R Series Manual –R150 to R2500

Terms and Conditions of Sale

Listed below are some basic operational and installation conditions that must be adhered

to for Aqua Coolers warranty to remain valid and more importantly for trouble free chiller

operation. These are also the conditions under which Aqua Cooler will provide the

purchaser with products

Operation

The units are sophisticated pieces of equipment and must be operated in accordance with

the manner in which they are manufactured. Aqua Cooler warrants these products if they

are installed, commissioned, operated and serviced in a manner consistent with the

guidelines set out in this document. Aqua Cooler will not be liable for products

·Where the minimum flow rate specified in the manual is not maintained through the

units at all times. This applied to units not supplied with a pump.

·Where the commissioning data is not returned to Aqua Cooler or at the very least be

retained for the warranty period of the product to be accessible in the event of a

fault developing with the product.

·Where the operational settings on the controller are altered without first consulting

Aqua Cooler in writing

·Where the temperature cut out set point is set below 5°C without first consulting

Aqua Cooler in writing

·Where the water bypass in the chiller is set to be fully closed without first consulting

Aqua Cooler in writing

·Where the chiller is not installed on level surface

·Where the chiller has not been powered up for at least 4 hours before starting the

chiller to allow for the sump heater to warm the compressor oil.

·Where the pressure in the sealed refrigeration system has not been checked by a

refrigeration mechanic before starting the chiller to ensure that the pressure on the

suction side is at least 400kPa for R407c chillers and 200 kPa for R134a chillers

·Where the chiller is installed too close to either other chillers, too close to walls or

too close to a roof or awning to prevent proper ventilation of the cooling system.

·Where the information supplied to Aqua Cooler for specifying the chillers is incorrect

with regards to, but is not limited to, flow rates, ambient operating condition and

heat load

·Where the cooling medium used in the product causes corrosion to the product

Service

·Aqua Cooler will not warrant product where service work is not carried out by Aqua

Cooler

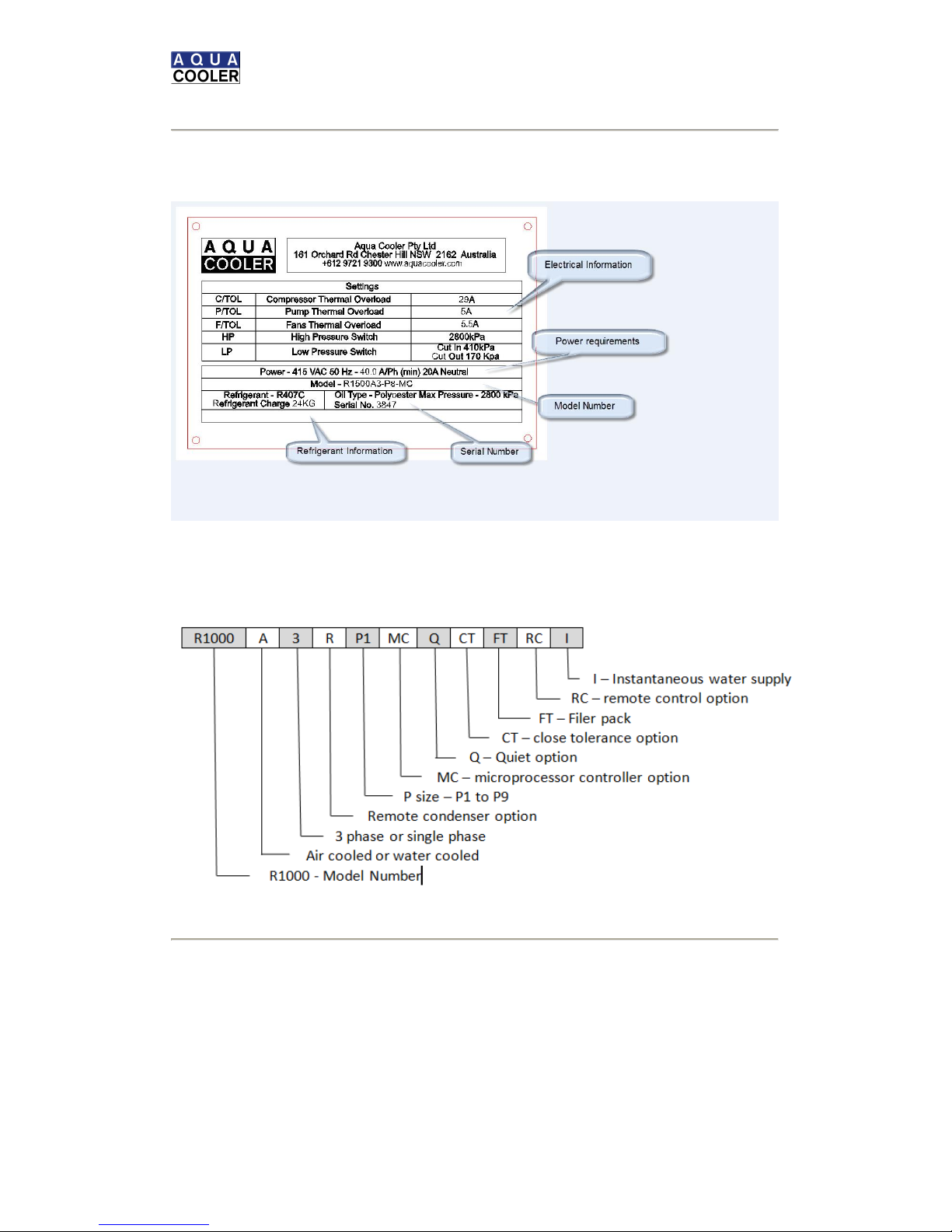

·Aqua Cooler will only cover costs of refrigerant to the value of the specified charge

indicated on the marking plate of the unit

·Aqua Cooler will pass on extra cost associated with service work carried out on

chillers where neat access to facilitate servicing in a manner that is compliant with

safe work practices is not provided. This also includes additional charges will apply

for sites where access to the chiller is unsafe or restricted

·Aqua Cooler takes no responsibility for repairs carried out on the chiller by un-

authorised service agents or if parts are installed that are not from Aqua Coolers

approved supplier list