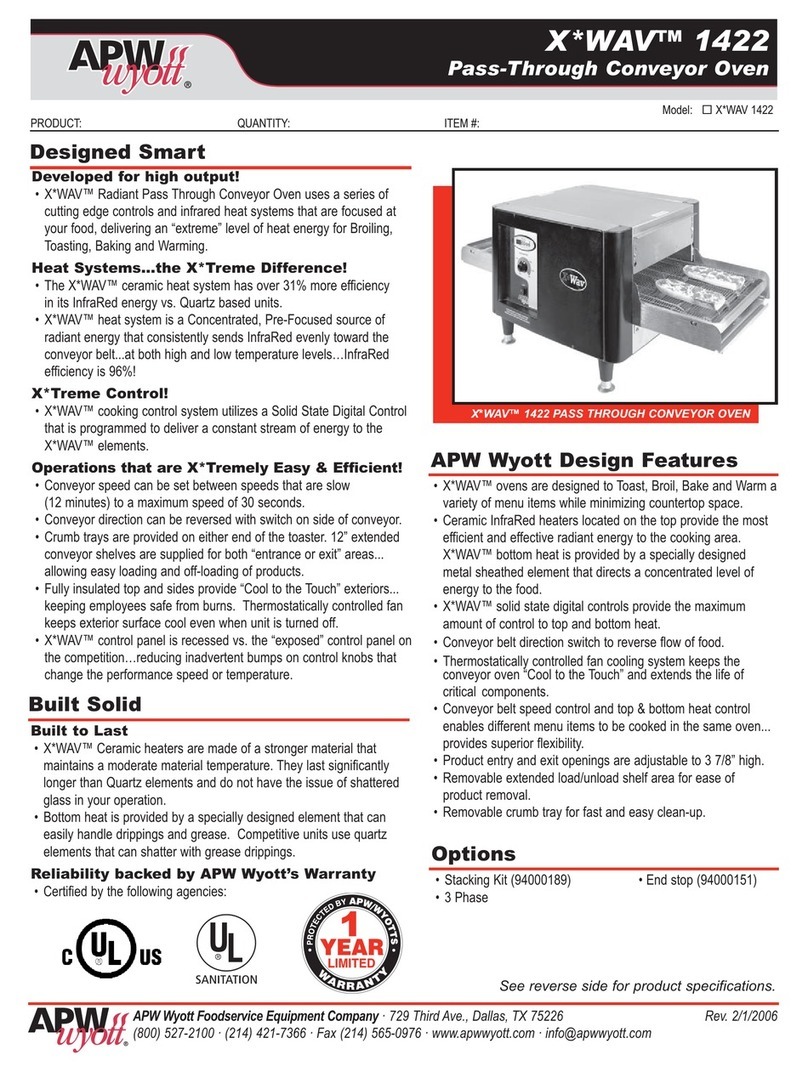

Warning: Operating environment

Ensure that operation location is at a reasonable distance from combustible walls and materials

otherwise combustion or discoloration could occur. Stand-off/Air-divider located on rear panel is

important in maintaining proper division of inlet and exhaust air flow - If removed it could result in

improper functioninq of unit and MAY cause personal injury and WILL void your warranty.

Caution. Operating environment

Place unit on a stable, level counter at a convenient height for use. Turn the adjustable feet so

that unit is level to countertop. The top of the unit is not intended for use a shelf. Materials

placed there are at risk for fire.

8. Before plugging unit into wall, make sure that the switch is in the off position.

9. Warning: Ensure no hands, tools or parts or other unintended items are located on the conveyor

as injury will result when unit is turned on.

10. Plug unit into grounded electrical outlet with correct voltage, and plug configuration.

Warning: Using any receptacle that is not designed to match the attached cord and plug MAY cause

personal injury and WILL void your warranty. Please attach the XWAV1422/Medium Size unit,

208V, 5400Wonly, to an individual branch circuit.

Oven Stacking

The stacking kit will consist of 4 corner posts to be inserted

between stacked units.

Warning: When stacking, unit must have proper

stacking kit installed. This will prevent overheating

and damaging of electrical components.

Warning: Do not stack more than three units tall or do

not use more than two stacking kits.

Warning: Standoff on rear panel of unit is important to

allow proper inlet and exhaust fan airflow. Do not

cover inlet or exhaust fan openings as this could

damage electrical components.

1. Ensure bottom unit is mounted on secure

surface, with feet installed.

2. Remove respective corner end caps and

screws. This will allow each of the stacking

spacer retaining fingers to slide into the

extrusions.

3. Remove the feet from the top unit as shown.

4. Secure each stacking spacer to the bottom of

the unit as shown by using the bolts and

washers provided. You should have four total

of each.

5. Once the stacking kit spacers are secure, place

top unit onto bottom unit. The stacking kit

spacers each have tapered guides to allow the

unit to lock into position.

6. Refer to Figure 1. Install rear support bracket

and screws as shown. Each stacking kit

requires that two brackets be mounted on the

backside only. One bracket near the strain

relief and one at the opposite end.

7. Refer to Cleaning Instructions for cleaning of

stacking spacers and cleaning between units.