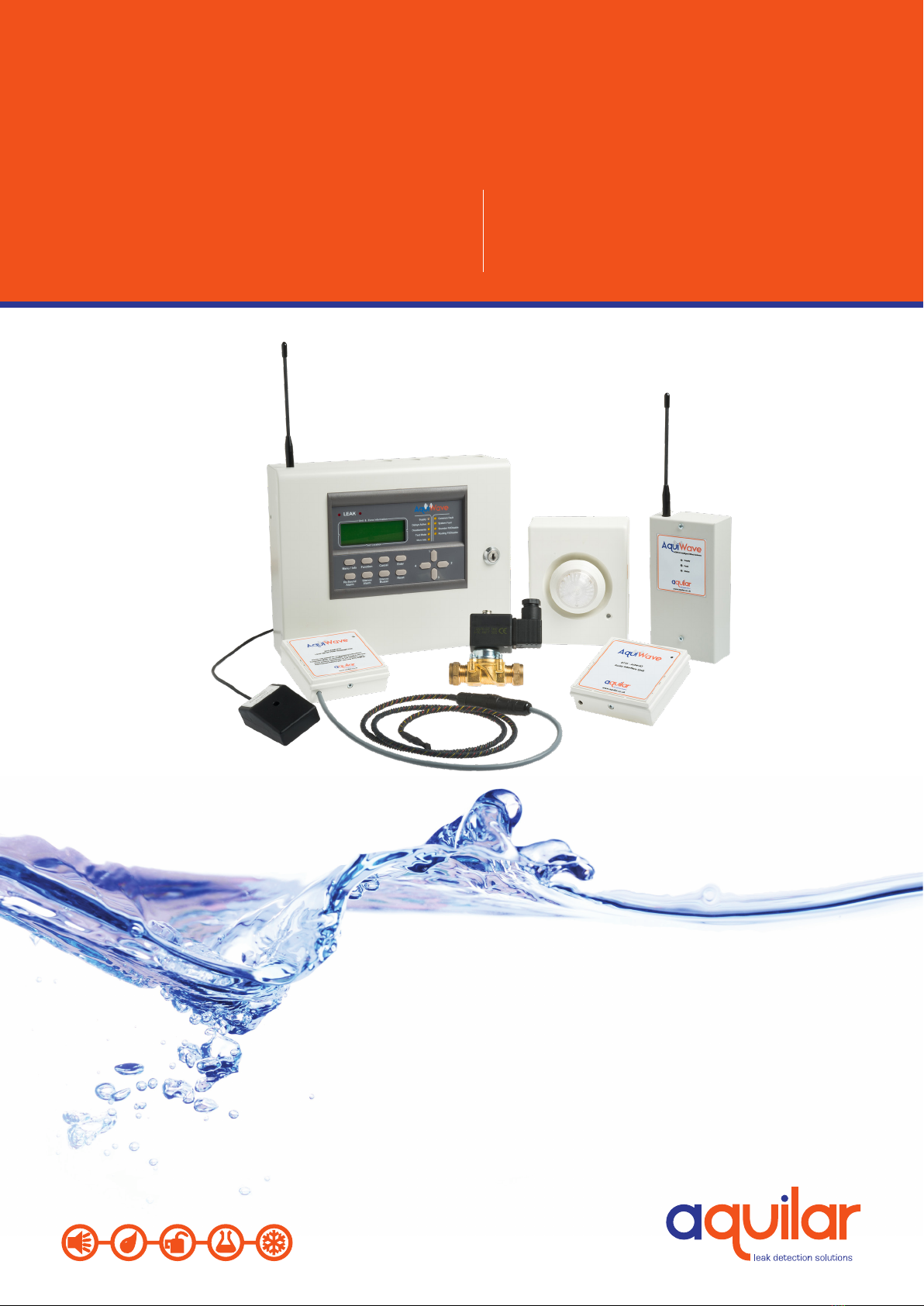

aquilar Aquitron User manual

AquiWave

Wireless Leak Detection System

Aquitron

INSTALLATION

INSTRUCTIONS

INSTALLATION ITEMS

(NOT SUPPLIED)

• Wall fasteners for surface mounting (four

screws)

• Rubber or elastomeric washers to seal

at mounting points

• Semi-ush recess ange (optional)

TOOLS REQUIRED

• Drill or hole punch for electrical

conduit entries

• Phillips (cross-head) screwdriver

• Small at-head screwdriver

STORAGE

Keep the module in a dry place prior to

installation to avoid possible damage to

internal components.

ADDITIONAL ITEMS

Please read these

instructions carefully

and keep them in a

safe place (preferably

close to the module)

for future reference.

These instructions

must be followed

carefully to ensure

proper operation.

AquiWave™

Wireless Leak Detection System

A. GENERAL INFORMATION

Based on the same ultra-reliable technology used for radio re alarm systems since 1987. The

AquiWave wireless leak detection system has been designed to be capable of handling 240

devices. Typical installations would include small oces, private houses, guesthouses and small

hotels and any location where traditional wired leak detection would be a problem to install.

This manual contains information to enable an engineer to install, service and operate the

AquiWave control panel and the range of AquiWave devices. This product should be installed,

commissioned and maintained by qualied service personnel in accordance with codes of

practice, statutory requirements and IEE regulations for electrical equipment in buildings. The

system has been designed to allow very simple set up, with a user friendly menu structure

and full-text capability. There is no need to connect devices with a programming lead, as

conguration is achieved by radio. Text locations can be entered on the panel itself or by

connecting a standard USB keyboard to the panel. Prior to installation, the building where the

system is to be installed must be surveyed to ensure that each device to be tted has a good

radio communication path to the control or booster panel. This is done with an AW-Survey Kit.

When installing devices, they must be positioned as per the survey. Installing a device even a

few inches from the surveyed position can aect the signal strength signicantly, especially if

any metalwork is contained in the ceiling above the new position (e.g. air-conditioning ducting).

IMPORTANT

Failure to perform an accurate survey could result in the system being unreliable. These errors

can be costly to correct

• Position the panel where it is to be installed.

• Ensure devices are surveyed for their exact positions. A few inches either side may

substantially aect the signal strength.

• In order to have an accurate survey the batteries in the survey detector should be changed at

least once a year.

LEAK DETECTION SOLUTIONS

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

1

AquiWave™

Wireless Leak

Detection System

LEAK DETECTION SOLUTIONS

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

2

MAXIMUM NUMBER OF ZONES

20

MAXIMUM NUMBER OF DEVICES

240

MAXIMUM NUMBER OF REPEATER

PANELS

7

MAXIMUM TOTAL NUMBER OF

ANTENNAS

15

DIMENSIONS (W X H X D)

275 x220 x 85mm not including antenna

WEIGHT

4kg Not including battery

OPERATIONAL TEMPERATURE

-5oC to +40oC

IP RATING

IP30

ALARM INDICATORS

Twin ashing red LEDs

LEAK message on LCD with 40 characters of

text

FAULT INDICATORS

Amber LEDs and LCD providing details and

location of fault with 40 characters of

location text

EVENT LOG MEMORY

1000 events maximum

MAINS SUPPLY

230V 50Hz 0.3A max

MAINS FUSE

1 x 250V 3.15A

BATTERY

1 x 12V 7.0Ah sealed lead acid giving 72 hour

standby

BATTERY FUSE

1 x 250V 3.15A

RELAY FUSES

4 x 250V 500mA

RS485 FUSE

1 x 250V 500mA

INPUTS

2 x wired monitored circuit. 4k7Ω (±5%) end

of line (EOL) resistor monitored for open and

short circuit, 470Ω (±5%) alarm load

RELAYS

4 x programmable

Leak Relay: Clean Contact

Fault Relay: Clean Contact

Fault Relay Safe: Clean Contact

Accessory Relay: 10-18V, 500mA, 4k7Ω (±5%)

EOL

Monitored Relay 10-18V, 500mA, 4k7Ω (±5%)

EOL

OPERATING FREQUENCY

868MHz (868.025 to 868.575MHz)

MODULATION

2-GFSK

OUTPUT POWER (ERP

<25mW (<14dBm)

CHANNEL SPACING

50KHz

ERROR CHECKING

CRC

ERROR CORRECTION

Hamming

NUMBER OF CHANNELS AVAILABLE

12

COMPATIBLE WITH

AquiWave products only

PROTOCOL

ZPNet V1.00

B. SPECIFICATIONS

LEAK DETECTION SOLUTIONS

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

3

AquiWave™

Wireless Leak

Detection System

CONTENTS

1.0 Installation

1.1 Contro Panel Installation

1.2 Transmitter Installation

2.0 Front Panel Layout

3.0 User Operation

3.1 System Normal

3.2 Fault Conditions

3.3 Silence Buzzer

3.4 Reset a Fault

3.5 Alarm Conditions

3.6 Silence the Alarm

3.7 Re-sound the Sounders

3.8 Reset the Alarm

3.9 Access Levels

4.0 Manual Operation

4.1 Quick Menu

5.0 Setup Menu

5.1 Time and Date

5.2 Access Codes

5.3 Default Access Codes

5.4 Programming Agent Details

5.5 Panel Information

5.6 Set up a New System (Standard)

5.7 User Options

5.8 System Options

5.9 Fault Options

5.10 User Tones

5.11 User Relays

5.12 Input Options

5.13 Input Text

5.14 Keyswitch Options

5.15 Panel Text

5.16 SIM Operations

5.17 Device Assignment

5.18 Panel Assignment

5.19 Add Antenna

5.20 Add Repeater/Booster Panel

5.21 Add Pager

5.22 Remove Hardware

5.23 Panel Network

5.24 Network Auto Congure

5.25 Device Information

5.26 Add Device

5.27 Remove Device

5.28 Remove All Devices

5.29 Edit Device

5.30 Device Text

5.31 Reprogram Device

5.32 System Test

6.0 Disable/Enable Menu

7.0 Test Mode

7.1 Test Zone

7.2 Clear Zone In Test

7.3 Lamp and Buzzer Test

7.4 System Test

7.5 Disable System Test

8.0 Event Log

8.1 Alarm Counter

8.2 View Event Log

8.3 Clear Event Log

8.4 Dump Event Log to USB

8.5 Save Event Log

8.6 View Saved Log

8.7 Shutdown Log

9.0 Verify Table

9.1 View Summary

9.2 View Detailed

9.3 Clear Verify Table

9.4 Dump Table to USB

9.5 View Panel Table

9.6 Clear Panel Table

10.0 View Airwaves

11.0 Battery Reset

12.0 Faults

12.1 Device Faults

12.2 Panel Faults

13.0 Delays

14.0 Common Problems & FAQ

15.0 Maintenance

16.0 Component Replacement

17.0 AquiWave Compatible Hardware

LEAK DETECTION SOLUTIONS

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

AquiWave

Wireless Leak

Detection System

1.1 CONTROL PANEL

INSTALLATION

The electronic components within the panel

are vulnerable to electrostatic discharges. It

is advisable to wear a wrist strap designed to

prevent the build-up of static charges within

the body before handing any electronic

components. Do not remove or unplug any

components while the panel is powered up.

MOUNTING

The panel should be mounted on an internal

wall in a suitable position. If tted, the

antenna should be away from any solid

objects, especially electronic equipment and

metal structures. The wall should be even,

clean and dry and not prone to vibration.

Should the wall not be level, the panel

should be mounted on a wooden board. The

temperature should be in the range of -5oC

to +35oC and the humidity should not exceed

95%. Mount the panel using 3 x No. 10 screws

of a suitable length, and ensure washers

(supplied) are used to meet the IP30 rating.

The smaller washer (25mm diameter) is to be

used for the mounting hole next to the PSU.

CABLING

A 230V AC 50Hz supply capable of providing

500mA with a minimum diameter of 7mm

and a maximum diameter of 10.5mm should

be derived from a separate fused spur. This

spur should not incorporate a switch and

should be labelled ‘Leak Alarm Equipment –

Do Not Switch O’. A cable with a core cable

size no greater than 2.5mm2 should be

used. Always ensure that the mains supply

is completely isolated before working on any

mains rated components.

Cables should only enter the panel housing

through the knockouts provided. Do not

remove more knockouts than is needed

to terminate the cables, as additional

apertures in the panel will compromise the

ingress protection. A nylon M20 IP66 cable

gland should be used. The cable should be

connected to the terminal block as labelled

from above with the Live (brown) connected

to the top terminal, the Earth (green/yellow)

to the middle and the Neutral (blue) to the

bottom. Care should be taken to ensure no

loose strands protrude from the terminal

block and that the wire insulation is trimmed

to the correct length so that no exposed

wire is left visible. Any earth cables should

not be removed. Once the connection has

been made, the panel fuse (3.15A ceramic T

type) should be removed from the panel by

pulling on the fuse holder. The fused spur

can then be energised. To power up the

panel, insert the fuse holder with the correct

value of fuse tted. As there is a high inrush

current there is likely to be a spark produced.

This is normal. Mains power should always

be applied prior to connecting the standby

battery. Once the mains supply has been

applied, the green LED on the bottom edge

of the processor board should begin to ash

once a second. The system normal screen

will be displayed. Connections to the panel

inputs should be made using 2 core cable

with a core diameter of 1.0mm2. A nylon M20

IP66 cable gland should be used. A suitable

core diameter should be used depending on

the loading of the circuit. The Panel has been

type approved to IP rating IP30.

BATTERY

An AT-BU (part no: 3485) battery should

be tted. This will give a 72 hour standby,

assuming no external equipment (e.g.

wired antennas) has been added. Connect

the battery using the supplied terminal

connections. The red wire is +12V and the

black wire is 0V. Do not confuse the colour of

the terminal connectors. Once connected, the

Reset button on the keypad can be pressed. If

‘Battery Fault’ appears; check the connections

and polarity. If the battery is connected

4

LEAK DETECTION SOLUTIONS

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

AquiWave

Wireless Leak

Detection System

incorrectly it is likely that the fuse will blow.

The wiring should be corrected and the fuse

The PSU will only charge batteries measuring

10.5V and above. Batteries measuring less

than 10.5V are regarded by the system as

faulty and will not be charged. A ‘Battery

Fault’ will be displayed on screen. If the

battery voltage is below 10.5V it will need to

be removed from the panel to be charged

and reconditioned, or replaced. The battery

voltage can be viewed on the PSU Info section

of the 5.5 – Panel Info menu. When replacing

the battery always do so with a product

of equal specication. Always dispose of

batteries responsibly. Never dispose of

batteries in general waste. If unsure contact

your local authority for guidance.

ANTENNA (IF FITTED)

The standard helical stub antenna (part

no: 6775) supplied with the panel should

be tted to the antenna bracket assembly

before it is mounted into the panel. Fit the

antenna onto the SMA connector as shown

below. This should be screwed hand tight.

Over tightening will cause the antenna to

break. The supplied antenna retaining washer

should then be placed over the top of the

antenna. The antenna and bracket assembly

should then be inserted through the antenna

aperture and mounted using the supplied M3

screw and an M3 serrated locking washer.

Once mounted, the antenna retaining washer

prevents the stub antenna being unscrewed

from outside the panel. Connect the antenna

assembly to the main processor board using

the SMA connector. If a high gain remote

antenna is being used, the stub antenna and

the antenna bracket assembly should be

removed. The new antenna should be tted

using a 50Ω SMA connector, suitable for use

with RG58 c/u coaxial cable, to the processor

board. When making o the cable, ensure

that no stray shielding wires are shorting.

Do not use non-radio connectors as they will

reduce the performance of the panel.

MONITORED INPUTS

The panel features two monitored inputs

that can be programmed either as latching

or non-latching. It is important to note that

before using these inputs they must be

enabled by programming them in the panel

options menu. If the inputs are enabled then

4K7Ω end of line resistors must be tted at

the termination. Applying a 470Ω resistor

across the inputs will produce a ‘LEAK’

message. The inputs are labelled ‘INPUTS’ and

‘No1’ and ‘No2’. These inputs can be assigned

a zone and text location, and then cause and

eects can be programmed for them. See

5.12 – Input Options for further information.

5

LEAK DETECTION SOLUTIONS

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

AquiWave

Wireless Leak

Detection System

PCB LAYOUT

RS-485 CONNECTIONS

The RS485 connectors are used for wiring

hardware to the panel such as extra antennas

or a secondary display. A suitable data cable

should be used with 2 sets of twisted pairs.

Cat 5/5e/6 can be used but is not re rated.

Wired antennas and displays have two RS485

connectors, making it possible to make a

chain of up to 4 units. On the last unit in any

chain, a 100R resistor should be tted across

the D- and D+ terminals of the unused RS485

connection. If one of the control/booster

panel RS485 ports is unused then a 100R

should be tted between D- and D+. If none

of the panel RS485 ports are used then there

is no need to t the 100R resistor. The RS485

ports are capable of supplying 500mA at 15V.

PANEL RELAYS

The panel is equipped with four

programmable relays, each capable of

supplying 500mA. The total current draw

across all four relays must not exceed 1A. The

default relay types are:

Relay 1: Fault Relay - This activates on a fault

alarm condition. The default setting is Type

2 volt free fault relay. If set to type 3 or 5 the

relay can be used to power accessories (i.e.

Beacon or sounder). It switches 12V onto the

output and is monitored for short and open

circuit, with a 4K7Ω EOL. In this situation the

circuit should be connected between the C

and the NO terminals. The fuse should be

tted and the links put in the lower position.

Relay 2: Fault Failsafe Relay - This

energises on power-up and de-energises in

fault. Consequently the normally open and

normally closed terminals are reversed. The

fuse should be removed and the links tted

in the upper position as shown on the PCB

layout diagram.

6

LEAK DETECTION SOLUTIONS

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

AquiWave

Wireless Leak

Detection System

Relay Type Normal State Contacts in Alarm Fuse EOL Link Position

1. Leak Relay Not energised Clean contact None None Up/Right

2. Fault Relay Not energised Clean contact None None Up/Right

3. Sounder Circuit -4.5V 500mA +15V 500mA 500mA 4K7 Down/Left

4. Fault Relay Safe Energised Clean contact None None Up/Right

5. Accessory Circuit -4.5V 500mA +15V 500mA 500mA 4K7 Down/Left

DISPLAY CABLE

A ribbon cable connects the two panel boards

together. It should be connected to the

system link/bus connections on the boards.

Do not remove or connect the ribbon cable

while the panel is powered up, as damage

can occur to the processor board.

BUZZER LINK

The buzzer can be disabled by removing the

buzzer link (see page 8 – PCB Layout).

MEMORY CARD

The memory card stores a complete set of

the system settings including device/zone

text and options. The memory card should

be tted at all times unless instructed by the

panel (i.e. when adding a repeater panel).

USB SOCKET

The USB socket can be used for connecting

a keyboard to program device text. It is also

used to plug in a memory stick to download

the event log, device info and the verify table

so a hardcopy can be retained for records.

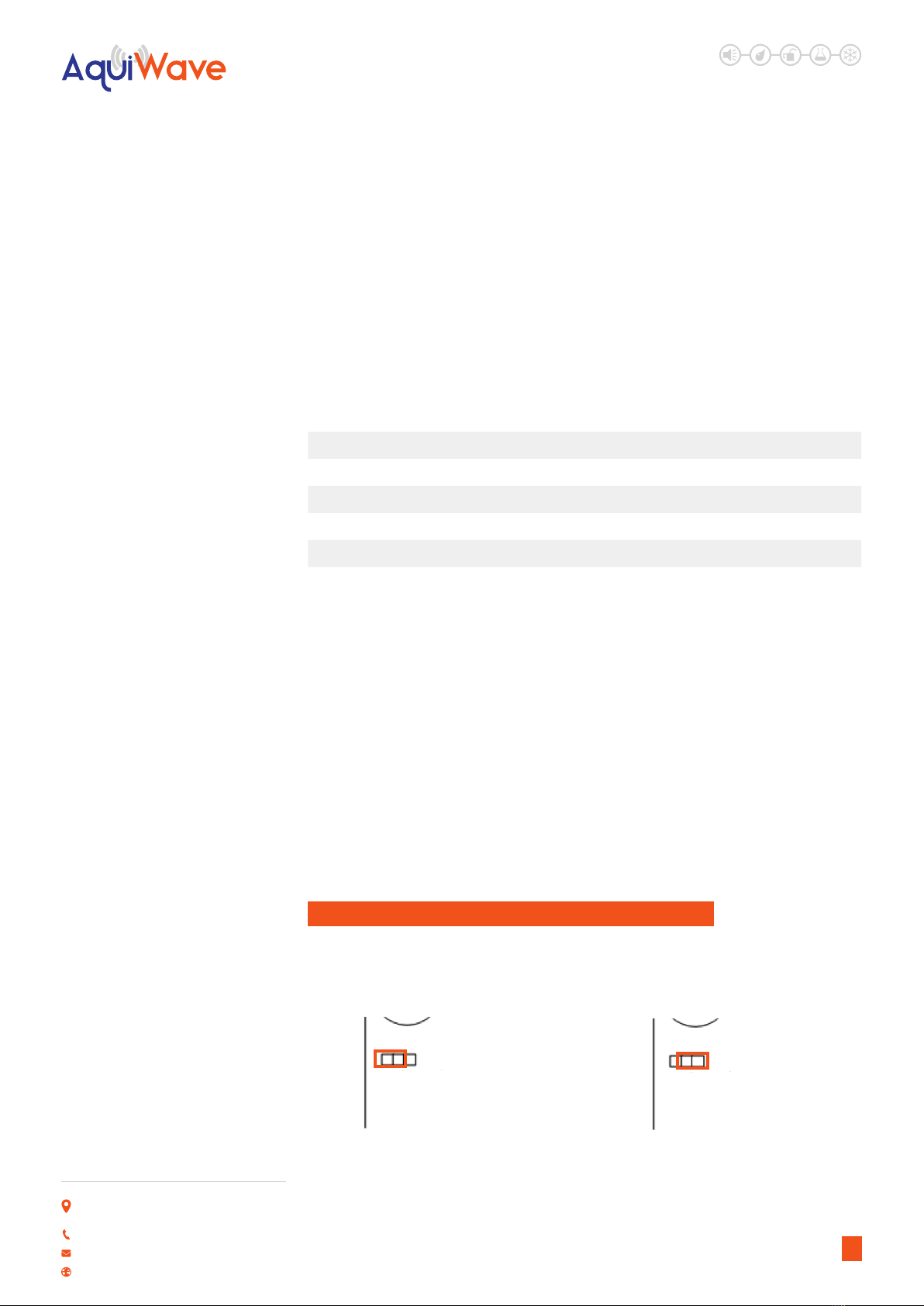

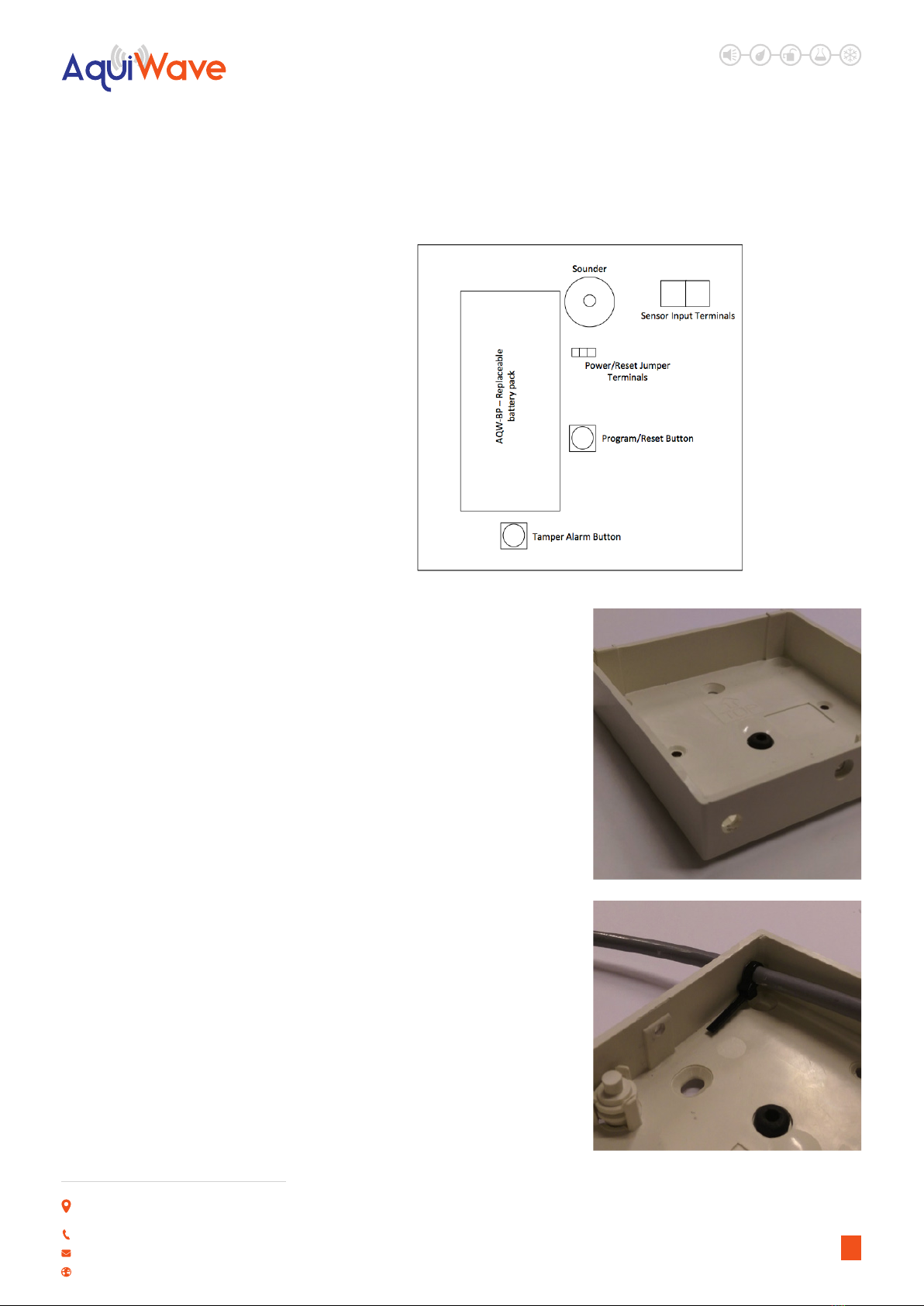

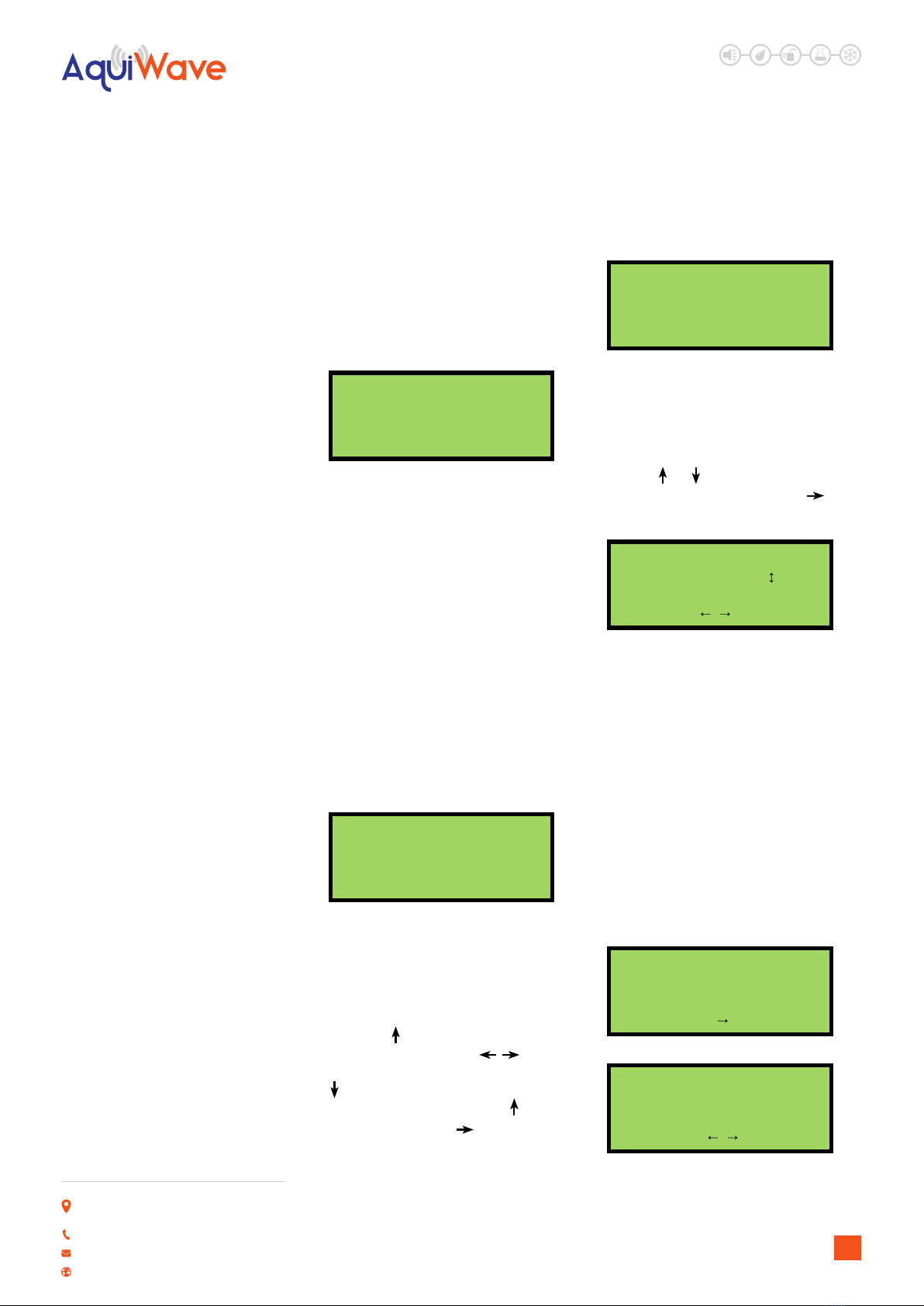

1.2 TRANSMITTER (AQW-RTX) INSTALLATION

The AquiWave radio transmitter units (AQW-RTX) contain delicate electronic components and

should always be handled with care.

ON JUMPER POSITION OFF JUMPER POSITION

Power/Reset Jumper

Terminals

Power/Reset Jumper

Terminals

Relays 3 & 4: Leak Relays -Default setting

is volt free. These relays are each capable of

supplying 500mA at 12V. Both the sounder

circuit fuses should be tted in the fuse

holders and the links tted in the left or

lower positions as shown on the PCB layout

diagram. The circuit should be connected

between the S+ and the S- terminals. A

4K7Ω end of line resistor should be tted

to monitor the circuit. The relays can be

congured as accessory circuits, sounder

circuits, monitored outputs or volt free

clean contact relays. The relay type can

be changed in 5.7 – User Options and by

positioning the jumper links and fuses as

detailed below. When relays are congured

as ‘Volt Free’ accessory or as sounder circuits,

the associated terminal pin (V+) must not be

used.

7

LEAK DETECTION SOLUTIONS

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

AquiWave

Wireless Leak

Detection System

When xing the AQW-RTX care must be

taken choosing its location. Consideration

must be given to its physical and potential

environmental surroundings. The transmitter

itself is not IP rated and must not be

positioned in an area that will get wet if a leak

occurs. It is recommended a leader cable be

run from the transmitter to the leak sensor,

positioned in the potentially wet area. If the

tamper feature is to be used, the transmitter

must be rmly xed back to an even surface.

IMPORTANT NOTE: It is important to locate

the transmitter in the position indicated

during the site suitability survey. Even

moving a small distance could potentially

aect its performance. If the AQW-RTX is

relocated, its radio connection to the system

in its new position must be veried as

suitable. If a descriptive location reference

has been added to the main control panel

programming, this should also be altered

accordingly.

Prior to xing a small 5.5mm hole should be

drilled into the bottom left corner of the back

box for leader cable entry.

8

LEAK DETECTION SOLUTIONS

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

AquiWave

Wireless Leak

Detection System

The two core leader cable should be

terminated into the sensor cable terminals.

Only connect one leader cable/sensor to each

AQW-RTX.

Once the back box is in place and sensor

connected follow the instructions in

section 5.26 to add the device to the

system.

The AQW-RTX has anti-tamper and sensor

fault monitoring. Both removing the sensor

and/or the box will register as a fault on the

control panel.

The ant-tamper can monitor both device

removed and device open. Both are achieved

by using the spring loaded button positioned

on the back box.

NOTE : By default this is set for device

open only. For Device removal the

retaining clips must be removed to allow

the button to protrude from the rear of

the box. In this case the box must be xed

to a at surface to prevent a removal fault

showing on the control panel.

9

LEAK DETECTION SOLUTIONS

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

AquiWave

Wireless Leak

Detection System

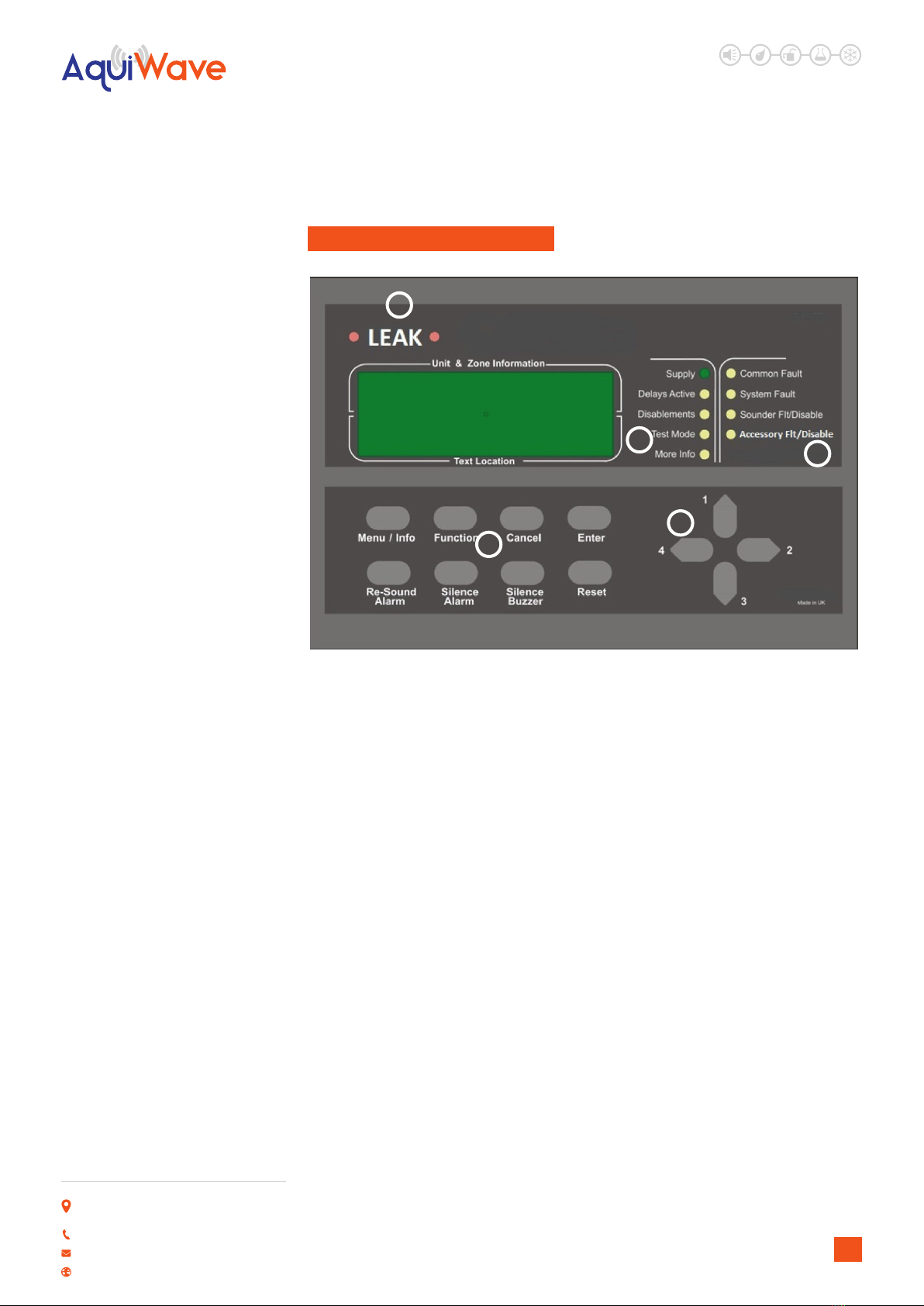

2.0 FRONT PANEL LAYOUT

1 LEAK LEDS

In a Leak condition, these LEDs will ash.

3 STATUS LEDS

Supply: This LED will be illuminated when

mains power is present.

Delays Active: Illuminated if delays are

enabled.

Disablements: Illuminated for any

disablement.

Test Mode: Illuminated if any test modes are

operational.

More Info: More information on the system

condition is available in the event log.

4 FAULT LEDS

Common Fault: Device or panel has a fault.

See main display for details.

System Fault: Fault that aects system

performance. See main display for details.

Sounder Flt/Disable: If the LED is ashing,

there is a fault with one or more sounders.

If the LED is solid, the sounders have been

disabled.

5 KEYS

Menu/Info: Press to initiate the menu

system. If held down for longer than 2

seconds, the LEDs will follow a test sequence

(lamp test).

Function: This button is disabled by default,

though it can be programmed to do a

number of functions. See 5.7 – User Options.

Cancel: Used to return to the main screen

from a menu or to return to the menu from a

programming screen.

Enter: This is used to accept information

programmed into the panel.

Re-sound Alarm: Following an alarm

condition that has been silenced, this button

will re-sound the alarm.

Silence Alarm: If the panel is in a leak

condition this will silence the sounders.

Silence Buzzer: Silences the panel buzzer for

all currently displayed faults or alarms.

Reset: Resets the panel from an alarm or

fault condition. Note that the system must be

silenced before it can be reset from a leak

condition.

1

34

5

6

10

LEAK DETECTION SOLUTIONS

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

AquiWave

Wireless Leak

Detection System

6 NAVIGATION KEYS

Use to navigate through the menu structure

and programming/status screens. In a

multiple fault or alarm condition, the up and

down arrow keys allow the user to scroll

through all the current events. The display

will also scroll automatically every 4 seconds.

The navigation keys are numbered 1 to 4.

This is to allow the user to enter a 4 digit

access code when prompted.

3.0 USER OPERATION

3.1 SYSTEM NORMAL

In normal operation the screen will show

either the date and time, or the supplier/

service contact details. The unit can also be

congured to alternate between the two. If

congured this way, the display will change

every 4 seconds. See 5.4 – Programming

Agent Details. Also a single green ‘Supply’

LED will be illuminated.

Tuesday

01-01-2013

12:04:36

3.2 FAULT CONDITIONS

If a fault occurs, the internal buzzer will sound

and a message will be displayed. The rst line

details the current fault number, the zone

and the type of fault. The second line details

the device type and the device number. The

third and fourth lines display the device

location text (if programmed). The description

has a maximum length of 40 characters

across 2 lines. Appropriate action should be

taken to remedy the fault as this may aect

the operation of the leak alarm system. If in

doubt, the system maintenance company

should be contacted. If more than one fault

exists on the system they will scroll round

every 5 seconds. Pressing the or cursor

key will display the next or previous fault.

001 Zn:001 VFY FAULT

Leak Detection TX

001

Entrance Hall

3.3 SILENT BUZZER

If the panel buzzer is sounding following a

fault or alarm, it can be silenced with the

Silence Buzzer key. Once the Silence Buzzer

button has been pressed the panel assumes

that the fault has been acknowledged and

does not re-sound the buzzer, unless a

new fault occurs. The LED on the device will

continue to ash until the fault is reset – see

below.

3.4 RESET A FAULT

A fault will be displayed on the panel until

the system is reset, even if the fault condition

has been rectied. Assuming the fault has

been rectied; pressing Reset on the panel

will reset the panel and the devices on which

the fault has occurred. The system normal

screen will then be displayed. If the fault

is still present or re-occurs, it will be re-

displayed. Where there are multiple faults,

all will be reset at the same time. It is not

necessary to silence a fault before resetting

it. The particular device or devices in fault will

also ash a green LED and beep. The system

silence and reset function can be protected

with an access code by turning on ‘Code

Protect’; see 5.8 – System Options.

11

LEAK DETECTION SOLUTIONS

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

AquiWave

Wireless Leak

Detection System

Resetting

Please Wait

3.5 ALARM CONDITIONS

In a leak Alarm condition, a screen similar to

this will be displayed. The leak LEDs will ash.

Assuming the system is programmed to do

so, the leak relays will be activated. The rst

line of the display shows the event number

and the zone number. The second line details

the device type and its number. If the device

location has been programmed into the

panel, it will be displayed on the third and

fourth lines. Scroll through multiple alarms

using the and keys.

001 Zone 001

Leak Detection TX

001

Conference Room

3.6 SILENCE THE ALARM

Only when the leak or fault has been

investigated should the Silence Alarm button

be pressed. The system silence and reset

function can be protected by an access code

by turning on ‘Code Protect’; see 5.8 – System

Options.

3.7 RE-SOUND THE SOUNDERS

There may be times when the sounders have

been mistakenly silenced – for example if the

alarm was genuine but someone pressed

silence. The Re-Sound Alarm button followed

by a valid access code will activate the

sounders again.

3.8 RESET THE ALARM

Assuming the reason for the alarm condition

has been investigated; pressing Reset after

silencing the alarm will return the system

to its normal operation screen and reset

the devices that prompted the alarm. The

system silence and reset function can be

protected by an access code by turning on

‘Code Protect’; see 5.8 – System Options.

If code protect is enabled the user will be

prompted to enter a valid access code using

the navigation keys before being able to reset

the system.

If a device has remained in alarm (i.e. the leak

has not been cleared/dried, or fault rectied)

after silencing the alarm and pressing Reset,

the panel will redisplay the alarm and go back

into an ‘alarm state’.

3.9 ACCESS LEVELS

The panel is protected from misuse by means

of four access levels. The access levels are as

follows:

Level 1: Untrained user

Level 2A: Basic user

Level 2B: Advanced user

Level 3A: Service and Maintenance Engineer

Level 3B: Commissioning Engineer

Level 4: Manufacturer – Access tools required

Enter Access Code

----

A Level 1 untrained user can view the current

system state including any faults, alarms,

disablements and tests. They can also silence

and reset alarms unless code protection has

been enabled. See 5.1 – Quick Menu.

A Level 2A basic user can view the current

operational condition of the system, access

the disable/enable menu and may silence

and reset alarms with code protection active.

A Level 2B advanced user in addition has

access to test mode and the event log.

A Level 3A engineer in addition has access to

system and device information and the verify

table.

A Level 3B commissioning engineer has

access to all system options, including

programming and conguration of devices

and hardware.

12

LEAK DETECTION SOLUTIONS

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

AquiWave

Wireless Leak

Detection System

All menus, settings and options described in

this manual show the required access level in

the title. For example: 7.4 - Enable System Test

– service and commissioning users

Each access level (excluding level 1) requires

a 4 digit code to access the menus. See 5.2 –

View Access Codes.

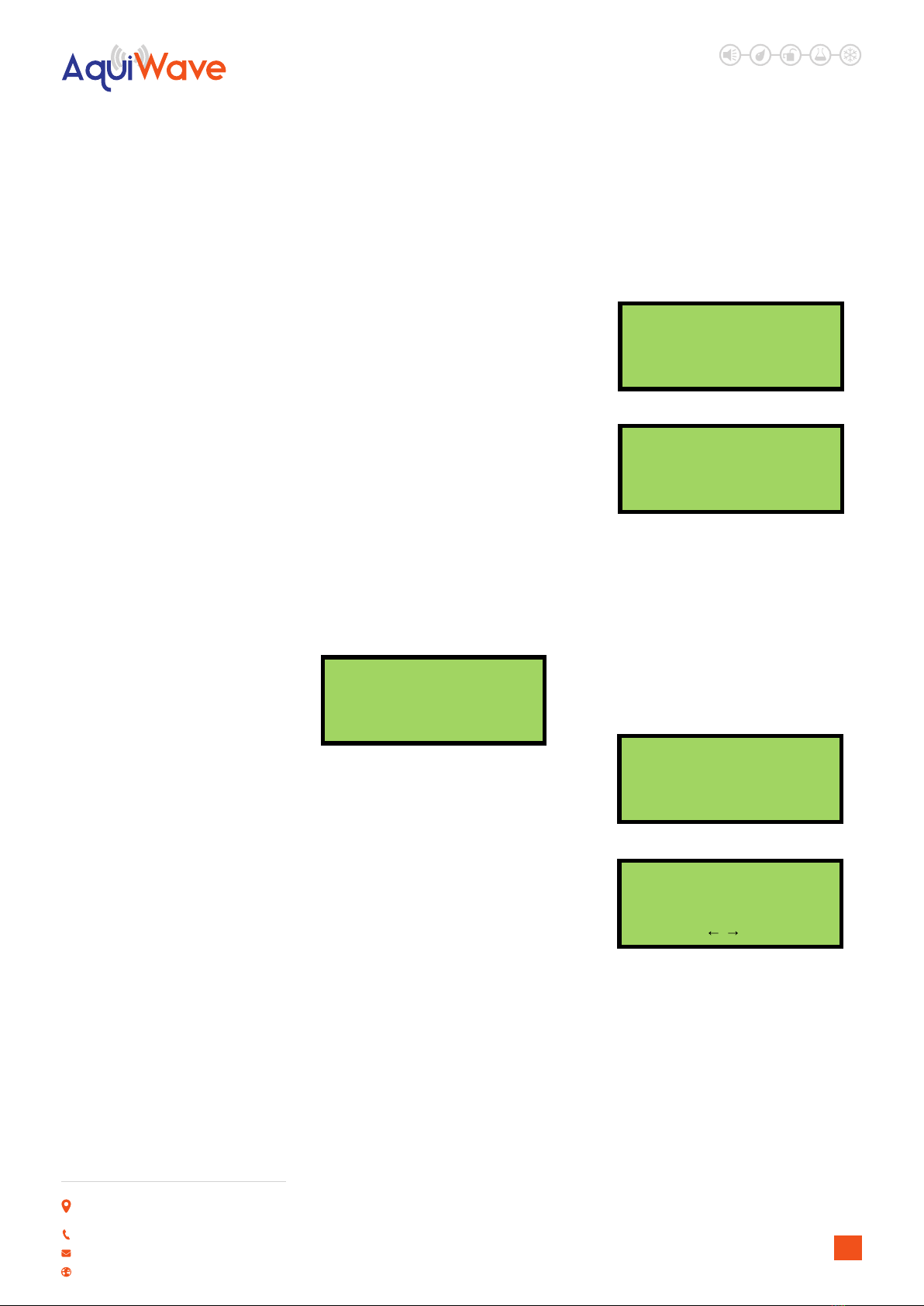

4.0 MENU OPERATION

To enter the menu system, press Menu.

This will display an overview of any alarms,

faults, disablements or tests that are

currently active, along with an option to

access the Main Menu. The options available

on the main menu and sub-menus will be

dependent on the access code entered and

its corresponding access level. To scroll

through the menu the and keys should

be pressed. In order to select a menu option

the key should be pressed. To return to

the previous menu screen from a sub-menu

the key should be pressed. Pressing

Cancel will return to the system screen

where any faults or alarms will be displayed

if present.

For every menu option listed in this manual,

its place in the menu structure will be shown

in grey text underneath the heading. For

example, the event log can be found by

selecting the ‘Main Menu’, followed by ‘View

Events’ and selecting ‘View Event Log’.

1.Main Menu>>4.View Events>>2.View Event

Log

If a non-menu screen is selected the Cancel

button should be pressed to return to

the menu without making any changes.

Subsequently, then pressing Cancel for

a second time will return to the system

screen. If any changes are made to settings,

these are generally saved using the Enter

key as detailed on the display. If an alarm

occurs while in menu mode, the menu will

be automatically cancelled, and the alarm

message displayed. If a fault occurs while in

the menu mode, the fault LED will light but

the display will remain in the menu mode

until cancelled in the usual way.

4.1 QUICK MENU – ALL ACCESS

LEVELS

Pressing Menu once will display the Quick

Menu. Navigate using the cursor keys. Any

active alarms, faults, disablements or tests

will be displayed. No access code is needed

to view the events listed. You will only be

prompted to enter an access code if you

select ‘1-Main Menu’.

1>Main Menu

2 Alarms(000)

3 Faults(002)

4 Disablements(000)

When a category (e.g. Faults) is selected, the

rst screen will display information such as

the device number, zone, type of fault and

any text location.

001 Zn:001 SHORT CCT

CONTROL IP1

13

LEAK DETECTION SOLUTIONS

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

AquiWave

Wireless Leak

Detection System

Pressing the key will display the time and

date that the event happened.

Time:12:00:08

Date:25/06/13

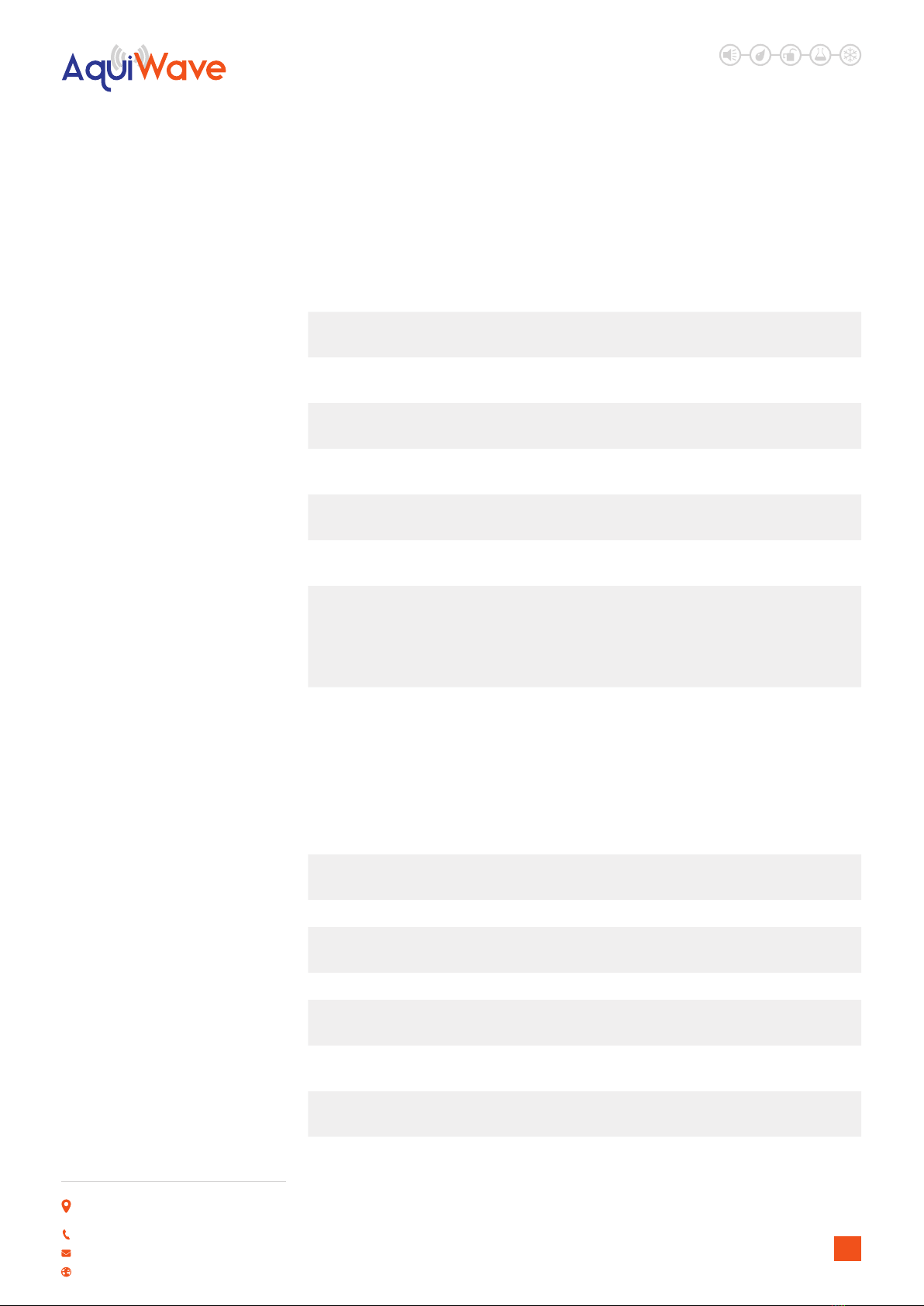

5.0 SETUP MENU

5.1 CHANGING THE SYSTEM TIME

AND DATE – ALL ACCESS LEVELS

1. Main Menu>>1.Setup>>1.Time & Date

To change the time and date settings use the

and keys to navigate to the value, and

the or keys to select the desired value.

Press Enter to accept or Cancel to exit. The

AquiWave panel automatically adjusts the

clock for daylight savings. Should complete

power be lost the panel will revert the time

back to the default of 01/01/2013 12:00:00

Time: 12:39:00

Date: 01-01-2013

ENTER to save

5.2 - VIEW ACCESS CODES

– ADVANCED, SERVICE AND

COMMISSIONING USERS

1. Main Menu>>1.Setup>>2.Access Codes>>1.

View Codes

The access code is a 4 digit number; with

each digit ranging from 1 to 4. Selecting ‘1-

View Codes’ will display the screen opposite.

Only access codes for the access level you

have entered and those below it will be

displayed.

AL1 1111 AL2 2222

CANCEL to exit

CHANGING ACCESS CODES

– ADVANCED, SERVICE AND

COMMISSIONING USERS

1. Main Menu>>1.Setup>>2.Access Codes>>2.

Change Codes

Using the cursor keys select the access level

for which the access code is to be changed.

Users can only change the access code for

their level and below. Once selected, press

the key to continue. Using the numbered

keys enter the current access code.

Enter Current Code

----

CANCEL to exit

If correct, you will be prompted to enter your

chosen new access code, then to re-enter

it to conrm. Press Enter to save the new

access code, a message will be displayed

that the access code is being saved. Press

Cancel to exit without saving at any time.

Enter New Code

----

CANCEL to exit

SET ACCESS CODES TO DEFAULT –

COMMISSIONING USERS

1.Main Menu>>1.Setup>>2.Access Codes>>3.

Set to Default

Use this option to reset the user access

codes to their default settings. Press Enter to

conrm.

14

LEAK DETECTION SOLUTIONS

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

AquiWave

Wireless Leak

Detection System

5.3 - DEFAULT ACCESS CODES

Basic User (AL2A): 1111

Advanced User (AL2B): 2222

Service Engineer (AL3A): 3333

Commissioning Engineer (AL3B): 4444

AL2A 1111 AL2B 2222

AL3A 3333 AL3B 4444

CANCEL to exit

Note: Ensure that the access codes AL3A

& AL3B are changed from the default

settings to ensure that only authorised

personnel can make changes to the

system

5.4 - PROGRAMMING AGENT DETAILS

– SERVICE AND COMMISSIONING

USERS

1.Main Menu>>1.Setup>>3.Panel Display

The system normal screen can be adjusted to

display either the date and time, the agent’s

name and telephone number or alternating

between the two every 4 seconds. In order to

display the agent’s details, they will need to

be programmed into the panel. 20 characters

per line can be programmed.

Tuesday

01-01-2013

12:04:36

Text can be programmed into the control

panel using a USB keyboard or via the panel

buttons. From the ‘Panel Display’ menu select

‘1-Agent Name’. Enter text then press Enter to

save. Select ‘2-Agent Phone’. Enter text then

press Enter to save. If entering text via the

panel use the key to display the characters.

Browse the characters using the

keys; select the highlighted character using

the . Menu key is SPACE and Function is a

BACKSPACE. Once complete press to hide

the characters and press . Conrm the

text is correct and press Enter to save. To

return to the menu press Cancel.

A.N Other Firm

01403 216100

12:04:36

CHANGE DISPLAY OPTIONS –

SERVICE AND COMMISSIONING

USERS

1.Main Menu>>1.Setup>>3.Panel Display>>3.

Display Options

Using the or keys, select ‘Time/Date’,

‘Agent Details’ or ‘Alternating’. Press to

select the option. Press Enter to save.

Alternating

Use keys

5.5 - PANEL INFORMATION

1.Main Menu>>1.Setup>>4.System Setup>>1.

Panel Info

It is possible to view information regarding

the panel, such as the software version,

system number and the number of devices

programmed onto the system.

PANEL STATUS – SERVICE AND

COMMISSIONING USERS

1.Main Menu>>1.Setup>>4.System Setup>>1.

Panel Info>>1.Status

Using the or keys, select ‘Time/Date’, ‘Agent

Details’ or ‘Alternating’. Press to select the

option. Press Enter to save.

Sys No:00699

Devices:001

Use key

Panel No:01/01

Antennas:01

Use keys

15

LEAK DETECTION SOLUTIONS

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

AquiWave

Wireless Leak

Detection System

Ver:01.00 20Mar13

Uptime:0000d 03h 13m

Use key

TxRx

Version:01.02

Uptime:0000d03h13m45

Use key

Display

Version:01.01

Uptime:0000d04h16m33

Use key

Sys No: System number.

Devices: Number of devices added to the

panel.

Panel No: Panel number and last panel

number on system.

Antennas: Number of antennas assigned to

the panel.

Ver: Software version.

Uptime: Operational time since panel was

last powered down.

PANEL READINGS – SERVICE AND

COMMISSIONING USERS

1.Main Menu>>1.Setup>>4.System Setup>>1.

Panel Info>>2.Panel Readings

IP1: The resistance level on input 1.

IP2: The resistance level on input 2.

OP1: The resistance level on output 1.

OP2: The resistance level on output 2.

OP3: The resistance level on output 3.

OP4: The resistance level on output 4.

Vbus: The voltage of the PSU.

Light: Light sensor voltage

IP1:4535 IP2:4513

OP1:4579 OP2:>10K

OP3:4528 OP4:4671

01314 01862

Vbus:14.9

Light:00.00V

Use key

VIEW ANTENNA INFORMATION –

SERVICE AND COMMISSIONING

USERS

1.Main Menu>>1.Setup>>4.System Setup>>1.

Panel Info>>3.Antenna Info

Ant: The currently selected antenna.

Sys: The system number programmed

at the antenna.

RSSI: Received signal strength indicator,

from -20 to +20.

RF Chan: The channel the system is using.

Pan: The number of the panel

programmed at the antenna.

Slot: Device protocol slot.

Squelch: RF interference lter. Non-user

adjustable.

Ant:01 Sys:00699

RSSI:20

RF Chan:09 Pan:01

Slot:195 Sqlch:100

VIEW PAGER INFORMATION –

SERVICE AND COMMISSIONING

USERS

1.Main Menu>>1.Setup>>4.System Setup>>1.

Panel Info>>4.Pager Info

This menu displays information for any alert

pagers that have been set up on the system.

VIEW POWER SUPPLY INFORMATION

– SERVICE AND COMMISSIONING

USERS

1.Main Menu>>1.Setup>>4.System Setup>>1.

Panel Info>>5.PSU Info

Vin: Input Voltage.

Vbus: The voltage of the PSU.

Vbat: The voltage of the battery.

Ib: Battery current.

16

LEAK DETECTION SOLUTIONS

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

AquiWave

Wireless Leak

Detection System

Io: PSU output current.

Status: PSU fault status.

State: PSU state.

PWM: Duty cycle.

Temp: PSU temperature (oC).

Version: The rmware version of the power

supply PCB.

Uptime: Operational time since PSU was last

powered down.

5.6 - SET UP A NEW SYSTEM

(STANDARD) – COMMISSIONING

USERS

1.Main Menu>>1.Setup>>4.System Setup>>2.

New Setup>>1.Standard System

Devices are programmed via a radio link to

the control panel. If the system is known to

have been used before then all the devices

that are logged on to the system must be

removed rst. To add or remove devices on a

system that is already set up; see 5.26 – Add

Device and 5.27 – Remove Device.

System Setup

ENTER to continue

Press Enter to start. You will be asked if you

would like to put the system into test mode

(see 7.0 – Test Mode). Select YES or NO and

press Enter. The control panel will now check

the airwaves for any radio interference and

select a suitable channel for the system. Press

Enter to continue. Select the antenna type. At

the Device Programming screen, the device

needs to be put into programming mode.

First remove the device from its base.

1. If a leak detection TX is being

programmed; hold the reset button

down while you place the jumper link to

the ON position

2. If a sounder, beacon, transmitter or I/O

unit is being programmed; hold down

the unit removal button while holding a

magnet over the reed switch and place

the jumper link to the ON position.

Some newer devices are equipped with

a log on button and do not require the

magnet to log on; simply hold down the

button while the jumper link is moved to

the ON position.

System will test

radio channel

ENTER to continue

Channel 09

RSSI -20

/

Please wait

Continue to hold the button(s) for

approximately 5 seconds until a conrmation

of 3 beeps from the device is heard. The LED

on the device will now ash green. The device

is now in its programming mode. Press Enter

on the panel to search for the device and

follow the prompts to set the device options.

When complete press Enter to program the

device.

Device Programming

ENTER to continue

Device Found

Leak Detection TX

Use keys

Once the device has restarted you will be

asked to enter location text; see 5.30 –

Device Text. Text can be added at any time.

Devices can be added at any time in the

Device Setup menu.

If the system has booster panels or additional

antennas tted, an auto assignment for

all devices should be performed once all

devices have been added. See 5.17 – Device

Assignment.

17

LEAK DETECTION SOLUTIONS

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

AquiWave

Wireless Leak

Detection System

5.7 - USER OPTIONS – COMMISSIONING USERS

1.Main Menu>>1.Setup>>4.System Setup>>3.Edit Panel>>1.Panel Options>>1.User Options

Detailed below are the other options that can be changed related to the panel. The default

settings are strongly recommended. Selecting some of the available options may result

in a system which may not provide suitable protection. If unsure, contact Aquilar or your

installation/service representative for advice.

Panel Zone The zone the panel is located in.

Func Key Set the function key as disabled, evacuate, alert or delay toggle.

Default settingis - disabled

Func Tone The tone to be sounded if the function key is pressed and has been

programmed as either evacuate or alert.

Func Relay The relay to be operated if the function key is pressed and has been

programmed as either evacuate or alert.

Double Knock Whether double knock is enabled. See 13.0 – Delays.

Double Knock Tone The tone to be sounded after second device activates.

Double Knock Relay The relay to be operated after second device activates.

Double Knock Zone Whether a second device in the same zone or any second device

operates the double knock.

Relay 1 Type Choose relay type 0 to 5. Default setting is 2. Fault relay is default.

Relay 1 Reset Whether Relay 1 is cleared upon pressing silence or upon pressing

reset.

Relay 2 Type Choose relay type 0 to 5. Default setting is 4. Failsafe fault relay is

default.

Relay 2 Reset Whether Relay 2 is cleared upon pressing silence or upon pressing

reset.

Relay 3 Type Choose relay type 0 to 5. Default setting is 1. Leak Relay is default.

Relay 3 Reset Whether Relay 3 is cleared upon pressing silence or upon pressing

reset.

Relay 4 Type Choose relay type 0 to 5. Default setting is 1. Leak Relay is default.

Relay 4 Reset Whether Relay 4 is cleared upon pressing silence or upon pressing

reset.

Relay1 Type 1

Leak Relay

Use keys

The relay types are listed below:

Type 0 Disabled

Type 1 Leak Relay

Type 2 Fault Relay

Type 3 Sounder Circuit

Type 4 Fault Relay Safe

Type 5 Accessory Circuit

IMPORTANT!: The relay types are congured not only in the panel software but also by

physically placing jumper links on the panel PCB. Refer to page 8/9 for relay link positions

and fuse requirements.

18

LEAK DETECTION SOLUTIONS

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

AquiWave

Wireless Leak

Detection System

5.8 - SYSTEM OPTIONS – COMMISSIONING USERS

1.Main Menu>>1.Setup>>4.System Setup>>3.Edit Panel>>1.Panel Options>>2.System Options

This menu allows the user to change overall system settings.

Alarm Verify Time (seconds) that a device has to be in alarm to generate an alarm

condition on the panel.

Antenna Type Specify if the main panel is using a Stub (6775), Dipole (6745) or

Intelligent antenna (6740).

Code Protect Whether an access code is needed to silence or reset an alarm or

fault. Default is set to OFF.

Sil Alm Delay Length of time (seconds) the ‘Silencing – Please Wait’ screen is

displayed.

Res Alarm Delay Delay between pressing the reset button and the system resetting

an alarm condition.

Res Flt Delay Delay between pressing the reset button and the system resetting a

fault condition.

Auto Resound When set to By Zone; if an alarm condition has been silenced and

another device goes into alarm, the sounders will only start sounding

again if the device is in a dierent zone. When set to By Device; if an

alarm condition has been silenced, any other device which goes into

alarm will cause the sounders to start sounding again.

5.9 - FAULT OPTIONS – COMMISSIONING USERS

1.Main Menu>>1.Setup>>4.System Setup>>3.Edit Panel>>1.Panel Options>>3.Fault Options

This menu allows the user to enable or disable certain types of faults, and to change the

levels or time periods required to produce a fault condition. The default settings are strongly

recommended. Selecting some of the available options may result in a system which may not

provide suitable protection. If unsure, contact your installer or Aquilar for advice.

Verify Time Time without communication from a particular device before the

system generates a verify fault. The default is 390 seconds.

Show Batt Low Enable or disable faults for low battery alerts from devices.

Batt Low T/out If disabled, the time period until faults for low battery automatically

re-enable.

Show Int Fail Enable or disable faults for internal failures from devices.

Int Fail T/out If disabled, the time period until faults for internal failures

automatically reenable.

Interference The level of interference required for the panel to generate an

interference warning. This is set to o by default.

Interference Period The minimum length of the interference required for the panel to

generate an interference warning.

Show Batt Warning Enable or disable warning messages for low panel battery.

19

This manual suits for next models

1

Table of contents

Other aquilar Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Rover Instruments

Rover Instruments CNG 90 user guide

Nelson-Jameson

Nelson-Jameson 926S Operator's manual

Emerson

Emerson Daniel 3410 Series Maintenance and troubleshooting manual

Preventice Solutions

Preventice Solutions ER920W Patient Instruction Manual

KAM

KAM Simple Precision PKF user manual

AEMC instruments

AEMC instruments Simple Logger AmpFlex AL24-2500 user manual