AR Blue Clean 600 Series Guide

ASSEMBLY, CARE AND USE

INSTRUCTIONS FOR

PRO600-CCRT

SPECIAL EDITION

IMPORTANT: RETAIN THESE

INSTRUCTIONS AND ATTACH RECEIPT

TO MANUAL FOR FUTURE REFERENCE.

READ CAREFULLY

Questions, problems, missing parts?

Before returning to your retailer, call our customer service department

at 1-866-235-5112, 8 a.m. - 5:00 p.m., CST, Monday - Friday.

www.arblueclean.com

PRO600CCRT

600 Series Cart and Accessories Kit

2

Important Notice

Winterizing or long time storage: Drain all water out of your pump. Flush pressure

washer with a 50/50 mix of RV antifreeze and water. Relieve system pressure by

squeezing gun trigger. When ready to use again, ush pressure washer with clean

water to remove antifreeze.

WARNING: This product can expose you

to chemicals including lead, DEHP, DINP

which is known to the State of

California to cause cancer and or lead to

birth defects. For more information go to

www.P65Warnings.ca.gov

PRECAUCIÓN: Este producto puede

exponerle a los productos químicos

incluyendo el plomo, DEHP, y DINP, que se

saben al estado de California para causar el

cáncer y/o defectos de nacimiento. Para más

información, vaya a www.P65warnings.gov

Safety Instructions 3-4

Included in the Box 5

Assembly 6-7

Operating Instructions 8-9

Troubleshooting 10

Pressure Washer Limited Warranty 11

Warranty Returns 12

Notes 13-15

Table of ConTenTs

3

safeTy InsTruCTIons

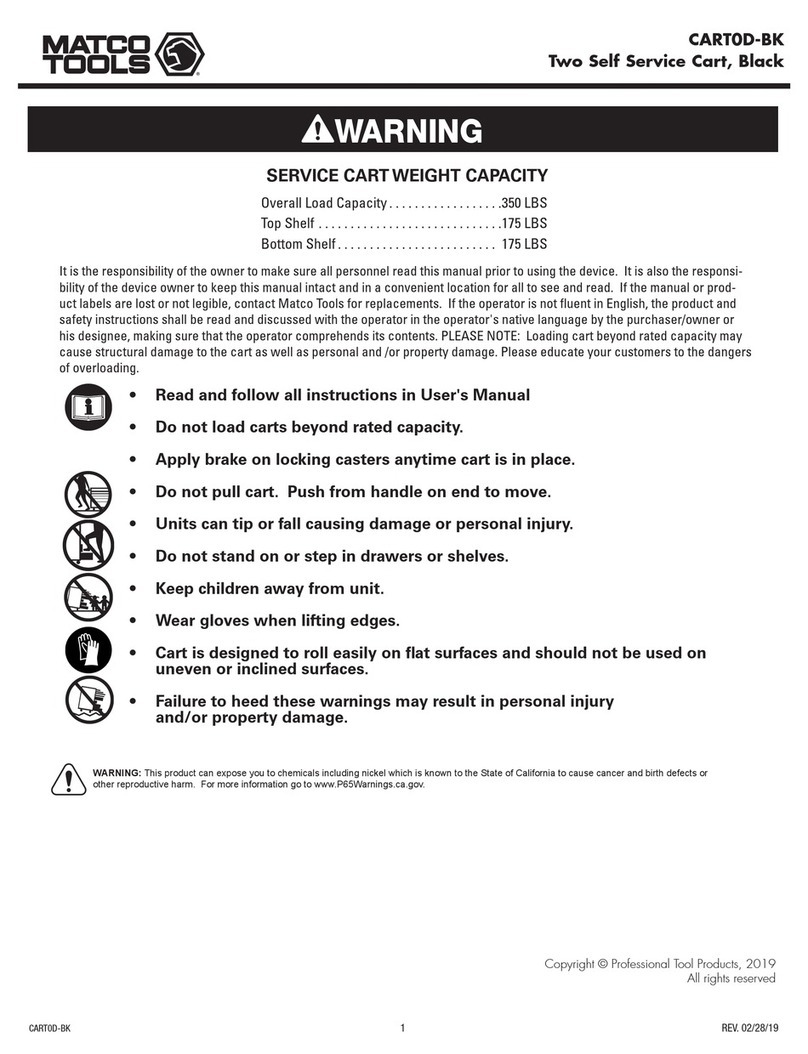

Read and understand these instructions as they pertain to safety.

Pay special attention to the safety symbol throughout this manual.

Failure to comply with these instructions may result in personal

injury or property damage. DO NOT allow children to operate or

play on or around this equipment.

WARNING: Improper grounding can result in electrical shock.

WARNING: High pressure spray can be extremely dangerous.

Always point the nozzle away from people and animals.

WARNING: Always turn the power switch on the Pump Unit to

the “OFF” position when not in use.

Seek emergency medical assistance immediately if any uid

penetrates the skin. The cut may be deeper and more serious

than it appears.

Always wear eye protection and appropriate clothing when

operating the unit.

Never spray any part of this pressure washer or any other

electrical machine.

Do not alter the machine from the manufacturer’s design.

Keep all safety devices active on the machine.

Do not make alterations to the unloader relief valve.

Never operate the unit with broken or missing parts.

Never use an undersized discharge nozzle.

Keep the pressure hose connected to the machine and wand

while unit is pressurized.

Never leave the wand unattended while the machine is running.

Do not secure the wand in the squeezed“ON”position.

Follow the chemical manufacturer’s recommendations when

using chemicals in the soap injector.

Understand all safety precautions and rst aid for chemicals

being used

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

4

safeTy InsTruCTIons

Never spray ammable liquids.

Do not operate this machine in or around an explosive

environment.

Position the machine in an area that is protected from external

damage.

Always place the machine on a level surface.

Do not move the unit by pulling on the hose or electrical cord.

Never use the unit when under the inuence of drugs, alcohol,

or medication.

No smoking while operating the machine.

Only operate the machine with sucient water supply to the

pump.

Always use water that is clear and free from particles.

Always follow all other guidelines and Safety Instructions

described on pg. 3-4 of this manual.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

Tighten all connections and replace worn parts before

starting any machine. Sudden release of high pressure

streams may result if connections detach during use.

This can cause serious injury. Never disconnect any part

of your machine while running or before relieving system

pressure, it is dangerous. Seek medical attention if an injury

ever occurs.

5

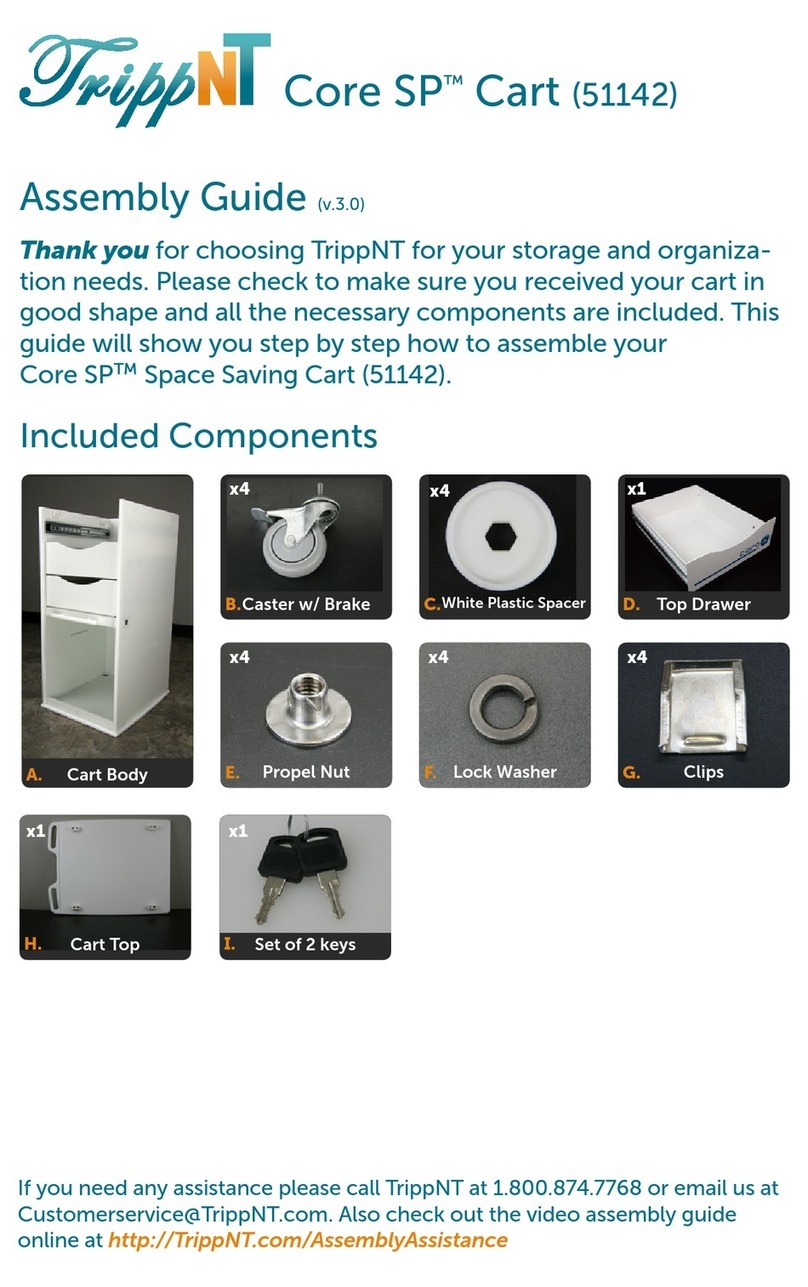

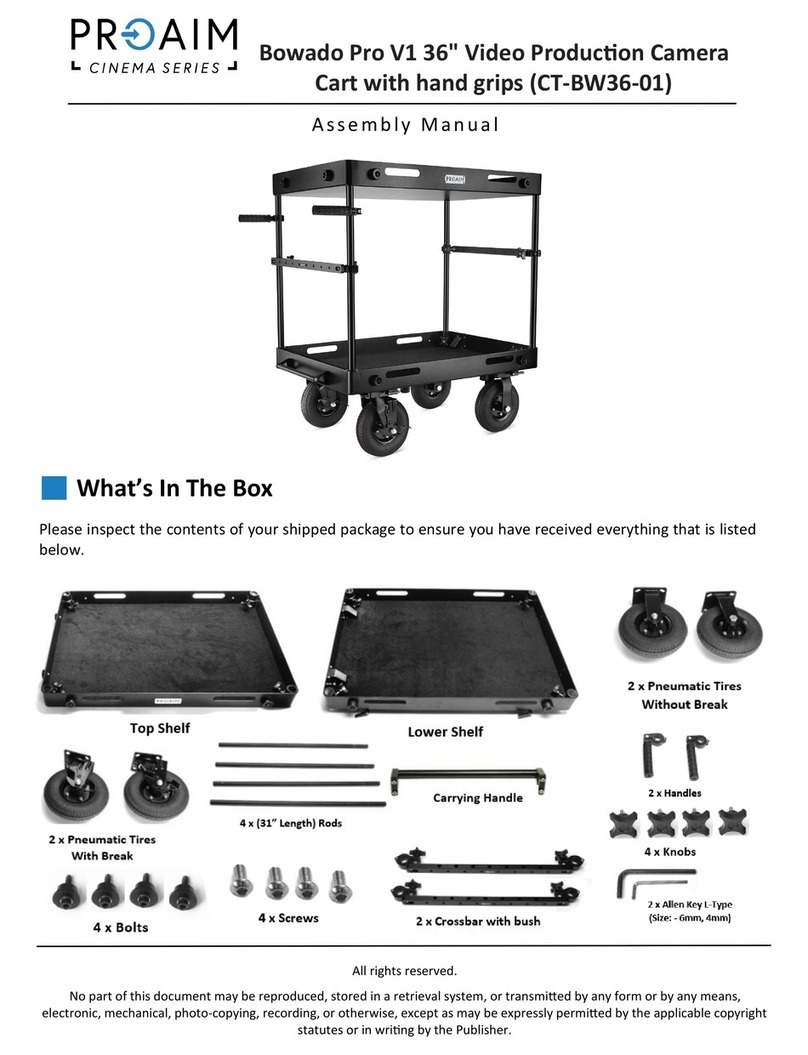

InCluded In The box

Box Weight: 61lbs | Box Dimensions: 29x23x23”

15°25°40°

Soap

Injection

Size 3.5 Nozzles

(Pre-attached to cart)

Trigger Gun

Cart Top/Reel

Foam Cannon Kit

(Pre-assembled size 1.5)

Wand and Nozzle Protector

Cart Base

Mounting Hardware

ARBB539114-B Mounting Studs

AR3120110 Nut

ARVC-312-8 Cap

6

assembly

requIred Tools for assembly (noT suPPlIed)

CarT assembly

Remove all cart components from the box. Gather necessary

tools and parts for assembly listed above.

*For ease of assembly, Cart Base and Cart Top/Reel have been

pre-assembled.

Attach the Cart Top/Reel to the Cart Base. A rubber

mallet may be helpful to fully insert. Hand-tighten

the star bolts to secure.

3.

Place your Pump Unit on the Cart Base by lining up

the 4 mounting studs to the 4 pre-drilled holes on

the Cart Base.

Note: You will see red stickers to help guide you to the

correct holes when using an AR630 Pressure Washer.

Note: You may need to add studs with rubber caps to

your unit prior to assembly.

1.

Once placed on the Cart Base, remove protective

rubber caps from mounting studs. Using 13mm

wrench, secure the Pump Unit using the 4 washers

and 4 nuts (included).

2.

10mm Wrench

13mm Wrench

17mm Wrench

Phillips Screwdriver

Rubber Mallet

4mm Allen Wrench

Wrenches: Optional:

7

Attach the 22”black jumper hose to the outlet of

the unloader. Hand tighten until secure.

Gun assembly

assembly

Assemble the gun by attaching the wand to the

gun outlet by pulling back the collar of the quick

connect.

Choose one of the included 3.5 nozzles and attach

to the end of the wand.

Attach blue hose to inlet of gun by pulling back the

collar of the quick connect.

Once all parts are assembled, connect water supply

using a standard non-collapsible garden hose.

Connect to garden hose adapter on Pump Unit.

Your pressure washer is now ready to use. It is important to read through your

instruction manual on proper use of your machine.

1.

2.

3.

4.

4.

8

oPeraTInG InsTruCTIons

usInG foam Cannon

Mix preferred detergent with fresh, clean water in foam cannon

bottle and shake contents thoroughly.

Ensure suction tube is in place in the foam cannon body, and

screw the bottle into the body.

Connect foam cannon to end of wand by pulling back the collar

on the quick connect, and foam away!

When foaming is complete, remove the bottle from the body

and squeeze trigger on spray gun to allow clean water through

foam cannon.

1.

2.

3.

4.

9

oPeraTInG InsTruCTIons

Nozzles: The gun nozzles included with your pressure washer

provide optimum results for universal cleaning applications. If used

with after-market parts, results may vary.

Chemicals: Cleaning agents are most eective when the surface is

rinsed rst to loosen dirt. After pre-rinsing to loosen dirt, then clean

with the detergent.

Detergent should be applied from the bottom to the top of the

washing area. Apply detergent and allow the detergent to react

with the dirt, then rinse from the top to the bottom. This detergent

applying and rinsing technique will help to avoid streaks and skips

in the washing area.

Never use more detergent than is necessary to clean the surface.

Always follow directions supplied by the detergent manufacturer on

the container.

Cleaning: For best results, hold the gun 6 – 12”away from the

washing surface and use long, slow deliberate side to side strokes,

similar to using a paint sprayer. This technique will provide the most

eective cleaning impact and minimize streaks and skips in the

cleaning process.

Wax: If the pressure washer is used to apply wax, the gun should be

held further from the surface to optimize the “misting” eect during

application. For best results, follow the directions supplied by the

wax manufacturer.

CleanInG TIPs

10

low Pressure

surGInG Pressure

TroubleshooTInG

Causes soluTIons

Plugged Nozzle. Clean and check for blockage.

Insucient ow of water to

the pump. Increase water ow to the pump.

Plugged inlet screen. Pull out and clean screen carefully.

Using restrictive supply hose. Use larger diameter supply hose.

Debris in pump valves. Worn or

damaged pump valves.

Remove valve caps. Inspect valves for

debris, wear, or damage. Replace if

needed. Torque valve caps to 300 in/lbs.

Causes soluTIons

Restricted supply by under-sized

ttings or inlet.

Use larger ttings and clean the inlet

screen.

Insucient ow of water to the

pump. Increase water ow to the pump.

Air trapped in the pump head.

Squeeze the gun trigger before

starting the machine. Start the engine

and run water until air is purged out of

the system.

Debris in pump valves. Worn or

damaged pump valves.

Remove valve caps. Inspect valves for

debris, wear, or damage. Replace if

needed. Torque valve caps to 300 in/lbs.

11

Pressure washer lImITed warranTy

☑ AR600 Series Electric Pressure Washers come with a 1 Year

Commercial Warranty.

☑ Electric Pressure Washer Accessories come with a 90 Day Warranty.

☑ Warranty is to the original purchaser and is non-transferrable.

☑ Warranty Claim may require product inspection by the Manufacturer.

(See Liability)

Warranty Conditions:

• Warranty does not apply to normal wear (such as but not limited to: seals/

packings, valves, plungers and sealing O-rings), freight damage, freezing

damage.

• Warranty does not apply to misuse when pump or accessories are altered

operated above recommended speeds, pressures, or temperatures.

• Warranty does not apply to damage caused by aftermarket accessories

not included with original unit.

• Warranty is void when failure to follow recommended operating and

maintenance procedures, or failure to use OEM replacement parts.

• Warranty is void when pump is damaged by:

1) The use of caustic (corrosive) liquids

2) Pump was operated under abrasive or corrosive environments where

conditions could cause pump cavitation.

Liability of manufacturer:

☑ Warranty is limited to repair or replacement of parts only.

☑ Warranty Products must be inspected by the manufacturer.

☑ Returned Product will be Repaired or Replaced Free of

Charge if found to be defective and subject to warranty.

After a completed inspection by the manufacturer, warranty is

granted/ denied at the sole discretion of the manufacturer when

such products are found to be of original defect or workmanship at

the time it was shipped from factory.

This warranty is in lieu of all other warranties, expressed or implied, including any

warranty of merchantability of any and all other obligations or liabilities on the

part of the manufacturers or equipment.

12

Pressure washer lImITed warranTy

warranTy reTurns

Instructions:

☑ Have a Purchase receipt ready

☑ Contact us and receive an RMA# and Packing directions

Contact us:

☑ General Questions

☑ Troubleshooting

☑ RMA/ Warranty

Call our toll-free number at 1-866-235-5112. Customer service is available M-F

8am to 5pm Central Standard Time (CST). A customer service representative

will work with you to x the problem.

Customer Return Liability:

☑ Pumps and Accessories must have a Return RMA#

☑ Pumps must be shipped back with Shipping plug

☑ Shipments without RMA# will be denied

☑ Under no circumstance will the manufacture bare

any responsibility for loss of unit, loss of time or

inconvenience in any manner.

• Customer is responsible for freight costs to return product for warranty

evaluation.

• The nozzle(s) being used must be returned with the pump unit to be

considered for warranty.

• A shipping plug (supplied) must be installed in the pump before

shipping to prevent oil seepage. Failure to secure the plug will result in a

maintenance charge.

• The manufacturer is not liable for freight damage, insurance, labor, or any

consequential damages incurred as a result of defective product.

• If returned product is found non-warrantable, associated repair costs

and return freight are the responsibility of the customer.

13

noTes

14

noTes

15

noTes

This manual suits for next models

1

Table of contents