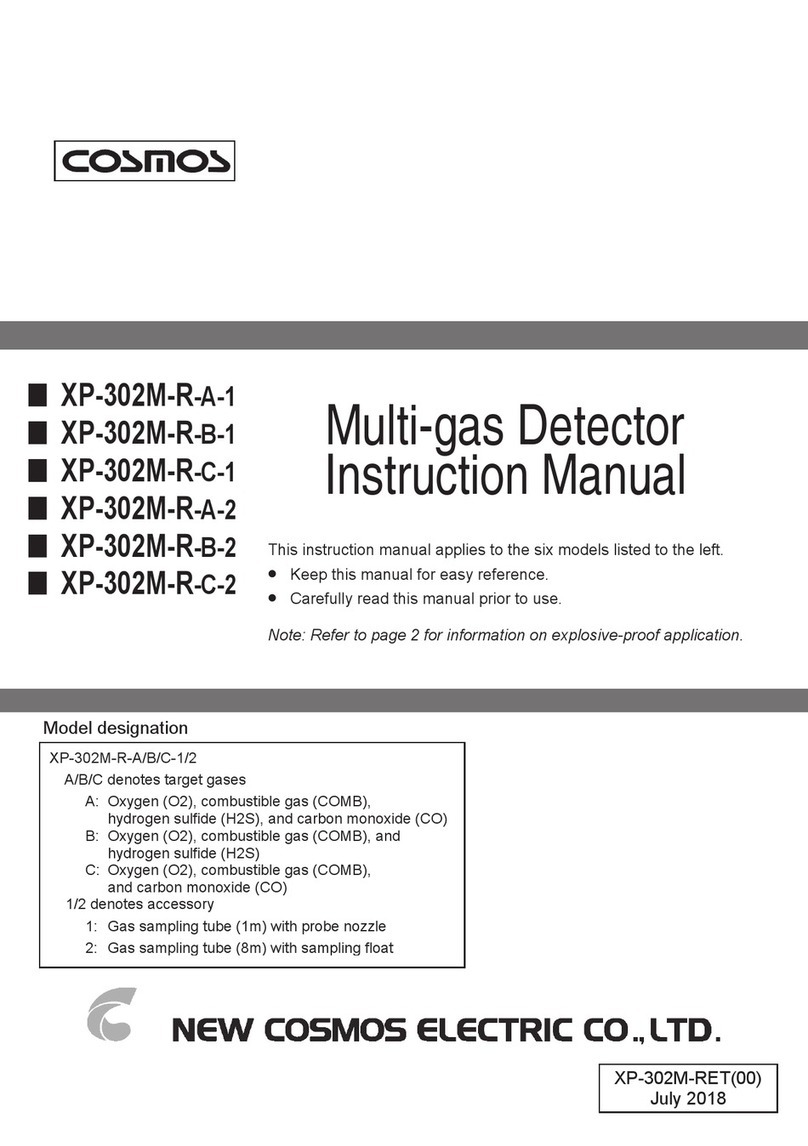

Table of Contents

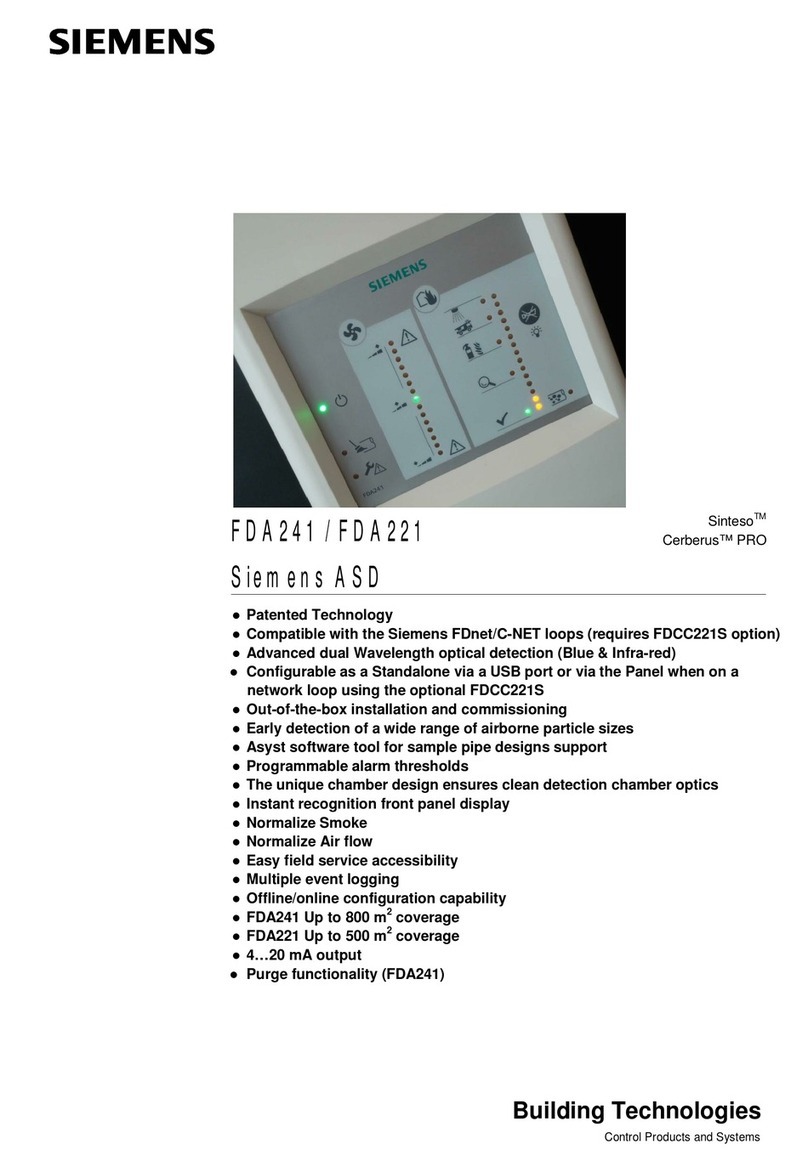

1. Introduction................................................................................................................................1

2. General Precautions..................................................................................................................2

3. Package Contents.....................................................................................................................3

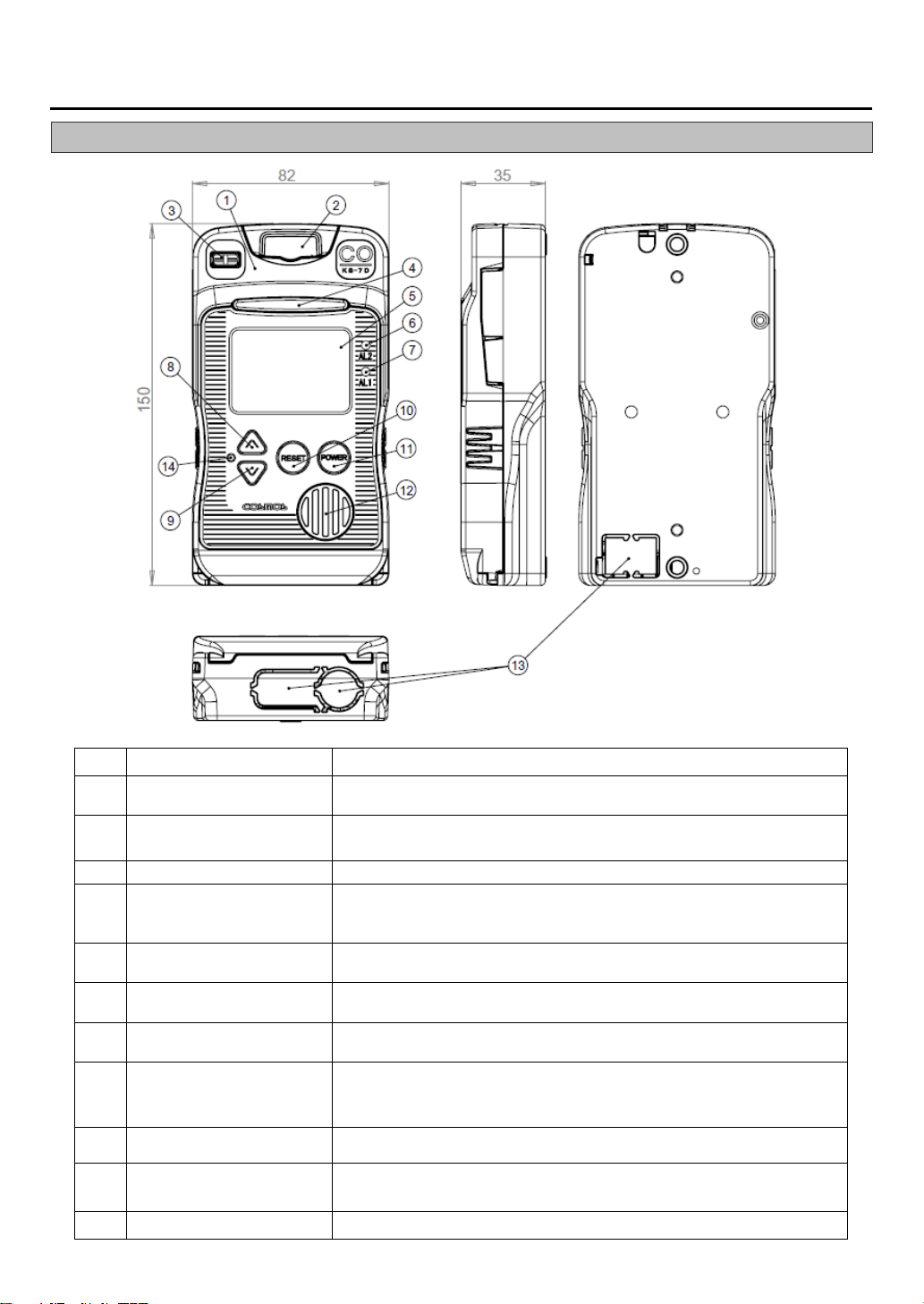

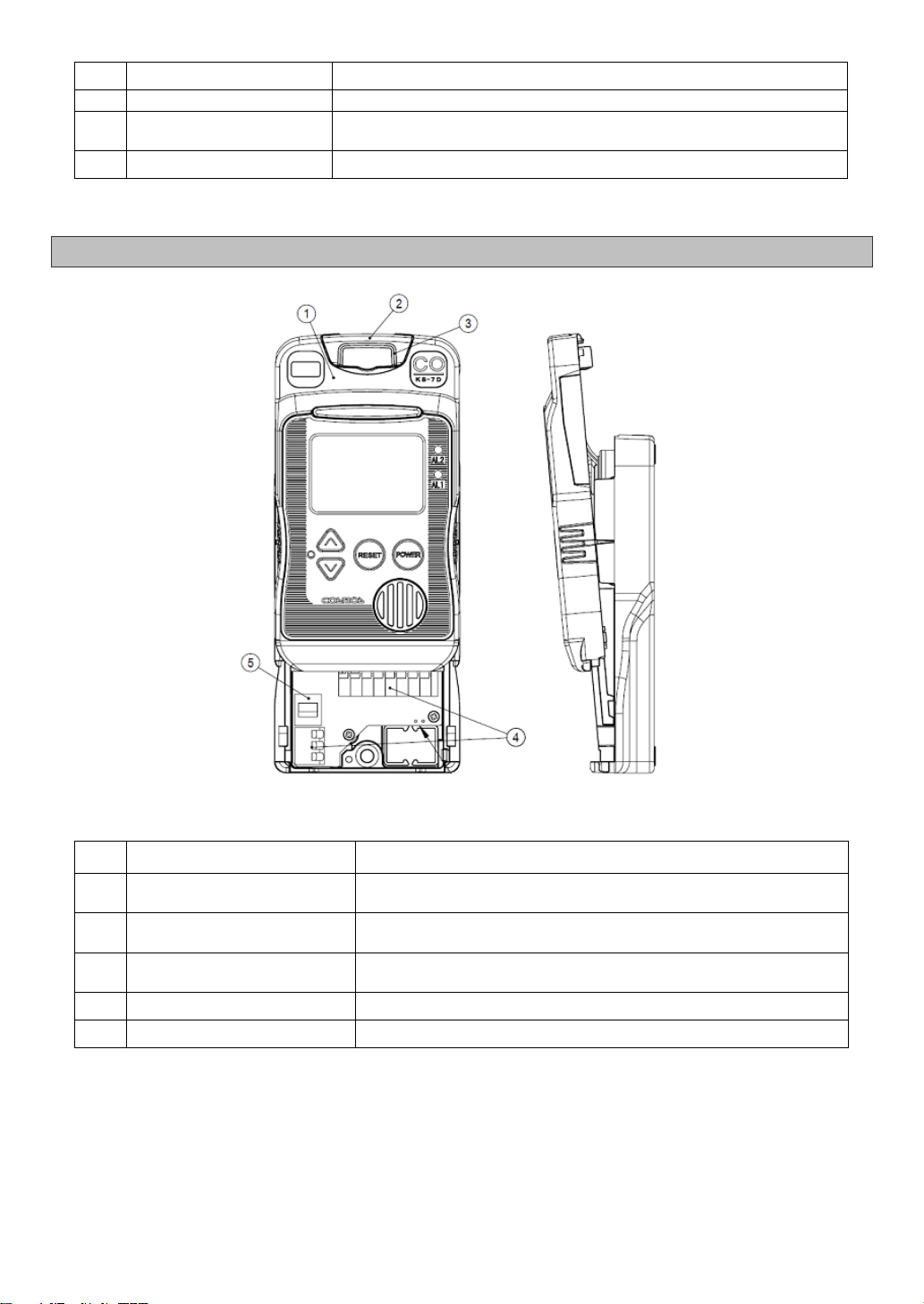

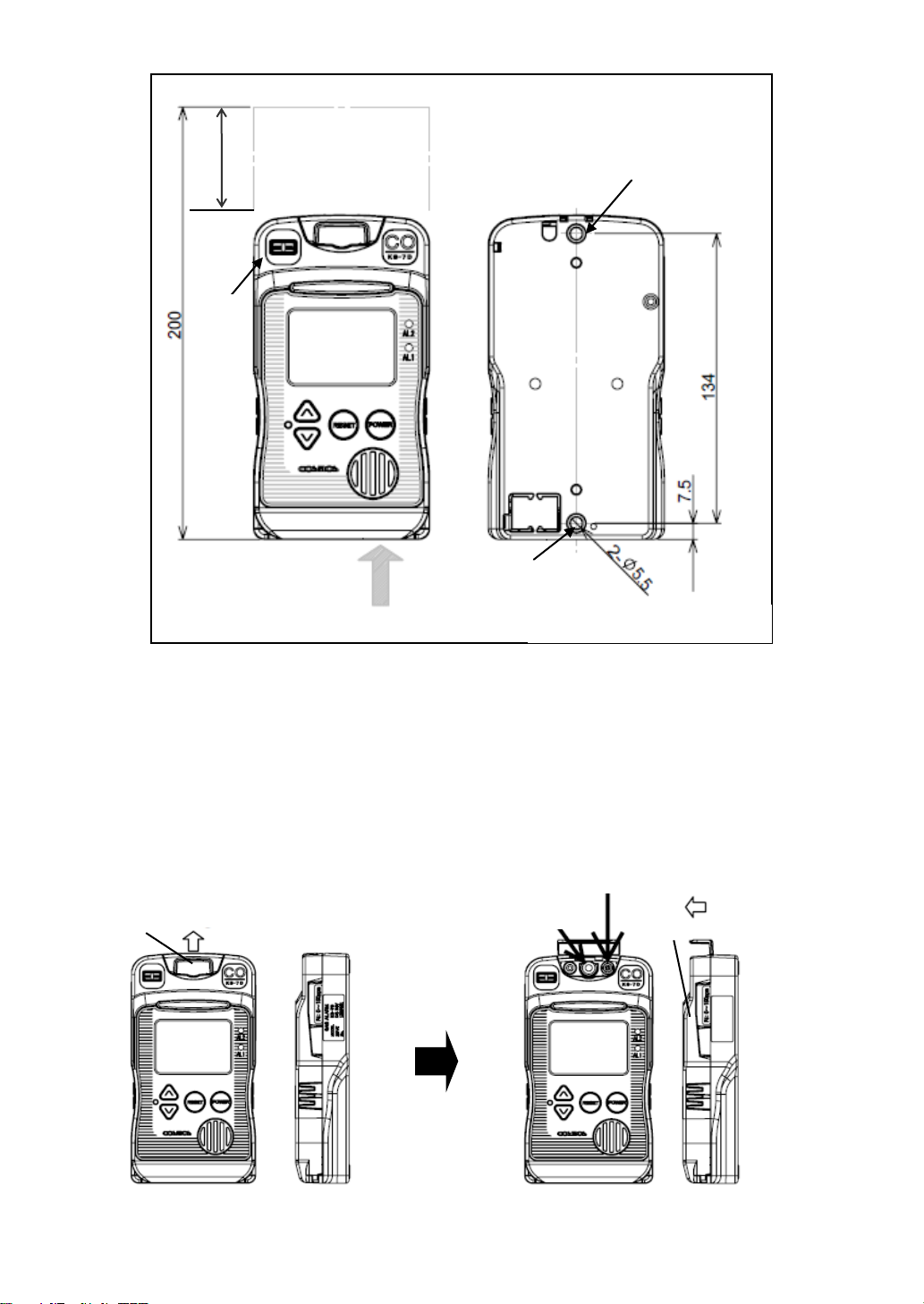

4. Unit Dimensions and Components............................................................................................4

4-1. Outer Appearance..............................................................................................................4

4-2. Inner Components .............................................................................................................5

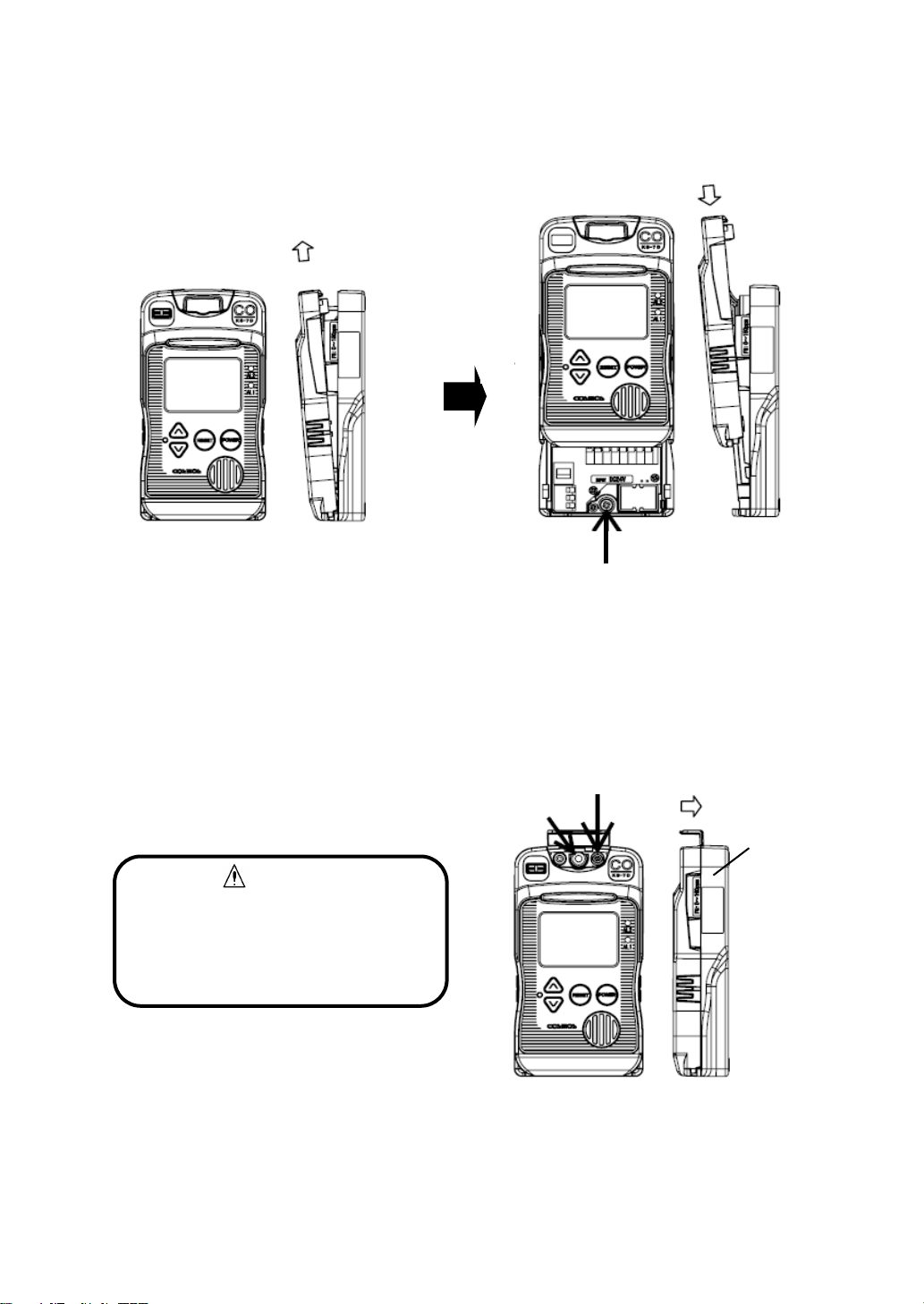

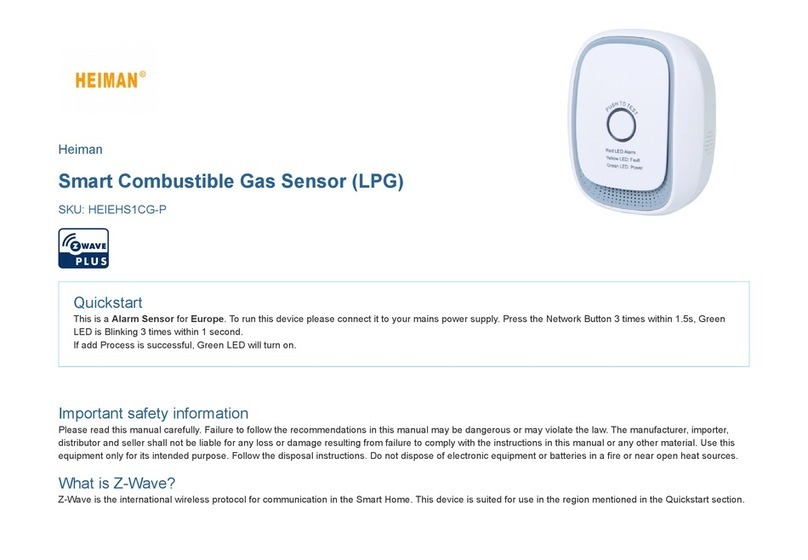

5. Installation .................................................................................................................................6

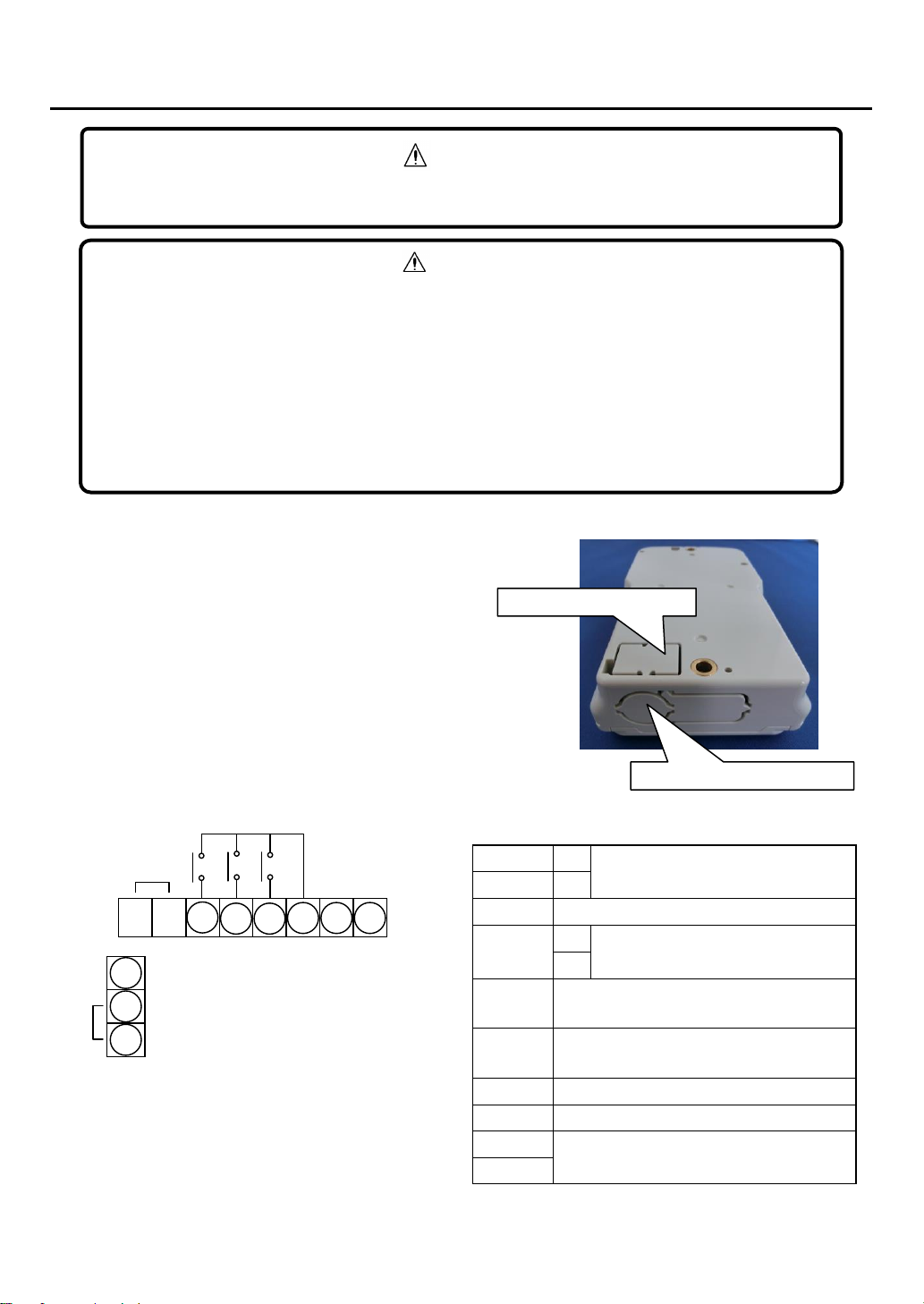

6. Wiring ........................................................................................................................................9

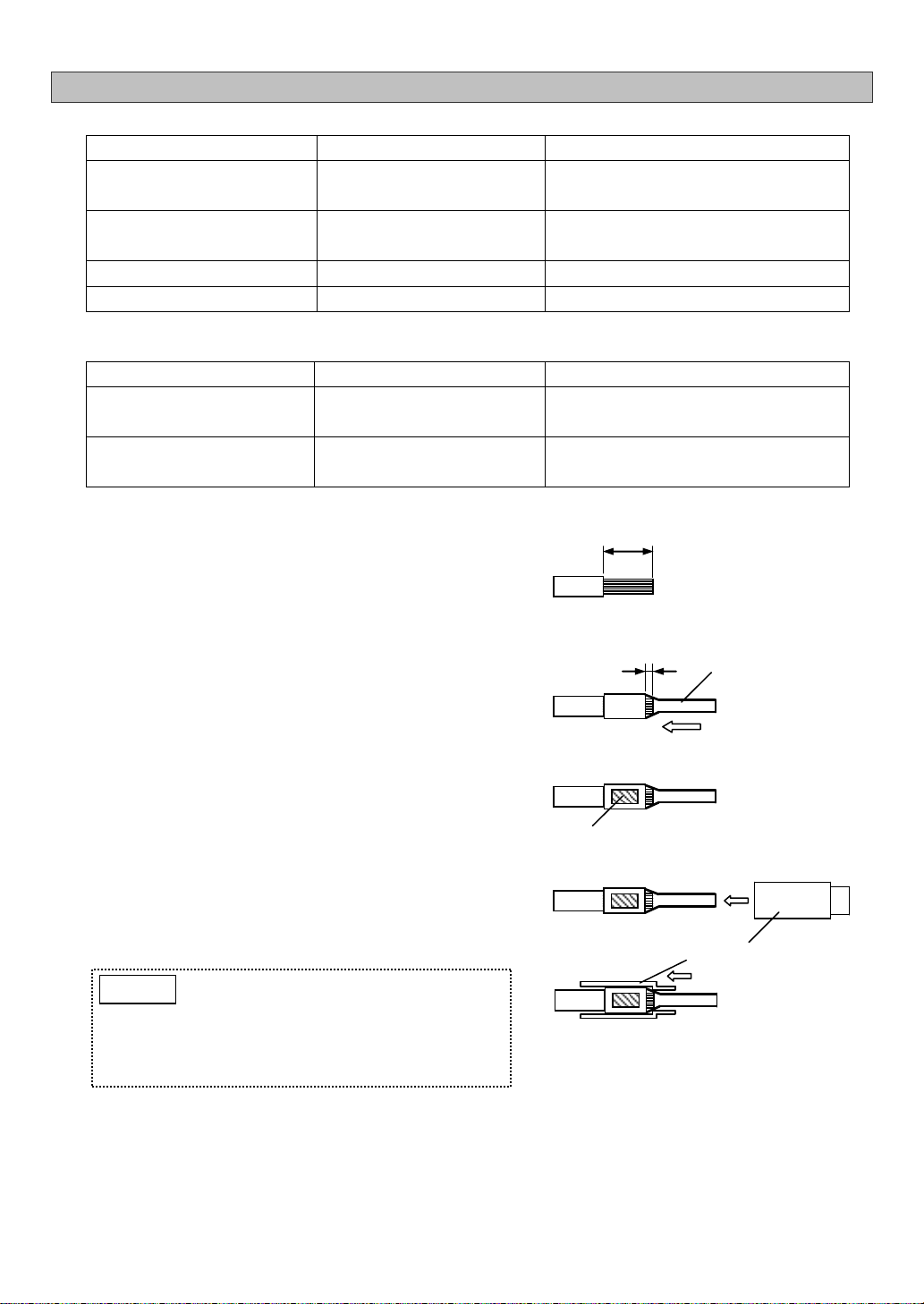

6-1. Pin Terminal/Insulated Sleeve Installation.......................................................................10

6-2. Wire Connection/Disconnection to/from Terminal Block..................................................11

6-2-1. Power Terminal Block ...............................................................................................11

6-2-2. External Output Terminal Block.................................................................................11

6-3. Cable Tie Installation .......................................................................................................11

7. Operation.................................................................................................................................12

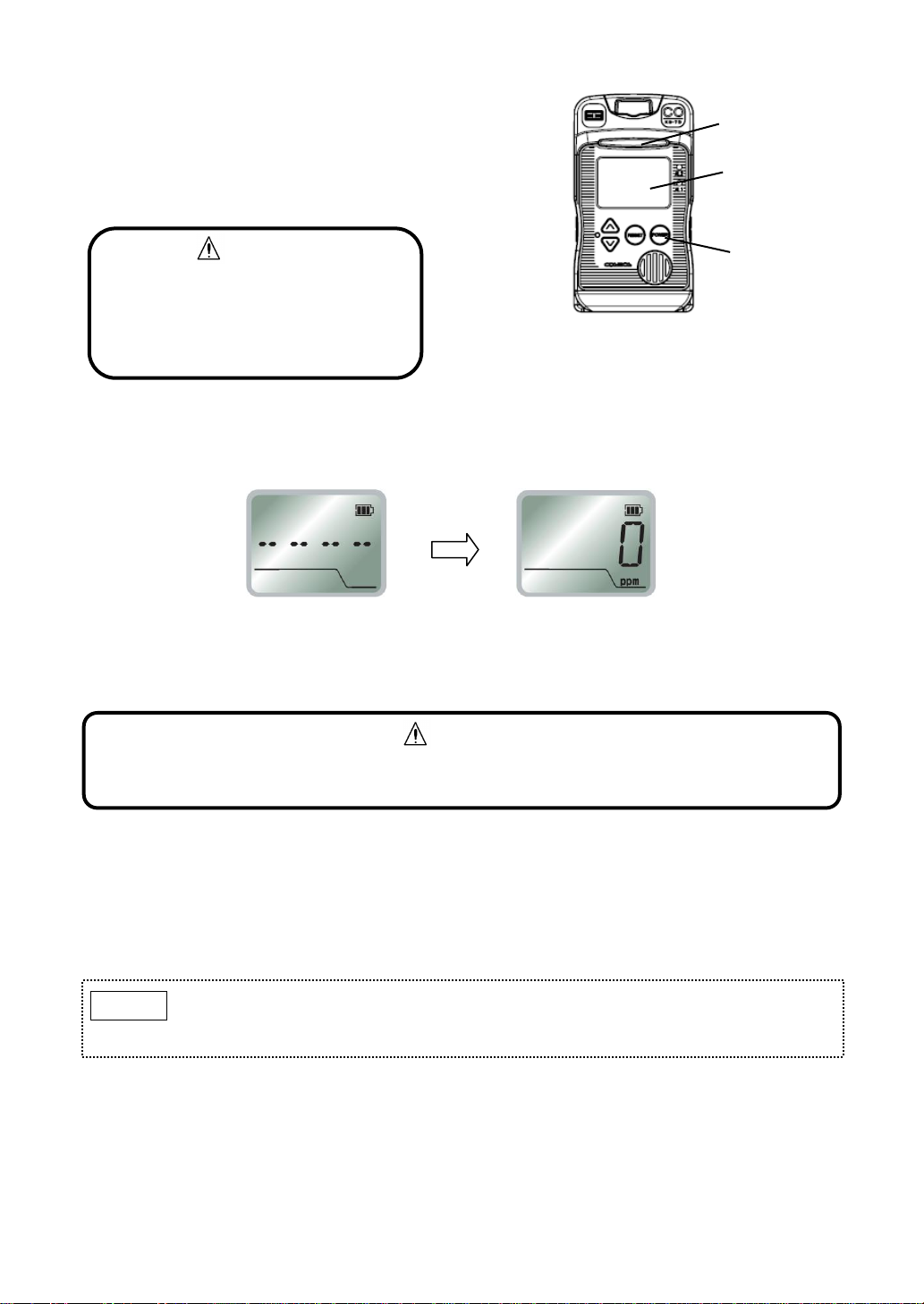

7-1. Precautions before Use...................................................................................................12

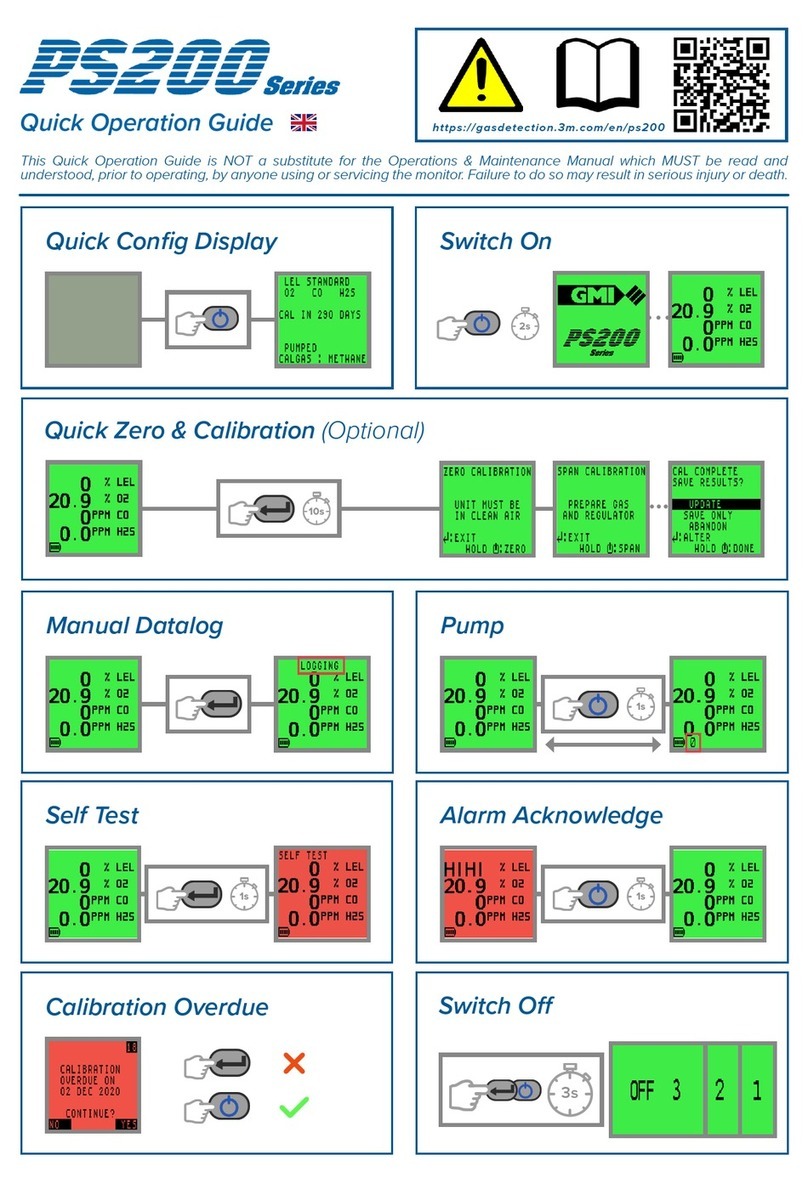

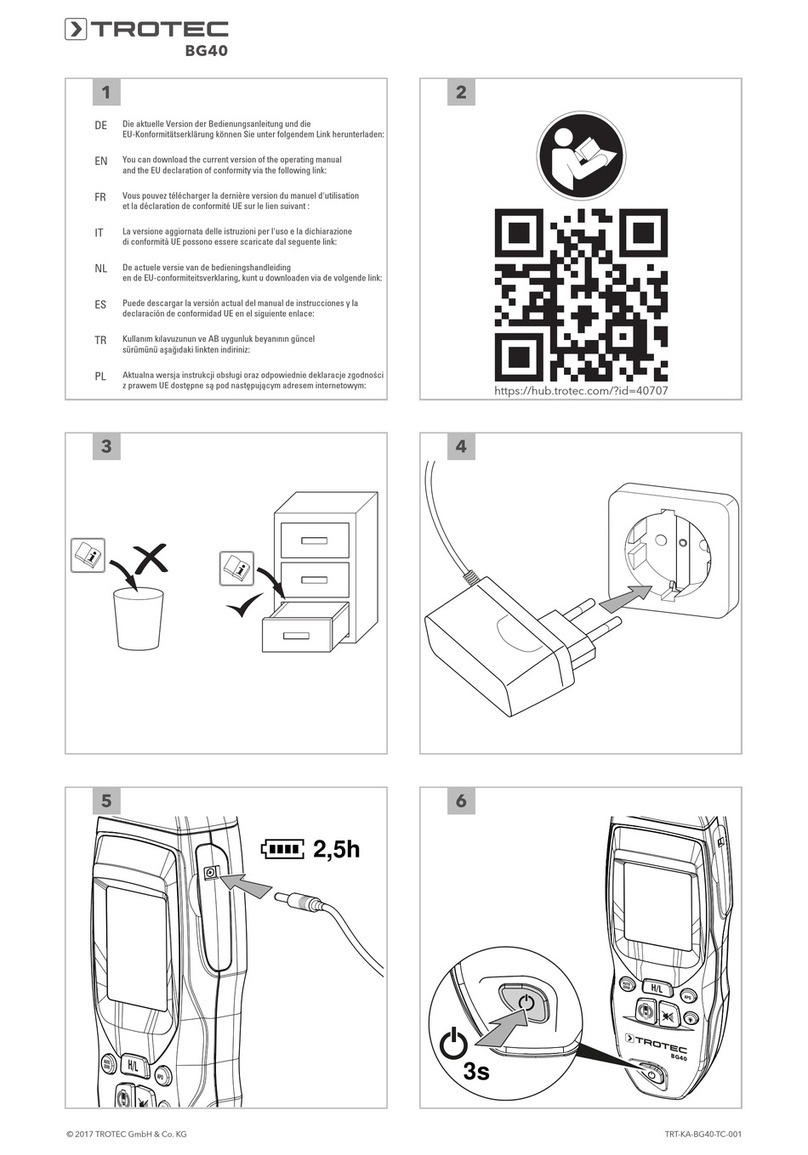

7-2. Operating Procedure .......................................................................................................12

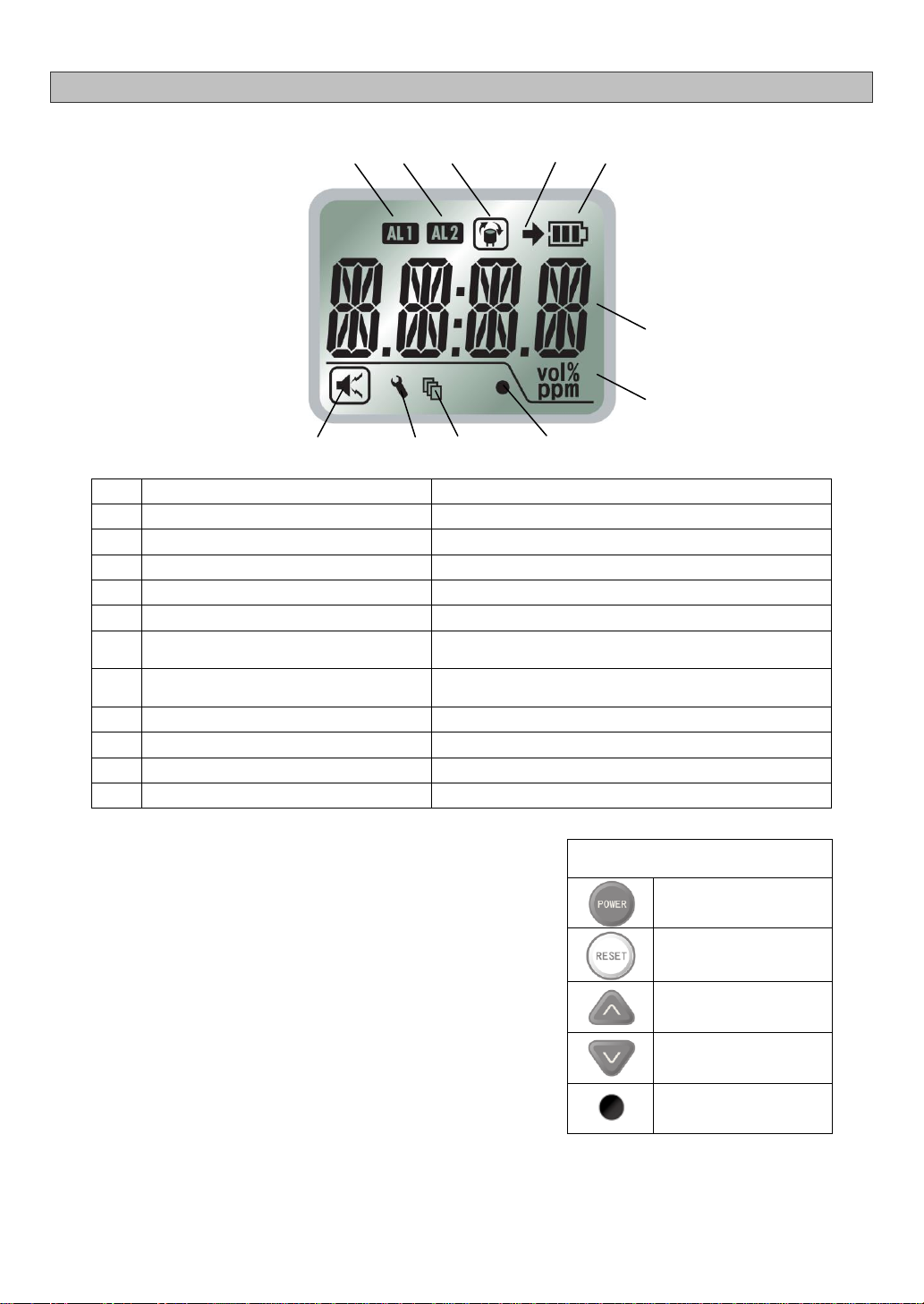

7-3. LCD Operation.................................................................................................................14

7-3-1. LCD...........................................................................................................................14

7-3-2. Normal Operation Status...........................................................................................14

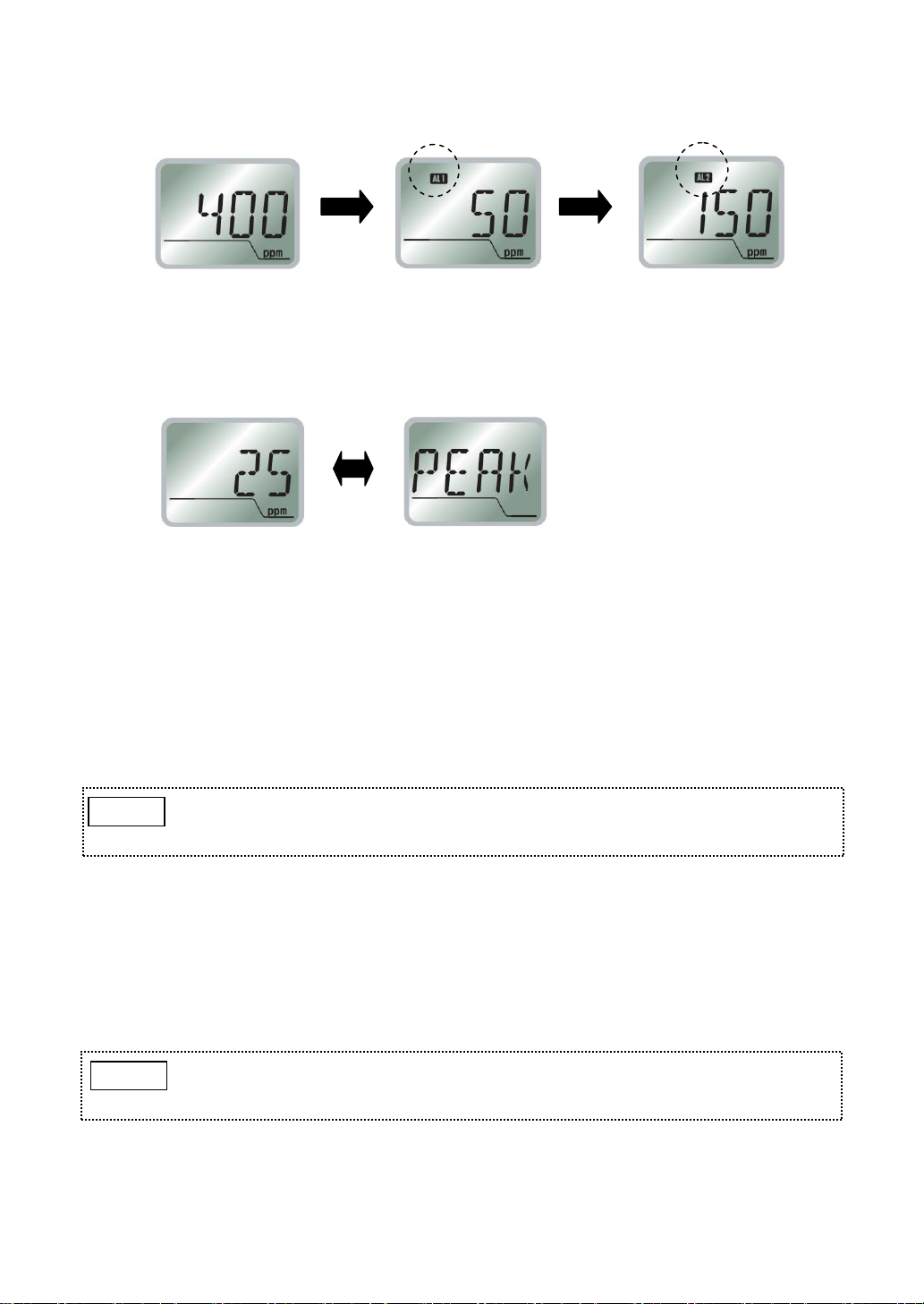

7-3-3. Full Scale and Alarm Set Values Display..................................................................15

7-3-4. Peak Value Display and Reset..................................................................................15

7-3-5. Operation during Gas Alarm .....................................................................................15

7-4. User Mode .......................................................................................................................16

7-4-1. User Mode Operation................................................................................................16

7-4-2. Switching Maintenance Mode On/Off [Mode1] .........................................................17

7-4-3. Zero Adjustment [Mode 2].........................................................................................18

7-4-4. Span Adjustment [Mode 3]........................................................................................18

7-4-5. Alarm Test [Mode 4] ..................................................................................................19

7-4-6. Alarm History [Mode 5]..............................................................................................20

7-4-7. Clock Setting [Mode 6]..............................................................................................21

7-5. Maker Mode.....................................................................................................................22

7-5-1. Maker Mode Activation..............................................................................................22

7-5-2. Operating Time Refresh............................................................................................22

7-5-3. Alarm Set Value Change...........................................................................................24

8. Maintenance............................................................................................................................25

8-1. Inspection Contents and Frequency................................................................................25

8-2. Backup/Clock Battery Replacement................................................................................27

9. Troubleshooting.......................................................................................................................29

10. Specifications.........................................................................................................................31

11. Warranty ................................................................................................................................32

12. Expected Sensor Life ............................................................................................................32

13. Detection Principle ................................................................................................................33

14. Glossary ................................................................................................................................34

15. Proper Product Disposal At End of Life.................................................................................35