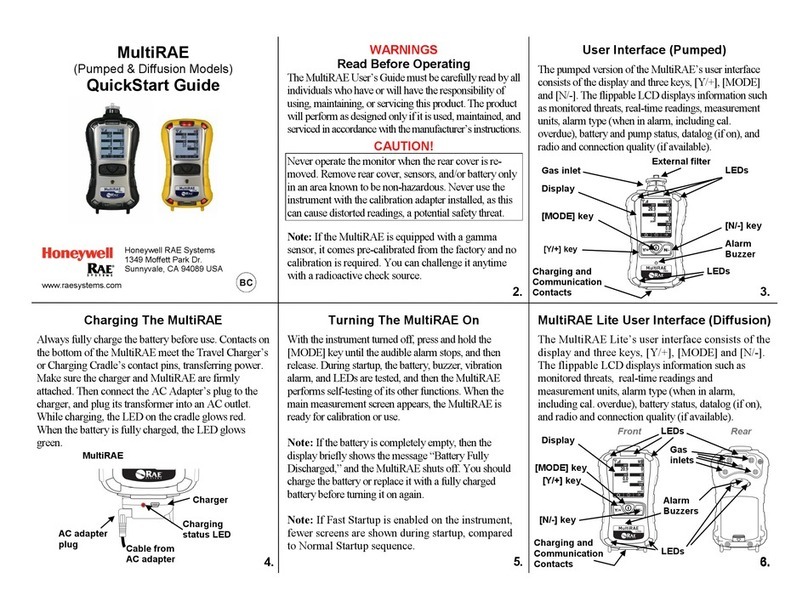

aquilar AquiTron AT-G-DETECT Use and care manual

AT-G-DETECT

Refrigerant Gas Sensing System

Check / Calibration Procedure

AquiTron

CALIBRATION

PROCEDURE

*Technician use only

– This procedure

must be carried

out by a suitably

qualified technician in

accordance with these

instructions and the

standards set down

in their particular

industry/country.

AT-G-DETECT

Gas Sensing System

Check / Calibration Procedure

A. INTRODUCTION

The frequency and nature of testing or calibration may be determined by local regulation or

standards.EN378 and the FGAS Regulation require an annual check in accordance with the

manufacturer’s recommendation.

• For 1 level models, Aquilar recommends an annual check consisting of resetting units

electrically to the factory calibration settings and carrying out a bump test to ensure correct

operation. A gas calibration should be carried out every three years.

• For 2 level models, Aquilar recommends annual checks by resetting units electrically to

the factory calibration settings, a bump test and replacement of the sensors with a pre-

calibrated certified sensor every three years. The alternative to replacement is an on-site

gas calibration. Sensor replacement may be more cost effective, eliminate end of life

concerns and constantly renew the detection system

If the sensor is exposed to a large leak it should be tested to ensure correct functionality by

electrically resetting to the factory calibration settings and carrying out a bump test.

There are two concepts that need to be differentiated: bump test and calibration

LEAK DETECTION SOLUTIONS

1

BUMP TEST

This consists of exposing the sensor to a gas.

The objective is to establish if the sensor is

reacting to the gas and all the sensor outputs

are working correctly. A quantified bump test

is one where gas of a know concentration is

used.

CALIBRATION

This consists of exposing the sensor to a

calibration gas, setting the “Sensor Standby

Voltage”, the alarm set points “Alarm

Threshold Voltages” and checking/adjusting

all the outputs so that they are activated at

the specified alarm gas concentrations when

exposed to this gas.

It is required by EN378 to record the check results in the Logbook

Before you carry out the test or calibration

procedure:

1. Advise occupants, plant operators and

supervisors

2. Check if the AT-G-DETECT is connected

to external systems such as sprinkler

systems, plant shut down, external

sirens and beacons, ventilation etc. and

disconnect as instructed by the customer.

3. For 1 level systems you must deactivate

the 3 minute alarm delay, if selected, by

removing jumpers JP1 to offposition. For

2 level systems upon power up there is a

delay of 3 minutes before the green power

LED turns on.

4. For bump test or calibration, AT-G-

DETECT’s should be powered up overnight.

5. If a unit has been powered offfor a

short time, say due to maintenance, it

will normalise within a few minutes. If

sensors have been in long term storage

or have been turned offfor a long period,

normalisation would be much slower.

However, within 1-2 hours sensors

should have dropped below the low

alarm level and be operational. You can

monitor normalisation progress exactly by

monitoring the sensor output, see Table 1.

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

AT-G-DETECT

Gas Sensing System

LEAK DETECTION SOLUTIONS

2

B. TRICAL RESET / BUMP TEST (EVERY YEAR)

Electrical reset is based on the calibration found on the label on the side of the enclosure and is

unique to that sensor.

TOOLS REQUIRED

• A voltmeter – crocodile clips recommended

• Aquilar’s set point values, as shown on the rating label

• Estimate 10 minutes per sensor

C. ELECTRICAL RESET OF 1 LEVEL SYSTEM

Reset, if necessary, the Standby and Alarm

Threshold Voltage to the factory settings as

shown on the calibration label.

First disable the 3 minute alarm delay on a

one level system by moving the jumper link

at JP1 to the “OFF” position, diagram 1.

Two adjustments are required and they are

all performed on the controller unit.

For Sensor Standby Voltage, connect your

DC voltmeter between 4(0V) and 2(+V) on

CN1, CN2, etc as shown in Diagram 1 and

adjusting pot P1 for channel 1, P2 for channel

2, etc.For Alarm Threshold Voltage, connect

your DC voltmeter between 4(0V) and 1(+V)

on cal header as shown in Diagram 1 and

adjusting pot P3 for 1/2channel units and P7

for 4/6 channel units. For CO2 1 Level units

there is only one adjustment - the alarm

level, as the SSV is fixed. This can be adjusted

by connecting your DC voltmeter between

4(0V) and 1(+V) on cal header as shown

in Diagram 1 and adjusting pot P3 for 1/2

channel units and P7 for 4/6 channel units.

Carry out a bump test to ensure the sensor is

functioning correctly. If the sensor does not

go into alarm carry out a gas calibration.

If the factory set point information is not

on the calibration label (as with older units)

check the serial number of your gas detector

on the rating label and sensor PCB and

contact Aquilar for the appropriate set point

values. Finally return the jumper JP1 to the

original position.

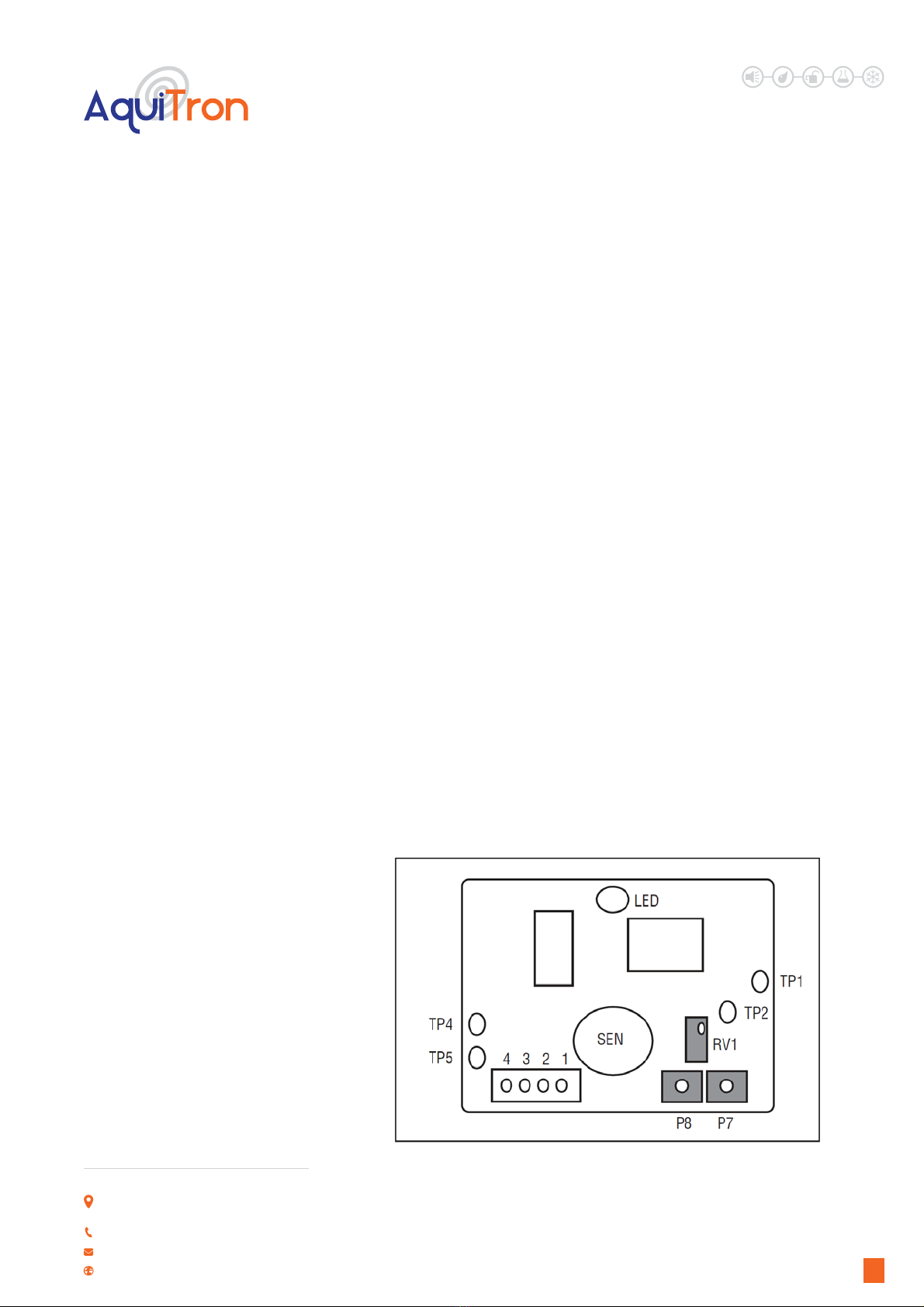

C. ELECTRICAL RESET OF 2 LEVEL SYSTEM

Reset, if necessary, the Standby and low /

high Alarm Threshold Voltages to the factory

settings as shown on the calibration label.

For Standby voltage, connect your DC

voltmeter between TP5 (0V) and TP4 (+V) as

shown in Diagram 2 and adjusting pot RV1.

For low-level alarm voltage, connect your DC

voltmeter between TP5 (0V) and TP2 (+V) as

shown in Diagram 2 and adjusting pot P8.

For high-level alarm voltage, connect your DC

voltmeter between TP5 (0V)and TP1 (+V) as

shown in Diagram 2 and adjusting pot P7.

For CO2 2 level units there are 2 adjustments

for the alarm levels, again the SSV is fixed

and these can be found on the controller.

They can be adjusted by connecting your DC

voltmeter to the cal header between 4(0V)

and 2(+V) low alarm and adjusting P8 and for

high alarm between 4(0V) and 1(+V) adjusting

P7. If the sensor does not go into alarm

exchange the sensor and carry out a gas

calibration.If the factory set point information

is not on the calibration label (as with older

units) check the serial number of your gas

detector on the rating label and sensor PCB

and contact Aquilar for the appropriate set

point values.

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

AT-G-DETECT

Gas Sensing System

LEAK DETECTION SOLUTIONS

3

D. BUMP TEST

Ideally bump tests are conducted on site in a

clean air atmosphere.

SEMICONDUCTOR SENSORS

We offer cylinders of calibration gas at known

concentration and ampoules for ammonia

(NH3) at 100ppm and1.000 ppm and using

these constitute a quantifiedbumptest.

the gas onto the sensor and force it into

alarm. Check that alarm lights and relays are

activated.

INFRARED SENSORS FOR CO2

DETECTION

For a quantified bump test you can check the

infrared sensors for carbon dioxide using

Aquilar ampoules filled with CO2 at 2000ppm

in air or calibration cylinders. If these are not

available, you can carry out a non-quantified

bump test by breathing on the sensor. The

human breath has enough CO2 to trigger the

alarm. If the bump test is not successful then

carry out a gas calibration, see below.

E. BUMP TEST USING GAS AMPOULES

1. Make sure that both the ampoules and the

calibration beaker are clean and dry.

2. Unscrew the beaker hold screw and place

the ampoule so that it sits in the base of

the beaker

3. Tighten on the screw onto the ampoule

without breaking it

4. Remove the enclosure lid of the gas sensor

(not in Ex area and in one level units as

monitoring of voltage can be done on

controller). If this is a CO2unit also remove

the yellow cap (if on your model) on the

calibration port

5. Connect volt meter to monitor sensor

response

6. Place the beaker over the sensor head

(using an adaptor if required)or, if an

Exd or Remote sensor head version, M35

or M42 thread, screw the beaker on the

remote sensor head. It should be as tight

a fitting as possible to allow maximum

exposure to the gas.

7. CO2 ampoule: hold the beaker in a

45-degree angle as per illustration. This

allows gas to flow through the front back

of the sensor and though the calibration

ports).

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

AT-G-DETECT

Gas Sensing System

LEAK DETECTION SOLUTIONS

4

8. Tighten on the ampoule until it shatters

allowing the content to diffuse in the

beaker. It should be left in place for

approximately 5 min.

9. Voltage output will increase. This confirms

that the sensor is responding. In the case

of ampoules a response equivalent to 50%

F. BUMP TEST USING GAS AMPOULES

or greater of the ampoule concentration

will be satisfactory.

10. Carefully remove any ampoule remains

from the gas detector, replace yellow cap

(only CO2 sensors), and replace the sensor

enclosure.

Remove the enclosure lid of the gas sensor and controller (non applicable to Exd Remote

sensor and vent pipe model, 1L units as monitoring of voltage can be done on controller) if

this is a CO2 unit also remove the yellow cap on the calibration port, if on your model.Connect

the voltmeter to the controller to monitor sensor response. Expose the sensor to gas from the

cylinder. You can place the entire sensor into a plastic bag or use a plastic hose/hood to direct

gas to the sensor head.

G.CALIBRATION

The alternatives we describe are:

• Exchanging the sensor board – only

available for 2 level units

• Gas Calibration

H. EXCHANGING THE SENSOR BOARD

Aquilar recommends exchanging your PCB for a newly pre-calibrated certified unit every 3 years

TOOLS REQUIRED

• A pre-calibrated sensor board

• A voltmeter – crocodile clips recommended

• Estimate 10 min per sensor

EXCHANGINF THE SENSOR

1. Power offthe unit and remove lid of

sensor enclosure.

2. Note the colour code of the cable in

positions 1,2,3,and 4 of the connector

block.

3. Undo the cable and 2 screws securing

sensor board and remove.

4. Fit the new pre-calibrated sensor and

reconnect the cable in the correct colour

sequence at positions 1,2,3 and 4.

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

AT-G-DETECT

Gas Sensing System

LEAK DETECTION SOLUTIONS

5

5. Power on the unit and allow to stabilise for

15 min.

6. Check voltage readings on positions 1,2,3,

and 4 as per procedure in Table 1, page 5,

to ensure that wiring is correct. Note also

in the table how to monitor the sensor as it

normalises.

7. Carry out a bump test to confirm the

sensor is responding.

8. Keep records of the test date, sensor serial

number, and any observation.

There are a number of advantages to sensor

exchange. It is simpler and quicker than gas

calibration. Aquilar guarantees the correct

calibration and functioning of the new

sensor, which is supplied with a calibration

certificate and finally, you won’t face any

problems of sensor deterioration or end-of-

life.

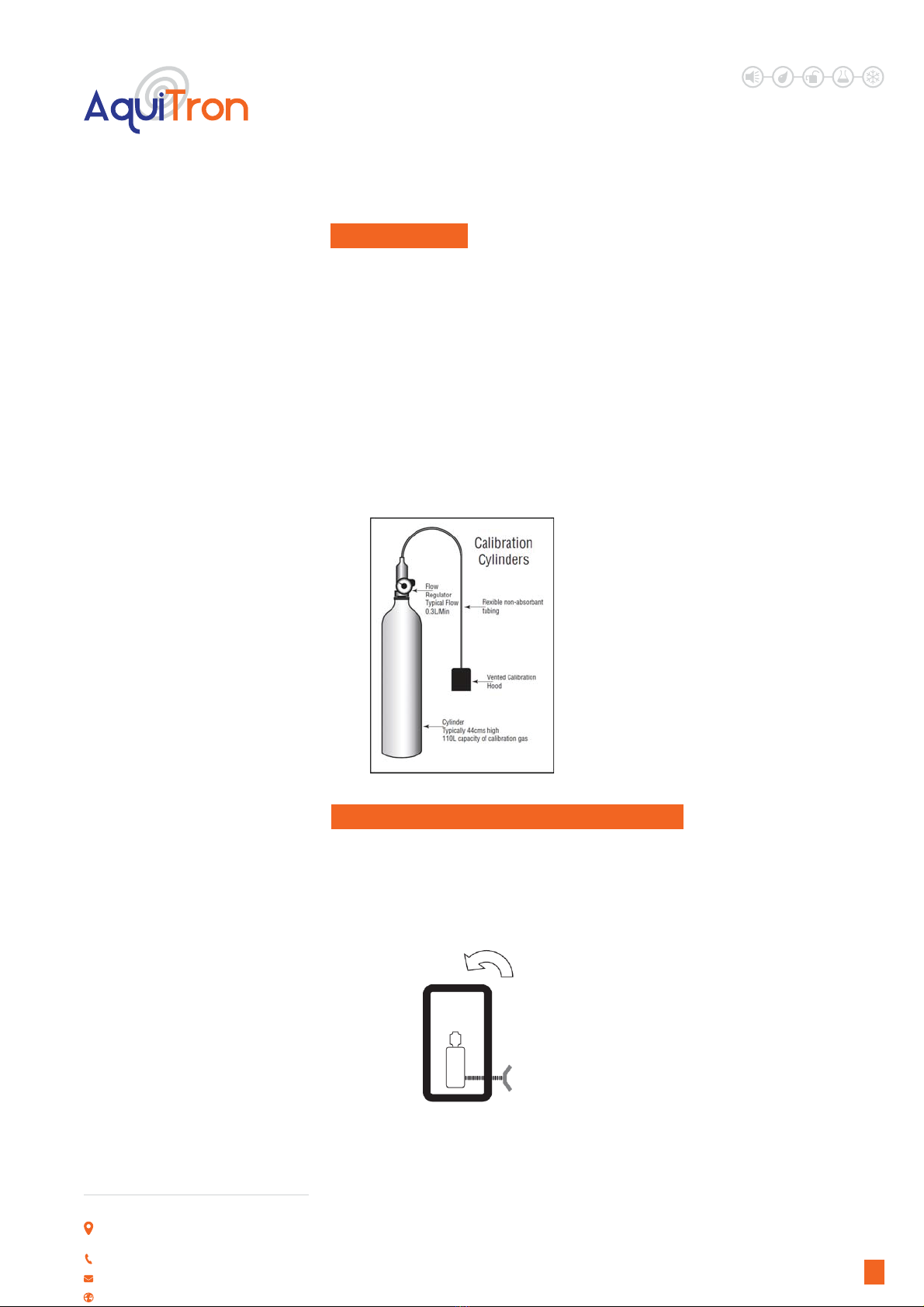

This is the adjustment of the gas detector

using calibration gas. Aquilar offers a

calibration kit that consists of a Calibration

gas cylinder and a flow regulation valve.

In some cases this option may be expensive

relative to sensor exchange because of

the cost of visiting a site, calibration gas

and valve, and a surcharge on the freight

cost of the calibration gas as it is classified

as a hazardous substance (ampoules are

not classed as hazardous).The procedure

involves electrical set-up followed by

adjustment using calibration gases.

EQUIPMENT REQUIRED

• Gas cylinders with the appropriate

calibration gas concentrations

• Gas canister with zero air to calibrate /

check the Sensor Standby Voltage, required

if the sensor environment is not clean.

• Flow gas valve – rate 0.3L/min

• A voltmeter

• Estimate 30 min per sensor.

The procedure differs slightly depending on

the number of alarm levels.

ONE LEVEL SYSTEM - CALIBRATION

First disable the 3 minute alarm delay on a

one level system by moving the jumper link

at JP1 to the offposition. Two adjustments

are required and they are all performed on

the controller unit.

A. Sensor Standby Voltage (SSV)

This is the standby output for the sensor in

I. GAS CALIBRATION clean air. When gas is present around the

sensor, this voltage will increase.IF SSV is

greater than the alarm threshold voltage,

as in when a gas leak occurs, then an alarm

condition occurs - red LED, siren, relay

operates. (When JP1 is in “on” positions there

is a 3 minute delay) IF SSV falls below 0.18

V, a fault condition will be shown on the

controller - red LED, no siren, relay does not

operate. Connect a Voltmeter between Pins

4 (-Ve) & 2 (+Ve) of sensor terminal connector

block for each channel in turn (CN1, CN2 Etc.)

and adjust calibration pot (P1, P2 Etc.) to the

SSV value as per calibration label on side of

enclosure.This value should be already set

unless age or background has caused drift.

B. Alarm Threshold Voltage (ATV)

ATV is the voltage at which the alarm and

relay activate at a given gas concentration.

This voltage is normally set 3.5V. Connect a

Voltmeter (0-10 volt scale) across pins 4 & 1

of the header marked “CAL” on the controller

board.

This voltage (3.5V normal factory setting) is

set using:

1 or 2 channel system controllers - the

threshold pot “P3”

4 or 6 channel system controllers - the

threshold pot “P7”

Connect a Voltmeter between Pins 4 (-Ve)

& 2 (+Ve) of the sensor terminal connector

block for each channel in turn (CN1, CN2

Etc.) Apply calibration gas of the desired

concentration e.g. 1000 ppm in air to the

sensor and wait until the sensor output

signal stabilises, then adjust the pot that

corresponds to the channel being calibrated,

i.e. P1for channel 1, P2 for channel 2, etc.

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

AT-G-DETECT

Gas Sensing System

LEAK DETECTION SOLUTIONS

6

This should be adjusted until the sensor

goes into alarm - the red LED turns on (a

voltage of approximately 3.55V). Remove the

calibration gas and allow the sensor to return

to its standby voltage. Record this voltage

reading and keep on record for subsequent

electrical set –ups. This is now calibrated for

the gas concentration used.Repeat for any

subsequent channels. Finally return jumper

JP1 to its pre calibration position.

TWO LEVEL SYSTEM - CALIBRATION

The delay on a 2L system is approximately

25 seconds and cannot be deactivated. All

adjustments are performed on the sensor

PCB and there are three elements to be

adjusted: the Standby Voltage and two Alarm

Thresholds.

A. Sensor Standby Voltage (SSV)

The factory settings are shown on the

calibration label on the side of the enclosure.

Connect the voltmeter between TP5 (0V) &

TP4 (+Ve) and adjust pot RV1 for 0.3V.

This value should be already set correctly

unless age or background has caused drift.

B. Alarm Threshold Voltage (ATV)

• Low Treshhold: Connect voltmeter

between TP5 (0V) & TP2 (+Ve), set the

voltage asshown on the calibration label by

adjusting pot “P8”.

• High Threshold: Connect voltmeter

between TP5 (0V) & TP1 (+Ve), set the

voltage as shown on the calibration label by

adjusting pot “P7”.

Please remember there is an inbuilt

delay response to an alarm of approx. 25

seconds on both alarm levels

Monitor voltage between TP5 (0V) & TP4

(+Ve).Apply the low concentration calibration

gas to the sensor and wait until the sensor

output signal stabilises. Record this voltage.

Apply the high concentration calibration

gas to the sensor and wait until the sensor

output signal stabilises. Record this voltage.

If the voltages recorded for the low and high

alarms differ from the factory settings shown

on the calibration label then adjust P8 and P7

as above to the new values. Record and use

these new values for subsequent electrical

set-ups.

The High threshold voltage must be set higher than the low threshold, or the unit will not

function correctly

2 Level Sensor

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

AT-G-DETECT

Gas Sensing System

LEAK DETECTION SOLUTIONS

7

J. AT-G DETECT 1 OR 2 CHANNEL UNIT

K. AT-G-DETECT 4 OR 6 CHANNEL UNIT

L. ADDITIONAL RECOMMENDATIONS

False Alarms

If false alarms are being triggered by

background gases, paint fumes, etc, or

extreme humidity or temperature conditions,

you may adjust the settings to compensate.

One Level Systems

You should reduce the SSV level in 0.5V

increments until the condition clears.

Two Level Systems

You should adjust the relevant alarm

threshold upwards in 0.2Volt increments

until the condition clears.

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

AT-G-DETECT

Gas Sensing System

LEAK DETECTION SOLUTIONS

8

M. DOUBLE CHECK CONNECTIONS ARE CORRECT

To make sure the gas detectors are wired up correctly you can check the voltages at the sensor

cable terminal blocks on the controller PCB or sensor PCB using a 0-10V voltmeter as outlined

below in Table 1.

Place the negative probe on terminal position 4 and with the positive on1, 3, 2, check the Volts

values. The readings are lower at the sensor due to power drop in the line.

The terminals should have the under listed values:

Position

Number

At the sensor Controller Without sensor

fitted

4 Is the negative side of the power supply Negative Negative

1 Power Supply 7.2V minimum, unless you

have power drop reduction

+10V +12 – 15V

3 Approximately 4-5V +4.8 – 5V +5V

2 One level system – sensor standby

voltage* as shown on the calibration

label on the side of the enclosure.

Two level system – typical internal

reference values, approximately

(0=Fault)

+0.4V

+1.6V

+2.8V

0

Sensor in standby

Low Alarm Condition

High Alarm Condition

* The voltage signal from the sensor will on power up start high and gradually fall (in clean air)

to the SSV value shown on the calibration label.

You can monitor this as follows:

1 level systems: Connect a Voltmeter and monitor voltage between Pins 4 (-Ve) & 2 (+Ve) of the

sensor terminal connector block for each channel in turn (CN1,CN2 Etc.)

2 level systems: Connect voltmeter and monitor voltage between TP5 (0V) & TP4 (+Ve).

Important: All information, including illustrations, is believed to be reliable. Users, however,

should independently evaluate the suitability of each product for their application. Aquilar

Limited makes no warranty as to the accuracy or completeness of the information, and

disclaims any liability regarding its use. The only obligations of Aquilar Limited are those in

the Aquilar Standard Terms and Conditions of Sale for this product, and in no case will Aquilar

Limited be liable for any incidental, indirect, or consequential damages arising from the sale,

resale, use or misuse of the product. Specifications are subject to change without notice. In

addition, Aquilar Limited reserves the right to make changes – without notification to Buyer

– to processing or materials that do not affect compliance with any applicable specification.

AquiTron is a trademark of AquiTron Limited

Aquilar is a trademark of Aquilar Limited

V204.2019

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

Table of contents

Other aquilar Gas Detector manuals

Popular Gas Detector manuals by other brands

STATUS SCIENTIFIC CONTROLS

STATUS SCIENTIFIC CONTROLS FGD10A Installation, Commissioning & Routine Gas Testing Manual

CPS

CPS GS40 instruction manual

WatchGas

WatchGas AirWatch Mk 1.0 Quick reference card

RKI Instruments

RKI Instruments GX-3R Pro Operator's manual

BEINAT

BEINAT NASE25/K Quick user guide

IGD

IGD 2-Wire Systems Installer's guide

Elliwell

Elliwell LKD 500 user manual

MSA

MSA ALTAIR 2X operating manual

Trolex

Trolex Sentro 1 TX6351 user manual

New Cosmos Electric

New Cosmos Electric KS-7D instruction manual

Quatrosense Environmental

Quatrosense Environmental QEL Installation, operation and maintenance manual

Tecnogas

Tecnogas CD-34 quick start guide