4

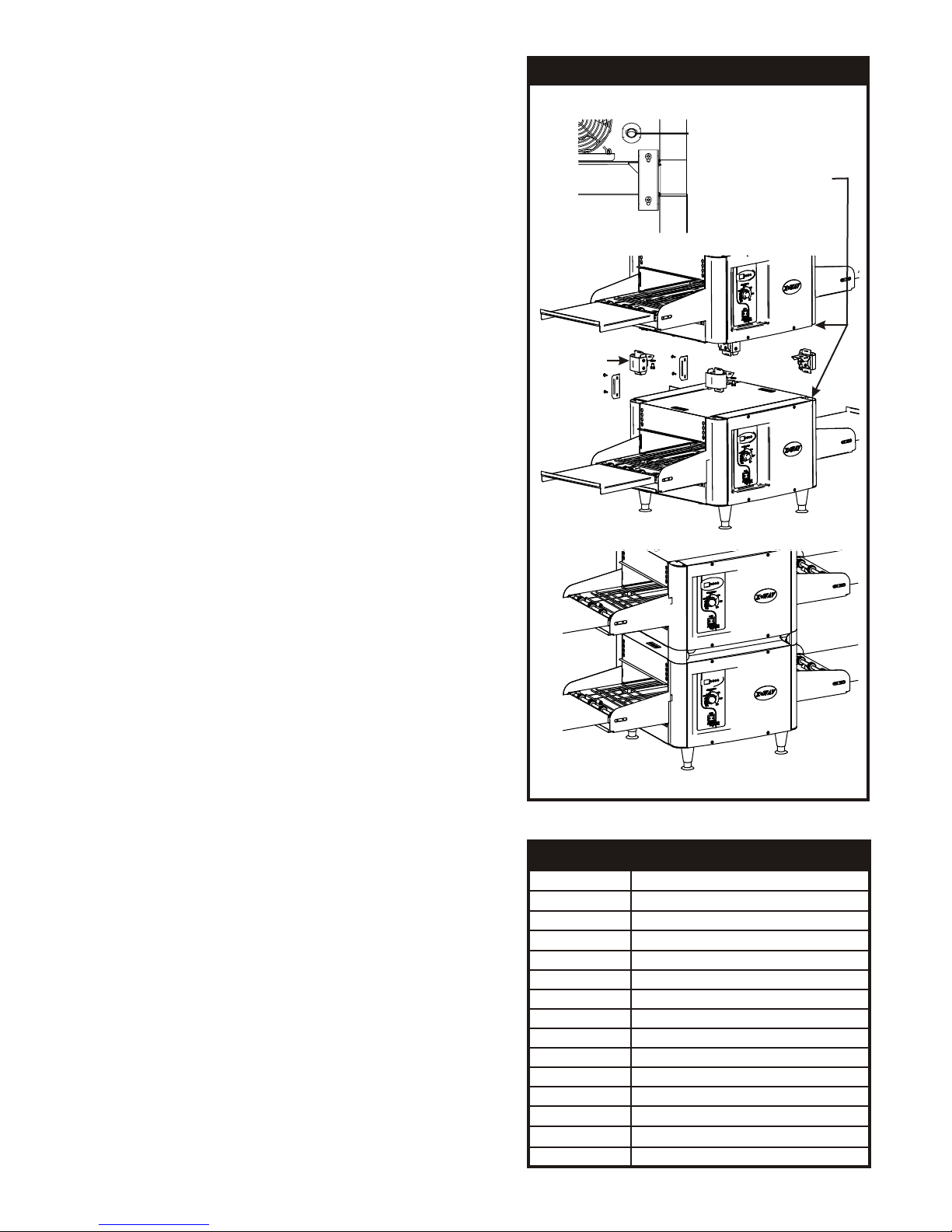

1. Remove all external packaging that is protecting top portion of unit.

2. Remove unit from shipping container while in the upright position. The unit can be lifted out of the

carton by grasping under the conveyor on each side of the appliance. Please remove the plastic

bag.

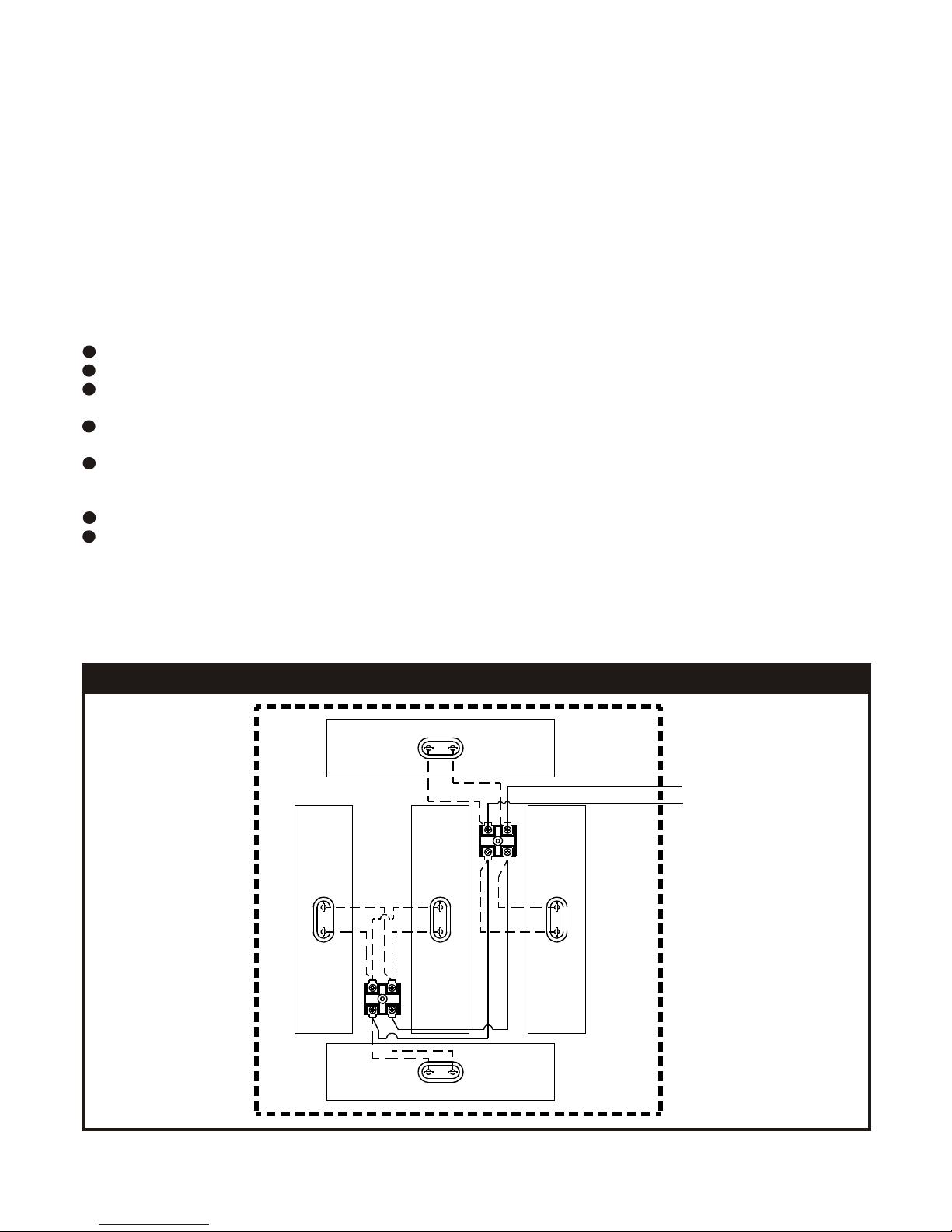

3. Remove all internal packaging to the unit. Important: Remove urethane supports located

inside the tunnel oven between the top heaters and the conveyor. Remove tape from

conveyor trays. Remove tape from extrusion corners. Remove tape from deflecting curtains

located just above entrance and exit of conveyor.

4. Visually inspect all external and internal portions of unit for damage. Important: Inspect the

top white ceramic elements located inside the oven tunnel after removal of urethane

supports. To inspect these white ceramic elements, use a small mirror held under each element to

detect cracks. Important: The Ceramic elements are fragile and will break under

stress. Do not twist, pull, push, or otherwise subject the white ceramic elements to

stress.

5. Wipe down the exterior of the unit using a damp cloth with warm water. Do not use abrasive pads or

cleaners as they will damage the stainless steel surface and high temperature plastic.

NOTE: DO NOT USE CLEANERS OF ANY KIND ON THE WHITE CERAMIC HEATERS.

6. Remove four feet from box and install into threaded nuts located at the four corners underside of the

left and right housings; Also remove conveyor extension tray(s). Conveyor extensions should be

hung off end of conveyor frame. As our standard, Model XWAV 1417A will only have one extension

intended for the exit end.

7. Place unit in operating location.

Note: Ambient Conditions - Make sure that the operating location is in an area where the

ambient temperature is held constant (minimum 70°F). Please avoid areas such as near

exhaust fans and air conditioning ducts.

Warning: Operating environment

Ensure that operation location is at a reasonable distance from combustible walls and materials

otherwise combustion or discoloration could occur. Stand-off/Air-divider located on rear panel is

important in maintaining proper division of inlet and exhaust air flow - If removed it could result in

improper functioning of unit and MAY cause personal injury and WILL void your warranty.

Caution: Operating environment

Place unit on a stable, level counter at a convenient height for use. Turn the adjustable feet so

that unit is level to countertop. The top of the unit is not intended for use a shelf. Materials

placed there are at risk for fire.

8. Before plugging unit into wall, make sure that the switch is in the off position.

9. Warning: Ensure no hands, tools or parts or other unintended items are located on the conveyor

as injury will result when unit is turned on.

10. Plug unit into grounded electrical outlet with correct voltage, and plug configuration.

Warning: Using any receptacle that is not designed to match the attached cord and plug MAY

cause personal injury and WILL void your warranty.

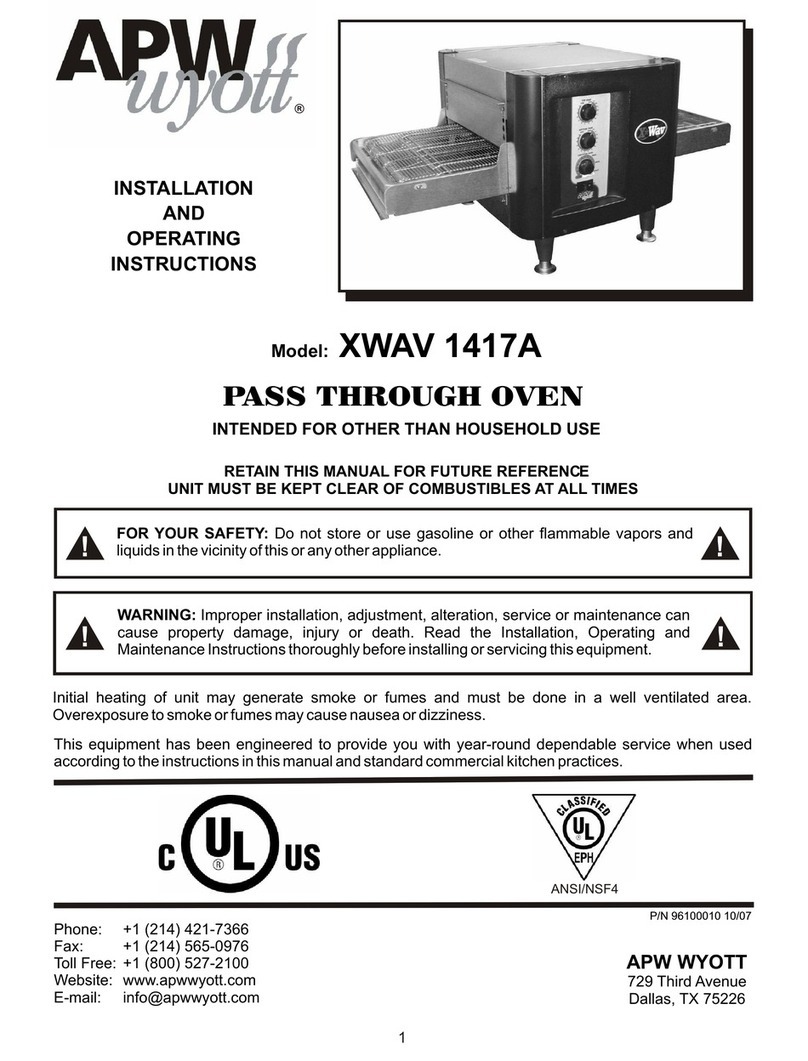

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual for the life of the equipment. For

Warranty Service and/or Parts, this information is required.

Model Number Serial Number Date Purchased