Aquila Pelletizer PE80 User guide

2

Aquila

Triventek

A/S

·

Industrivej

9

·

DK-5580

Nørre

Aaby

·

Tel.

+45

70

22

12

92

·

info@

aquila-triventek.com

·

www.aquila-

triventek.com

Table of contents

1

INTRODUCTION

4

1.1

What

is

dry

Ice?

4

1.2

The

Dry

Ice

Pelletizing

Process

-

How

does

the

Pelletizer

function?

4

1.3

Pellet

Sizes,

Denominations

and

Applications

5

1.4

Storage

Tank

for

Liquid

CO2

supplied

to

the

pelletizer

5

2

SAFETY

6

2.1

Safety

data

for

Carbon

Dioxide

(CO

2

)

6

2.2

Safety

data

for

Pelletizer

PE80

8

3

EQUIPMENT

FOR

OPERATION

9

3.1

Delivery 9

3.2

Equipment 9

3.3

Connecting

the

equipment

9

3.3.1

Power 9

3.3.2

Hoses

10

3.3.3

Important

notice

before

start

10

4

OPERATING

THE

EQUIPMENT

11

4.1

Operation panel

-

Main

menu structure

of

the

PLC

11

4.2

Start-up

sequence

13

4.3

Re-start

sequence

13

4.4

Shut-down

sequence

14

5

ALARM

MESSAGES

15

5.1

Low

inlet

CO

2

error

15

5.2

Motor

protection

error

15

5.3

Power

supply

error

15

5.4

Emergency

stop

message

16

5.5

Low

oil

pressure

16

5.6

Low

oil

level

16

5.7

Error

Co2 16

6

STORING

DRY

ICE

PELLETS

17

7

OPTIMISING

PRODUCTION

OUTPUT

17

8

CHANGING

EXTRUSION

PLATES

17

DIP

-

D

RY

I

CE

P

RODUCTION

3

Aquila

Triventek

A/S

·

Industrivej

9

·

DK-5580

Nørre

Aaby

·

Tel.

+45

70

22

12

92

·

info@

aquila-triventek.com

·

www.aquila-

triventek.com

Table of contents

9

AUTOMATION

18

9.1

Power

supply

protection

system

18

9.2

Pressure

protection

system

18

9.3

Automatic

stop

when

supply

of

liquid

from

tank

is

closed

18

10

MAINTENANCE

18

10.1

Maintenance

intervals

18

10.2

Removing

the

cover

and

identification

of

main

components

20

10.3

Checking oil level (main oil pump)

20

10.4

Checking

oil

level

(gearbox)

20

10.5

Dismantling

and

inspecting

the

solenoid

valves

21

10.6

Inspection

and

renewal

of

inlet

filter

22

10.7

Inspection

of

the

gas

separator

23

10.8

Inspection

of

CO2

liquid

supply

and

level

sensor

24

11

CLEANING

THE

EQUIPMENT

24

12

STORAGE

24

13

RECOMMENDED

SPARE

PARTS

LIST

25

14

TROUBLESHOOTING

27

15

TECHNICAL

DATA

30

16

EC

DECLARATION

OF

CONFORMITY

31

17

GUARANTEE

32

18

DELIVERY

REPORT

33

DIP

-

D

RY

I

CE

P

RODUCTION

4

Aquila

Triventek

A/S

·

Industrivej

9

·

DK-5580

Nørre

Aaby

·

Tel.

+45

70

22

12

92

·

info@

aquila-triventek.com

·

www.aquila-

triventek.com

Introduction

We

are

pleased

that

you

have

chosen

the

Pelletizer

PE80

by

Triventek

for

your

company.

This technology is the subject of several pending patent applications worldwide, including US patent application No.

10/363,762 and European patent application No. 01960192.1.

To obtain long and trouble-free operation of the equipment we recommend reading this manual carefully. All new opera-

tors of the equipment should also familiarize themselves with the content of this document.

1.1

What is Dry Ice?

Carbon dioxide is a chemical compound formed by combining one atom of carbon with two atoms of oxygen and is

expressed by the chemical symbol CO

2

. It can exist in three states: a gas, a liquid or as a solid.

Dry ice is solid carbon dioxide (CO

2

). The unique property of carbon dioxide is that at normal, atmospheric pressure

and temperature, it changes state directly from solid to gas without going through a liquid phase. This process, called

sublimation, makes the ice ‘dry’.

Dry ice is stable at (minus) -7ºC 9/-109ºF, at atmospheric pressure. It expands up to 800 times by volume when it subli-

mes, and this property is exploited for instant cooling of food and pharmaceutical products during processing, trans-

portation and storage.

The properties of dry ice are also used for other industrial applications, such as dry ice blasting

(cleaning of machinery through thermal shock).

1.2

The

Dry

Ice

Pelletizing

Process

The Pelletizer takes liquid carbon dioxide from the carbon dioxide storage vessel and feeds it into the main pelletisati-

on chamber. Within the main chamber three injection valves are located to allow the liquid into the three compressing

chambers.

The volume of liquid CO

2

injected into the compressing chambers, and consequently the rate of dry ice production, is

determined by varying the valve opening time.

A sudden pressure and temperature drop occurs when the liquid enters the compression chambers, by which

approxi-

mately 50% transforms into ’carbonic snow’ and about 50% transforms into gas (known as ´revert´ gas).

The revert gas is usually

vented to the atmosphere and lost. However it can be recycled by connecting a Recovery Unit

RE80 to the Pelletizer PE80. Up to 90% of the revert gas can be re-compressed and chilled back to liquid state.

An electrical motor with a gearbox drives a crank shaft and 3 mechanical pistons in order to compress the carbonic

snow that has been retained in the compression chambers. The snow becomes a block of dry ice which is subsequently

pressed through extrusion plates to form ‘spaghetti’ strings. The strings will tend to break at the break line formed by

each compression stroke to make the characteristic ‘pellets’

.

DIP

-

D

RY

I

CE

P

RODUCTION

5

Aquila

Triventek

A/S

·

Industrivej

9

·

DK-5580

Nørre

Aaby

·

Tel.

+45

70

22

12

92

·

info@

aquila-triventek.com

·

www.aquila-

triventek.com

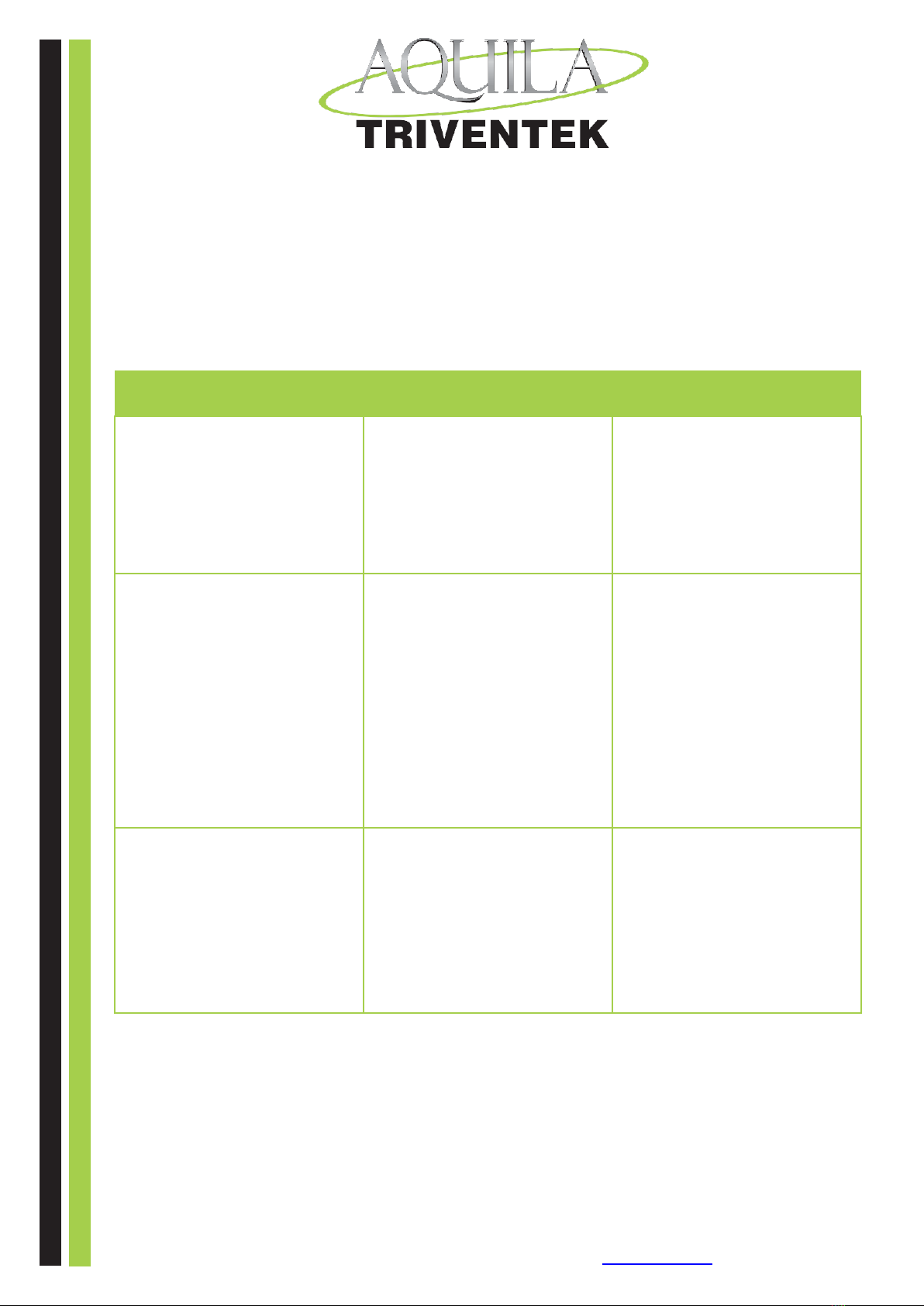

1.3

Pellet

Sizes,

Denominations

and

Applications

Pellets can be made in a variety of sizes (diameters) for different applications. The size (diameter) of pellets depends on

the size of the holes in the extrusion plate.

A set of 3 extrusion

for manufacturing

pellets of Ø3 mm (1/8”) is provided

with the Pelletizer PE80 as standard. The nominal production capacity of the equipment has been rated with this format.

Production capacity will be marginally different for pellet sizes other than 3 mm.

Size

Denomination

Applications

Ø 1,7 mm

(1/16”)

and

Ø 2,2 mm ( 3/32”)

”Micro-

pellets”

For dry ice blasting (cleaning) of ob-

jects and surfaces. They are used for

cleaning of objects and surfaces with

small cavities and fine patterns that

need to be penetrated with smaller

particles. Micropellets are for instant

use shortly after their production.

Ø 3 mm ( 1/8”)

”Rice

pellets”

/“traditional” pellets /

just “pellets”

For dry ice blasting and for quick coo-

ling of food and biopharmaceutical

products. Especially used in wineries

during the vintage season, in order

to

prevent premature fermentation of the

grapes.

Rice pellets (Ø3 mm) are used for the

vast majority of dry ice blasting / clea-

ning applications and should be used

no later than 3 days after production

in order to preserve the needed quality

and density.

Ø 8 mm ( 5/16”)

and

Ø 16 mm ( 5/8”)

”Nugget”

For cold chain applications (trans-

portation and conservation of food

and biopharmaceutical products).

Nuggets are mainly used for cooling

applications since the reduced ratio

of surface area to mass, reduces the

rate of sublimation. so that the last for

a longer period of time, before they

evaporate.

1.4

Storage

Tank

for

Liquid

CO

2

Dry

ice

manufacturing

starts

with

liquid

carbon

dioxide

flowing

to

the

pelletizer

from

a

storage

tank

where

The

liquid

is

held under pressures between 14-23 bar

(200-330 psi)

The

PE80’

Pelletizer’s

nominal

production

capacity

is

rated

at

a

pressure

of

18

bar

(260

psi).

DIP

-

D

RY

I

CE

P

RODUCTION

Table of contents

Popular Dispenser manuals by other brands

BOWMAN

BOWMAN CL003-0111 manual

SIKA

SIKA Power Cure operating instructions

Silver King

Silver King Majestic SK12MAJ Technical manual and replacement parts list

Franke

Franke F3Dn Twin Service manual

HURAKAN

HURAKAN HKN-MT1 manual

STIEBEL ELTRON

STIEBEL ELTRON UltraHot Plus Operation and installation instructions