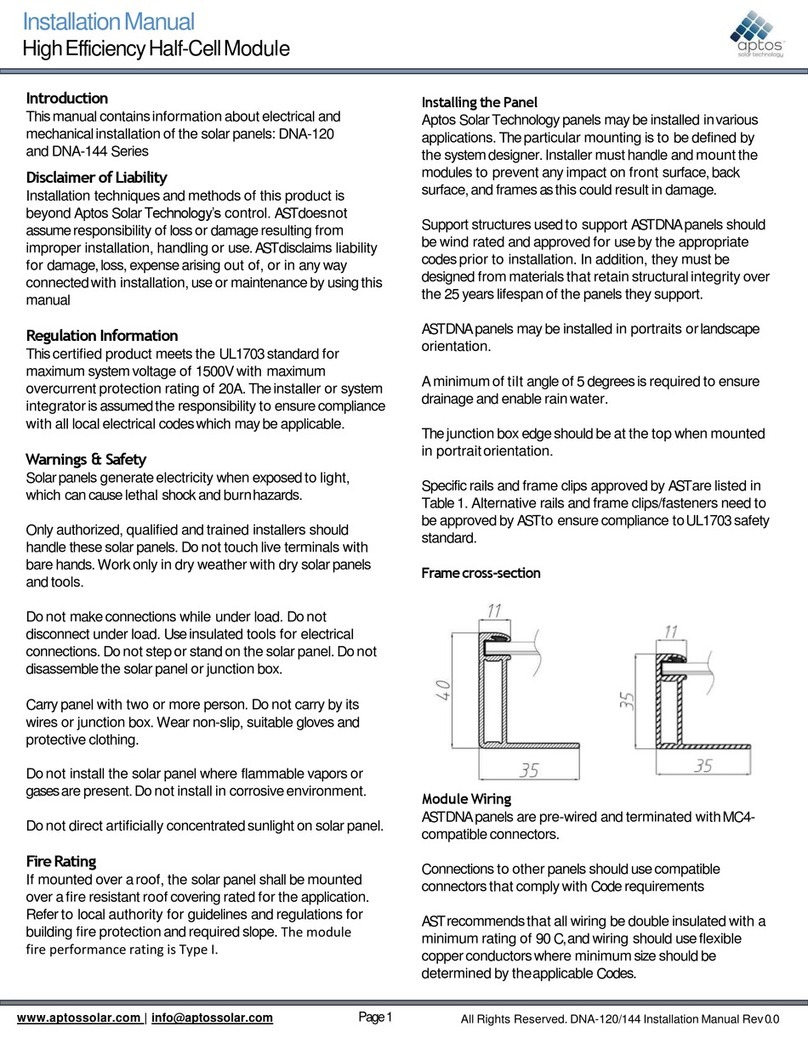

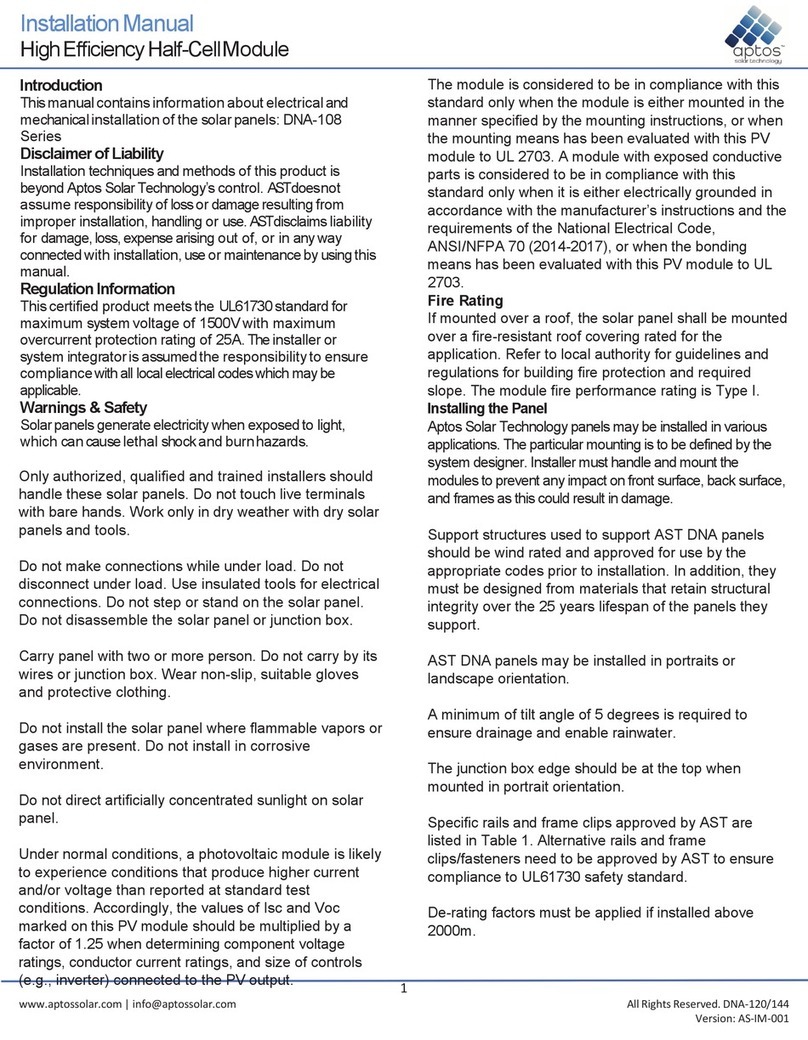

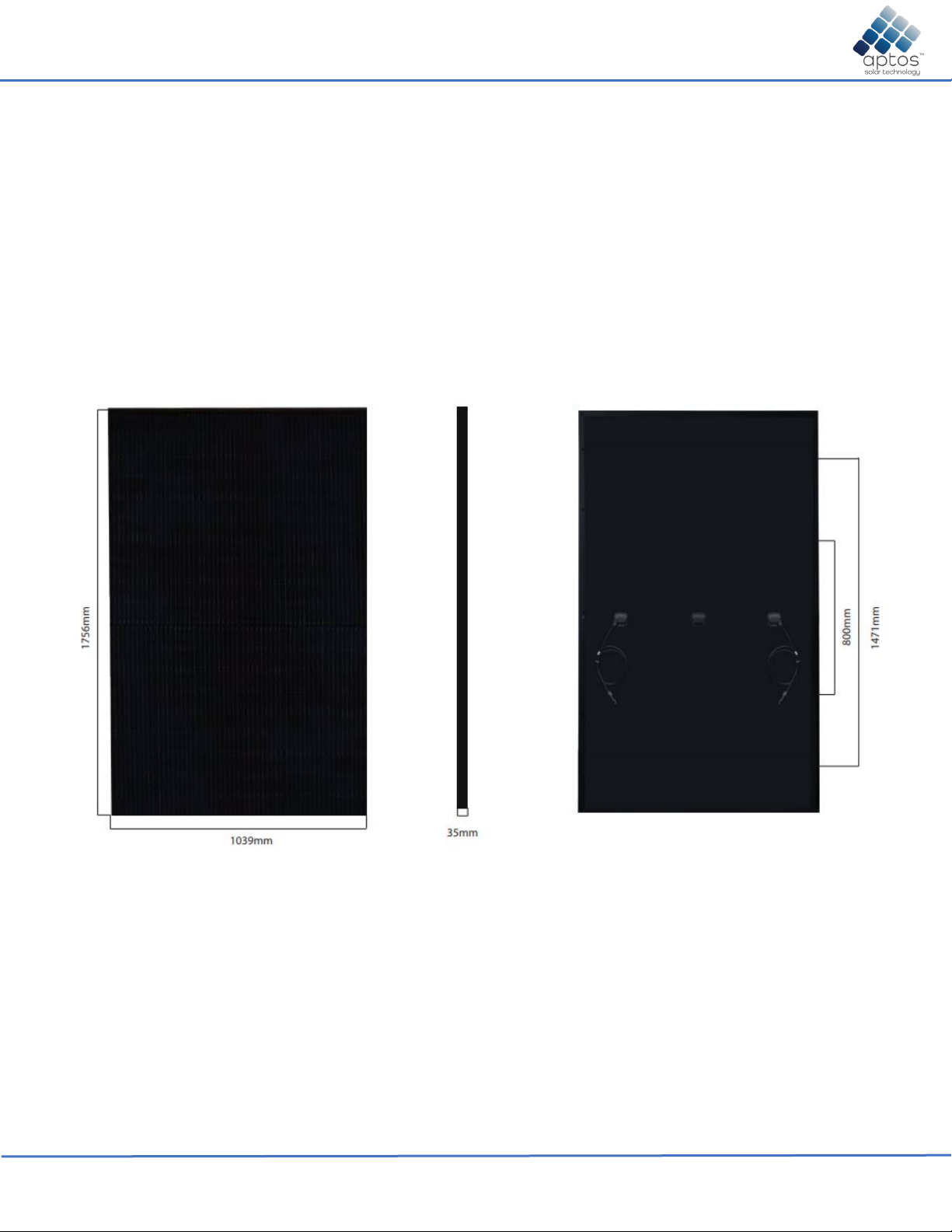

Installing the Panel

Aptos Solar Technology panels may be installed in various

applications. The particular mounting is to be defined by the

system designer. Installer must handle and mount the

modules to prevent any impact on front surface, back surface,

and frames as this could result in damage.

Support structures used to support AST DNA panels

should be wind rated and approved for use by the

appropriate codes prior to installation. In addition, they

must be designed from materials that retain structural

integrity over the 25 years lifespan of the panels they

support.

AST DNA panels may be installed in portraits or

landscape orientation.

A minimum of tilt angle of 5 degrees is required to

ensure drainage and enable rainwater.

The junction box edge should be at the top when

mounted in portrait orientation.

Specific rails and frame clips approved by AST are

listed in Table 1. Alternative rails and frame

clips/fasteners need to be approved by AST to ensure

compliance to UL61730 safety standard.

De-rating factors must be applied if installed above

2000m.