Page - 1

SECTION 1 - CONTACTING AQUACAL AUTOPILOT, INC.

For further assistance, please contact AquaCal AutoPilot, Inc. Technical Support. To better assist you,

please have the chiller model and serial number available. See "Identifying Model Specifications" on page

26.

Website www.AquaCal.com

Request Service Online www.AquaCal.com/request-heat-pump-service/

Phone (1) 727-823-5642

Hours 8-5 pm, Eastern M-F

SECTION 2 - SAFETY

lFor personal safety, and to avoid damage to equipment, follow all safety instructions displayed on the equipment

and within this manual. Repair and service of chiller must be performed by an authorized service center.

lWarranties may be voided if the equipment has been improperly installed, maintained or serviced.

lIf service is deemed necessary, please contact AquaCal®Technical Support. See "Contacting AquaCal

AutoPilot, Inc." on page 1.

SAFETY SIGNALS

Throughout this document, safety signals have been placed where particular attention is

required.

WARNING - signals relate to personal safety.

CAUTION - signals promote avoiding damage to the equipment.

When installing and using your chiller basic safety precautions must always be followed, including the

following:

WARNING - Failure to heed the following may result in injury or death.

lInstallation and repairs must be performed by a qualified technician.

lThe chiller contains refrigerant under pressure. Repairs to the refrigerant circuit must not be attempted by

untrained and / or unqualified individuals. Service must be performed only by qualified HVAC technicians.

Recover refrigerant before opening the system.

lThe chiller utilizes high voltage and rotating equipment. Use caution when servicing.

lElectrical installation and service should be performed by a Licensed Electrician only.

lImproper water chemistry can present a serious health hazard. To avoid possible hazards, maintain pool / spa

water per standards detailed in this document.

lProlonged immersion in water colder than normal body temperature may cause a condition known as

Hypothermia. The symptoms of Hypothermia include shivering (although as hypothermia worsens, shivering

stops), clumsiness or lack of coordination, slurred speech or mumbling, confusion and poor decision-making,

drowsiness or low energy, lack of concern about personal welfare, progressive loss of consciousness, weak

pulse and slow or shallow breathing. In addition, persons having an adverse medical history, or pregnant

women, should consult a physician before immersing in a cold body of water. Children and the extreme elderly

should be supervised by a responsible adult.

CAUTION - Failure to heed the following may result in equipment damage.

lMaintain proper water chemistry in order to avoid damage to pump, filter, pool shell, etc.

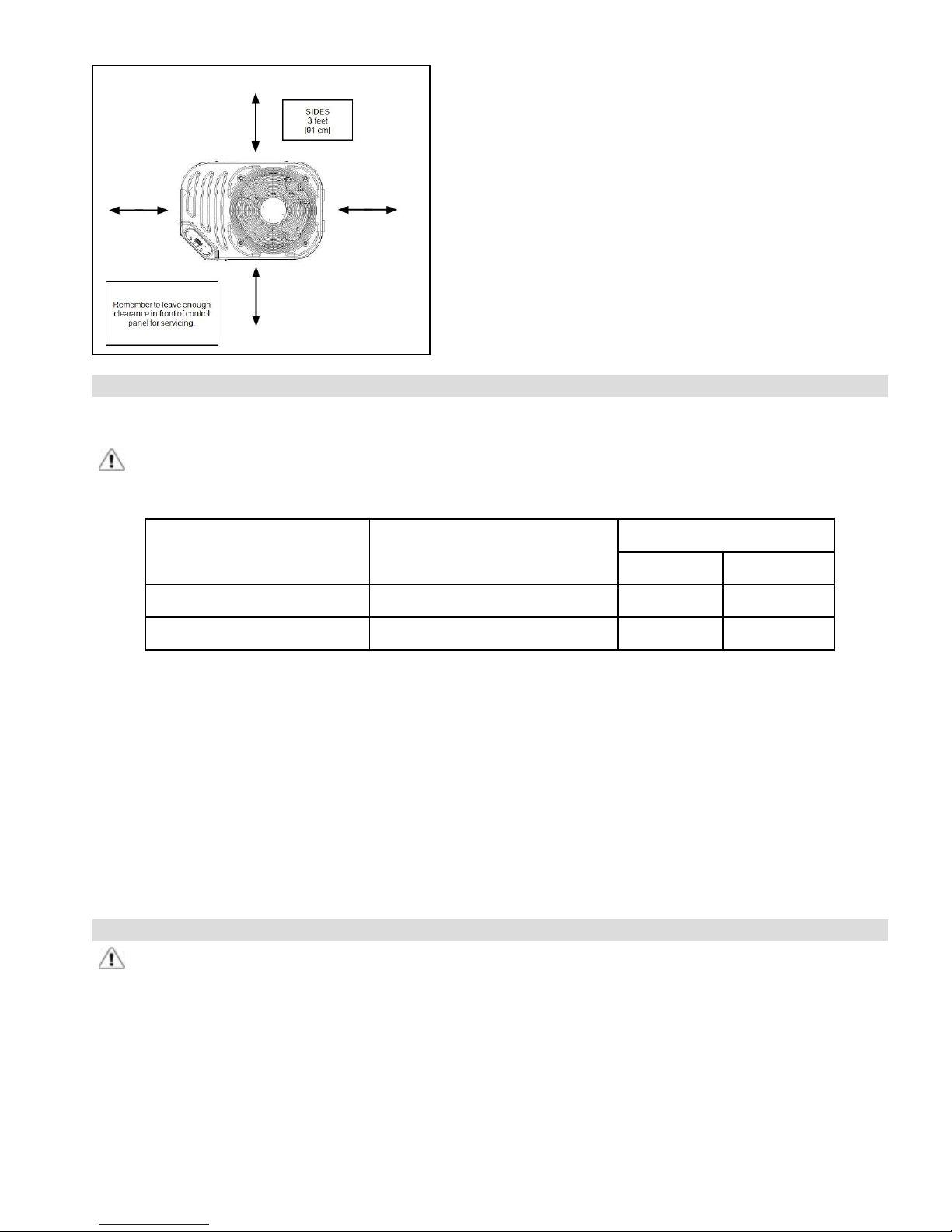

lWater flow exceeding maximum flow rate requires a bypass. Damage due to excessive water flow will void

warranty.

SAVE THESE INSTRUCTIONS