5

OvenStacking

The stacking kit will consist of 4 corner posts to be

insertedbetweenstackedunits.

Warning: When stacking, unit must have proper

stacking kit installed. This will prevent overheating

anddamagingofelectricalcomponents.

Warning: Donotstackmorethanthreeunitstallordo

notusemorethantwostackingkits.

Warning: Standoff on rear panel of unit is important

to allow proper inlet and exhaust fan airflow. Do not

cover inlet or exhaust fan openings as this could

damageelectricalcomponents.

1. Ensure bottom unit is mounted on secure

surface,withfeetinstalled.

2. Remove respective corner end caps and

screws. This will allow each of the stacking

spacer retaining fingers to slide into the

extrusions.

3. Removethefeetfromthetopunitasshown.

4. Secure each stacking spacer to the bottom of

the unit as shown by using the bolts and

washers provided. You should have four total

ofeach.

5. Once the stacking kit spacers are secure, place

top unit onto bottom unit. The stacking kit

spacers each have tapered guides to allow the

unittolockintoposition.

6. Refer to Figure 1. Install rear support bracket

and screws as shown. Each stacking kit

requires that two brackets be mounted on the

backside only. One bracket near the strain

reliefandoneattheoppositeend.

7. Refer to Cleaning Instructions for cleaning of

stackingspacersandcleaningbetweenunits.

FIGURE 1

Remove End

Caps & Screws

Before Installing Kit

Stacking Kit

#94000189

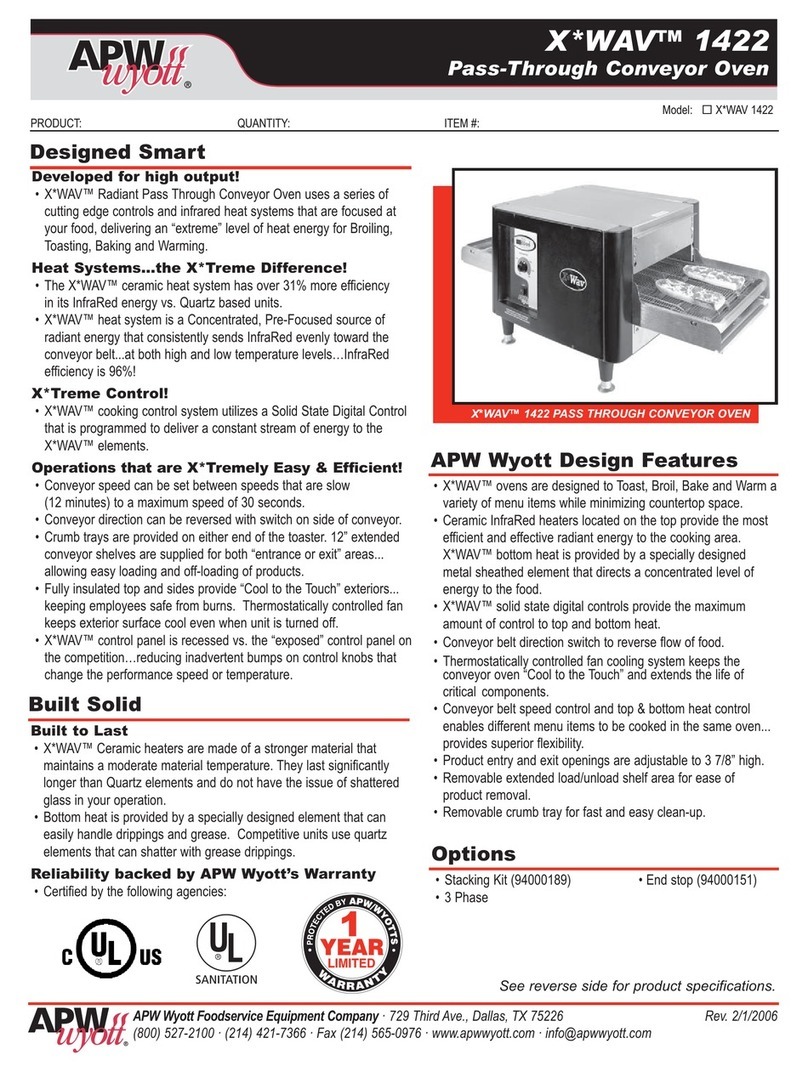

5. OPERATION

1. The controls that operate the unit, heaters and

conveyor are located on the front left side of the

unit.

2. The On/Off switch is used to turn the unit on or off.

Once the unit is turned on the conveyor will

automatically run. Warning: Ensure no hands,

toolsorpartsare located on the conveyor as injury

willresultwhenunitisturnedon.

3. The control areas (EGO’s) are used to control top

and bottom heat. The controls allow for separate

upper and lower zones. The settings for the upper

andlowerzonesare1-15;1beingthecoolestand

15beingthehottestsetting.

4. Note:BeforemovingtheOn/Offswitchtothe“On”

position,pleasereadthefollowingstatements:

1 28 seconds

2 29 seconds

3 32 seconds

4 43 seconds

5 52 seconds

6 1:01 minutes/seconds

7 1:16 minutes/seconds

8 1:29 minutes/seconds

9 1:45 minutes/seconds

10 2:07 minutes/seconds

11 2:44 minutes/seconds

12 3:35 minutes/seconds

13 5:26 minutes/seconds

14 9:35 minutes/seconds

15 OFF

SETTING EQUIVALENT COOK TIME