9

7. TROUBLESHOOTING

Always ask and check the following:

Not getting power:

Conveyor not working:

Food not cooking properly:

1. Is the unit connectedto a live power source of the propervoltage?

2. Check the rating label.Is the unit connected to the correct powersource?

3. Checkthecircuit breaker.

4. Is power switch ONand led displaying information?

5. If the above checksout, and you still have problems,call your local service agent.

1. Please refer to Notgetting power section.

2. Is the knob turned to correctsetting per desired speed?

3. Note: At slower settings the conveyor moves very slow and may appear stalled, which is not the

case.

4. If the above checksout, and you still have problems,call your local service agent.

1. Please refer to Notgetting power section.

2. Are the controller andspeed control adjusted to the desiredsetting?

3. Are the deflector curtains in the proper position?

4. If the above checksout, and you still have problems,call your local service agent.

6. CLEANING

Insure the appliance has been turned off and has had sufficient time for all surfaces to cool down before

cleaning. Use only mild soap and water to clean this appliance.Appliance cleaning should be performed daily.

DONOTUSEABRASIVEPADSORCLEANING SOLUTIONSONTHISAPPLIANCE.

Remove the crumb pans and wipe out debris with a damp rag andmild soap solution.

Remove the deflector panels located at the entrance and exit of the oven tunnel. Wipe down the area

under the deflector panels, and the deflector panels, with a damp rag and mild soap. Reinstall the

deflector panels by reversing the procedureused to remove them.

Using a damp rag with mild soapand water, wipe down the exteriorsurfaces of the appliance.

Using a damp rag with mild soap solution, wipe down all areas of the conveyor. DO NOTATTEMPTTO

CLEANTHE UPPER WHITE CERAMIC,OR LOWER METAL HEATERS.

NOTE:

Daily Cleaning

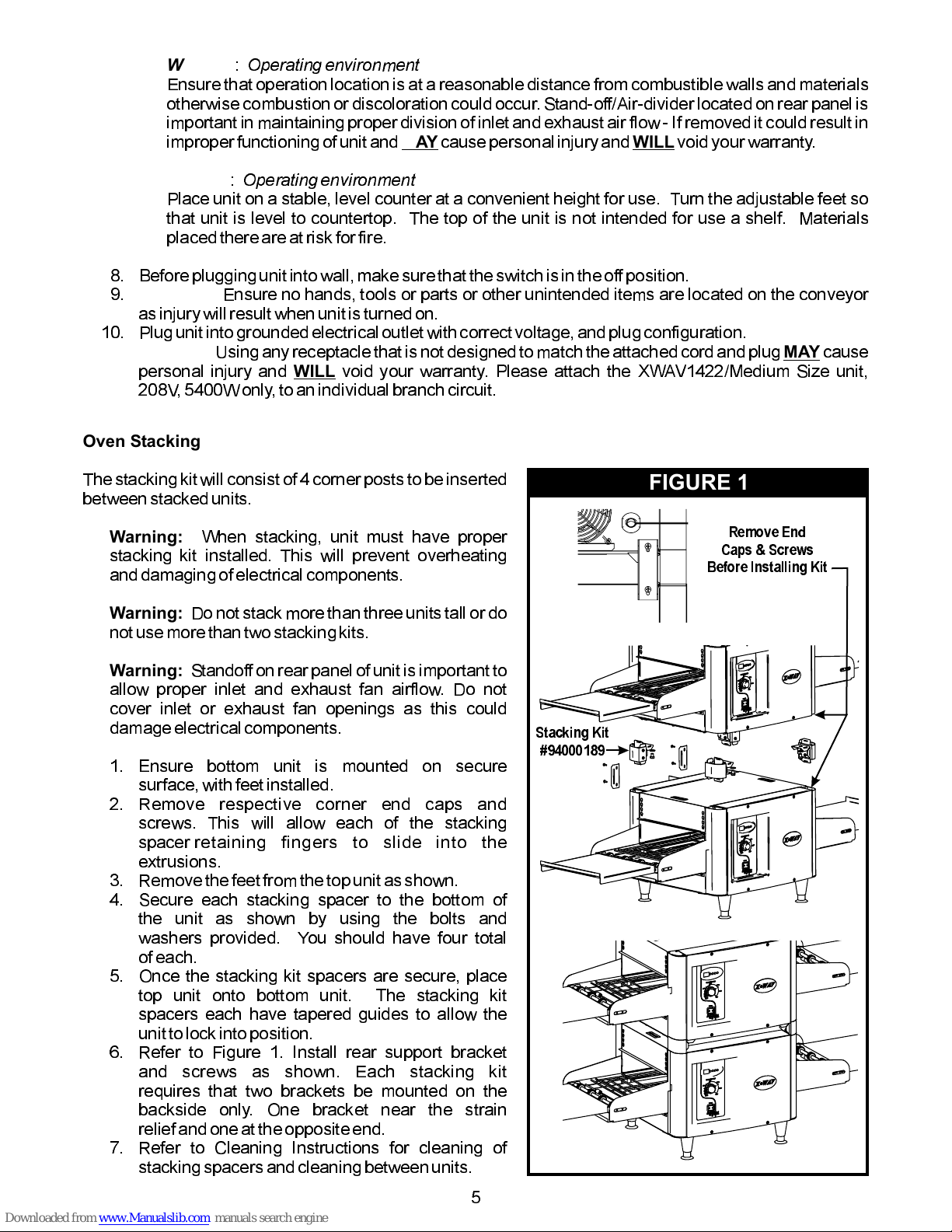

When units are in the stacked configuration, it is still necessary to clean between the units. Using a

damp rag with mild soap and water, wipe down the tops and undersides of all units. Ensure there are no

foreign objects between the units that could catch fire.

Using a damp rag with mild soap and water, wipe the surfaces of the stacking spacers on all four

corners.

Please follow the cleaning section for the daily preventative maintenance schedule.

DO NOT USE ABRASIVES OR CLEANING SOLUTIONS ON THIS APPLIANCE.

Routinely check before every operation that adequate distance is allowed between fans and

anything that would possibly allow foreign debris or substances to be taken in by inlet fan.

Clean fan guards on a daily basis to ensure proper inlet cooling to electrical components and

efficient hot air exhaust.

On a daily basis make sure side walls of tunnel oven remain clean to assist in maintaining even

cooking around product. Be careful not to bump or hit the upper ceramic heaters when wiping

down.

Ensure belt is properly tensioned as to prevent slippage or binding, which causes strain on motor.

DO NOTATTEMPTTO MAINTENANCE, SERVICE OR CLEAN THE UPPERCERAMICAND LOWER

METALHEATERS.

8. PREVENTATIVE MAINTENANCE SCHEDULE