14 15

Classic Hydroponics 200 GPD

5-Stage RO Unit

Model# 540474

Installation, Operation & Maintenance Guide www.aquaticlife.com

REVERSE OSMOSIS

FILTER BASICS

The membrane does most of the work by

removing up to 98% of the TDS from your

water. The sediment and carbon filters protect

the membrane from the many malicious

elements that shorten its life. The sediment

cartridge removes suspended particles larger

than 5 microns (3 times smaller than a mold

spore). The carbon block removes chlorine.

Timely replacement of the cartridges will

increase the membrane’s life.

The carbon cartridge is the most important

cartridge to change frequently. The carbon

cartridge can filter about 3,500 gallons of

water before being replaced if your chlorine

level is 1 ppm (parts per million). With a

2 ppm you can filter 1,750 gallons of water

before needing to change, with a 3 ppm

you can filter 1,166 gallons, and so on. Any

chlorine not absorbed by a spent carbon

cartridge will break down your membrane,

thus greatly shortening its life.

The 3,500 gallon threshold is TOTAL water

that passes through the unit. The RO unit

has an average rejection ratio of 1:1.5.

That means for every 1 gallon of good water

produced you will reject 1.5 gallons for a total

of 2.5 gallons of water passed through the

unit.

When the sediment cartridge needs to be

changed, the production of water will reduce.

Even with reduced water production, the

cartridge will not allow anything larger than

one micron to pass through the chamber. On

average the sediment cartridge should be

changed at every other carbon change.

With proper filter changes, the membrane

could last up to two years. The membrane’s

water production rating is based on 77°F

water at 65 PSI. Any deviation from this

will aect the water production. Reference

the conversion table that follows. You will

notice that the warmer the water, the better

the production. It is not advised that you

introduce water from your water heater to

increase water temperature. The membrane

cannot handle temps over 100°F.

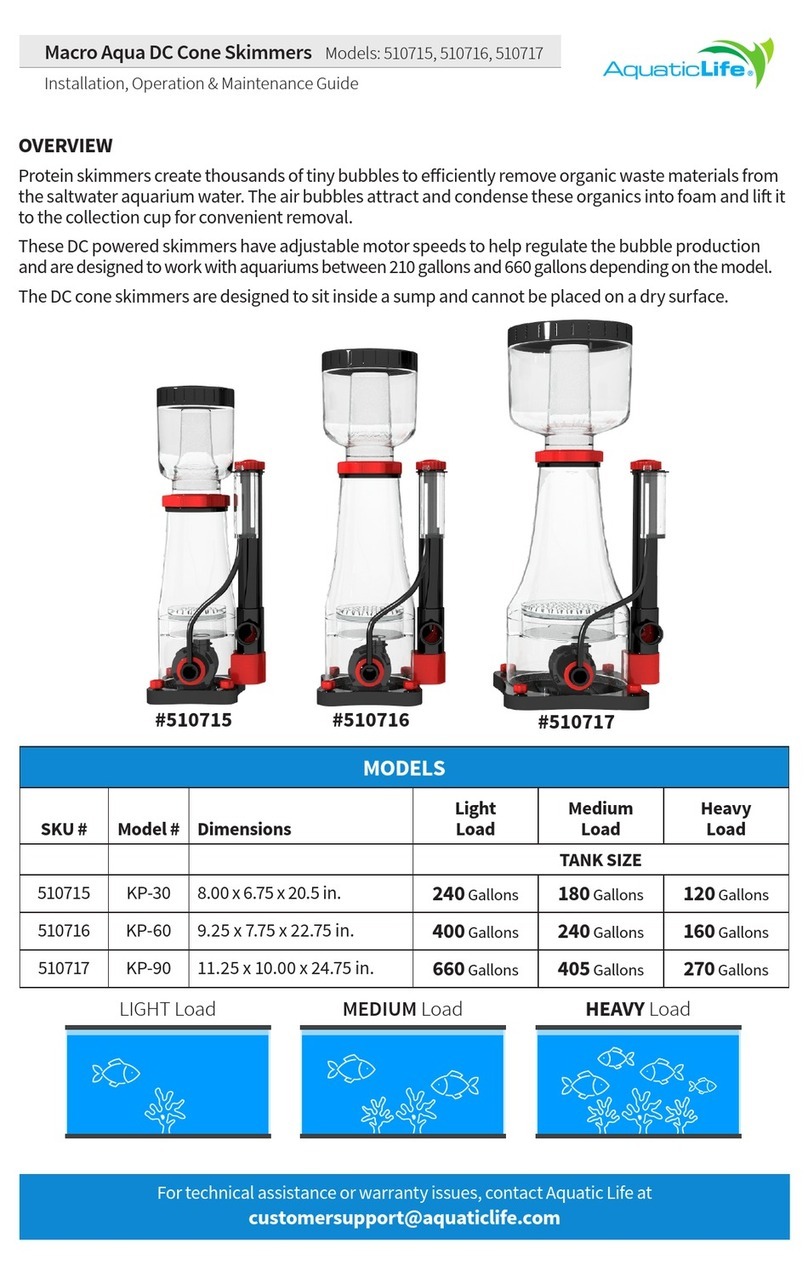

Example

The RO membrane production rate at 77ºF,

65 PSI = 200 gallons per day.

What is the production rate at 50º F?

Answer

Use the temperature correction factor

(from table above) = 0.58

New production flow rate at 50ºF is

200 x 0.58 = 116 gallons per day.

Temperature

Correction

Temp.

F/C

Correction

Factor

50/10 0.58

60/16 0.73

70/21 0.87

77/25 1.00

80/27 1.06

90/32 1.23

100/38 1.45

Pressure

Correction

Pressure

PSI

Correction

Factor

Less than 40 PSI

requires a

booster pump

40 0.67

50 0.83

65 1

70 1.17

80 1.33

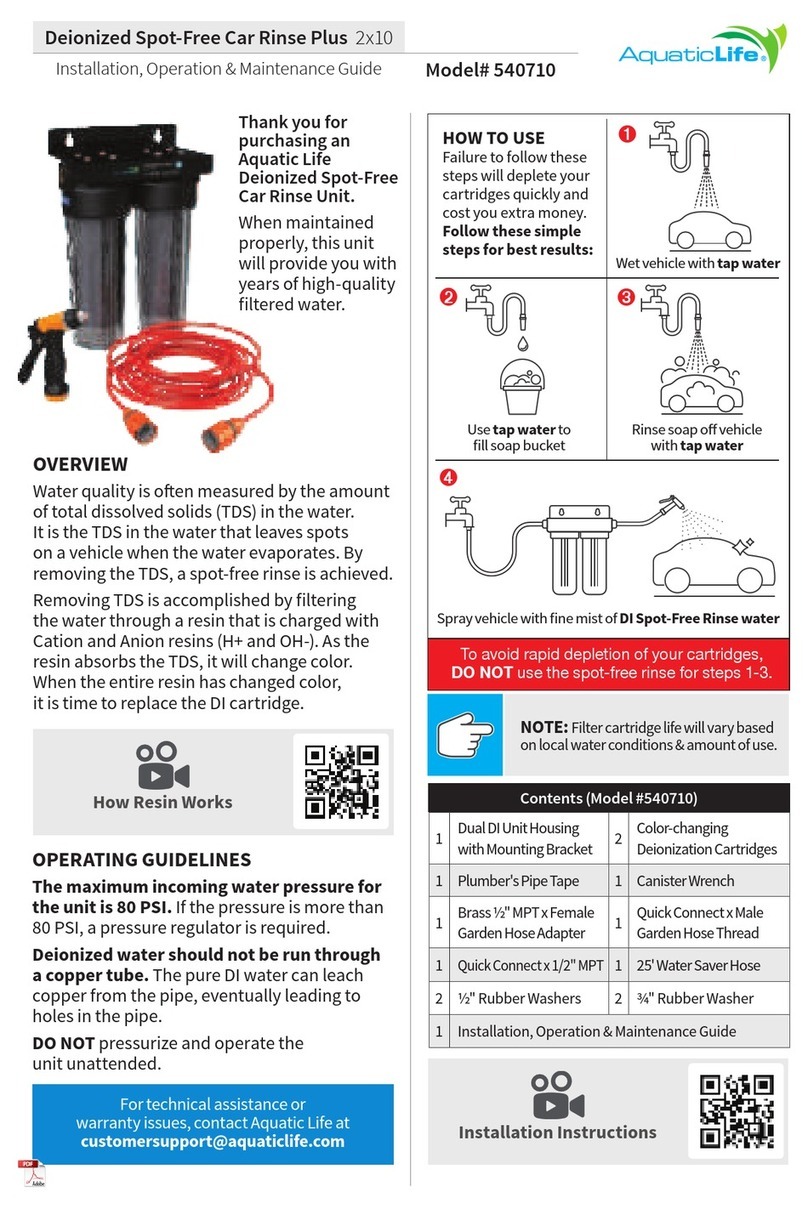

UNIT MAINTENANCE

Weekly Maintenance

This unit includes a flush valve to prolong the

life of the membrane. IT IS IMPORTANT TO

PERIODICALLY OPEN THE FLUSH VALVE FOR

45 SECONDS PRIOR TO MAKING FILTERED

WATER. This will clear debris that may have

built-up on the membrane.

Recommended change 3-6 months

or 3,500 gallons total or 900 gallons

of filtered water

Sediment Cartridge (Item # 330088)

Carbon Cartridge (Item # 330090)

12 Month Maintenance

100 GPD Membrane Cartridge

(Item # 330093)

Replace Clear Canister & O-ring

(Part # 9000928)

NOTE: The life span of the

cartridges are dependent on

water supply quality and amount

of use. Our recommended

replacement intervals are based

on average usage.

CLOSED

OPEN

OPERATION & CONSIDERATIONS

The unit includes a pressure gauge to show

the incoming water pressure. Your target

pressure is 60- 65 PSI. You will produce less

filtered water if your water pressure is below

60 PSI. Pressure above 60 PSI may produce

more water. If the incoming water pressure

is less than 40 PSI, you will need to add a

booster pump.

• Operating the RO unit using soened feed

water greatly reduces the chances of

membrane failure.

• Clear canisters have a limited life and

should be replaced on an annual basis

to prevent possible failure.

• Operating pressure less than 40 PSI

may require a booster pump.

• Water supply operating pressure greater

than 80 PSI requires a pressure regulator.

• With initial operation, check for leaks.

If a leak is observed, verify that the

tubing is pushed into the push-fitting far

enough to seal the tubing against the

o-ring and that the canisters and caps

are sealed properly with their o-rings.

• Many of the components in this unit

are plastic and subject to damage by

ultraviolet light.

• Never store or operate the unit in direct

sunlight or other bright lights.

• Do not store or operate the unit in

temperatures above 100°F.

• Do not store or operate the unit in

freezing temperatures.

• Do not leave the unit unattended while

connected to a water supply.