INSTALLATION

1. Examine carton for damage

a. Apparent damage or loss must be noted on the freight bill at the time of delivery.

must sign

b. Concealed damage or loss if not apparent until after the toaster is removed from

carton, Be sure to save all contents and packaging material.

2. VerifyParts

The freight carrier has assumed responsibility for its safe transit and delivery. If equipment is

received damaged,either apparent or concealed, a claim must be madewith delivering carrier.

The carrier representative (Driver) the freight bill. If this is not done, the

carriermay refuse theclaim.The carrier cansupply the necessaryforms.

a request for inspection must be made to the carrier within 15 days. The carrier

shouldarrange an inspection.

After removingunit from the shipping carton, unwrapping loose parts and remove any packing tape,

plasticwrap and nylontie-down. Verifythe following parts:

Item Packaging Qty

NOTE:

3. AssembleLegs

Legs In plastic bag 4

Feeder/Bun Chute Wrapped, loose in top of carton 1

Conveyor In individual carton 1

Instruction Manual Loose in carton 1

Teflon Sheet Kit (optional) Loose in carton Optional

PRIORTO INITIALSTART-UP,ALLREMOVABLE PARTSAND THE GRILLSURFACE SHOULD

BE CLEANED WITH WARM SOAPY WATER TO REMOVE MANUFACTURING OILS,THEN RINSED

AND DRIED THOROUGHLY. Apply oil (vegetable oil) to the conveyor chain after washing. (Bun oil can be

used if it contains no animal fats, salts or dairyproducts).

Lay the toaster on its back and install the four adjustable legs into the threaded holes on the bottom

of the toaster sides. Hand tighten the legs by gripping the black shank and turning until it is seated

firmly against the bottom of the toaster. Set the toaster upright on a flat surface. Unscrewing the

lower, chrome insert of each leg levels the unit. Flats are provided on two sides of the insert to allow

use of a wrench. Preciseleveling is not required for properoperation.

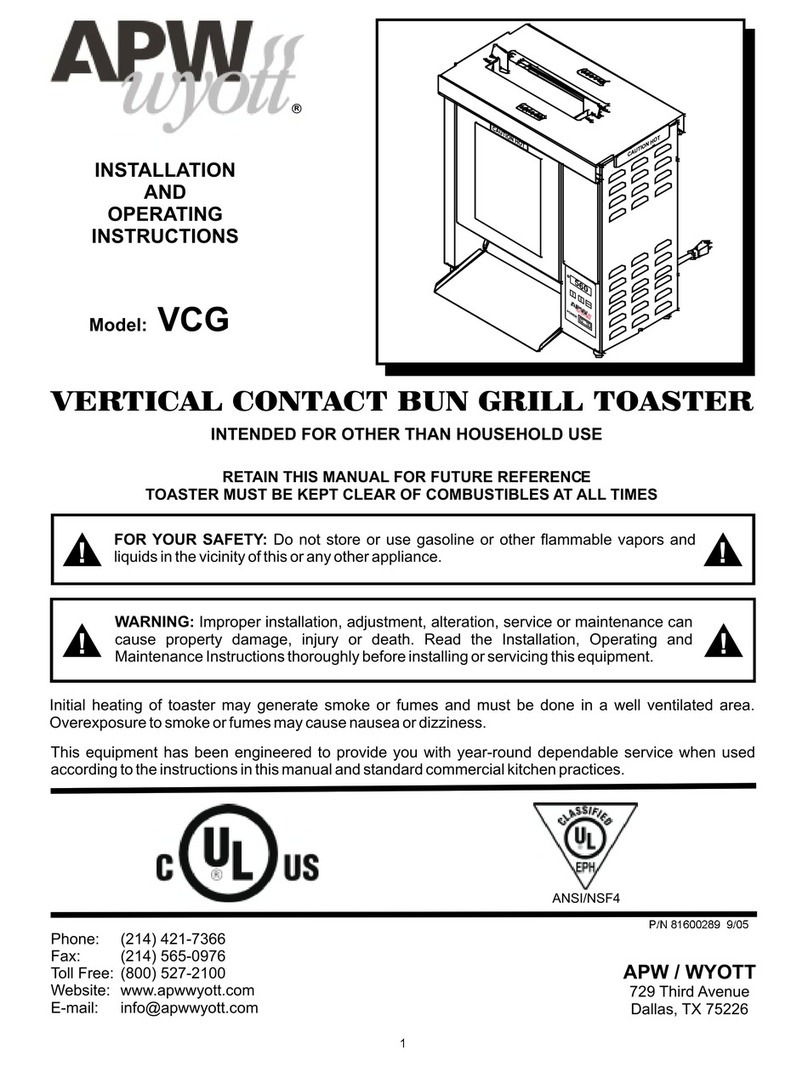

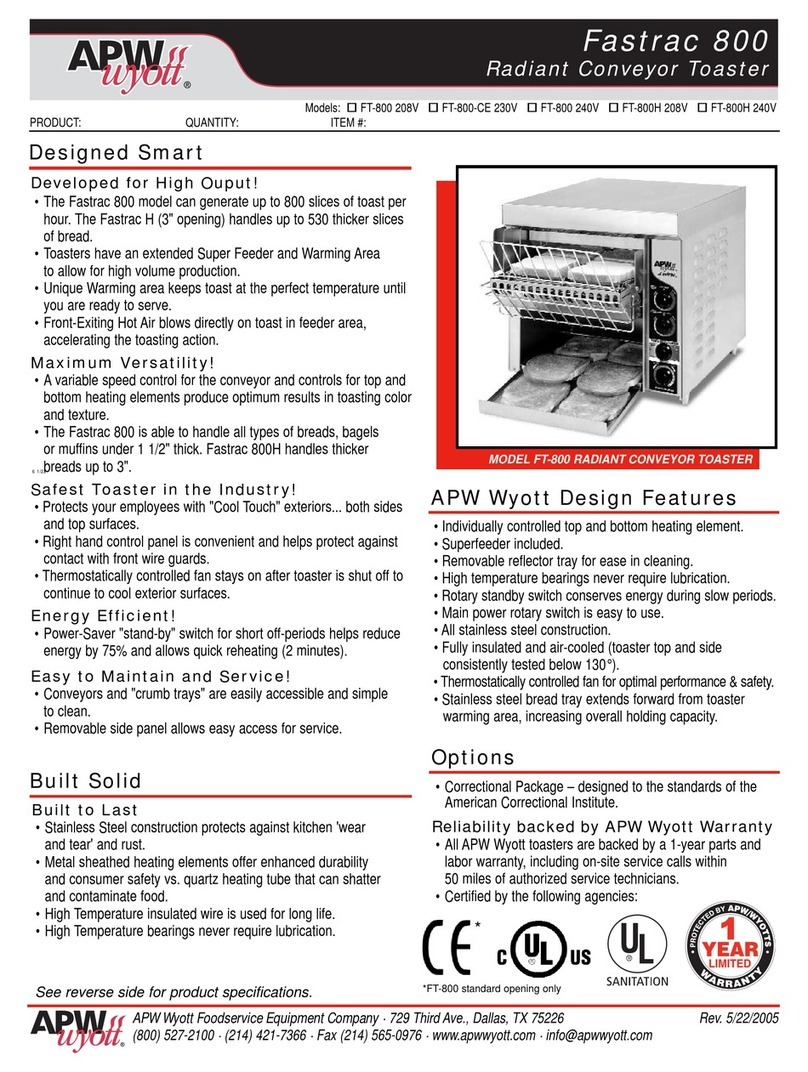

FIGURE 1. M2000 ASSEMBLY DRAWING

4. ConveyorInstallation

Remove the front panel by lifting it

straight up. (See Figure 1) Lift

conveyor assembly by using U

shaped handles on each conveyor

side bracket. Lower the conveyor

into the two conveyor hanger

brackets above the grill plate on

each side, so the four spacers on

the sides of the conveyor rest on

the bottom flange and the bottom

spacers are against the adjustment

screws. The conveyor hanger

brackets are factory adjusted.

However, before reinstalling the

front panels apply power to the unit

and run the conveyor to insure

proper gear engagement. If gears

are not properly engaged, adjust

the conveyor by loosening the jam

nuts on the conveyor hanger

brackets and adjusting the screw

(see Figure 2) to set the conveyor to

3

Bottom

Front

Panel

Top Front Panel

Feeder

Conveyor

Hanger

Main Power

Switch

Conveyor

Assembly